Abstract

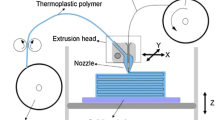

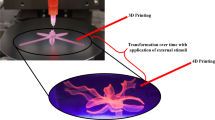

Development in additive manufacturing is exceptionally rapid than the expected forecast so far and it has traced out new dimensions in engineering applications. 3D printing technology becomes more glamorous when Skylar Tibbits incorporated the concept of “Time” as a fourth dimension by encapsulating smart materials in current additive manufacturing technique. Materials having an explicit response to external stimuli over a certain time span are designated as smart materials and additive manufacturing of such time-dependent, programmable, and intelligent materials is termed as 4D printing. In 4D printing, primary 3D printed configuration switched exclusively into a transformed shape when exposed to an external stimuli, e.g. heat, light, water, chemical, electric current, magnetic field or pH. Perhaps, additive manufacturing technology seems to be superseded exclusively by this modern technology in forthcoming years, and much effort is demanding from every discipline to actualize this technology. A task-oriented entire landscape of 4D printing followed by a comprehensive smart material perspective is presented in this review. Graphical abstract set forth a route to the complete process comprehension. Moreover, other components of 4D technology like customary techniques, computational challenges, reversibility and current stature of 4D printing are probed through recent experimental and theoretical literature. Finally, potential applications of 4D printing are summarised with promising research directions and outlook.

Graphic Abstract

4D printing: A future insight in additive manufacturing

.

Similar content being viewed by others

References

S. Tibbits, 4D printing: multi-material shape change. Archit. Des. 84, 116–121 (2014). https://doi.org/10.1002/ad.1710

Y. Forterre, J.M. Skotheim, J. Dumals, L. Mahadevan, How the Venus flytrap snaps. Nature 433, 421–425 (2005). https://doi.org/10.1038/nature03185

K. Song, E. Yeom, S.J. Lee, Real-time imaging of pulvinus bending in Mimosa pudica. Sci. Rep. (2014). https://doi.org/10.1038/srep06466

J. Kim, V.V. Varadan, V.K. Varadan, Modeling integrated sensor/actuator functions in realistic environments. vol. 1916, pp. 56–64 (1993). https://doi.org/10.1117/12.148504

F. Momeni, M. Mehdi, N.S. Hassani, X. Liu, J. Ni, A review of 4D printing. Mater. Des. (2017). https://doi.org/10.1016/j.matdes.2017.02.068

O. Ivanova, A. Elliott, T. Campbell, C.B. Williams, Unclonable security features for additive manufacturing. Addit. Manuf. 1, 24–31 (2014). https://doi.org/10.1016/j.addma.2014.07.001

X. Liu, Y. Zheng, S.R. Peurifoy et al., Optimization of 4D polymer printing within a massively parallel flow-through photochemical microreactor. Polym. Chem. 7, 3229–3235 (2016). https://doi.org/10.1039/C6PY00283H

A. Zolfagharian, A.Z. Kouzani, S.Y. Khoo et al., Evolution of 3D printed soft actuators. Sens. Actuators A Phys. 250, 258–272 (2016)

B. Gao, Q. Yang, X. Zhao et al., 4D bioprinting for biomedical applications. Trends Biotechnol. 34(9), 746–756 (2016). https://doi.org/10.1016/j.tibtech.2016.03.004

E. Pei, 4D Printing: dawn of an emerging technology cycle. Assem. Autom. 34, 310–314 (2014). https://doi.org/10.1108/AA-07-2014-062

H. Meng, G. Li, A review of stimuli-responsive shape memory polymer composites. Polymer 54, 2199–2221 (2013). https://doi.org/10.1016/j.polymer.2013.02.023

S.M. Felton, M.T. Tolley, B. Shin et al., Self-folding with shape memory composites. Soft. Matter. (2013). https://doi.org/10.1039/c3sm51003d

T.-H. Kwok, C.C.L. Wang, D. Deng et al., Four-dimensional printing for freeform surfaces: design optimization of origami and kirigami structures. J. Mech. Des. 137, 111413 (2015). https://doi.org/10.1115/1.4031023

A. Rashid, Additive manufacturing technologies, in CIRP Encyclopedia of Production Engineering, ed. by S. Chatti, L. Laperrière, G. Reinhart, T. Tolio (Springer, Heidelberg, 2019), pp. 39–46

C.W. Hull, Apparatus for production of three-dimensional objects by stereolithography. US Pat 4,575,330. p. 1–16. (1986)https://doi.org/10.1145/634067.634234

A. Mitchell, U. Lafont, M. Hołyńska, C. Semprimoschnig, Additive manufacturing—A review of 4D printing and future applications. Addit. Manuf. 24, 606–626 (2018). https://doi.org/10.1016/j.addma.2018.10.038

52900:2015 A, Standard terminology for additive manufacturing—general principles—terminology. ASTM Int. (2015). https://doi.org/10.1520/F2792-12A.2

A. Pandian, C. Belavek, A review of recent trends and challenges in 3D printing, in Proceedings 2016 ASEE North Central Section Conference. pp. 1–17 (2016)

T.Caffry, T. Wohlers, Wohlers report 2018, 3D Printing and Additive Manufacturing State of the Industry: Annual Woldwide Progress Report, Wohlers Associates 2018. Wohlers Assoc (2018)

T.D. Ngo, A. Kashani, G. Imbalzano et al., Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos. Part B Eng. 143, 172–196 (2018). https://doi.org/10.1016/j.compositesb.2018.02.012

J. Gardan, Smart materials in additive manufacturing: state of the art and trends. Virtual Phys. Prototyp. 14, 1–8 (2019). https://doi.org/10.1080/17452759.2018.1518016

R.T. Shafranek, S.C. Millik, P.T. Smith et al., Stimuli-responsive materials in additive manufacturing. Prog. Polym. Sci 93, 36–67 (2019). https://doi.org/10.1016/j.progpolymsci.2019.03.002

L. Sun, W.M. Huang, Z. Ding et al., Stimulus-responsive shape memory materials: a review. Mater. Des. 33, 577–640 (2012). https://doi.org/10.1016/j.matdes.2011.04.065

A. Zolfagharian, A. Kaynak, S.Y. Khoo, A. Kouzani, Pattern-driven 4D printing. Sens. Actuators A Phys. (2018). https://doi.org/10.1016/j.sna.2018.03.034

M. Bodaghi, A.R. Damanpack, W.H. Liao, Self-expanding/shrinking structures by 4D printing. Smart Mater. Struct. (2016). https://doi.org/10.1088/0964-1726/25/10/105034

D.G. Bekas, K. Tsirka, D. Baltzis, A.S. Paipetis, Self-healing materials: a review of advances in materials, evaluation, characterization and monitoring techniques. Compos. Part B Eng. 87, 92–119 (2016). https://doi.org/10.1016/j.compositesb.2015.09.057

G. Li, P. Xiao, S. Hou, Y. Huang, Graphene based self-healing materials. Carbon. N Y 146, 371–387 (2019). https://doi.org/10.1016/j.carbon.2019.02.011

W. Fan, Y. Zhang, W. Li et al., Multi-level self-healing ability of shape memory polyurethane coating with microcapsules by induction heating. Chem. Eng. J. 368, 1033–1044 (2019). https://doi.org/10.1016/j.cej.2019.03.027

X.F. Wang, Z.H. Yang, C. Fang et al., Evaluation of the mechanical performance recovery of self-healing cementitious materials – its methods and future development: a review. Constr. Build. Mater. 212, 400–421 (2019). https://doi.org/10.1016/j.conbuildmat.2019.03.117

P. Rastogi, B. Kandasubramanian, Breakthrough in the printing tactics for stimuli-responsive materials: 4D printing. Eng. J. Chem. 366, 264–304 (2019). https://doi.org/10.1016/j.cej.2019.02.085

A. Raza, U. Hayat, T. Rasheed et al., “Smart” materials-based near-infrared light-responsive drug delivery systems for cancer treatment: a review. J. Mater. Res. Technol. 8, 1497–1509 (2019). https://doi.org/10.1016/j.jmrt.2018.03.007

S. Tibbits, K. Cheung, Programmable materials for architectural assembly and automation. Assem. Autom. 32, 216–225 (2012). https://doi.org/10.1108/01445151211244348

S. Tibbits, Design to self-assembly. Archit. Des. (2012). https://doi.org/10.1002/ad.1381

W.M. Huang, Z. Ding, C.C. Wang et al., Shape memory materials. Mater. Today. 13, 54–61 (2010). https://doi.org/10.1016/S1369-7021(10)70128-0

E. Pei, G.H. Loh, Technological considerations for 4D printing: an overview. Prog. Addit. Manuf. (2018). https://doi.org/10.1007/s40964-018-0047-1

P. Popov, D.C. Lagoudas, shape memory alloys. In: Shape Memory Alloy. vol. 1, pp. 49–56 (2008).https://doi.org/10.1007/978-0-387-47685-8

K. Otsuka, X. Ren, Recent developments in the research of shape memory alloys. Intermetallics 7, 511–528 (1999). https://doi.org/10.1016/S0966-9795(98)00070-3

J. Mohd Jani, M. Leary, A. Subic, M.A. Gibson, A review of shape memory alloy research, applications and opportunities. Mater. Des. 56, 1078–1113 (2014)

K. Ullakko, Magnetically controlled shape memory alloys: a new class of actuator materials. J. Mater. Eng. Perform. (1996). https://doi.org/10.1007/BF02649344

S. Faehler, An introduction to actuation mechanisms of Magnetic Shape Memory Alloys. ECS Trans. (2007). https://doi.org/10.1149/1.2753250

D.I. Paul, W. McGehee, R.C. O’Handley, M. Richard, Ferromagnetic shape memory alloys: a theoretical approach. J. Appl. Phys. (2007). https://doi.org/10.1063/1.2740328

A. Planes, L. Mañosa, Ferromagnetic shape-memory alloys. Mater. Sci. Forum. 512, 145–152 (2006). https://doi.org/10.4028/www.scientific.net/MSF.512.145

J. Raasch, M. Ivey, D. Aldrich et al., Characterization of polyurethane shape memory polymer processed by material extrusion additive manufacturing. Addit. Manuf. (2015). https://doi.org/10.1016/j.addma.2015.09.004

Y. Bai, X. Zhang, Q. Wang, T. Wang, A tough shape memory polymer with triple-shape memory and two-way shape memory properties. J. Mater. Chem. A. 2, 4771–4778 (2014). https://doi.org/10.1039/C3TA15117D

M. Bodaghi, A.R. Damanpack, W.H. Liao, Triple shape memory polymers by 4D printing. Smart. Mater. Struct. (2018). https://doi.org/10.1088/1361-665X/aabc2a

W.M. Huang, Y. Zhao, C.C. Wang et al., Thermo/chemo-responsive shape memory effect in polymers: a sketch of working mechanisms, fundamentals and optimization. J. Polym. Res. 19, 9952 (2012). https://doi.org/10.1007/s10965-012-9952-z

P. Miaudet, A. Derré, M. Maugey et al., Shape and temperature memory of nanocomposites with broadened glass transition. Science 318, 1294–1296 (2007). https://doi.org/10.1126/science.1145593

C. Liu, H. Qin, P.T. Mather, Review of progress in shape-memory polymers. J. Mater. Chem. 17, 1543 (2007). https://doi.org/10.1039/b615954k

R. Langer, D.A. Tirrell, Designing materials for biology and medicine. Nature. 428, 487–492 (2004)

F. Pilate, A. Toncheva, P. Dubois, J.M. Raquez, Shape-memory polymers for multiple applications in the materials world. Eur. Polym. J. 80, 268–294 (2016). https://doi.org/10.1016/j.eurpolymj.2016.05.004

C. Liu, H. Qin, P.T. Mather, Review of progress in shape-memory polymers. J. Mater. Chem. (2007). https://doi.org/10.1039/b615954k

H. Xie, K.K. Yang, Y.Z. Wang, Photo-cross-linking: a powerful and versatile strategy to develop shape-memory polymers. Prog. Polym. Sci. 95, 32–64 (2019). https://doi.org/10.1016/j.progpolymsci.2019.05.001

F. Liu, M.W. Urban, Recent advances and challenges in designing stimuli-responsive polymers. Prog. Polym. Sci. 35, 3–23 (2010). https://doi.org/10.1016/j.progpolymsci.2009.10.002

Y.J. Liu, L.W. Liu, L. Jinsong, Electroactive polymer and its composites: theory, experiment and applications, in ICCM International Conference on Composite Materials. (2011)

K. Kruusamäe, K. Mukai, T. Sugino, K. Asaka, Impact of viscoelastic properties on bucky-gel actuator performance. J. Intell. Mater. Syst. Struct. 25, 2235–2245 (2014). https://doi.org/10.1177/1045389X14538538

Y. Osada, A. Matsuda, Shape memory in hydrogels. Nature 376, 219 (1995). https://doi.org/10.1038/376219a0

H. Tobushi, E. Pieczyska, Y. Ejiri, T. Sakuragi, Thermomechanical properties of shape-memory alloy and polymer and their composites. Mech. Adv. Mater. Struct. 16, 236–247 (2009). https://doi.org/10.1080/15376490902746954

D.C. Hofmann, Shape memory bulk metallic glass composites. Science 329, 1294–1295 (2010). https://doi.org/10.1126/science.1193522

J. Wu, C. Yuan, Z. Ding et al., Multi-shape active composites by 3D printing of digital shape memory polymers. Sci. Rep. (2016). https://doi.org/10.1038/srep24224

Q. Ge, H.J. Qi, M.L. Dunn, Active materials by four-dimension printing. Appl. Phys. Lett. (2013). https://doi.org/10.1063/1.4819837

M. Behl, M.Y. Razzaq, A. Lendlein, Multifunctional shape-memory polymers. Adv. Mater. 22, 3388–3410 (2010)

R.A. Weiss, E. Izzo, S. Mandelbaum, New design of shape memory polymers: mixtures of an elastomeric ionomer and low molar mass fatty acids and their salts. Macromolecules 41, 2978–2980 (2008). https://doi.org/10.1021/ma8001774

M.D. Dickey, Hydrogel composites: shaped after print. Nat. Mater. 15, 379–380 (2016)

S. Wang, J.M. Lee, W.Y. Yeong, Smart hydrogels for 3D bioprinting. Int. J. Biopr. 1(1), 3–14 (2015). https://doi.org/10.18063/IJB.2015.01.005

D. Han, C. Farino, C. Yang et al., soft robotic manipulation and locomotion with a 3D printed electroactive hydrogel. ACS Appl. Mater. Interfaces (2018). https://doi.org/10.1021/acsami.8b04250

R. Bogue, Smart materials: a review of capabilities and applications. Assem. Autom. 34, 16–22 (2014). https://doi.org/10.1108/AA-10-2013-094

K. Uchino, Antiferroelectric shape memory ceramics. Actuators. 5, 11 (2016). https://doi.org/10.3390/act5020011

W.M. Huang, B. Yang, Y.Q. Fu, Polyurethane shape memory polymers (CRC Press, Boca Raton, 2012)

B. Yang, W.M. Huang, C. Li, J.H. Chor, Effects of moisture on the glass transition temperature of polyurethane shape memory polymer filled with nano-carbon powder. Eur. Polym. J. 41, 1123–1128 (2005). https://doi.org/10.1016/j.eurpolymj.2004.11.029

J. Leng, X. Lan, Y. Liu, S. Du, Shape-memory polymers and their composites: stimulus methods and applications. Prog. Mater Sci. 56, 1077–1135 (2011). https://doi.org/10.1016/j.pmatsci.2011.03.001

A.S. Gladman, E.A. Matsumoto, R.G. Nuzzo et al., Biomimetic 4D printing. Nat. Mater. (2016). https://doi.org/10.1038/nmat4544

Campbell T a., Tibbits S, Garrett B (2014) the next wave: 4d printing programming the material world. Atl Counc

S. Tibbits, C. McKnelly, C. Olguin, et al., 4D printing and universal transformation, in ACADIA 14 Design Agency: Proceedings of the 34th Annual Conference of the Association for Computer Aided Design in Architecture (2014)

M. Behl, M.Y. Razzaq, A. Lendlein, Multifunctional shape-memory polymers. Adv. Mater. 22, 3388–3410 (2010). https://doi.org/10.1002/adma.200904447

K. Yu, M.L. Dunn, H.J. Qi, Digital manufacture of shape changing components. Extrem. Mech. Lett. 4, 9–17 (2015). https://doi.org/10.1016/j.eml.2015.07.005

O. Kuksenok, A.C. Balazs, Stimuli-responsive behavior of composites integrating thermo-responsive gels with photo-responsive fibers. Mater. Horiz. 3, 53–62 (2016). https://doi.org/10.1039/C5MH00212E

S.E. Bakarich, R. Gorkin, Panhuis M. In, Spinks G.M. Het, 4D printing with mechanically robust, thermally actuating hydrogels. Macromol. Rapid Commun. (2015). https://doi.org/10.1002/marc.201500079

D.C. Zuluaga, A. Menges, 3D printed hygroscopic programmable material systems, in Materials Research Society Symposium Proceedings. pp 24–31 (2015)

Q. Zhang, K. Zhang, G. Hu, Smart three-dimensional lightweight structure triggered from a thin composite sheet via 3D printing technique. Sci. Rep. (2016). https://doi.org/10.1038/srep22431

J.E.M. Teoh, Y. Zhao, J. An et al., Multi-stage responsive 4D printed smart structure through varying geometric thickness of shape memory polymer. Smart Mater. Struct. (2017). https://doi.org/10.1088/1361-665X/aa908a

H. Lv, J. Leng, Y. Liu, S. Du, Shape-memory polymer in response to solution. Adv. Eng. Mater. 10, 592–595 (2008). https://doi.org/10.1002/adem.200800002

C.M. González-Henríquez, M.A. Sarabia-Vallejos, J. Rodriguez-Hernandez, Polymers for additive manufacturing and 4D-printing: materials, methodologies, and biomedical applications. Prog. Polym. Sci. 94, 57–116 (2019). https://doi.org/10.1016/j.progpolymsci.2019.03.001

Z. Ding, C. Yuan, X. Peng et al., Direct 4D printing via active composite materials. Sci. Adv. (2017). https://doi.org/10.1126/sciadv.1602890

Z.X. Khoo, J.E.M. Teoh, Y. Liu et al., 3D printing of smart materials: a review on recent progresses in 4D printing. Virtual Phys. Prototyp. (2015). https://doi.org/10.1080/17452759.2015.1097054

A.Y. Lee, J. An, C.K. Chua, Two-way 4D printing: a review on the reversibility of 3D-printed shape memory materials. Engineering 3, 663–674 (2017). https://doi.org/10.1016/J.ENG.2017.05.014

S. Naficy, R. Gately, R. Gorkin et al., 4D printing of reversible shape morphing hydrogel structures. Macromol. Mater. Eng. (2017). https://doi.org/10.1002/mame.201600212

S. Miao, W. Zhu, N.J. Castro et al., 4D printing smart biomedical scaffolds with novel soybean oil epoxidized acrylate. Sci. Rep. (2016). https://doi.org/10.1038/srep27226

T. DebRoy, H.L. Wei, J.S. Zuback et al., Additive manufacturing of metallic components—process, structure and properties. Prog. Mater. Sci. 92, 112–224 (2018). https://doi.org/10.1016/j.pmatsci.2017.10.001

T. Zhao, R. Yu, X. Li et al., 4D printing of shape memory polyurethane via stereolithography. Eur. Polym. J. 101, 120–126 (2018). https://doi.org/10.1016/j.eurpolymj.2018.02.021

Y.Y.C. Choong, S. Maleksaeedi, H. Eng et al., 4D printing of high performance shape memory polymer using stereolithography. Mater. Des. (2017). https://doi.org/10.1016/j.matdes.2017.04.049

Q. Zhang, K. Zhang, G. Hu, Smart three-dimensional lightweight structure triggered from a thin composite sheet via 3D printing technique. Sci. Rep. (2016). https://doi.org/10.1038/srep22431

Q. Zhang, D. Yan, K. Zhang, G. Hu, Pattern transformation of heat-shrinkable polymer by three-dimensional (3D) printing technique. Sci. Rep. (2015). https://doi.org/10.1038/srep08936

P. Sitthi-amorn, J. Lan, W. Wang, MultiFab: a machine vision assisted platform for multi-material 3d printing. ACM Trans. Graph. (2015). https://doi.org/10.1145/2766962

K.S. Boparai, R. Singh, H. Singh, Development of rapid tooling using fused deposition modeling: a review. Rapid Prototyp. J. 22, 281–299 (2016). https://doi.org/10.1108/RPJ-04-2014-0048

M. Vaezi, S. Chianrabutra, B. Mellor, S. Yang, Multiple material additive manufacturing—Part 1: a review. Virtual Phys. Prototyp. 8, 19–50 (2013). https://doi.org/10.1080/17452759.2013.778175

L.E. Loh, C.K. Chua, W.Y. Yeong et al., Numerical investigation and an effective modelling on the selective laser melting (SLM) process with aluminium alloy 6061. Int. J. Heat Mass Trans. 80, 288–300 (2015). https://doi.org/10.1016/j.ijheatmasstransfer.2014.09.014

M.H. Elahinia, M. Hashemi, M. Tabesh, S.B. Bhaduri, Manufacturing and processing of NiTi implants: a review. Prog. Mater Sci. 57, 911–946 (2012)

S. Dadbakhsh, M. Speirs, J.P. Kruth et al., Effect of SLM parameters on transformation temperatures of shape memory nickel titanium parts. Adv. Eng. Mater. 16, 1140–1146 (2014). https://doi.org/10.1002/adem.201300558

M.T. Andani, J. Walker, C. Haberl, M. Elahinia, An investigation of effective process parameters on phase transformation temperature of Nitinol manufactured by selective laser melting, in ASME 2014 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, SMASIS 2014 (2014)

H. Meier, C. Haberland, J. Frenzel, R. Zarnetta, Selective laser melting of NiTi shape memory components, in 4th International Conference on Advanced Research in Virtual Physical Prototyping, VRAP 2009; Leir Port 6 Oct 2009 through 10 Oct 2009; Code 82905 pp. 233–238 (2010)

G.R. Donoso, M. Walczak, E.R. Moore, J.A. Ramos-Grez, Towards direct metal laser fabrication of Cu-based shape memory alloys. Rapid Prototyp. J. 23, 329–336 (2017). https://doi.org/10.1108/RPJ-02-2016-0017

Y. Mao, Z. Ding, C. Yuan et al., 3D printed reversible shape changing components with stimuli responsive materials. Sci. Rep. (2016). https://doi.org/10.1038/srep24761

D. Kokkinis, M. Schaffner, A.R. Studart, Multimaterial magnetically assisted 3D printing of composite materials. Nat. Commun. (2015). https://doi.org/10.1038/ncomms9643

M. Zarek, M. Layani, S. Eliazar et al., 4D printing shape memory polymers for dynamic jewellery and fashionwear. Virtual Phys. Prototyp. 11, 263–270 (2016). https://doi.org/10.1080/17452759.2016.1244085

ISO/ASTM 52915 Standard specification for additive manufacturing file format (AMF) version 1. 2 1. ISO/ASTM Stand. (2016). https://doi.org/10.1520/f2915-12.2

E.S.A. Nasr, A. Al-Ahmari, K. Moiduddin, CAD issues in additive manufacturing, in Comprehensive Materials Processing (2014)

Technology GI of S and Development of a Contents Configuration Management System and a Simulator for 3D Printing Using Smart Materials (2017)

S. Chung, S.E. Song, Y.T. Cho, Effective software solutions for 4D printing: a review and proposal. Int. J. Precis. Eng. Manuf. Green Technol. 4, 359–371 (2017). https://doi.org/10.1007/s40684-017-0041-y

F. Momeni, J. Ni, Nature-inspired smart solar concentrators by 4D printing. Renew. Energy 122, 35–44 (2018). https://doi.org/10.1016/j.renene.2018.01.062

F. Momeni, S. Sabzpoushan, R. Valizadeh et al., Plant leaf-mimetic smart wind turbine blades by 4D printing. Renew. Energy 130, 329–351 (2019). https://doi.org/10.1016/j.renene.2018.05.095

J. An, C.K. Chua, V. Mironov, A Perspective on 4D Bioprinting. Int. J. Bioprinting (2016). https://doi.org/10.18063/IJB.2016.01.003

A. Haleem, M. Javaid, 4D printing applications in cardiology. Curr. Med. Res. Pract. (2018). https://doi.org/10.1016/j.cmrp.2018.10.001

Q. Ge, A.H. Sakhaei, H. Lee et al., Multimaterial 4D printing with tailorable shape memory polymers. Sci. Rep. (2016). https://doi.org/10.1038/srep31110

K. Kuribayashi, K. Tsuchiya, Z. You et al., Self-deployable origami stent grafts as a biomedical application of Ni-rich TiNi shape memory alloy foil. Mater. Sci. Eng. A 419, 131–137 (2006). https://doi.org/10.1016/j.msea.2005.12.016

V. Mironov, 4D bioprinting: biofabrication of rod-like and tubular tissue engineered constructs using programmable self-folding bioprinted biomaterials, in International Bioprinting Congress. Biopolis (2014)

R.J. Morrison, S.J. Hollister, M.F. Niedner et al., Mitigation of tracheobronchomalacia with 3D-printed personalized medical devices in pediatric patients. Sci. Transl. Med. (2015). https://doi.org/10.1126/scitranslmed.3010825

K. Hammond, U.K. Ghori, A.I. Musani, Tracheobronchomalacia and Excessive Dynamic Airway Collapse. Clin. Chest Med. 39, 223–228 (2018). https://doi.org/10.1016/j.ccm.2017.11.015

G. Priniotakis, Intelligent/smart materials and textiles: an overview. Anal. Electrochem. Text (2005). https://doi.org/10.1533/9781845690878.3.215

J. Leng, X. Lan, Y. Liu, S. Du, Shape-memory polymers and their composites: stimulus methods and applications. Prog. Mater. Sci. (2011). https://doi.org/10.1016/j.pmatsci.2011.03.001

J.Z. Gul, M. Sajid, M.M. Rehman et al., 3D printing for soft robotics—a review. Sci. Technol. Adv. Mater. 19, 243–262 (2018). https://doi.org/10.1080/14686996.2018.1431862

A. Sydney Gladman, E.A. Matsumoto, R.G. Nuzzo et al., Biomimetic 4D printing. Nat. Mater. (2016). https://doi.org/10.1038/nmat4544

C.Y. Yap, C.K. Chua, Z.L. Dong et al., Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2, 041101 (2015). https://doi.org/10.1063/1.4935926

Y. Mao, K. Yu, M.S. Isakov et al., Sequential self-folding structures by 3D printed digital shape memory polymers. Sci. Rep. (2015). https://doi.org/10.1038/srep13616

Acknowledgements

The author would like to express sincere gratitude to Tsinghua University and Chinese Scholarship Council for financial aid during his Ph.D.

Funding

The National Key R&D Program of China (2017YFB1103300), State Key Laboratory of Tribology Tsinghua University China (SKLT2018B06) and National Natural Science Foundation of China (51975320) supported this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

It is solemnly declared that there is no conflict of interest between authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zafar, M., Zhao, H. 4D Printing: Future Insight in Additive Manufacturing. Met. Mater. Int. 26, 564–585 (2020). https://doi.org/10.1007/s12540-019-00441-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00441-w