Abstract

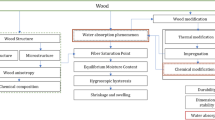

The purpose of this review is to report on the state-of-the-art on the interaction of moisture with natural materials and fabricated biomimetic functional materials, with an emphasis upon the hygro-responsive behaviour of wood. The primary objective is to examine how water sorption affects dimensional behaviour and how knowledge of this property in natural plant-based (mainly, but not exclusively wood) materials can be used to inform biomimetic design of moisture-responsive materials and devices. The study examines the literature on natural and bio-inspired materials, concentrating upon sorption kinetics, water migration and location of the sorbed water in the materials and their microstructure and mechanical response of the microstructure and how this affects molecular mobility of the sorbate translating to macrostructural changes. Also included within this review, it is an overview of the main experimental techniques which have been used to investigate the interaction of water with these materials at molecular length scales and how modern techniques can resolve the response of these materials at the cell wall level.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

This review explores the relationship between sorption behaviour and structure in composite materials that have a hygro-responsive matrix combined with non-responsive elements such as fibres, rods, plates or sheets. The particular focus is upon furthering the understanding of the sorption behaviour of wood in particular and natural fibres to a lesser extent, but biomimetic materials based upon these principles are also included. This type of material exhibits swelling behaviour in the presence of moisture, but because the ‘inert’ phase exhibits some form of structural heterogeneity, the observed swelling behaviour is consequently anisotropic. This is often a problem with wood-based materials but can be used to advantage when designing biomimetic structures.

The interaction of moisture with natural hygro-responsive materials (such as wood and textiles) has been a topic of immense scientific interest for over a century. Much initial research was directed at trying to better understand the water vapour sorption behaviour of wood to improve kiln-drying schedules and to reduce the negative properties associated with dimensional instability [1]. One of the key pieces of information for understanding the relationship between solids and water vapour is the sorption isotherm, which is the relationship between the relative humidity (RH—also referred to as water activity aw) of the surrounding atmosphere and the moisture content (MC) of the material at equilibrium (equilibrium moisture content, EMC) at a constant temperature. One critical aspect of making such measurements is to ensure that a true equilibrium state has been achieved, although wood in service conditions seldom achieves an equilibrium state. There are many sorption isotherm models that have been developed to describe the sorption behaviour of natural materials, and this topic has been very well explored elsewhere e.g. [2,3,4,5,6,7,8]. However, these models suffer from various limitations, and there is still a need to develop a theory that better explains the observed behaviour [2, 9], not just for wood, but other lignocellulosic/cellulosic materials as well as foodstuffs, textiles, etc.

Hygro-responsive materials change dimensions when they interact with water vapour. They comprise a dynamic polymeric structure which absorbs water vapour, but they may also have an essentially inert fibrillar or layered structure embedded within the hygro-responsive matrix. In the latter case, these materials exhibit anisotropic responses when they gain or lose water molecules. For lignocellulosic materials, such as wood, sorption models additionally need to include consideration of hygro-inert reinforcing crystalline cellulose microfibrils embedded in a hygro-responsive amorphous lignin/hemicellulose matrix. It is argued in this review that the properties of these materials are best described by consideration of the molecular dynamics in these materials, giving rise to the phenomena, such as swelling pressure, the sigmoidal sorption isotherm, sorption hysteresis, characteristic dynamic sorption behaviour and associated changes in static and dynamic mechanical properties (modulus, strength and viscoelastic behaviour).

Studies of moisture interactions with natural materials are very instructive from a biomimetic design perspective, and the review also briefly covers this subject from the perspective of how water sorption/desorption leads to dimensional changes. The intention of the review is not to analyse the existing and very comprehensive literature of biomimetic moisture-activated materials; but rather to approach the subject from the point of view of how location of sorbed water in hierarchical heterogenous natural materials (such as wood) affects the dimensional behaviour of these materials. Such studies may provide insights into refining the design of new biomimetic moisture-activated ‘smart’ materials.

The next section of the review considers some basic principles which may assist with a generic understanding of the sorption properties of the dynamic polymeric matrix of natural materials and how this relates to dimensional changes.

General considerations regarding polymer microstructure and moisture-induced behaviour

Water in rubbery and glassy polymers

There are materials which absorb water vapour because they contain pores of small dimensions allowing for capillary condensation. However, these materials are inert and do not swell to accommodate the absorbed water (an example in this category would be activated carbon [10]); materials of this type generally exhibit IUPAC Type V sorption isotherms [11], or Type I if they are hydrophilic [12] (Fig. 1).

Hygro-responsive materials are, for the purposes of this review, defined as a class of polymeric materials that contain chemical moieties that interact with water molecules and exhibit molecular mobility. They can therefore change their structure to accommodate the sorbed water molecules and to allow for transportation of these penetrant molecules through the macromolecular network. This molecular mobility is facilitated by the presence of the sorbed water molecules which creates additional void volume within the structure (usually referred to as plasticization or softening) resulting in macroscopic viscoelastic behaviour [13, 14]. Transport therefore does not rely on an interconnected porous structure (which is necessary in inert materials), but rather mobility of the polymeric matrix molecules. Materials of this class exhibit isotherms which are classed as Type II, but also often exhibit hysteresis between the absorption and desorption branches of the isotherm. Before a discussion of the sorption behaviour of these systems, there is a brief introduction to how solvent systems interact with dynamic polymers.

The Flory–Huggins (F–H) model is a relatively simple theory that is often invoked to describe the solvent-induced swelling behaviour of polymers. The F–H approach uses a lattice-based model, which considers the entropy of mixing of a polymer chain in a solvent. The parameters used to describe the sorption behaviour are the volume fraction of the polymer, volume fraction of the solvent and a term to describe the solvation of the polymer. The sorption behaviour is expressed as follows:

where: p1 is the pressure of the solvent, p10 is the saturation pressure of the solvent, ϕ1 is the volume fraction of the sorbate and ϕ2 is the volume fraction of the polymer. The term χ is the Flory–Huggins interaction parameter, which is related to the difference in energy between the solvent molecule in the pure solvent (in this case, liquid water) and the molecule in the polymer matrix. The F−H interaction parameter is a measure of thermodynamic miscibility of a solvent with a polymer in binary systems and is treated as a constant in the F–H theory. The relationship between the sorption curve and the interaction parameter is shown in Fig. 2. The F–H polymer dissolution model produces an isotherm that exhibits a continuous upward curvature as the RH increases up to a maximum, but finite value at total saturation (IUPAC Type III), with the steepness of the curve controlled by the magnitude of the interaction parameter (χ). A strong interaction between the solvent and polymer yields a low value of χ (Fig. 2).

Although a popular approach, the F–H model has been shown to have shortcomings. It is possible to determine χ independently using, e.g. scattering methods to determine polymer–solvent interactions [15], but this can be problematical and different measurement methods usually give different values for χ [16]. When fitting to sorption isotherm data, it is more common to use the interaction parameter as a fitting variable for experimental isotherm data, rather than using it as a fixed parameter obtained from an independent experiment, which is unsatisfactory for a fundamental approach to the problem. According to F–H theory, the interaction parameter should be independent of the concentration and molecular weight of the polymer, but in practice, this independence does not usually hold, especially for polar systems [17,18,19]. It has been shown that the interaction parameter can vary depending on the inhomogeneity of distribution of the solvent molecules [20] as well as exhibiting a concentration dependence [20, 21]. Furthermore, the underlying lattice model has been shown to have limitations when representing the behaviour of real polymers [22].

Polymer hydrogels (PHGs) are a sub-class of hygro-responsive polymers. Sorption isotherms of PHGs typically exhibit a shape that is characterized by IUPAC Type II or Type III curves. PHGs can exhibit extremely high levels of water uptake, a property that is at least partially determined by the crosslinking density of the polymer structure [23]. They are not soluble in water unless the crosslinking structure is not stable in the presence of water or can be disturbed by the application of mechanical energy. There also exist ‘dual network’ hydrogels which have chemical and physical (e.g. hydrogen bonding) crosslinking regions. Such materials exhibit mechanical behaviour that is dependent upon an applied strain rate [24].

In the context of the present review, the hydrophilic chemical entities associated with the polymers that are of most interest are hydroxyl (OH) groups. These groups are capable of hydrogen bonding to sorbed water molecules and are usually referred to as primary sorption sites for this reason. A higher concentration of OH groups in the polymer increases the hydrophilicity of the polymer and consequently affects the interaction parameter with water as a solvent [25].

It is thought that hydrogen bonding to OH groups attached to the polymer chains reduces the mobility of sorbed water molecules [26]. As the concentration of water in the expanding polymer network increases, these incoming molecules are associated with other water molecules rather than the essentially static polymeric OH groups and consequently have much higher mobility compared to those H-bonded to the sorption sites. However, the whole system is dynamic, with constant exchange of water molecules between these different environments [27]. This leads to the question of whether the different water environments can be readily identified and whether there are any measurable differences in terms of mobility, which is discussed later.

The water molecules in the polymer matrix also create space between molecules within the network, which results in increased mobility of the polymer chains. This phenomenon is referred to as plasticization. Before any further discussion, it is helpful at this stage to consider the different types of volume that exist within a polymeric matrix. According to the model of Duda and Zielinski, polymer volume is divided into three components [28]:

-

Occupied volume is the volume occupied by the polymeric components and is constant for all temperatures.

-

Interstitial free volume is the free volume that is not accessible by penetrant molecules and represents the free volume arising from vibrational motion of the polymer and increases slightly with temperature.

-

Hole free volume (herein referred to as free volume) is the volume arising from relaxation and plasticization of the polymer upon heating and cooling. This free volume is accessible by penetrant molecules and can be changed by the presence of these molecules. In rubbery polymers, the free volume is in equilibrium, but in glassy polymers, the molecular relaxations are slow and extra hole free volume may become trapped within the structure.

In some hydrogel systems at low MC, there is insufficient free volume for the polymer segments to change structure without cooperative motion of adjacent segments [29], which is characteristic of glassy polymers below the glass transition temperature (Tg) [30]. A glassy state in a polymer system occurs when the rate of cooling of that system is faster than the rate of relaxation of that system and free volume can be trapped within the matrix. Glassy polymers exhibit non-Fickian diffusion processes because the rate of diffusion is determined by the polymer relaxation processes, rather than a concentration gradient. The viscoelastic relaxation of amorphous polymers in the glass transition region is best described in terms of a relaxation spectrum, with the characteristic relaxation times spanning several decades [29, 31]. Solvents can increase the free volume in the polymer matrix, which results in an increase in molecular mobility through the matrix. Characteristics of the sorption behaviour of glassy polymers are the sigmoidal shape of the sorption isotherm, hysteresis between the adsorption and desorption loops, as well as non-Fickian sorption kinetics [30, 32].

A popular model describing the changes in free volume of glassy polymers due to penetration by solvent molecules has been developed by Vrentas and Vrentas [33, 34], which produces the observed sigmoidal isotherm. This model is an extension of the F–H model (Eq. 1), with the introduction of a new term, F, which takes account of the elastic energy stored in the polymer matrix, when sorption occurs below Tg. The model is represented as follows:

The magnitude of the F term can be calculated from first principles, given knowledge of the heat capacities of the polymer above and below Tg, the molecular weight of the penetrant, the Tg of the polymer–solvent combination and the mass fraction of the polymer [35]. At Tg, the term F becomes zero and the equation consequently reduces to the F–H expression.

The model of Vrentas and Vrentas was further developed to account for hysteresis between the absorption and desorption branches of the sorption isotherm in glassy polymeric materials, with the introduction of a new parameter (k), which is calculated based upon knowledge of the glass transition temperature of the pure polymer [34].

A key concept on which the model is based is that removal of penetrant molecules from the polymer-penetrant mixture results in the creation of a glassy structure and that this process can be considered mathematically equivalent to cooling the polymer-penetrant mixture. Since the terms F and k can both be calculated from first principles, this means that both the absorption and desorption branches of the isotherm can be predicted without the use of arbitrary fitting parameters (at least in principle) [36].

Both the F–H and the Vrentas–Vrentas (V–V) models were initially developed to explain the sorption behaviour of non-polar polymer–solvent systems. However, the use of the V–V model has been extended to describe polar polymer systems interacting with water, but with mixed results [36,37,38,39,40,41]. Although sorption and desorption in a glassy polymer are a non-equilibrium process [42], Argatov and Kocherbitov argue that models of the sorption and diffusion phenomena can still be based upon a classical thermodynamic approach [41]. They have developed a model that is based upon the F–H isotherm but reintroduces the idea of a solvent concentration dependence of the χ interaction parameter, which is related to the V–V F term in the following way:

They maintain that the use of a concentration dependent interaction parameter is a requirement for non-equilibrium systems in order to describe observed experimental behaviour of sorption with glassy polymers and note that this has also been used elsewhere [43]. Argatov and Kocherbitov have studied the variation in the interaction parameter using experimental data and used this information to determine the onset of the glass transition temperature [41]. There is much interest in this subject in the coatings field, and researchers have developed diffusion models for glassy polymers which are based upon irreversible rather than classical thermodynamics [44]. There exists a considerable body of literature on this topic which falls outside the boundaries of this review, but some references can be found in Arya et al. [30].

Much of the early work on water sorption in gel systems was conducted by Wilfred Barkas of the Forest Products Laboratory in Princes Risborough, UK. He explored the use of gel models to explain the sorption behaviour of wood and noted that in circumstances where the swelling of a gel was restricted in some way, that shear stresses are developed; resulting in sorption hysteresis being observed [45]. It has been shown that the water uptake rate and extent in sorption isotherms is reduced in gels which have a higher crosslink density [20, 46, 47]. In one study, it was shown that the extent of hysteresis decreased as the crosslink density increased, which is contrary to what would be predicted [47]. However, the hysteresis in this case was attributed to water that was somehow trapped within the polymer network during the desorption cycle, but this is not the origin of the hysteresis phenomenon discussed here. The intention when recording reliable sorption isotherms is to avoid water or solvents of any kind being trapped as inclusion compounds within the polymer matrix [48, 49]. It is interesting to note that the observed sorption isotherm and associated hysteresis loop of crosslinked hydrogels is affected by the previous history of the sample [50]. Sorption behaviour which is dependent of the previous sorption history of the sample is typically observed with glassy polymers [33, 51,52,53,54].

The essential point made in this review is that an understanding of sorption phenomena in many hygro-responsive natural materials can only be obtained through an approach that considers glassy polymers, the glass transition temperature, free volume and the related mobility of the matrix polymers as affected by the sorbate solvent molecules (in this case water). For solution-based models, the presence of OH groups affects the interaction between water and the polymer, but in such models, it is not necessary to consider the these groups as sorption sites.

Sorption sites, water clustering and nano/microporosity

It is usually assumed that at low levels of uptake, sorbed water molecules will diffuse in some manner through the polymer matrix until they reach a ‘sorption site’ (usually a hydroxyl group). In models of this type, OH groups have a very significant role to play in determining sorption behaviour but usually exclude other important phenomena, such as mechano-sorptive responses. The experimental determination of accessible OH groups in polymeric materials commonly uses hydrogen/deuterium exchange between deuterium oxide as a sorbate and the material of interest. Quantification of the thus-generated -OD groups can use gravimetric, IR or NMR methods [48, 55,56,57]. The distribution of sorbed water molecules in the polymer matrix will depend upon the concentration of OH groups that are available as sorption sites within a given volume (accessible OH groups) and a balance between the tendency of water molecules to cluster around these sorption sites or to distribute throughout the polymer matrix in the manner of a solvent.

A common method used to determine the extent of water clustering in polymer-water systems is that introduced by Zimm and Lundberg [32, 43, 58, 59]. The Zimm–Lundberg (Z–L) method has the advantage that clustering data can be determined directly from the equilibrium sorption isotherm but suffers from the disadvantage that it is not a direct measure of actual cluster size. In order to determine applicability to water-polymer systems, there have been studies where the predictions of the Z–L model have been independently tested using FTIR spectroscopy, which showed that the Z–L approach tended to underestimate cluster size. [60]. As already noted with the F–H model, the failure of the Z–L model to correctly describe water solubility and water clustering in glassy polymers is partially due to the equilibrium constraints on these models in contrast with the non-equilibrium conditions which apply below Tg [60, 61]. In addition (as with the F–H model), the Z–L model was originally developed to describe solvent solubility in weakly interacting non-polar systems, which means that extension to water-polymer systems may not be reliable. This has resulted in the development of improved models for the clustering of water molecules in hydrophilic polymers, e.g. [62, 63]. Other clustering models are also available, such as the Langmuir/Flory–Huggins model [64]. It should be noted that the clustering of water molecules within the polymer matrix can lead to marked deviations from Henry’s Law [28].

The water molecules which are involved in H-bonding with the polymeric OH groups are usually referred to as ‘bound’ water, whereas the water molecules which are not directly associated with sorption sites are called ‘free’, or sometimes ‘intermediate’ water [65]. These terms can lead to confusion, in that some papers refer to bound water as the water that is located within the polymer matrix and free water as existing in larger pores that may be located in the matrix. In wood, the bound water usually means the water located within the cell wall, whereas the free water is located in larger void spaces, such as the cell lumen. Water molecules that hydrogen bond to polymer sorption sites have less mobility compared to water molecules that are not so directly bonded. However, the residence times of water molecules in association with matrix OH groups may be very short, meaning that such molecules are in reality indistinguishable from the free water molecules, due to very rapid exchange [27]. Water mobility can be determined using nuclear magnetic resonance (NMR) relaxation times or dielectric relaxation spectroscopy (DRS), [65], as is discussed later. In NMR, the relaxation of protons is mainly dipolar and in water both translation and rotation relaxation mechanisms are important. In addition, the exchange of protons between the water molecules and polymer hydroxyl sites is also a significant relaxation mechanism [27, 66,67,68]. This makes the determination of water mobility in the matrix problematical. The water molecules in ‘bound’ and ‘unbound’ environments would be expected to exhibit different mobilities, although exchange between the different environments can be very rapid, so individual molecules are unlikely to exist in a specific state for long.

There exist nm-sized pores within the polymer matrix that are often termed micropores (IUPAC definition meaning pores with diameter less than 2 nm), but the more general term ‘nanopores’ is used in this review to mean nm-sized pores, with no strict definition. Water that is confined within the nanopores of the polymer structure exhibits a freezing point depression compared to unconfined water [69]. This freezing point depression is caused by a combination of osmotic and capillary effects. It is possible to determine the relationship between the freezing point depression and water amount using techniques, such as NMR [27, 70] or calorimetry [71]. The results are usually expressed as a pore size distribution (PSD), where the pore size is related to the freezing point depression by the Gibbs–Thomson equation. There is also a proportion of the water that is described as non-freezing, in that it does not exhibit a phase change at reduced temperatures and this population is assigned to water that is in a ‘bound’ state, i.e. closely associated with the polymer network [72]. However, it is not necessary to invoke a special state of water (‘bound’) to explain non-freezing water and it is difficult to provide unambiguous evidence for the existence of water that might be described as ‘bound’ [27]. Other experiments with non-polar solvents in swollen polymer networks have also cast doubt on the hypothesis that non-freezing water is necessarily attributable to hydrogen bonding with polar groups on the polymer [73]. It is clearly problematical to assign water populations unambiguously to ‘bound’ or ‘unbound’ states.

The pre-existing (residual) free volume within the polymer matrix consists of nm-sized pores, but the geometry of this nanoporosity can evolve as water molecules enter and exit the polymer matrix and this dynamic behaviour is referred to as transient porosity. The evolving properties of this nanoporosity can be investigated using positron annihilation lifetime spectroscopy (PALS) [74]. For example, PALS measurements in carbohydrate matrices in sorption experiments show that the nanopore size initially decreases but then increases as the MC is raised, due to the accompanying plasticization of the polymer chains [75,76,77]. The initial decrease is observed because the initially ‘empty’ voids associated with residual free volume begin to fill with water molecules. The existence of transient microporosity in polymers, gels and the cell wall of plant materials is an important factor which must be considered when explaining sorption and diffusion phenomena. This dynamic behaviour is quite different from an inert porous material, such as a zeolite or nanoporous carbon, in terms of hygroscopic properties and origin of hysteresis [78, 79].

Sorption kinetics and diffusion within the polymer matrix

When water molecules enter a polymeric matrix, the macromolecules will rearrange their structure to accommodate the sorbed water molecules at a rate that depends on the ambient temperature and the concentration of solvent, in addition to steric effects related to the chemical structure. The relative time scales of the diffusion of solvent molecules and polymer relaxation determine the nature of the transport process. This can be represented in terms of a diffusion Deborah number (De), which is the ratio of the characteristic relaxation time and the diffusion time [80]. For a value of De less than 1, the changes in polymer structure occur much faster than the rate of diffusion of the solvent molecules and classical Fickian diffusion is observed. This is typical for rubbery polymers above Tg. When De is greater than 1, the polymer chains rearrange much more slowly compared to the rate of diffusion of solvent molecules and the diffusion process is relaxation-limited rather than determined by a concentration gradient. This behaviour is characteristic of polymers below Tg, and diffusion of water through glassy polymers is non-Fickian in nature [60]. When De is close to 1, anomalous diffusion is observed, with a coupling of relaxation-limited and Fickian processes. Pseudo-Fickian models of this type include that developed by Berens and Hopfenberg, amongst others [81,82,83,84]. The relaxation term is actually an average of many relaxation processes, but for many polymer/penetrant systems, a single relaxation term is sufficient to represent the behaviour in macroscopic systems [85]. The sorption kinetics of glassy polymers is often interpreted using a model which incorporates two independent relaxation terms describing contributions from diffusion and relaxation processes [81, 82]. Another interpretation for a two-component kinetic model is the movement of a penetrant solvent front through the sample with associated swelling [86].

This two-component anomalous diffusion process is not to be confused with the dual-mode model which has been developed to describe sorption in glassy polymers. The dual-mode model assumes that there are two populations of water, one of which acts as a solvent for the polymer (called the Henry’s Law population) and is therefore intimately mixed within the structure. The other population is sorbed onto the surface of nanopores that are considered to exist within the structure (called the Langmuir population) as a consequence of excess free volume that is frozen into the glassy matrix below the glass transition temperature [61, 87, 88].

Although dual-mode sorption models can quite successfully model the sorption behaviour of glassy polymers, they are empirical; requiring temperature-specific parameters to be evaluated for sorption and different ones for desorption. Furthermore, in order to describe differences between absorption and desorption isotherms, it is necessary to assume that there is an exchange between the two water populations (a proportion of the dissolved population now becomes part of the Langmuir population). In addition, it must be assumed that this change must be instantaneous at the point of transition from absorption to desorption (which does not appear to be represented by a realistic physical phenomenon). The explanation for this behaviour assumes that the hole population increases with the concentration of sorbate molecules. For this to occur, there must be sufficient free volume for the polymer chains to move and allow for diffusion of the sorbate molecule. Furthermore, when the polymer relaxes back to the original configuration, this then prevents the penetrant molecule from diffusing back to its original position. The diffusing molecule is effectively ‘trapped’ in the new site that has been created, with a large energy barrier preventing further movement [89]. Based upon this modification of the dual-mode model, the Tg represents the point at which the last hole is created as the temperature is reduced until the structure is ‘frozen’ [90].

The ability of sorbed water molecules to act as a plasticiser for glassy polymer networks and to increase the free volume (thereby facilitating polymer reconfiguration) has been widely discussed [91,92,93,94,95,96]. In free volume models, diffusion of low molecular weight penetrants into amorphous polymers above Tg is considered to take place by the hopping of the penetrant molecules into free-volume nanopores which are formed by random thermal fluctuations of the matrix molecules [97, 98], as the MC increases, this ‘stop/go’ motion is facilitated [99]. Below Tg, rearrangement of the polymer networks requires cooperative relaxation processes [29, 100, 101] and as the temperature of the polymer is reduced, the size of the domain of cooperation increases, reducing the likelihood of reconfiguration events. However, the presence of water molecules acting as a plasticiser within the matrix creates free volume, which facilitates rearrangement of the polymers and consequently reduces the Tg of the system. The rate of diffusion of water in the nanopores of the gel is affected by the connectivity or tortuosity of the network [68, 102], depends on the MC [103] and decreases as free volume decreases [104]. However, this porosity network is dynamic, rather than fixed as it would be in an inert material with concepts such as tortuosity giving the misleading impression that interconnectivity between nanopores is persistent.

Transport of sorbate molecules through the dynamic nanoporous network within the matrix is therefore dependent upon molecular mobility of the matrix. Where the sorption behaviour is dominated by bulk diffusion, the principal model that has been used to describe sorption kinetics has been based upon Fickian diffusion. However, for materials that exhibit sorption-induced dimensional changes, it has been long realized that a simple Fickian diffusion model is inadequate to describe sorption kinetics; applying particularly to glassy polymer/penetrant systems, where deviations from Fickian behaviour are commonly noted [105]. This has led to the development of alternative models where the kinetics is defined as being relaxation limited and is dominated by the relatively slow viscous relaxation of the polymer matrix [106]. Models of this type consider the dimensions of the penetrant molecules, the interactions between penetrant and polymer (solvation) and the creation of free volume within the polymer matrix. Because of the dramatic change in behaviour observed with glassy polymers, the effect of penetrant molecules upon the Tg is of major importance [84, 107, 108].

Hydrogels

Hydrogels are three-dimensional crosslinked hydrophilic polymeric materials, which can absorb large amounts of water, with associated swelling of the structure, but without dissolution. Hydrogels consist of a region where crosslinking occurs between sections where there is high polymer chain mobility, plus chemical groups that interact with water molecules [109]. The sorption behaviour of non-ionic hydrogels is controlled by factors that control the swelling of the network structure, namely:

-

The hydrophilic properties of the polymer chain which affect the polymer-water mixing and the swelling of the network (represented by the F–H interaction parameter).

-

The elastic response of the crosslinked network (entropic in nature), which counteracts the swelling.

Although crosslinking can be achieved through the formation of non-covalently-bonded regions (known as physical hydrogels), these may not be stable when subjected to mechanical forces, and covalent linkages are usually required to ensure long-term stability, although metal ion-complexed crosslinks are usually hydrolytically-stable under neutral conditions [110]. A higher crosslink density results in an increase in mechanical strength and modulus, but a decrease in the degree of swelling and rate of diffusion of water molecules through the polymer network [20, 111,112,113,114,115]. The amount of water that hydrogels can hold is a function of the crosslink density and stability within the polymer network, as well as the nature of the hydrophilic groups on the polymer backbones [23].

The dipole–dipole interaction between the water molecules and the polymer network creates an osmotic pressure within the matrix that results in swelling when the hydrogel is exposed to water. When a hydrogel is exposed to moisture, it will exchange water molecules with its environment until it reaches an EMC; where there is a balance between the elastic strain stored in the polymer matrix and the osmotic pressure [116, 117]. The sorption process is viewed as not being one of molecules attaching to sorption sites on a surface (internal, or external), but rather analogous to a process of dissolution of the polymer chains.

Natural hydrogels are based upon polysaccharides (e.g. cellulose, starch, gels, carrageenan, alginates, dextran, pullulans, chitosan, chitin) [118], proteins [119,120,121,122,123,124] and polyphenols (e.g. lignin) [109, 125]. The most commonly used polymers for synthetic hydrogels are poly(vinyl alcohol), poly(lactic acid), poly(ethylene glycol|), poly(ethylene oxide), poly(acylic acid), poly(arylamide), poly(vinylpyrrolidone) and poly(caprolactone) [23]. This group of materials also includes nanocomposite hydrogels, which comprise inorganic and organic components, such as exfoliated clay platelets dispersed in a hydrogel matrix [126].

The swelling kinetics is either diffusion-limited or relaxation-limited. In the first case, the diffusion of water molecules through the polymer matrix occurs at a much faster rate than the relaxation of the polymer chains, and the rate of swelling is controlled by the concentration gradient. In the latter case, the rate of penetration of the water molecules is controlled by the relaxation of the polymer network.

A development of the F–H model is the Flory–Rehner (F–R) theory that describes the swelling behaviour of gel networks [116, 127]. The swelling of the polymer network is determined by the elastic energy of the polymer chains and a mixing function that is determined by the interaction between the water molecules and the polymer network (and hence the interaction parameter described earlier). The free energy of the hydrogel can therefore be expressed as:

where ΔGgel represents the contribution of the elastic strain energy and ΔGmix is the energy of mixing.

However, F–R theory does not completely describe the swelling behaviour of gels, and various modifications have therefore been proposed [128]. Furthermore, the F–H/F–R models are only able to describe the sorption behaviour of polymer solvent systems in the rubbery state (above the Tg). One characteristic of the sorption isotherm of glassy polymers is the presence of a pronounced ‘shoulder’ at low sorbate concentrations, which is not predicted by F–H theory. Attempts have been made to model this behaviour by making the interaction parameter (χ) adjustable, but such an approach is not really satisfactory, since it reduces χ to an arbitrary fitting parameter rather than a well-defined constant [38].

Many gels exhibit a sigmoidal isotherm curve (IUPAC Type II), for which a modification of the F–H/F–R model is required. One approach is to combine the F–H model with a polymer structural relaxation model [129]. Water molecules entering the polymer network can result in a plasticising effect, resulting in non-ideal volumetric changes. The result is that there is an additional free energy change beyond that predicted by the F–H model. Different models attempted to take account of this behaviour and explain the observed Type II isotherm by taking account of the free volume created by the sorbate molecules [33, 35, 130].

These free volume methods take account of the polymer being in a glassy state, which however is not an equilibrium state and, in principle, classical thermodynamic-based theories of sorption are not applicable [131]. However, it has been shown that free volume theories do have a physical basis, because the excess sorption found in the glassy state is related to the elastic energy stored in the polymer network [132]. During the process of absorption, the polymer network swells to accommodate the penetrant molecules resulting in changes in the configuration of the polymer network, which is stored as strain energy. This is an entropic property, since the configuration of the polymers has changed as a result of the presence of the penetrant molecules. The equilibrium point is reached when the energy of mixing and the elastic strain energy are balanced [133].

The properties of water absorbed in hydrogels are determined by the polymer–water interactions and by the geometry of the nanopores in the 3D structure. Different water states have been claimed to exist in hydrogels—‘bound’ water associated with sorption sites, ‘intermediate’ water and ‘free’ water with no specific association with the polymer chains [65, 134]. Molecular dynamic studies of hydrogels have shown that the structure of water is significantly modified in the region of the polymer chains [135]. Calorimetric measurements in a hydrogel of poly(2-hydroxyethylmethacrylate) indicate that water undergoes a glass to liquid transition in two stages, which was interpreted as water interacting with either the hydrophobic or hydrophilic segments of the polymer chains [136].

The interaction of moisture with wood and other lignocellulosic materials

The molecular components of plant cell wall lignocellulosic materials and their interaction with moisture

This subject area has been extensively covered in numerous reviews, e.g. [137,138,139,140,141], and only a brief introduction is included here, giving a generalized description. Lignification occurs in various plant cell types (tracheary elements, schlerenchyma cells, endodermal cells, seed coat cells and siliques cells) and can occur as a natural part of cell development or in response to biotic or abiotic stresses [142]. The discussion that follows and the main subject of the review is concerned with the tracheary elements, with an emphasis on wood products.

The properties of wood and other lignocellulosic materials are derived from the behaviour of the constituent molecules, and this behaviour is strongly influenced by the presence of water [143,144,145,146]. The influence that water has upon the molecular dynamics of the cell wall matrix molecules (lignin-hemicellulose) is particularly important. The cell wall of lignocellulosic materials comprises long thin microfibrils of crystalline cellulose embedded within a matrix of hemicelluloses in combination with lignin (Fig. 3). The structure and composition of the lignin and hemicelluloses vary within and between plant species with some plant fibres (e.g. cotton) being essentially lignin-free [147]. The majority of the OH content is associated with the polysaccharidic components of the cell wall. However, although the cellulose component has a high OH/C ratio, only a proportion of this OH content is accessible to water molecules, with the remainder being inaccessible because it is located in crystalline regions within the core of the microfibril [57, 148,149,150,151,152,153,154]. Because of the extended crystalline structure and extensive hydrogen bonding network within the microfibrils, they are very strong and stiff [155,156,157,158,159,160,161]. Since the interior of the microfibrils is not accessible to water molecules, they remain largely unaffected by the presence of moisture in the cell wall, although it has been shown that the crystalline lattice of cellulose is changed by the absorption and desorption of water [162, 163]. This observation has been attributed as being due to external pressure applied by the surrounding matrix material upon cell wall hydration [164]. However, Paajanen et al. [165] noted that that the crystalline lattice expands in the [200] direction (and becomes distorted) in the dry state due to interaction with the neighbouring fibrils and the matrix polysaccharides. In the swollen state, the cellulose crystals can adopt a higher degree of order with a smaller lattice spacing in the [200] direction. There therefore is no need to explain this phenomenon by invoking a swelling pressure and MD models produced the correct results without any restriction of swelling at high MC. It is difficult to treat each cell wall component in isolation, for example when determining properties, such as elastic modulus, although values for cellulose have been reported in the literature [166, 167].

A diagram showing the location of the cell wall within the wood structure and illustrating the different cell wall levels with a microscopic view of the microfibrils embedded within a matrix (composed of lignin and hemicelluloses) (a). In b, the effect of the presence of sorbed water molecules in the inter-microfibrillar matrix results in the expansion of the matrix (leaving the microfibrils unaffected). In the upper part of (b), the microfibrils are oriented in a longitudinal direction and this results in expansion in the transverse direction only.

By contrast with the cellulose, the hemicellulosic components have a lower crystalline content and consequently contain a much higher proportion of accessible OH content [168,169,170,171]. The lignin is an amorphous three-dimensional network polymer comprised of phenolic building blocks that has a much lower OH/C ratio compared with the polysaccharide content [172,173,174]. Simplistically, the structure of the cell wall can be viewed as similar to a fibre-reinforced composite, with the cellulose microfibrils being the reinforcing element, the lignin the matrix material, and the hemicelluloses acting as an interfacial coupling agent [139]. Reliably measuring the softening point of lignin and hemicellulose is extremely difficult, and although values of Tg for these components have been reported, these are expected to be different when determined in situ, rather than when determined for the isolated molecular species [166, 175,176,177,178,179]. There is not a single well-defined glass transition temperature of wood, due to its complex composition and structure, and this makes application of models invoking a relationship between sorption properties and Tg problematical [36]. A useful approach in this context is to study the same species but use genetic manipulation to change one of the molecular components and study the resulting change in properties. For example, a study of the effect of different lignin types on the thermal softening of transgenic aspen showed that a reduction in lignin content reduced the softening temperature, but that changing the syringyl/guaiacyl ratio did not affect the Tg [180].

The presence of water in the enveloping hemicellulose-lignin matrix has a significant influence upon molecular motion of the matrix molecules in a manner analogous to a water-gel polymeric network [181]. When dry wood absorbs moisture, this causes the structure to swell and if restraint is placed upon the wood sample, then a swelling pressure is generated. The absorption of water into the cell wall results in swelling of the cell wall matrix which creates additional void volume [182, 183], resulting in an increase in the spacing between adjacent microfibrils [184]. However, it must be noted that wood in its native (never-dried) state is already saturated with water and that macroscopic stresses arise when the wood is dried from this native state to a MC below the fibre saturation point [185]. These macroscopic strains can be annealed out by re-wetting the wood (often with the application of heat). These macroscopic stresses are not the same as the micromechanical stresses that arise in the macromolecular matrix when water molecules enter the structure giving rise to stored elastic strain energy which is released when water leaves the cell wall. The amount of water that is contained within the cell wall is determined by the thermodynamics of the system. When the bound water chemical potential is in equilibrium with the free water chemical potential, then a state of equilibrium is realized [186]. A recent paper has presented an alternative view of the interaction of water with wood and other semi-rigid swelling materials [187]. In this model, internal conformational strain is stored in the structure during the drying, with the swelling of the materials having an enthalpic origin. It is further pointed out in this paper that the relationship between the temperature-dependent isotherm, heat of swelling and swelling pressure/work of swelling is incompletely understood and needs further experimental investigation.

In terms of molecular mobility, the hemicelluloses are the component most affected by the presence of water in the cell wall; because the cellulose is constrained by extensive hydrogen bonding networks and the lignin by extensive crosslinking [139, 166, 188,189,190,191,192,193,194,195]. The interface between the surface of the cellulose microfibril and the hemicellulosic component has an important role to play when considering the properties of lignocellulosic materials under load in the presence of moisture [196, 197].

As a result of the presence of essentially hygro-inert microfibril elements embedded within a dynamic matrix, the orientation of the microfibrils gives rise to anisotropic behaviour. For example, the microfibril angle within the S-2 layer of the wood cell wall affects the swelling behaviour of the wood at a macroscopic level. In most types of wood, the microfibrillar winding angle is typically 10–30° relative to the longitudinal axis of the cell wall, which results in swelling in the transverse orientation being greater than in the longitudinal direction. In certain types of wood (such as compression wood in gymnosperms or juvenile wood), higher winding axes result in much greater transverse swelling [198, 199]. This is shown in Fig. 3.

However, usually the microfibrils are oriented at a finite angle to the longitudinal cell axis, which results in some expansion in the longitudinal as well as the transverse direction. This property is determined by the magnitude of the microfibril angle (Fig. 3).

An interesting approach to furthering understanding the interactions of moisture with lignocellulosic materials is to use molecular modelling [200]. For example, a study of the molecular dynamics of biopolymers considered the effect of moisture and heat upon the hygric swelling, thermal expansion and mechanical properties of lignin [201]. This study investigated an uncondensed lignin (a linear polymer) with a degree of polymerisation (DP) of 100 and consisting of five chains, as a model for the condensed (crosslinked) lignin found in the cell wall of plants. Water molecules were inserted into the model and effect on molecular dynamics investigated. A molecular modelling study which included all of the cell wall components found that the hygromechanical behaviour of the cell wall composite was not much affected by the lignin, which was found to be largely hydration independent [202]. The main problem with such an approach is the complexity of the molecular arrangements in the cell wall which requires simplification for the models to work. Furthermore, the exact molecular arrangements are not known, so when creating the models, it is necessary to base these on limited experimental evidence. The challenge is not to simplify to the point where the model no longer offers useful insights.

The sorption isotherm

The relationship of wood and other cellulosic materials with water vapour has been extensively studied for more than a century, yet remains incompletely understood. Before proceeding further, it is important to distinguish the difference between an isotherm obtained with previously-dried, compared to desorption of water-saturated lignocellulosic material (Fig. 4). It was originally thought that the boundary curve followed in the first desorption cycle from the ‘green’ state was unique and that subsequent desorption cycles would follow a different path. However, this has been shown to be erroneous and that subsequent desorption cycles will rejoin this boundary curve, although the exact behaviour depends strongly on the drying conditions employed after the first desorption cycle [203]. The isotherms discussed in this paper exclusively refer to the sorption behaviour of lignocellulosic material that has been previously-dried. The sorption isotherm of lignocellulosic materials is a characteristic sigmoidal IUPAC Type II curve exhibiting hysteresis between the absorption and desorption isotherm branches [204,205,206,207,208,209,210]. The properties of the desorption isotherm depend upon the point at which desorption is initiated and whether it is a scanning or boundary desorption isotherm curve [211, 212].

Sorption isotherm showing the first desorption from the water-saturated state and subsequent sorption cycles (lhs) and absolute hysteresis for these two cycles (adapted from [211]).

There are many sorption models that have been applied to experimental sorption isotherms of hygro-responsive natural materials. Models which treat the substrate as an inert porous material, with a defined internal surface are not appropriate [2, 204], but nonetheless have been extensively applied to sorption isotherms of wood and many other natural materials, foodstuffs, etc. [2, 3]. In models of this type, the internal surface area and monolayer versus multilayer coverage are parameters of interest but have no physical meaning when applied to dynamic systems. Many of these static material models either consider the substrate as a planar surface or an inert porous material, but take no account of the changes in dimension occurring when the material interacts with moisture. In the static pore models, hysteresis arises from consideration of mechanisms of pore filling and pore emptying, which is applicable to inert porous, but not hygro-responsive lignocellulosic or cellulosic materials. Although inert substrate models can apparently reproduce the experimental data, they do not provide any insights into the physical nature of sorption and desorption of natural materials (such as wood and plant fibres) that exhibit dimensional changes as a result. They certainly provide no information regarding how the mechanical properties are changed by the presence of moisture.

At a given temperature, a sample of wood will absorb or desorb water until it reaches a state of equilibrium, which can take a considerable amount of time, even for small (mg) samples [214, 215]. The equilibrium MC represents the point at which the MC at a particular RH remains constant and where the rates of absorption or desorption are the same [216]. Establishing these points experimentally can be very time-consuming and usually involves the setting of a weight change criterion to establish an approximate ‘equilibrium’ point. This usually involves a decision where the weight change over a period of time is no more than a small percentage of the ‘true equilibrium’ value [3]. This can be a particular problem with using dynamic sorption equipment if only one sample is tested per sorption run, since the weight change criteria necessary to establish an ‘equilibrium’ value can lead to extremely long time periods (months) being required to establish one isotherm. In addition, it is recommended that a minimum of two and preferably three isotherm runs be performed on the same sample consecutively in order to establish reproducibility of the data [217]. Furthermore, several samples of the same material should also be measured to establish reproducibility. This makes production of isotherm data logistically impractical with single sample devices. Glass et al. [214] have identified slow sorption processes with characteristic times of the order of 500–2000 min that can only be identified if hold times of the order of 24–50 h are used for each RH step. The question of whether the more logistically practical equilibrium criteria can be used in comparative studies remains open.

However, even when great care is taken to establish the EMC, this state is not considered a true thermodynamic equilibrium because there is hysteresis between the absorption and desorption branches. This does not mean that a ‘true’ equilibrium would be established if the experiment was run for a sufficient length of time, since the differences between the absorption and desorption branches of the isotherm are not related to the time of exposure in the experiment. Most sorption isotherms are recorded up to a RH of 95% since there is an increasing likelihood of capillary condensation of water within the macropore structure of the cell wall and difficulties in maintaining an accurate stable RH much above 95% RH [211]. There have been attempts to project the absorption isotherm curve up to a value of 100% RH and use this cross-over point to estimate a fibre saturation point (FSP). This point may, or may not, coincide with a region where there is a change in physical wood properties with cell wall MC [218,219,220]. Thybring et al. point out that FSP (determined by changes in wood properties with cell wall MC) should not be confused with maximum cell wall MC, for which values depend upon the measurement method employed [70].

Sorption hysteresis

Sorption hysteresis is the property where the sorption behaviour of the material is different, depending upon whether the MC is increasing or decreasing. For the purposes of this review, only hysteresis within the hygroscopic range (from 0% to approximately 98% RH) is considered here [211, 213]. Water sorption within the hygroscopic range occurs in the cell wall, and sorption behaviour is linked to the mechanical response of the cell wall (and hence macromolecular dynamics). Although universally observed in the sorption isotherms of lignocellulosic materials (as well as other hygro-responsive materials), there is still much discussion regarding the origins of hysteresis. Some general observations are here made about sorption hysteresis in lignocellulosic materials:

-

Sorption hysteresis is generally determined by subtracting the absorption EMC from the desorption EMC at the same RH value—this is referred to as absolute hysteresis (simply referred to as hysteresis in this review) (Fig. 4). An alternative approach is to divide the desorption EMC by the absorption EMC to provide the hysteresis ratio – not referred to any further in this paper.

-

Empirical observations have shown that the absolute hysteresis is dependent upon the lignin content of the sample—with materials having a larger lignin content displaying a higher hysteresis value [221].

-

Thermally modified wood shows a lower level of moisture uptake throughout the isotherm overall, but the hysteresis is greater than that observed with unmodified wood of the same species [139, 222]. However, this only applies to the first sorption cycle; in subsequent cycles, the sorption hysteresis is considerably reduced. This behaviour has been attributed to changes in cell wall mechanical properties.

-

The area bounded by the sorption hysteresis loop decreases as the isotherm temperature is raised [221, 223,224,225,226,227].

-

Sorption hysteresis is history dependent, with the previous sorption history of the sample affecting the behaviour [49, 204, 217, 228, 229].

Early attempts to explain sorption hysteresis were based upon models that assumed that the availability of sorption sites was different during absorption and desorption cycles [230] or by considering the sorption behaviour of porous materials [231]. Models of this type treat the cell wall substance as an essentially inert porous material with hysteresis explained by considering the physics of pore filling and emptying [221]. This model considers both film-forming in pores, which does not exhibit hysteretic behaviour and capillary condensation, which does. Independent domain theory has been applied to this underlying theory to model a series of scanning desorption curves, which can, in turn, be used to create a desorption boundary curve [232,233,234,235,236]. The modified Mualem model [237] is a simplification of the independent domain model in which no interaction between pores is considered and where the adsorption and desorption of the pore system are only determined by the pore necks and pore bodies. This model requires the use of an adjustable parameter which is determined from a selected calibration point on the desorption curve, with good fits to the desorption curve obtained using this process [237]. However, the use of models which treat the cell wall as a static porous network do not offer useful insights into the behaviour of dynamic swelling systems, even less so if the model relies on arbitrary fitting parameters. The independent domain model can be applied to populations of sorption sites [235], but the details of the interaction of water with these sites are not considered in the model. The model is concerned with the interaction of a material with a sorbate where the sorption steps are finite, with the sorption sites being in one of two possible states [238, 239]. An alternative approach is to model the number of excess absorption sites which are postulated to exist during the desorption process [240]. Why extra sites would be generated at the instant of desorption is hard to explain through any known physical process (similar to the problem with applying the dual-mode model). Invoking the state or number of sorption sites as an explanation of hysteresis also does not provide insights into the links with dynamic swelling behaviour and molecular motion within the cell wall. In an interesting development, the relationship between swelling behaviour and sorption hysteresis was explored, in particular by examining differences in hydrogen bond networks formed during absorption and desorption cycles of the isotherm [241]. This model was further refined to include the effect of cellulose nanocrystal elements embedded within an amorphous matrix, the presence of which limited the swelling of the matrix, leading to a reduction in sorption and hysteresis [242], a result that has been experimentally observed [243].

There is a considerable body of evidence indicating that sorption hysteresis in hygro-responsive materials has to be linked in some way to the molecular mobility behaviour of the cell wall polymer network and this approach has been used to explain hysteresis in various water–polymer systems [41, 221, 225, 243,244,245,246,247]. According to many such models, the phenomenon of hysteresis is observed in glassy polymers, where the response of the polymer matrix to the ingress or egress of sorbate molecules is not instantaneous, but limited, due to a lack of void volume resulting in a restriction in molecular motion. This results in the matrix being in different configurations during absorption and desorption. Plasticization of the matrix by sorbate molecules will lead to a reduction in hysteresis, as will an increase in isotherm temperature. According to such a model, a collapse of sorption hysteresis will be observed when the Tg of the matrix is exceeded. The idea that hysteresis is linked to plastic deformation of the cell wall, which can be considered an analogue of a gel-like polymer system, is certainly not new and was first proposed by Barkas as far back as the 1930s [45, 183, 248,249,250,251].

Noting that dry, native cellulose decomposes before reaching its Tg [252], Salmén and Larsson used a modified cellulose polymer which exhibited a moisture-induced softening within the temperature range of 20–65°C [225]. By studying this material using humidity scanning dynamic mechanical analysis (DMA) and conducting sorption experiments, at different temperatures, they were able to determine the relationship between Tg and hysteresis of the isothermal sorption loops. This work showed that there was such a relationship and, furthermore, that sorption hysteresis vanished above the glass transition temperature, in agreement with previous work reported for glucomannan [243] and more recently for other water-polymer systems [41, 245]. This explanation for hysteresis is able to explain the disappearance of hysteresis above Tg, or where the moisture levels are sufficient to change the state of the polymer network from glassy to rubbery, but there are examples of cellulosic systems where the hysteresis is mainly in the higher part of the hygroscopic range, but essentially absent at lower moisture contents [253, 254]. It is well known that the sorption behaviour of lignocellulosic materials is influenced by the previous sorption history of the material, and it is for this reason that the ‘gripped-box’ model was introduced to describe sorption hysteresis [228]; however, this model is empirical and does not relate to any of the physical properties of the material. It should be noted that at very high levels of relative humidity (above 95%), an additional hysteresis phenomenon is observed, which has been thoroughly discussed elsewhere [213, 255] and will not be considered further in this review.

Sorption sites

The primary sorption sites in wood are the OH groups associated with the cell wall polymers (cellulose, hemicellulose and lignin), plus some ionic groups [26]. The main method for determining the concentration of accessible OH groups in wood and cellulosic materials is to use deuterium (2H, or D) exchange with D2O; a subject that has been thoroughly reviewed [204, 256]. Dynamic vapour sorption (DVS) equipment of various types has proven to be very useful for these deuterium exchange experiments, but it is essential to use the correct protocols in order to obtain reliable results [48]. By the use of such studies in wood samples, it has been found that accessible OH content is not affected by the MC of the sample, but that there was a low concentration of OD groups persisting after deuterium exchange and subsequent re-protonation [257]. This latter observation is probably linked to the existence of both fast and slow exchange processes. The slower process is affected by many experimental variables, such as sample geometry, deuteration conditions, RH and temperature; but the crystalline core of the microfibrils remains resistant to these exchange processes [258]. In Fig. 5 below, a comparison of the number of water molecules per OH group (‘sorption site’) is shown, based upon the Z–L model, or based upon the assumption that there are 9 mmol of accessible OH groups per gram of dry wood material. Also shown is an isotherm from which these data were derived. It can be seen that the number of water molecules per accessible OH group or mean cluster size does not exceed 2 water molecules even at 95% RH.

Water in the cell wall of lignocellulosic materials is usually considered to either be directly hydrogen bonded to the primary sorption sites or hydrogen bonded to other water molecules and is thus considered to form two populations within the cell wall. This idea was supported by the observation in DSC scans that there were both freezing and non-freezing water populations. However, as was noted earlier in this review with previous work on polysaccharide gels [27], it has been shown that the presence of freezing and non-freezing water in the wood cell wall is not necessarily due to distinct water populations but may be an experimental artefact [204, 259]. Experimental techniques, such as NMR and inelastic neutron scattering, have been used as evidence for identifying different water populations, as is discussed later. There has been some analysis of water clustering in the wood cell wall using the Z–L model [260,261,262,263,264,265,266,267,268,269]; which could possibly be interpreted in terms of different water populations (i.e. directly H-bonded to polymeric OH groups and indirectly-bonded via an intermediary water molecule), but the applicability of the Z–L model for such purposes is questionable. The issue of whether water tends to form clusters around sorption sites or is more evenly distributed is an important one and continues to elicit interest [6, 260, 261, 263, 266, 270, 271]. Even if such separate populations do exist, it is possible that the dynamics of exchange between these populations is over such short time scales that they cannot be resolved.

Various estimates can be found for the total accessible OH content of wood samples, and it is essential to be aware that some experiments are compromised because of the application of inappropriate experimental protocols, but values in the region of 8.5–9.5 mmol g−1 appear to be representative [257, 272]. Various estimates can be made for the saturation level of water in the wood cell wall, which typically varies between 20–50% by mass, depending upon the method used for measurement (higher values have been reported) [70]. These data allow for a very crude estimation of the number of water molecules per polymeric OH site in wood (between 1.2 and 3.3 water molecules per OH group at cell wall saturation): Berthold et al. estimated this to be 1–2 water molecules per OH site at 92% RH [26]. This is an average value and assumes an even distribution of water molecules throughout the matrix in the manner of a solvent. Obviously, as the MC of the cell wall reduces, so does the ratio of water molecules to accessible OH groups, with the possibility of water molecules bridging adjacent OH sites at lower MCs.

Hygro-responsive behaviour

Dimensional changes occur in response to variation in the cell wall MC of the lignocellulosic material. With an increase in cell wall MC, swelling occurs in the lignin–hemicellulose matrix, resulting in an increase in the distance between the cellulose microfibrils [273, 274] and some disaggregation of supramolecular microfibrillar structures [275], leading to macroscopic dimensional changes which are controlled by microfibrillar orientation [167, 276, 277] and accompanied by an increase of the water diffusion coefficient in the surrounding matrix [165, 182, 274, 278]. These dimensional changes in the cell wall couple to produce visible anisotropic changes in the shape of macroscopic specimens in a complex way [1, 186, 279, 280] manifested as swelling/shrinking of the samples and the development of macroscopic stresses if the material is restrained [281,282,283]. The main cell wall layer that is associated with dimensional changes in wood is the S-2 layer, with the microfibrillar orientation of the S-2 layer having a major influence on the anisotropy of swelling [284], although other cell wall layers and the surrounding wood substance do influence this behaviour [285,286,287].

When attempting to model the interaction of moisture with swelling materials, such as wood, the molecular dynamics of the interfibrillar matrix in the presence of moisture must be considered [107]. If a gel model for the hygro-responsive behaviour of the cell wall is adopted, then the equilibrium established during absorption/desorption is linked to the elastic strain energy stored in the matrix and the relationship of this to the activity of the water at different RH levels [45]. However, the gel behaviour of the cell wall is, in reality, restricted to the hemicellulose/lignin matrix, and the global behaviour is better represented by consideration of an inert reinforcement (the microfibrils) embedded within the matrix [288] and models for such composite morphologies have been developed [289]. The presence of moisture-inert reinforcing elements (microfibrils) within the hygro-dynamic gel-like matrix gives rise to anisotropic dimensional changes in response to changing RH [284]. Many other materials in nature also employ a composite structure with fibres, rods or sheets embedded in a gel-like matrix to impart properties such as toughness or specific geometrical changes [200].

In lignocellulosic materials, the mobility of the molecular chains of the lignin–hemicellulose matrix is an important factor that must be considered when modelling sorption and diffusion behaviour [107, 246, 290] and, as noted, also applies to the phenomenon of hysteresis [221, 225, 243, 246, 291]. Although there is still much debate regarding the dynamic response of wood and other lignocellulosic materials to changes in RH of the surroundings, there does appear to be the development of a consensus that some sort of relaxation-limited model is the best approach [107].

It is very well known that the mechanical properties of wood change with variation in cell wall MC. There is a reduction in stiffness and strength, but an increase in toughness as the MC of the wood is raised [198, 292, 293]. These properties change up to a nominal FSP but remain approximately constant thereafter; although this correlation is not as simple as is sometimes assumed [70, 294]. Carrington noted that the mechanical properties of wood change at approximately 5% MC [295], an observation subsequently confirmed by others [296,297,298]. The reasons for this are not fully explained, but it is assumed that at lower cell wall MC, there is some disruption of H-bonding within the polymer network and that at higher cell wall MC plasticization of the polymer network occurs [299]. A recent review of the DMA literature has shown that there is distinct minimum in tan − δ at 5% MC in almost all studies for measurements in the longitudinal direction [300]. That review is comprehensive, and the reader is directed to this reference for further analysis and discussion regarding the use of DMA for investigating the interaction of moisture with wood and the effect on dynamic mechanical behaviour. Useful DMA experiments for studying the interaction of moisture with natural materials should vary the surrounding RH and keep the temperature constant (as with isotherms). Unfortunately, DMA studies that only vary the temperature are of little to no value for understanding the hygro-dynamic behaviour of wood.

Mechanosorption is a term that is used to define the mechanical properties of a material when it is simultaneously exposed to atmospheric moisture and is concerned with the time-dependent properties. It is also observed that the sorption behaviour of wood is affected by any external mechanical forces that may be applied [301, 302]. It is generally assumed that mechanosorptive behaviour has two components. One is an instantaneous phenomenon which is linked to the mechanical response of wood during drying or wetting when it is under load. The second is a delayed effect, which is referred to as mechanosorptive creep and which is accelerated under conditions of RH change [303,304,305,306,307]. It is known that wood and other lignocellulosic materials, such as natural fibres [308], will exhibit creep when subjected to constant load and that creep is magnified if the load is applied under conditions of changing RH [309, 310]. Partial creep recovery occurs if a wood sample is subject to a static load and then remoistened [311]. The mechanosorptive creep effect can result in premature failure of wood samples depending on the rate of loading [312]. It has been observed that the magnitude of deformation occurring due to mechanosorptive creep is dependent upon the rate at which the MC of the wood changes, with much larger deformations occurring in environments which exhibit corresponding rapid changes in RH [306]. Most studies of wood behaviour examine properties either under conditions of equilibrium or constant RH, but wood in service is subjected to fluctuating environmental conditions, meaning that dynamic experiments are of great interest [223]. When water molecules enter the cell wall of wood, some of the hydrogen bonds associated with the matrix or matrix-microfibril interface are broken and replaced by water-OH bonds, resulting in a decrease in stiffness of the cell wall [196]. This is linked with a decrease in the energy barrier associated with the breaking and reforming of hydrogen bonds and facilitates viscoelastic creep under an external load. Mechanosorptive creep results in the so called ‘hygro-lock’ effect which occurs when wood is dried under load and which locks in distortion of the material. This can be reversed during a subsequent moistening period. It has be postulated that this permanent deformation effect is related to the ‘stick–slip’ mechanism of breaking and reforming of hydrogen bonding networks within the polymer structure [276, 313,314,315,316,317,318,319,320,321,322,323]. This hydrogen bond breaking is facilitated by the presence of interstitial water between the surface of the microfibrils and the matrix polymers in the hydrated cell wall [140].

Cell wall nanoporosity

The cell wall of wood is essentially non-porous in the dry state [324,325,326,327,328], in common with other lignified materials [329,330,331,332], but porosity is generated as water molecules enter the cell wall. This transient porosity evolves as the MC of the cell wall changes. It is problematical to image or measure this porosity, since many potential techniques require the samples to be dry [324]. Much of the earlier work used solute exclusion to determine the accessible microporosity of the water-saturated cell wall [324]. More recently, dual-axis electron tomography has been used to probe the architecture of the S-2 layer of the wood cell wall of never-dried Norway spruce at nanometre scale [333]. However, this experiment required mild-delignification prior to heavy metal staining. This technique allowed for resolution of the cell wall polymers and the micropore geometry, the latter having diameters predominantly below 3 nm. It is not clear how representative this geometry is of a water-saturated lignified cell wall, but diameters of this order are often reported using other techniques [324]. Another physical method to resolve cell wall microporosity uses silicon nanocasts [334]. This technique involves the penetration of swollen wood samples with a silica sol–gel, followed by calcination in a furnace to remove all the organic material, producing a negative cast of the wood, which was then examined using scanning electron microscopy and nitrogen sorption. Techniques of this type can be used to prove the existence of cell wall nanopores but cannot give information about pore dynamics.

A variety of techniques have been applied to investigating the nanoporosity of the cell wall, including: atomic force microscopy [335], NMR [336, 337], neutron scattering [338], fluorescent probes [339], nitrogen sorption [340], krypton sorption [326] and solute exclusion [341]. Thermoporosimetry is based on the observation that water-saturated porous materials (e.g. wood, pulp fibres) contain both freezing and non-freezing water, with the latter thought to be associated with water located in the cell wall nanopores [68]. This has led to the development of isothermal measurement methods to determine the amounts of freezing and non-freezing water in cellulosic samples [342]. However, differential scanning thermoporosimetry is claimed to give a more accurate measurement of pore size distribution compared to isothermal methods [71]. Note earlier comments regarding the interpretation of freezing and non-freezing water.

Sorption kinetics

The rate at which lignocellulosic materials take up, or lose, moisture depends on a range of factors:

-

Sample size—it is self-evident that the surface of the sample being directly exposed to the atmosphere will respond much faster to changes in RH compared to the interior of the sample [343]. However, even with small samples, moisture transport must be considered [344, 345].

-

Orientation of the sample—in thin samples, the orientation of the sample is important and affects the sorption kinetics [344].

-

Temperature—increased temperature leads to a higher rate of penetration of the water molecules in the sample.

-

Concentration gradient—the rate at which the sample changes mass depends upon the difference in concentration between the penetrant in the sample and in the surrounding environment.