Abstract

The most important variable of biomass-based fuels is moisture, because it affects the entire logistic chain by creating problems related to transport, handling, storage, and combustion. Recently, there has been a growing interest in thermal pre-treatment of biomass-based fuels by torrefaction. Torrefaction is intended to overcome the moisture-related problems by significantly reducing hygroscopicity and thus the logistics of solid biofuels could be improved. In order to gain a deeper insight on the changes induced by torrefaction, the sorption properties of Finnish birch and spruce wood were investigated. The sorption isotherms, hysteresis, accessibility, and surface area were investigated with dynamic vapour sorption. Also the particle size distributions and the clustering behaviour of water molecules were examined. As a result of the thermal pre-treatment, accessibility, adsorption of water vapour, and hysteresis were reduced. Particle size distribution was shifted towards smaller particles and the surface area measured with the BET method was reduced. Hysteresis was also reduced, which may be linked to the overall reduction in material’s hygroscopicity, as well as changes in porosity. The particle size affects sorption by increasing the surface area, but has a dual effect on accessibility, as it also blocks access to pores through agglomeration. In practice, the most important result is the increased hydrophobicity, but also the increased porosity and reduced particle size are to be considered as they can affect the handling and storage properties of torrefied and charred material negatively.

Similar content being viewed by others

References

Bergman PCA, Boersma AR, Zwart RWR, Kiel JHA (2005) Torrefaction of biomass co-firing in existing coal-fired power stations. Biocoal ECN-C—05-013

González-Peña MM, Curling S, Hale MDC (2009) On the effect of heat on the chemical composition and dimensions of thermally-modified wood. Polym Degrad Stab 94:2184–2193

Sivonen H, Maunu SL, Sundholm F, Jämsä S, Viitaniemi P (2002) Magnetic resonance studies of thermally modified wood. Holzforschung 56:648–654

Nakano T, Miyazaki J (2003) Surface fractal dimensionality and hygroscopicity for heated wood. Holzforschung 57(3):289–294

Hakkou M, Pétrissans M, Zoulalian A, Gérardin P (2005) Investigation of wood wettability changes during heat treatment on the basis of chemical analysis. Polym Degrad Stab 89:1–5

Rowell RM, Pettersen R, Han JS, Rowell JS, Tshabalala MA (2005) Cell wall chemistry. In: Rowell RM (ed) Handbook of wood chemistry and wood composites. CRC Press, Boca Raton, pp 35–74

Rautkari L, Hill CAS, Curling S, Jalaludin Z, Ormondroyd G (2013) What is the role of accessibility of wood hydroxyl groups in controlling moisture content? J Mater Sci 48:6352–6356. doi:10.1007/s10853-013-7434-2

Ciolkosz D, Wallace R (2011) A review of torrefaction for bioenergy feedstock production Biofuels. Bioprod Bioref 5:317–329

Svanberg M, Halldórsson A (2013) Supply chain configuration for biomass-to-energy: the case of torrefaction. Int J Energy Sector Manag 7(1):65–83

Kymäläinen M, Havimo M, Louhelainen J (2014) Sorption properties of torrefied wood and charcoal. Wood Mater Sci Eng 9(3):170–178

Hill CAS, Norton AJ, Newman G (2010) The water vapour sorption properties of Sitka spruce determined using a dynamic vapour sorption apparatus. Wood Sci Technol 44:497–514

Hill CAS, Norton AJ, Newman G (2010) Analysis of the water vapour sorption behaviour of Sitka spruce [Picea sitchensis (Bongard) Carr.] based on the parallel exponential kinetics model. Holzforschung 64:469–473

Hill CAS, Ramsay J, Keating B, Laine K, Rautkari L, Hughes M, Constant B (2012) The water vapour sorption properties of thermally modified and densified wood. J Mater Sci 47:3191–3197. doi:10.1007/s10853-011-6154-8

Popescu C-M, Hill CAS, Curling S, Ormondroyd G, Xie Y (2014) The water vapour sorption behaviour of acetylated birch wood: how acetylation affects the sorption isotherm and accessible hydroxyl content. J Mater Sci 49:2362–2371. doi:10.1007/s10853-013-7937-x

Popescu C-M, Hill CAS, Anthony R, Ormondroyd G, Curling S (2015) Equilibrium and dynamic vapour sorption properties of biochar derived from apple wood. Polym Degr Stab 111:263–268

Pönni R, Rautkari L, Hill CAS, Vuorinen T (2014) Accessibility of hydroxyl groups in birch kraft pulps quantified by deuterium exchange in D2O vapour. Cellulose 21(3):1217–1226

Zimm BH (1953) Simplified relation between thermodynamics and molecular distribution functions for a mixture. J Chem Phys 21:934–935

Zimm BH, Lundberg JL (1956) Sorption of vapors by high polymers. J Phys Chem 60:425–428

Hartley ID, Avramidis S (1993) Analysis of the wood sorption isotherm using clustering theory. Holzforschung 47:163–167

Rawat SPS, Khali DP (1998) Clustering of water molecules during sorption of water in wood. J Polym Sci B 36(4):665–671

Davis EM, Elabd YA (2013) Water clustering in glassy polymers. J Phys Chem B 117:10629–10640

Kymäläinen M, Havimo M, Keriö S, Solio J (2014) Biological degradation of torrefied wood and charcoal. Biomass Bioenerg 71:170–177

Wang J, Mukhopadhyaya P, Morris PI (2012) Sorption and capillary condensation in wood and the moisture content of red pine. J Build Phys 37(4):327–347

Prins MJ, Ptasinski KJ, Janssen FJJG (2006) Torrefaction of wood part 2. Analysis of the product. J Anal Appl Pyrolysis 77:35–40

Grønli MG (1996) A theoretical and experimental study of the thermal degradation of biomass. PhD dissertation, Norwegian University of Science and Technology

Stamm AJ (1964) Wood and cellulose science. The Ronald Press Co., New York

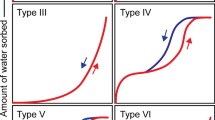

Sing KSW, Everett DH, Haul RAW, Moscou L, Pierotti RA, Rouquérol J, Sieminiewska T (1985) Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity. Recommendations 1984. Pure Appl Chem 57(4):603–619

Brunauer S, Deming LS, Deming WE, Teller E (1940) On a theory of the van der Waals adsorption of gases. J Am Chem Soc 62(7):1723–1732

Jalaludin Z, Hill CAS, Xie Y, Samsi HW, Husain H, Awang K, Curling SF (2010) Analysis of the water vapour sorption isotherms of thermally modified acacia and sesendok. Wood Mater Sci Eng 5(3–4):194–203

Alén R, Kotilainen R, Zaman A (2002) Thermochemical behaviour of Norway spruce (Picea abies) at 180–225 °C. Wood Sci Technol 36:163–171

Candelier K, Dumarçay S, Pétrissans A, Desharnais L, Gérardin P, Pétrissans M (2013) Comparison of chemical composition and decay durability of heat treated wood cured under different inert atmospheres: nitrogen or vacuum. Polym Degrad Stab 98:677–681

Hill CAS, Norton A, Newman G (2009) The water vapour sorption behaviour of natural fibres. J Appl Polym Sci 112:1524–1537

Shafizadeh F (1971) Thermal behavior of carbohydrates. J Polym Sci 36:21–51

Vrentas JS, Vrentas CM (1996) Hysteresis effects for sorption in glassy polymers. Macromolecules 29:4391–4396

Keating BA, Hill CAS, Sun D, English R, Davies P, McCue C (2013) The water vapor sorption behavior of a galactomannan cellulose nanocomposite film analyzed using parallel exponential kinetics and the Kelvin-Voigt viscoelastic model. J Appl Polym Sci 129:2352–2359

Rouquerol F, Rouquerol J, Singh K (1999) Adsorption by powders and porous solids. Academic Press, London

Hoffmeyer P, Engelund ET, Thygesen LG (2011) Equilibrium moisture content (EMC) in Norway spruce during the first and second desorptions. Holzforschung 65:875–882

Engelund ET, Thygesen LG, Svensson S, Hill CAS (2013) A critical discussion of the physics of wood-water interactions. Wood Sci Technol 47:141–161

Müller EA, Rull LF, Vega LF, Gubbins KE (1996) Adsorption of water on activated carbons: a molecular simulation study. J Phys Chem 100:1189–1196

Hartley ID, Kamke FA, Peemoeller H (1992) Cluster theory for water sorption in wood. Wood Sci Technol 26:83–99

Rai Puri B, Muraru K, Singh DD (1961) The sorption of water vapour by charcoal as influenced by surface oxygen complexes. J Phys Chem 65(1):37–39

Pfriem A, Zauer M, Wagenführ A (2009) Alteration of the pore structure of spruce (Picea abies (L.) Karst.) and maple (Acer pseudoplatanus L.) due to thermal treatment as determined by helium pycnometry and mercury intrusion porosimetry. Holzforschung 63:94–98

Elder T (1991) Pyrolysis of wood. In: Hon DNS, Shiraishi N (eds) Wood and cellulosic chemistry. Marcel Dekker Inc., New York, pp 665–699

Della Rocca PA, Cerrella EG, Bonelli PR, Cukierman A (1999) Pyrolysis of hardwood residues: on kinetics and chars characterization. Biomass Bioenerg 16:79–88

Rutherford DW, Wershaw RL, Cox LG (2005) Changes in composition and porosity occurring during the thermal degradation of wood and wood components, Scientific investigations report 2004-5292, U.S. Geological Survey

Hao B, Avramidis S (2001) Wood sorption fractality in the hygroscopic range. Part I. Evaluation of a modified classic BET model. Wood Fiber Sci 33:119–125

Ismadji S, Sudaryanto Y, Hartono SB, Setiawan LEK, Ayucitra A (2005) Activated carbon from char obtained from vacuum pyrolysis of teak sawdust: pore structure development and characterization. Bioresour Technol 96:1364–1369

Mathlouthi M, Rogé B (2003) Water vapour sorption isotherms and the caking of food powders. Food Chem 82:61–71

Yan R, Liang DT, Tsen L, Wong YP, Lee YK (2004) Bench-scale experimental evaluation of carbon performance on mercury vapour adsorption. Fuel 83:2401–2409

Yah A-I, Huang Y-C, Chen SH (2010) Effect of particle size on the rate of enzymatic hydrolysis of cellulose. Carbohydr Polym 79:192–199

Acknowledgements

Maija Kymäläinen is grateful for the financial support of Walter Ahlström foundation and Niemi foundation, and for the help of Juha Solio and colleagues for preparation of the material. Furthermore, the authors would like to thank BSc Anna Hämäläinen, Mrs Marja Kärkkäinen, Mrs Rita Hatakka, and MSc Tiina Belt for technical support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kymäläinen, M., Rautkari, L. & Hill, C.A.S. Sorption behaviour of torrefied wood and charcoal determined by dynamic vapour sorption. J Mater Sci 50, 7673–7680 (2015). https://doi.org/10.1007/s10853-015-9332-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9332-2