Abstract

Thermal modification is a well-established commercial technology for improving the dimensional stability and durability of timber. Numerous reviews of thermally modified timber (TMT) are to be found in the scientific literature, but until now a review of the influence of cell wall moisture content during the modification process on the properties of TMT has been lacking. This paper reviews the current state of knowledge regarding the hygroscopic and dimensional behaviour of TMT modified under dry (cell wall at nearly zero moisture content) and wet (cell wall contains moisture) conditions. After an overview of the topic area, the review explores the literature on the thermal degradation of the polysaccharidic and lignin components of the cell wall, as well as the role of extractives. The properties of TMT modified under wet and dry conditions are compared including mass loss, hygroscopic behaviour and dimensional stability. The role of hydroxyl groups in determining the hygroscopicity is discussed, as well as the importance of considering the mobility of the cell wall polymers and crosslinking when interpreting sorption behaviour. TMT produced under wet processing conditions exhibits behaviour that changes when the wood is subjected to water leaching post-treatment, which includes further weight loss, changes in sorption behaviour and dimensional stability, but without any further change in accessible hydroxyl (OH) content. This raises serious questions regarding the role that OH groups play in sorption behaviour.

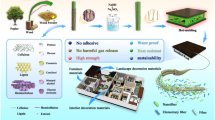

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Background

The commercial production of thermally modified timber (TMT) usually takes place between temperatures of 160 and 240 °C. This results in a material that is darker in colour [1], has improved dimensional stability and microbial resistance compared to unmodified wood, but there is a significant reduction in strength, especially fracture resistance. The reduction in ductility makes the use of TMT problematic for many load-bearing applications [2]. The chemistry of thermal degradation, particularly of the lignin, is different below about 150 °C [3, 4], and thermal modification is herein defined as being above this temperature, although irreversible changes also occur to wood heated below this temperature [5, 6]. Thermal modification processes do not employ temperatures above 240 °C, since the degradation of the wood becomes too severe to make the process commercially useful.

The first reports of the thermal modification of wood date back as far as 1915 to the work of Harry Tiemann, a kiln specialist at the Forest Products Laboratory in Madison Wisconsin, who heated air-dry wood in superheated steam at 150 °C, finding a reduction in hygroscopicity of the TMT. In the 1930s and 1940s, the Forest Products Laboratory continued this research [7, 8], resulting in the granting of a patent [9]. Early ventures to exploit this technology took place in the USA, involving the heating of wood which was submerged under molten metal at temperatures between 160 to 260 °C (Staybwood) [8]. Perhaps unsurprisingly, this was not a commercial success. Research and development continued into the 1970s and 1980s, with further attempts at commercialisation in Germany [10, 11], but again without success. However, in the 1990s there was renewed interest in thermal modification and the commercial landscape was finally favourable to the exploitation of this technology. This renewed interest, in Europe especially, was driven by environmental concerns and the introduction of legislation, such as the European Biocides Directive. As a response, there were commercial processes developed in France (rétification), Finland (Thermowood), Germany (Menz Holz) and the Netherlands (Plato Wood) [12]. In the twenty-first century, TMT is finding increasing application in exterior cladding, decking and joinery applications and is a well-established commercial technology, with European production of TMT now exceeding 500,000 m3 [13].

Description of process conditions

The primary purpose of this review is to examine the differences in properties of wood that has been thermally modified under ‘wet’ and ‘dry’ conditions. Initial stages of dry thermal modification involve an increase in temperature (ramp) during which the wood loses sorbed water. Alternatively, the heating can take place under conditions designed to keep the water in the wood cell wall, in a wet process. Wet conditions are herein defined as being thermal modification where the cell wall of the wood still contains moisture during the process, whereas dry conditions (HTdry) are defined as those in which the wood has been dried to close to zero moisture content before the thermal modification process. In HTdry processes, the timber can be heated under an inert gas blanket of nitrogen, in a vacuum, under superheated steam or in ambient air. The presence of water vapour or water in the thermal modification process affects the heat transfer process and the chemistry taking place in the wood. The types of thermal modification process differ, depending on time and temperature of treatment (including ramp-up, hold and ramp-down stages), treatment atmosphere (inert gas, air, vacuum), open or closed systems, wood species (with important differences between hardwoods and softwoods) and ‘wet’ or ‘dry’ systems. Wet conditions can be formally divided into processes which use saturated steam as the heating medium (hygrothermal or HTwet) and those in which the wood is completely immersed in water during the process (hydrothermal or HDTwet). HTwet conditions produce degradation products that remain in the cell wall until a subsequent leaching step is performed. Apart from being used as one of the thermal modification stages in the Plato process [14], HDTwet treatments are mainly used to extract cell wall degradation products for biorefinery or torrefaction processes and are not the main subject of this review [15] and much higher weight losses are recorded with HDTwet compared to HTwet processes [16]. The technical details of the different thermal modification processes have been discussed in considerable detail in many reviews of the topic [2, 12, 17,18,19,20], and only a brief overview of the most pertinent differences is given herein. Despite a considerable amount of attention being given to reviewing this subject in the peer review literature, we were not able to locate any review of the differences observed in the properties of wood modified under wet and dry conditions, hence the need for the current work.

The different conditions under which thermal modification is performed are categorised as shown in Fig. 1.

In addition to the options presented in Fig. 1, there is the possibility of running the modification plant with a closed vessel or an open system. With closed processes, there is a build-up of degradation products and steam in the vessel creating a pressurised system. With an open system, it is possible to employ a continuous flow, where the degradation products and exhaust gases are vented to the atmosphere (subject to effective emissions controls) or a re-circulating system, where the hot gases are returned to the autoclave, with the condensable fraction being removed. Open flow systems are invariably operated at atmospheric pressure, although a re-circulating system can be employed with a pressurised vessel. With a pressurised system, pressure is applied with the addition of nitrogen or steam (saturated or superheated steam, depending upon the temperature and pressure conditions). Careful control of pressure is required in a closed system to modify the wood under constant saturated or superheated steam conditions.

Willems and Altgen [21] give a detailed description of the differences between dry and wet thermal treatment processes by defining them in terms of water activity against temperature (Fig. 2). Heating at high temperatures (over 200 °C) and low water activity, results in dry thermolysis, with the pressure making little contribution to the variables and the main controlling factor being the process temperature. Wet processes operate at lower temperatures (160–180 °C) in saturated steam, with the necessary moist conditions ensured by control of temperature and pressure, although pressure is the most important parameter when determining mass loss (before and after post-treatment leaching) [22, 23]. Saturated steam is in equilibrium with liquid water at the same temperature and pressure, whereas superheated steam is dry water vapour that has been heated above its saturation point. The degradation of wood is also mainly controlled by the pressure when nitrogen rather than steam is used [11].

Definitions of different moisture conditions in thermal modification according to [21]

The symbol aw is the water activity (the ratio of the vapour pressure of water in a material to the vapour pressure of pure water at the same temperature).

Although air is included for completeness’ sake; in reality the atmospheric systems are operated so that there is a build-up of steam in the vessel from the wood moisture and driving off of the water of constitution so that the thermal modification operates under essentially non-oxidative conditions (although saturated steam conditions will not be realised). The presence of air results in oxidative degradative processes taking place, and, in the absence of a steam blanket, fire is a risk. Vacuum systems require a means of heating the wood during the modification cycle, and this can be achieved using heated plattens or by initiating a thermal degradation reaction in air and then applying a vacuum.

Property changes

A summary of the main properties of thermally modified timber is given in Table 1.

Thermal modification results in weight loss, and there is usually a change in macroscopic dimensions of the wood accompanying this. This weight loss is related to the time and temperature of treatment under dry conditions [12], and there may be an associated reduction in volume of the wood. Loss of weight is dependent on wood species, with hardwoods exhibiting higher weight loss than softwoods under identical conditions [24], and is dependent on whether dry or wet conditions are employed [25]. The weight loss after modification is often used as an indicator of other properties of the TMT, but an accumulation of water-soluble degradation products can occur, which often leads to an underestimate of actual weight loss due to thermal modification [26]. When wood is heated under saturated steam (HTwet) conditions, this can (depending on the exact process conditions) result in a greater loss of weight, starting at a lower temperature, compared with heating under dry, but otherwise identical conditions. This higher weight loss with HTwet processes may not be observed immediately after treatment, but is always seen when a post-treatment water-leaching step is performed post-treatment [23, 27,28,29]. The weight loss is usually associated with a reduction in apparent density, although this depends upon treatment conditions and wood species [30]. Weight loss can also be correlated with other properties, such as hygroscopicity, but a leaching step may be necessary to reveal this relationship [31].

Hygrothermal treatment results in both irreversible and reversible changes to the wood, the latter being erased by exposure to high RH or liquid water [6]. There is a volume decrease which occurs during the heat treatment, but additional reductions in volume (and weight) may also be observed during subsequent leaching cycles. In part, this reduction in volume can be directly attributed to the loss of degraded cell wall material, but there is also the likelihood that there are rearrangements in molecular structure within the cell wall. These changes in structure can be ‘frozen’ at the end of the thermal modification process, and water-soaking restores the mobility of the structure, allowing for an annealing process with associated changes in hygroscopicity and dimensional behaviour [32]. Apart from the extremes of 0% or 100% RH, there have been relatively few studies where the effect of relative humidity during thermal modification has been investigated, but this is an area of considerable interest [5].

Degradation processes

Thermal degradation is accompanied by the emission of water, carbon dioxide, methanol, acetic acid and formic acid [33], with non-volatile degradation products often remaining in the wood. The degradation products arise from the breakdown of cell wall polymers and from the wood extractives. Wood extractives can also migrate to the surface if they are mobile under the thermal modification conditions. Thermal degradation of the amorphous polysaccharide content occurs, mainly associated with the hemicelluloses, which is also facilitated by the presence of water [12, 34]. The most mobile parts of the polymer network are also the most accessible to water and have void volume around them when water-saturated, which also makes them the most susceptible to degradation under HTwet conditions. Degradation of carbohydrates under HTdry conditions is likely to lead to dehydration products, such as furfurals, which have the potential to polymerise and form insoluble hydrophobic materials in the cell wall, which are less susceptible to leaching. The formation of furfurals under hydrolysis conditions is not favoured. Thermal degradation of the hemicelluloses commences at lower temperatures compared to lignin [4]. Because thermal modification results in the degradation of cell wall polymers, there should be no swelling associated with the production of TMT. The hemicelluloses display chain mobility when moisture is present, and their removal means that this property is reduced in TMT. The mobility of the amorphous part of cell wall polymer network is also restricted if crosslinking takes place. The wood polymer matrix of thermally modified wood then acts as a stiff, elastic, brittle material [35, 36]. This change in mobility affects the mechanosorptive properties of the material. For example, it is known that the sorption hysteresis is affected by the extent of crosslinking of hydrogels [37].

The degradation products may escape from the cell wall during the thermal process by migration, evolution of volatiles or leaching in wet conditions, which will result in a reduction in cell wall volume. This may be recorded as a reduction in macroscopic volume if the lumen dimensions do not increase, but if the lumen increases in size, there may be no recorded change in macroscopic dimensions. If the degradation products remain inside the cell wall, there may be no change in cell wall dimensions until they are removed in a subsequent leaching stage. Changes in dimension also require mobility of the cell wall matrix macromolecules, and this may be restricted if thermal modification takes place in dry conditions.

The presence of water in the cell wall has an important influence upon the degradation processes taking place during thermal modification. As noted, water molecules in the cell wall in a wet thermal modification process increase the mobility of the cell wall polymers and also potentially of the degradation products during the process. The presence of hydronium ions in the water can also catalyse the hydrolysis of glycosidic bonds and of acetyl groups in the hemicelluloses. The weight loss is attributed mainly to loss of hemicelluloses, which are considered to be the most thermally labile of the wood cell wall polymers and is greater for hardwoods compared to softwoods treated under identical conditions. Degradation of hemicelluloses has been observed at temperatures as low as 100 °C, when wood was heated for extended periods of time (48 h) [38] and indirect evidence for thermal degradation at temperatures as low as 64 °C under wet conditions has been obtained using dynamic mechanical analysis [39]. Wood will slowly undergo irreversible changes even at room temperature and the study of wood ageing and attempts to mimic or accelerate these effects for use in musical instruments continue to elicit interest [6].

There is also a smaller reduction in amorphous cellulose content, but a relative proportional increase in the lignin content. However, some caution is advised when determining the lignin content of thermally modified wood, since the breakdown products of hemicelluloses could contribute to char formation when analysing residual lignin by acid digestion techniques [40]. Although the hemicelluloses are considered the most thermally labile component, there are also reactions that take place in the lignin network, which include chain scission and/or crosslinking. Whether the overall crosslink density of the lignin increases as a result of thermal modification is not known.

There is a decrease in the O/C ratio which is accompanied by degradation of the less ordered carbohydrate regions, hemicellulose depolymerisation accompanied by the generation of acetic acid, furfural products, aldehydes and lignin breakdown/modification [41,42,43,44,45,46]. Hemicellulose (acetic acid, furfural, methyl furfural, hydroxy methyl furfural) and lignin (acetic acid, guaiacol, syringol, vanillin, syringaldehyde, acetovanillone, acetosyringone) degradation products are found in increasing amounts as treatment temperature is increased [25] or with increase in treatment pressure in closed systems [23]. The presence of water facilitates the cleavage of hemicellulosic acetyl groups; furthermore, the use of closed systems ensures that the released acetic acid remains, as well as any formic acid that may be produced [16, 23, 47]. These acidic conditions catalyse the depolymerisation of polysaccharides. The decrease in O/C ratio correlates with other properties, such as changes in microbial durability and EMC [48,49,50], and is also related to the reduction in the number of polar sites (mainly OH groups) in the TMT, with a concomitant decrease in surface free-energy [51] and changes in wettability [52].

TMT contains stable free-radicals, which can be detected by electron spin resonance (ESR) [21, 53]. The ESR signal is invariably relatively broad without fine structure, with a magnitude that increases with temperature of treatment and correlates with mass loss. The source of stable radicals may be found in the conjugated structure of thermally modified lignin associated with semiquinone radicals and diamagnetic quinhydrones [54].

The degradation reactions taking place within the wood cell wall during thermal modification are extremely complex, and for this reason, many studies have been performed on isolated well wall polymers. Although this may provide useful information, it is certain that the behaviour of the isolated polymers will be different from that when they are located in the cell wall. For example, it has been shown that lignin inhibits the thermal degradation of polysaccharides in pine wood flour [55] and isolated cellulose [56, 57]. The following sections mainly detail the current level of understanding of those changes that take place in the cell wall.

Chemical changes

Polysaccharides

For the purposes of this review, the polysaccharides are treated as one group, but are classified according to whether they are amorphous or crystalline. The crystalline polysaccharides primarily comprise the cellulose in the microfibrils, whereas the amorphous content is mainly, but not exclusively, associated with the hemicelluloses. This review is not concerned with the details of the morphology of the elementary fibrils and how they combine to form aggregated structures, which is covered in detail elsewhere [58, 59]. However, the issue of polysaccharide chain accessibility and mobility is of crucial significance when discussing the role of water in the degradation processes and the properties of TMT.

Cellulose has a major reinforcing structural function in the cell wall, and chains of cellulose were originally supposed to be aggregated into units of 36, but are now thought to be created in groups of 18 or 24 to form elementary microfibrils in the wood cell wall [58]. The shape of the microfibril cross section is unknown, but various structures can be envisaged, which present different hydrophobic and hydrophilic faces for interaction with the matrix. There is an amorphous and crystalline component to the cellulose, with the amorphous part being accessible to water molecules and also susceptible to thermal degradation. The proportion of accessible OH groups which are available to water depends upon the dimensions of the microfibril aggregates, with deuterium exchange indicating that 28% are exchangeable [58]. Cellulose is composed solely of glucopyranose units, linked with a regular β-(1,4) linear bonding motif, with no branching or substitution of the chains. The degree of polymerisation (DP) of cellulose is very high (at least 104), and the crystalline core of the microfibril is not accessible to water, as well as being stable under the conditions employed in timber thermal modification. Microfibrils cluster together to form aggregates which have different dimensions in various plant species. There is some evidence suggesting that microfibrillar aggregates in the cell wall of conifers may be up to 10–20 nm across [60].

The size of the cellulose crystal in wood influences the thermal degradation, with greater crystal size correlating with higher thermal stability [61]. It was found that the interfibrillar distance increased when wood was heated in saturated steam (HTwet) at 150 °C or 180 °C [62]. There is also a change in both the degree of crystallinity and the width of the cellulose crystal as a result of heat treatment, and differences in behaviour have been noted between HTwet and HTdry conditions. In one (albeit, preliminary) study, wood powder was heated in dry conditions in air for 20 h, at a range of temperatures from 120 to 220 °C or steam heated for 10 min at the same temperatures [63]. It was found that under HTwet conditions, there was a slight increase in the degree of crystallinity as temperature was increased, but a decrease under HTdry conditions. Meanwhile, the width of the cellulose crystal increased under HTdry conditions as temperature of treatment was increased, but decreased with the HTwet samples. Differences in behaviour were also noted between wet and dry treatment, when heated in water under pressure or in an oven in air at 180, 200 or 220 °C [64]. In all cases, there was an increase in degree of crystallinity (taking into account the sample weight loss) with time of heating; however, as heating was continued, the proportion of crystallinity fell. In these experiments, it was found that the width of the cellulose crystal increased in all cases (greater for HTwet compared to HTdry) until wood samples were exposed to extended heating times. Based on the determined activation energies, it was concluded that crystallisation occurred more readily under HTwet compared to HTdry conditions. Other studies have shown that the width of the cellulose crystal [65] and the crystallinity index [66, 67] increase, fall and then increase again [68], as the modification temperature rises, up to a maximum temperature. In order to determine the crystalline content, it is necessary to separate the crystalline part of the signal from the amorphous component in the scattering, with contributions not just from amorphous cellulose, but hemicelluloses and lignin, which is a non-trivial problem [69]. To circumvent these problems, the use of XRD experiments in combination with crystallographic texture analysis was used to show that cellulose reordering was found after thermal modification at 180 °C in moist air, in conjunction with a decrease in moderately ordered or amorphous regions [70]. Although there is some disagreement, the majority of studies indicate an increase in both crystallinity and width of crystal up to a maximum temperature or time of heating, which is facilitated by using HTwet conditions, followed by a decrease in these two parameters. It is apparent that further work is required to establish the behaviour with certainty. Apart from direct measurement using X-ray diffraction, crystallinity can be inferred using NMR or IR techniques. Determination of the crystallinity index using 13C CPMAS NMR is only indicative, and accurate data require methods in which the peaks from hemicelluloses and lignin can be reliably identified and removed [53]. Similar problems with interpretation are found when IR spectroscopy is used.

The hemicelluloses are thought to have a much lower DP than cellulose, but the DP is not known with certainty since they are easily depolymerised during extraction. They are composed of more than one sugar, branched and may be substituted by acetyl groups to varying extents. They also contain carboxylic functional groups associated with glucuronic and galacturonic moieties, which may participate in crosslinking reactions if calcium ions are present [71] and can form ester bonds with the lignin. They have a role as interfacial coupling agents between the predominantly hydrophilic surface of the cellulose microfibrils and the hydrophobic lignin. They can tether adjacent cellulose microfibrils or form loops which penetrate the lignin/hemicellulose matrix. There is some evidence that hemicelluloses are present within and between microfibrils in the primary cell wall of higher plants [72], and it has been speculated that this may also be the case for the secondary wall [73]. Bonding between the surface of the cellulose microfibrils and the hemicelluloses is exclusively by hydrogen bonding, which is facilitated by the β-(1,4) backbone of the hemicelluloses, allowing for an efficient steric fit [35, 74, 75]. However, the different orientation of the OH groups in the non-glycosidic residues reduces the hydrogen bonding interaction compared to a backbone consisting entirely of β-D-glucose units. Although xylose, the monomer of the backbone of xylans, is a pentose, the orientation of the OH groups of the sugar is identical to that of glucose, which facilitates H-bonding interactions [76]. Hardwoods (angiosperms) generally have a higher hemicellulose content, with a greater proportion of pentoses and greater extent of acetylation, compared to softwoods (gymnosperms).

Xylans (glucuronoxylans) are bound to the cellulose microfibril surface in angiosperm and gymnosperm cell walls [59, 77]. Xylans have a homo-polymeric backbone composed of xylose units and are the most abundant hemicellulose in hardwoods. In hardwood xylans, units of 4-O-methylglucuronic acid are bonded to the xylose backbone via α-(1,2)-glycosidic linkages and there are a few irregular and short side branches bonded to the C3 of the backbone. The distribution of substitution on xylans is not random but exhibits patterns related to cell wall type and plant species [71]. Hardwood xylans have a ratio of substitution of acetyl groups (xyl:acet) of 0.5–0.6 [78], consistent with alternative xylose units being acetylated, as is characteristic of dicotyledons [79]. This form of substitution means that the xylans have to adopt a twofold helical screw configuration, with the result that all the decorations are on one side, which thereby forms an unsubstituted xylan surface. This is able to dock with the hydrophilic surface of the microfibril, giving an apparent microfibril diameter of 3.5–4.2 nm [80]. This shielding of the hydrophilic surface creates a hydrophobic surface to interact with the lignin or prevent aggregation of adjacent microfibrils. Softwood xylans differ from hardwoods by having a lack of acetyl groups and with arabinofuranose units linked by α-(1,3)-glycosidic linkages to the xylose backbone, located two xylosyl residues apart. They also have a higher proportion of 4-O-methylglucuronic acid, which is located on every sixth xylosyl residue and fewer branches compared with hardwood xylans [81]. The pattern of substitution also allows for a distorted twofold helical screw configuration, facilitating interaction with the hydrophilic face of the microfibril. In this way, all of the branch points are facing outwards from the microfibril surface and are able to interact with the matrix. Removal of side groups enables a more extended structure, allowing for close interchain interactions and the formation of extended crystalline regions in the aggregated xylans [82].

The dominant hemicelluloses in softwoods are the galactoglucomannans, which have a hetero-polymeric backbone comprised of glucose and mannose units in a 3:1 ratio [78] with α-D-galactose residues linked to the backbone via the 6-C(OH) at approximately every 10th mannopyranosyl unit in spruce. Galactoglucomannans are acetylated, with a degree of mannose acetylation of 0.28–0.37 at the C2 and C3 positions in spruce [83]. Whereas xylans are bound to the faces of the cellulose microfibrils, much of the lignin and acetylated galactoglucomannans are located in the matrix between the macrofibrils [84]. Hardwoods contain only minor amounts of glucomannans, which are partially acetylated.

The degradation of polysaccharides in water/steam environments is referred to as autohydrolysis. Under autohydrolysis conditions, hemicelluloses and amorphous cellulose break down to a mixture of mainly oligomeric saccharides, under mild conditions, while higher temperatures yield higher levels of hydrolysis and a higher proportion of monosaccharides, as well as degradation products. Elevated levels of degradation products, such as furfurals, are found as the degradation temperature increases [73, 85]. The depolymerisation reaction in autohydrolysis involves the reaction of water with the glycosidic linkage between sugar monomers, being initiated by protonation of the glycosidic or ring oxygen to form a carbonium cation, which then reacts with a water molecule [78] (Fig. 3). This reaction is accelerated in acidic conditions and the de-esterification of hemicelluloses to produce acetic acid promotes acidic conditions (pH 2–4) [47, 86]. Since hardwoods contain a higher proportion of acetyl groups in the hemicelluloses, they degrade at lower temperatures. Furthermore, the xylans of hardwoods are acetylated, whereas those of softwoods are not, which would suggest that degradation reactions at the microfibrillar surface will occur more readily at the microfibril–matrix interface in hardwoods.

Potential routes for acid catalysed polysaccharide depolymerisation [78]

Furfural (2-furaldehyde) and HMF (5-hydroxymethyl-2-furaldehyde) are formed in increasing amounts with an increase in process temperature and acid concentration during the thermal degradation of monosaccharides under acidic conditions [87]. HMF is formed by the thermal degradation of hexoses, and furfural is mainly formed by the degradation of pentoses [88]. Both furfural and HMF have been detected in TMT [89]. Under the appropriate acidic conditions, furfural can further break down to formic acid and HMF can break down into a mixture of formic and levulinic acids (Fig. 4). Levulinic acid has been esterified with ethanol in the presence of a lignin-furfural-based catalyst and would presumably react in a similar manner to any available alcohol-OH groups in the wood cell wall [90]. However, the production of levulinic acid in the thermal modification of wood has not been reported and probably requires a stronger acid than acetic acid as a catalyst [91].

It is known that thermal degradation products accumulate in the wood under HTwet conditions at elevated pressure. The degradation of glucomannan with steam heat treatment of Picea abies, involving breakdown of glucuronic acid and loss of mannose units in the backbone, has been recorded [3]. Higher quantities of water-soluble sugars are found in the leachate of TMT produced by HTwet processes compared to HTdry, although the amount of acetic acid found in the HTwet TMT is lower [29]. Acetic acid does not form an azeotrope with water, and it was presumed that the difference was due to loss of acetic acid as a vapour, although why this is greater for the HTwet compared to HTdry process is not clear. Elevated moisture levels in the wood will contribute to higher levels of acetic acid production, and it would be expected that this would be seen in the leachate [14]. Lower levels of furfural were found in the HTwet TMT leachate, which was attributed to reduced production of these degradation products under wet conditions. This is because formation of furfural is a dehydration reaction, which is suppressed by the presence of water (Fig. 4). The formation of furfural can result in higher levels of lignin being recorded in TMT, when measured using sulphuric acid digestion assays [40, 92]. The furan-based polymers derived from the hemicellulose decomposition, under acidic conditions, may be involved in reactions with the more thermally resistant lignin, with the potential for participating in lignin-lignin condensation reactions, resulting in crosslinking [93].

There are covalent links between the hemicelluloses and the lignin—forming the lignin carbohydrate complex, with ether, ester and glycosidic linkages between the two components [94]. During the autohydrolysis of wood, xylan oligomers are extracted in the early stages, whereas xylan bound to lignin is found as the autohydrolysis reaction proceeds [95]. The existence of these covalent bonds between the lignin and hemicelluloses places limitations on hemicellulose removal during autohydrolysis reactions [96]. Four different types of linkage between the hemicelluloses and lignin are proposed in the literature, namely: benzyl ethers, benzyl esters, γ-esters and phenyl glycosidic [97, 98]. Depending on the treatment temperature, esters will be hydrolysed under autohydrolysis conditions, but ethers are generally more resistant [99].

Lignin

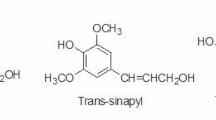

Lignin forms part of the matrix the wood cell wall and is a crosslinked amorphous network polymer comprised of phenyl propane units [78]. There are important differences in lignin isolated from softwoods (gymnosperms) and hardwoods (angiosperms), with hardwood lignins having significantly higher proportions of syringyl units. Syringyl components confer higher thermal stability on isolated lignin [100], and guaiacyl units appear to be preferentially involved with the condensation reactions [101]. Although lignin is considered to be more resistant to thermal degradation, evidenced by the relative increase in lignin content of TMT, there are nonetheless chemical changes that take place, depending on the conditions employed for the thermal treatment. Lignin thermal degradation is considered to start at 120 °C [102] and as the temperature of treatment is increased, the lignin becomes partially extractable by acetone up to a maximum temperature [103]. Loss of aromatic C = O at temperatures of 160 °C and above has been recorded [3, 66].

The literature on the autohydrolysis of lignin is extensive, due to the potential use of this as a pre-treatment for lignocellulosic biomass [86]. Lignin remaining in wood that is subjected to autohydrolysis has been reported to have a higher syringyl/guaiacyl (S/G) ratio (hardwood), higher molecular weight, fewer β-O-4 linkages, but an increase in condensed C–C linkages and a reduction in alcoholic OH groups, as well as a higher proportion of phenolic OH groups due to a reduction in OCH3 groups, which is also associated with the potential to form more condensed structures [104, 105], although -OCH3 groups are claimed to be stable up to 220 °C (with a heating time of 1 h) [38]. Increases in Klason lignin content following thermal modification are attributable to the reduction in polysaccharide content, but also condensation reactions between lignin and polysaccharide breakdown products [106]. It has been shown that alkali metal chlorides have a major effect upon the thermal degradation of lignin model compounds [107], which may have implications regarding any differences in HTwet and HTdry processes, where there is the potential for such salts to be leached out of the wood in wet thermal treatments, especially hydrothermal conditions. The presence of acidic residues does not catalyse the degradation of lignin [108].

One approach to understanding molecular changes taking place in situ is to employ cross-polarised magic angle spinning nuclear magnetic resonance spectroscopy (13C CPMAS NMR). The use of 13C CPMAS NMR has been employed to understand the changes occurring at a molecular level during the thermal modification of wood, which has shown an increase in phenolic OH content, assigned to the increase in a peak at 117 ppm, as well as an increase in the proportion of methylene bridges connecting phenolic nuclei, attributed to a peak at 29 ppm. However, 13C NMR signals at 125–135 ppm and 35 ppm which were noted in degraded holocellulose fractions were thought to be due to the formation of carbonaceous material in the polysaccharide component, in disagreement with previous interpretation as being due to lignin cross-linking and methylene bridges [109]. Later studies indicated that these signals were possibly associated with the LCC [101]. In one study [110], thermal modification did not change the signal pattern of 13C CP-MAS NMR. However, when pulse saturation transfer magic angle spinning NMR was used (13C PST-MAS NMR), this showed a decrease in the lignin -OCH3 signal with heating temperature, which was interpreted as the loss of small molecules with signals that overlapped that of lignin -OCH3. Sivonen et al. [53] reported changes in the 13C CPMAS NMR, on thermally modified Pinus sylvestris. They noted that the problem with 13C CPMAS NMR is the quantification of the data as well as frequent overlap of the peaks from the different components present in the wood, including the extractives. This is a common issue with many spectroscopic techniques applied to wood, potentially resulting in misinterpretation.

Apart from self-condensation reactions, lignin has the capability to react with furfural under acidic conditions. In acidic media, there is higher electron density located at the C2 and C6 positions of the phenylpropanoid units of the lignin, which can react with the electrophilic carbonyl carbon of the furfural (Fig. 5) [90, 93].

PCA analysis of FTIR spectra of dry wood thermally modified in air or under a nitrogen atmosphere revealed the formation of aldehydic and ether linkages in the wood, which was attributed to crosslink formation in the lignin with polysaccharidic degradation products [45]. Crosslinking within the lignin framework may also be facilitated by the production of formaldehyde during lignin degradation under acidic hydrolysis conditions [111]. Formaldehyde can also be produced by the thermal degradation of unsaturated fatty acids, which are produced by oxidative scission of triglyceride extractives in the wood, although it has not been reported as a VOC associated with TMT [112]; its absence in TMT suggests that it has already participated in reactions or been lost from the wood during thermal processing.

It is widely accepted that acidic degradation of biomass does cleave a proportion of aryl-ether linkages in lignin, but the mechanism is not fully understood. Such studies are complicated due to the unpredictable (and to an extent, unknown) structure of the lignin, plus the strongly heterogenous nature of reactions within the lignocellulosic cell wall and for this reason attention has been given to investigating model compounds representing various structural motifs. Two major pieces of work were conducted in this field in the 1970s and 1980s. Lundquist and coworkers [113] published a series of studies investigating the acid-catalysed cleavage of β-O-4 linkages in lignin. Yasuda and coworkers [114, 115] also conducted in-depth investigations into the sulphuric acid catalysed degradation of lignin, with the work of both groups being extensively reviewed by Sturgeon et al. [116] and Yokoyama [117]. Ionic mechanisms have been proposed to explain the acid-catalysed (O.2 M HCl in dioxane) cleavage of non-phenolic model dimers via an enol-ether intermediate [113]. Yokoyama [117] summarises the accepted mechanisms for β-O-4 cleavage based upon the studies of Lundquist and co-workers (Fig. 6).

Mechanisms of lignin β-O-4 cleavage under thermolysis via an enol ether intermediate [117]

The primary reaction of the β-O-4 linkage (I) in acid catalysed cleavage involves the formation of the benzyl cation intermediate (II) via reaction pathway (A). Under favourable conditions, this can be attacked by another lignin moiety to form product (III) (pathway (B)), increasing the crosslinking density. Loss of a proton, through pathways (C) and (D) forms the enol ethers (IV) or (V), respectively, which are susceptible to acidolysis, resulting in cleavage. Both cleavage reactions (E), (F) require the presence of water, although the first step (A) in the reaction involves the elimination of water and will be less favoured under ‘wet’ conditions. These reaction pathways are dependent of the type of acid used in the reaction (HBr, HCl, H2SO4), and their applicability to thermolysis reactions of wood, where the main acid generated is acetic acid, is unknown. Furthermore, Yokoyama [117] find discrepancies in the reaction rate that are not wholly explained by these accepted mechanisms. Rather, they propose that the β-O-4 cleavage reaction goes via a rearrangement of the carbo-cation intermediate, rather than an enol ether (Fig. 7). Cleavage of the β-O-4 linkage will potentially produce soluble fragments; however, repolymerisation of the lignin fragments via C–C linkages is a likely outcome [105], and there is competition between these two reactions. In this context, it is interesting to note that the use of carbocation scavengers during the autohydrolysis pre-treatment of lignocellulosic biomass can improve enzymatic digestibility of the cellulose [86]. The self-condensation of lignin via diphenyl methane C–C condensation reactions is less favoured under HTdry conditions [38].

Mechanism of β-O-4 cleavage under thermolysis via a carbo-cation intermediate [117]

Another proposed mechanism involving homolytic cleavage via quinone methide intermediates is considered unlikely [116]. Studies of the cleavage of β-aryl-ether linkages in lignin model compounds in the presence of 0.2 M H2SO4 at 150 °C have shown that those model compounds containing phenolic moieties reacted much faster [116]. They also propose an additional reaction for the carbocation, where it undergoes self-condensation via electrophilic aromatic substitution to give the product (III) (Fig. 8). Sturgeon et al. [116] did not detect any formaldehyde in their reactions and speculated that any formaldehyde that was released took part in polymerisation reactions to form char.

Extractives

The extractives in wood are either removed from the wood or degraded during the thermal modification process. Fats and waxes migrate along flow pathways, such as ray parenchyma at temperatures as low as 100 °C, whereas resin acids are detectable up to 100 °C [118]. Most of the native extractives are progressively lost or degraded as the process temperature increases, but new extractable compounds caused by thermal degradation of carbohydrate and to a lesser extent, lignin are formed [89, 119, 120]. In one study, extractives were shown to provide a small, but detectable, protective effect on the wood polymers during thermal degradation [55]. In contrast, other workers have found that the presence of extractives in wood resulted in lower thermal stability [61, 121], although this may be attributable to the degradation of extractives during thermal modification. New extractives are formed during the thermal modification process, and degraded residues of extractives may contribute to cell wall bulking and will affect sorption properties, possibly by masking accessible OH groups or may contribute to increased hygroscopicity if they contain sorption sites (more likely to occur with thermal modification under oxidative conditions). The importance of accessibility of OH content in controlling hygroscopicity is currently the subject of much debate in the literature and is considered in more detail in the following sections.

Hydroxyl (OH) content

The thermal modification of wood results in a reduction in accessible hydroxyl content. This can be directly determined by the use of hydrogen–deuterium exchange (HDX), by exposure of the TMT to liquid D2O or D2O vapour or by the use of spectroscopic techniques, such as near infra-red (NIR). With HDX, the hydrogen atoms of the accessible OH groups are exchanged for deuterium using D2O (liquid or vapour), the wood samples are dried and the mass increase due to HDX exchange is then determined. Alternatively, the exchange of OH groups can be measured by the intensity (with suitable corrections) of the O-D stretching band at 2500 cm−1 in the IR region [122,123,124,125]. It is vitally important that the HDX wood is not re-exposed to H2O before weighing; otherwise, re-exchange can rapidly occur [126].

Previous studies of cellulose deuteration have shown that the rate and extent of exchange depend upon the crystallinity of the cellulose sample, temperature and relative pressure of the D2O vapour, mode of deuteration (liquid or vapour) and preparation history of the sample [123]. Atalla et al. [127] used immersion in liquid D2O and Raman spectroscopy to show that drying of isolated native cellulose microfibrils resulted in a lower level of OH accessibility compared to never-dried microfibrils. This was attributed to hornification on drying. The exposure of deuterated samples to H2O will re-exchange the OD groups to OH, but if these regions are no longer accessible, some OD will remain. Thus, drying of an HDX sample in the absence of water molecules followed by exposure to H2O will reveal if any hornification has occurred. This was the approach adopted by Suchy et al. [123] who deuterium-exchanged native wood samples using liquid D2O and then dried the samples under controlled conditions. Depending on the drying conditions employed, subsequent exposure to H2O revealed that there were some residual OD groups remaining, although the effect was much more pronounced when wood pulp was examined using the same experimental protocol. However, it should be noted that in such accessibility experiments, it is vitally important that sufficient time is allowed during the H2O-soaking phase to ensure that slowly re-protonating OD groups are fully exchanged. It is known that the measured accessible OH content is affected by the mode of exposure of the wood to D2O and the drying protocols adopted [125]; Thybring et al. found that when wood samples were dried from the native state, the hydroxyl accessibility was not affected when determined by exposure to liquid D2O. However, if the wood samples were instead exposed to D2O vapour, the measured OH accessibility was reduced by differing amounts, depending on the drying protocol adopted [125]. This effect could be erased by subsequent exposure to liquid water, which (by definition) eliminated hornification upon drying as an explanation. The issue of hornification is discussed further in a later section. The use of HDX is potentially a useful technique for measuring accessible OH content, but needs to be carefully undertaken and interpreted.

When cellulose is exposed to D2O vapour, a two-stage exchange process is observed. Over a relatively short time frame (depending on sample size and morphology), there is exchange with the non-crystalline parts of the cellulose, with a much slower exchange presumably occurring with the crystalline regions. However, it is thought that the cores of the crystalline regions are totally inaccessible to H–D exchange processes [122]. It has also been shown experimentally that the OH(3) group of the C3-atom of the glucopyranose unit of cellulose on the microfibril surface cannot be deuterated, even though it is available to hydrogen bond with water molecules [128]. The lack of exchange of 1H for 2H of the OH(3) is thought to be due to the relative stability of the OH(3) – O(5) hydrogen bond. Although this has not been studied, this may also apply to the OH(3) of sugar residues of the backbone in hemicelluloses in close proximity with the microfibril. According to Kulasinski et al. [129], approximately 15% of OH groups of glucomannans and xylans were not accessible to deuterium exchange, when exposed to D2O vapour. But these experiments were performed on cast films of isolated hemicelluloses, which may produce hornified or otherwise inaccessible crystalline regions in the structure, which are not present when the hemicelluloses are located within the cell wall.

The earliest example of the use of HDX to determine the accessible OH content of TMT was reported by Phuong et al. [130], who thermally treated Styrax tonkinensis wood under dry conditions. TMT specimens were dried at 105 °C and then submerged in D2O in a vial which was then sealed. Exposure was for two days to achieve full exchange. Dried HDX samples were then ignited in a platinum crucible in an oxygen atmosphere and the released D2O determined using NMR. The number of accessible OH groups in unmodified wood was determined to be 6.8(± 0.2) mmol/g, with a reduction thereof with heat treatment. This technique is relatively time-consuming, and the advent of dynamic vapour sorption apparatus has (potentially) simplified the procedure of determining accessible OH content through HDX experiments, although the experimental protocol adopted is crucial to obtaining reproducible results. In DVS experiments, the water reservoir is filled with D2O and the wood is dried using an appropriate protocol and then exposed to a D2O vapour stream, with the final weight difference being recorded. Rautkari et al. [131] conducted the first such DVS study using multiple exposure cycles, which found that there was a poor correlation between the EMC of the wood at constant RH and the accessible OH content. However, subsequent work in this area has questioned the use of multiple sorption cycles in the D2O exposure step, and the use of a single cycle of sufficiently long exposure has instead been recommended [124, 125, 132], as well as changes in other experimental details, especially the drying protocol. The finding that the mode of drying from the native (never-dried) state also affects the apparent accessible OH content when wood samples are exposed to D2O vapour also adds to the potential sources of error [125]. In order to resolve this issue, Uimonen et al. [133] conducted a study to determine what DVS experimental parameters were required to obtain reliable data in HDX experiments. The variables studied included sample weight (minimum 10 mg), length of exposure to D2O vapour at 95% RH (10 h) and rate of mass change (dm/dt = 0.0005% min−1) of the drying steps (dm/dt = 0.002% min−1 was used previously). An initial wetting and drying stage was also recommended in order to release any potentially trapped solvents. There are still possible sources of error arising from the estimation of dry mass within the DVS [134], and although the HDX experiments using a modified protocol produced results with repeatable results, a higher drying temperature in the DVS in order to measure the dry weight was found to produce an increase in accessible OH content by + 0.5 mmol OH groups per gram of dry wood mass [135]. Further development is apparently required to produce reliably accurate OH accessibility data using a DVS apparatus in HDX experiments, but this remains a very convenient method for determination of accessible OH groups once reliability can be established.

The use of deuterium exchange has the advantage that accessible OH content can be directly measured, albeit taking into account the caveats presented in the preceding paragraph. There are also different spectroscopic techniques that can be applied to studying the OH content of TMT, such as FTIR [103, 136], NIR[137]. Mitsui et al. [137] used NIR to observe changes in OH content of TMT, concluding that the degradation reactions commenced in the amorphous polysaccharide regions before progressing to the crystalline regions and that the phenolic OH groups were not degraded. The use of NIR or FTIR requires the use of peak fitting to spectra that often exhibit indistinct and merged absorption peaks. This makes the quantitative evaluation of OH content subject to error. OH content can be determined by acetylation, followed by aminolysis with pyrrolidine and GC analysis [138]. This method relies upon the assumption that all of the H2O accessible OH groups are also accessible by acetylation.

Changes in physical properties

Hygroscopicity

Thermal modification reduces the amount of bound water in the wood cell wall [139, 140]. However, the behaviour of HTdry and HTwet wood is different. The behaviour observed depends upon whether the EMC of the wood is measured directly after post-treatment or if there is exposure to liquid water or high levels of moisture after the thermal modification. Although dry thermal modification of wood results in a reduction in EMC, the effects are partially reversible, in contrast to TMT produced by wet thermal processes (under thermal modification conditions where the RH is 100%). In the case of the hygroscopicity of dry thermally modified wood, exposure to high RH levels or liquid water can partially reverse the initial reduction in hygroscopicity [5, 32, 141,142,143,144,145,146]. The explanation for this behaviour was due to stress remaining in the wood after the dry thermal modification stage. When dry wood is heated, the amorphous region remains in a stressed state, which is relaxed by subsequent exposure to high moisture levels. When wood is modified under HTwet conditions, the amorphous content remains in a plasticised state and stress relaxation occurs during the thermal modification process [141]. This partial reversibility of the behaviour is also noted when thermal treatment is undertaken at an intermediate RH. Endo et al. [5] found that although the EMC of wood was reduced by thermal treatment at intermediate humidities, this reduction was effectively eliminated by exposing the wood to saturated water vapour at 25 °C. This was found for wood heated at 120 °C for two days at a range of different humidities. The reversible effect was observed at 0% treatment humidity and increased up to 60% treatment RH, reducing thereafter and becoming zero at a treatment RH of 95%. Borrega and Kärenlampi [147] heated wood at 150 °C or 170 °C in a pressure vessel at a range of treatment RHs up to saturation. They found that thermal modification at an intermediate RH produced TMT which had markedly reduced hygroscopicity compared to heating at 100% RH, in agreement with the experiments conducted at 120 °C [5]. This behaviour was attributed to the formation of irreversible H-bonds in the structure at intermediate RH, but as Obataya et al. [6] point out, these experiments did not examine the hygroscopicity after exposure to saturated water vapour and therefore did not take account of the reversible behaviour. By definition, hornification is not reversible. As noted previously, in a hygrothermal modification experiment performed at 120 °C at different RHs, wood samples heated at a RH of 100% exhibited reduced EMC at the lower end of the hygroscopic range, whereas at the highest end of the range, the EMC exceeded that of unheated wood. This was attributed to the presence of water-soluble and deliquescent degradation products that were formed in the cell wall during the hygrothermal process. After a leaching experiment, the EMC at higher RH was reduced. This change in behaviour after leaching was not found when such treatments were performed at RHs below 80%, where only minor mass losses were noted with the post-treatment leaching step [6]

The hygroscopicity properties of wood are undoubtedly linked in some way to the OH groups in the cell wall polymer matrix. This is often assumed to be because the OH groups are considered to be primary sorption sites and models involving close association of water molecules with the cell wall OH groups are invoked. Thermal modification results in a reduction of OH content (mainly due to hemicellulose degradation); hence, the EMC at any given RH would be expected to be lower compared to unmodified wood, assuming the primary sorption sites model to be the correct explanation for hygroscopic behaviour. This simple relationship between OH content and EMC, was called into doubt by the work of Rautkari et al. [131] who found that there was no direct correlation between OH content, as measured by HDX and the EMC of TMT. This led to the conclusion that there were additional mechanisms responsible for the reduction in EMC, other than the accessible OH content. However, as discussed, later work has shown that these data were adversely affected by the measurement protocol employed. More recent work [148] has shown that there is a linear relationship between the EMC at 25 °C and 93% RH and the accessible OH content was determined gravimetrically using DVS, using an improved method of measurement. Furthermore, the regression slope for HTdry TMT is much greater than that for HTwet TMT, because the EMC of the HTdry TMT is lower for the same accessible OH content. An accessibility of 1.01 H2O molecules per accessible OH group was determined for unmodified Scots pine (Pinus sylvestris). Willems [149] has suggested that each sorption site in the wood is actually comprised of a pair of OH groups which may be associated with a single or a pair of water molecules. In this model, the sorption isotherm at RHs below 50% is composed of strongly bound water monomers and at higher RH, the sorbed water is composed of loosely bound dimers. The elimination of a sorption site therefore requires the loss of only one OH group of an associated pair; however, if there is an opportunity for a molecular rearrangement to occur, new such-associating pairs can be created. Such a situation occurs during any HTwet process, where molecular mobility is facilitated during the thermal modification process or it can occur during a post-treatment annealing stage in the presence of liquid water or at high moisture levels. Using such a model only requires the number of accessible OH groups to be considered. Altgen et al. [148] used this model to suggest that thermal modification created single OH sites that were not able to act as sorption sites; however, under HTwet conditions, relaxation of the polymer network occurred allowing for the formation of new (albeit fewer overall) sorption site OH pairs. When wood was modified under HTdry conditions, the initial configuration of the polymer network left unpaired OH groups, subsequent annealing allowed new pairs to be formed and consequently an increase in hygroscopicity. This idea was further developed by Willems et al. [135] who measured the accessible OH content of the same HTdry sample before and after a post-treatment water saturation. They found that there was a slight decrease in OH content, but that the EMC increased significantly after the post-treatment water soaking experiment. The change in OH content was attributed to loss of degraded cell wall material during the water-soaking phase, but the important point was that the increase in EMC when exposed to 93% RH (from 8.45 to 9.72%) was not accompanied by an increase in OH content. It was also found that the accessible OH content did not increase when the sample was soaked in DMSO post-treatment, although the EMC was significantly higher after water exchange, drying in a desiccator over silica gel and then exposure to 93% RH (EMC = 11.31%). This is a very interesting observation, which was used in support of the hypothesis that the enhanced polymer mobility during the water-saturation phase allowed for the creation of new sorption site OH pairs; hence, there was an increased EMC noted in subsequent sorption experiments, even though the OH accessibility had not changed. However, there are other explanations for this behaviour apart from invoking the hypothesis of sorption site pairs or OH accessibility. These alternatives are discussed in more detail in a following section.

Apart from the destruction of sorption sites, other reasons that have been suggested for the reduction in hygroscopicity are linked to a degradation of the hemicelluloses with concomitant reductions in cell wall polymer mobility or to crosslinking reactions within the cell wall. In the case of crosslinking, any reduction in hygroscopicity would most likely be permanent. However, if the reduction is caused by the formation of H-bonding networks within the cell wall [147], then this could be reversed if the hydrogen bonds within such regions were broken (not invoking hornification as a mechanism). This structural rearrangement would occur when there was sufficient molecular mobility to allow for this, implying that a threshold moisture content is required. Regions of the network may be unable to relax to a lower energy configuration because they are in a glassy state and there is insufficient void volume to allow for molecular reconfiguration. This would lead to reduced EMC when exposed to water vapour at RH less than 95% or thereabouts. However, upon water soaking or exposure to high RH levels, a non-equilibrium configuration of the cell wall polymer matrix could then relax to a lower energy state due to the enhanced chain mobility conferred by the presence of water in the cell wall [141]. If linked to impermanent H-bonding networks, this suggests that measurements of accessible OH content using D2O would change before and after the water-soaking stage. But this has not been observed [135]. The loss of mobile cell wall components during thermal modification will result in a cell wall that is in a higher energy stressed state under HTdry conditions, which can then relax when subsequently exposed to higher levels of moisture. If wood is modified under wet conditions, then the continuing chain mobility that occurs throughout the wet thermal modification process allows for a lower energy state to be realised during the process. Hence, there is little further change in EMC observed in sorption isotherm experiments following any subsequent water exposure cycle [32, 135, 141]. This would not affect the accessible OH content.

Altgen et al. [29] found that the EMC and maximum swelling of HTdry TMT were lower than those of HTwet for the same weight loss. They attributed the reduction in hygroscopicity to the loss of accessible OH groups during thermal modification, mainly due to loss of hemicelluloses. However, the enhanced reduction in EMC of the HTdry TMT suggested an additional mechanism, which was thought to be related to increased levels of crosslinking in the cell wall resulting in an increase in the matrix stiffness. With HTwet, the presence of water in the cell wall favours the cleavage of the amorphous cell wall polymers, resulting in a decrease in chain length and an increase in free volume allowing for polymer rearrangement. In contrast, HTdry encourages the formation of crosslinks within the cell wall, increasing matrix stiffness and reducing polymer mobility. Stiffening of the hemicellulose matrix takes place during water removal in any case, which elevates the glass transition temperature of dry hemicellulose to over 200 °C [150]. Assuming that more extensive crosslinks are formed under HTdry conditions, the consequent reduction in polymer mobility is not sufficient to prevent the rearrangements necessary for new OH sorption site pairs to be formed, although the rate at which such rearrangements occur would be slower. If the crosslinking is confined to the amorphous polysaccharide domain, then it is possible that overall swelling in solvents, such as DMSO, may be unaffected.

Diffusion of water through the polymer matrix of the wood cell wall is dependent upon the molecular dynamics of the polymers in the non-crystalline regions. The diffusion process is dependent upon whether these polymers are in a glassy or rubbery state [151, 152]. Swelling of the amorphous regions of the cell wall is associated with an increase in the free-volume (and hence chain mobility) of the molecules. This ‘softening’ of the structure facilitates the transport of water molecules and is also associated with a reduction in the modulus of the cell wall. Mechanical and sorptive properties are inextricably linked. Loss of the hemicellulose component through thermal degradation will change the relationship between elastic modulus and MC, by removing components that exhibit higher molecular mobility in the presence of water molecules. It is well known that the elastic modulus of wood decreases as the cell wall MC increases. As water is introduced into the cell wall, the density of the hemicellulose component reduces, along with the elastic modulus. Simultaneously, the molecular mobility of the hemicellulose chains increases in line with the creation of free volume within the matrix. However, the elastic modulus of the lignin increases up to about 10% MC and 2.5% MC for the LCC. At low MC, the water molecules predominantly form hydrogen bonds with the cell wall polymers, whereas above approximately 10% MC, the water molecules increasingly self-associate into ‘nano-droplets’ [153]. The model that is described by Willems [149] does not include the formation of such water clusters (other than dimers), nor consider the chain mobility of the amorphous parts of the cell wall polymer matrix.

Dimensional stability

Post-modification, the wood is often subjected to wet/dry cycling in order to determine the dimensional stability. This can result in leaching of decomposition residues, but also facilitate molecular rearrangements within the cell wall. Loss of degraded cell wall material by diffusion is much more likely under conditions where water is present and leaching occurs during thermal modification, but some degraded material can still remain in the cell wall until a subsequent leaching stage. The remaining degradation products act as bulking agents inside the cell wall and when they are removed, there is a consequently a reduction in the volume of the cell wall, which is usually reflected as a reduction in the dry wood volume at a macroscopic level. The water-saturated volume of the wood may be reduced as a result of thermal modification, but this is not always observed [26]. If the dry volume is reduced and the water-saturated volume remains the same, then this results in a higher overall volume change and hence lower-dimensional stability. If crosslinking of the polymer network occurs, there is a restriction of swelling, leading to a reduced water-saturated volume; but if the thermal modification takes place in wood that is in a water-swollen state, there is subsequently unlikely to be any observed reduction in water-swollen volume as a consequence. By contrast, crosslinking of wood thermally modified in the dry state would result in restricted swelling when subsequently water-saturated.

There are two main methods for determining the dimensional stability of wood. Wood samples can be exposed to varying conditions of relative humidity, with dimensions of samples determined after the wood has reached equilibrium at a specified atmospheric RH and temperature. The difference in dimensions as a sample is transferred between conditions of high and low RH which is then expressed in a formula to give the dimensional stability. This is the principle behind the European Standard EN 1910:2016. The use of measurement methods which rely upon determining changes in dimensions of wood samples when exposed to conditions of high and low RH is perfectly reasonable for the determination of solid wood, wood-based laminates and composites, where the wood has not been modified. However, if the wood has been modified by a physical, chemical or biological process, it may be that such a modification is not permanent when this material is used under service conditions. For such situations, it is advisable to either include a water-leaching stage (such as EN 84) prior to the determination of dimensional stability or to determine dimensional stability by using a water soak/oven drying (WS/OD) test, as described by Rowell and Ellis [154]. In this test, the wood sample is vacuum impregnated with water and then left to soak for a specified interval before the water saturated external dimensions are determined. The wood samples are then dried in an oven, and the oven-dry dimensions and weight are then determined. In most cases, the oven-dry dimensions are determined after modification, before the first water soaking cycle. It is necessary to complete a number of cycles to determine the stability of the dimensional stabilisation effect (if any).

When water enters the cell wall of wood, the cell wall swells, which is reflected in macroscopic dimensional increases of the wood. One of the reasons for producing TMT on a commercial scale is to create a more dimensionally stable product, which consequently has superior performance in exterior applications. An understanding of these properties is therefore of great importance for product improvement.

Improved dimensional stability can be achieved by:

-

The presence of bulking agents within the cell wall. This will increase the dry dimensions of the wood. The water saturated dimensions are unlikely to be affected, meaning that the difference between the dry and wet volume is reduced, resulting in improved dimensional stability [2]. Thermal modification will not add bulking agents to the cell wall, and hence, there will be no increase in dry dimensions of the wood; on the contrary, a decrease in volume is usually observed (although this may only occur after a subsequent leaching stage post-treatment). However, thermally degraded components may remain in the cell wall, where they have a bulking property, and this filled space is not available to water molecules. The interaction with absorbed water will depend upon whether the bulking agent is hydrophobic or hydrophilic; if the latter happens, then the cell wall will be able to accommodate larger amounts of water compared to hydrophobic bulking agents. If the degraded components are subsequently leached out, the cell wall will lose these bulking agents, resulting in a reduction in dry volume.

-

Removal of OH groups, which will reduce the hydrophilicity of the wood [155]. This will change the free energy of mixing between the wood polymer network and the penetrating water molecules, which is related to the interaction parameter of the Flory–Huggins theory [156]. Loss of OH groups is also related to changes in hygroscopicity and surface energy (wetting). This loss also results in a reduction in primary sorption sites, but the importance of this compared to changes in the free energy of mixing is debatable.

-

Increased crosslinking within the cell wall polymers, which restricts the ability of the cell wall matrix to swell to accommodate sorbed water molecules; increased elastic modulus of the cell wall requires a greater internal swelling force (related to free energy of mixing) to achieve the same moisture content. Changing the crosslink density also affects the configurational entropy of the polymer network on swelling and the glass transition temperature [157]. This crosslinking can occur by the formation of covalent bonds due to the reaction of degradation products (such as furfurals) or due to hornification within the polymer network, if this occurs with lignified materials [147]. However, crosslinking is not solely associated with the lignin matrix.

-

Changes in the mobility of the polymer network. Removal, degradation or crosslinking of the more mobile hemicelluloses will produce a stiffer cell wall matrix, requiring a greater ‘internal pressure’ to be generated to produce the same volume increase as with the unmodified equivalent. This relationship between elastic strain of the matrix and free energy of mixing is considered in a later section.

Although details vary, most research data are reported in terms of a percentage swelling (or shrinkage) coefficient (S), as follows:

where Vwet is the volume of the wood under water-saturated conditions (or high humidity) and Vdry is the volume of wood under oven-dry (or low humidity) conditions.

The differences in swelling behaviour between modified and unmodified wood can be reported in terms of an anti-shrink efficiency (ASE):

where Sunmod is the swelling coefficient of the unmodified wood and Smod is the swelling coefficient of the modified wood. As the swelling coefficient of the modified wood approaches zero, the ASE approaches 100%.

The result of a dimensional stability experiment using over-dry/water-saturated conditions is shown in Fig. 9a. This represents a study of unmodified wood over three cycles, where there is no loss of material from the cell wall.

In Fig. 9b, the presence of a bulking agent in the cell wall swells the wood by an amount Vb and consequently the wood exhibits dimensional stability because the difference in Vwet and Vdry is smaller than it was in Fig. 9a. In this case, the bulking agent is non-leachable and consequently the dimensional stability is permanent, whereas in Fig. 9c, the bulking agent is leached out over the three wet/dry cycles and the dimensional stability is lost. In Fig. 9d, the swelling of the wood is restrained due to crosslinking in the cell wall, but this situation will only occur if the crosslinking does not involve any bulking due to the presence of the crosslinking agent. In Fig. 9e, there is crosslinking of the cell wall and the crosslinking agent also occupies cell wall volume. In Fig. 9f, there is loss of material from the cell wall, causing a reduction in Vdry and Vwet is lower due to crosslinking in the cell wall. An increase in Vdry requires the impregnation of the cell wall with an external bulking agent (not occurring with thermal modification). A combination of restriction of swelling by crosslinking and gradual loss of cell wall material is shown in Fig. 9g. Loss of cell wall material and reduction in crosslinking are illustrated in Fig. 9h, and loss of cell wall material with no additional restraint upon swelling is shown in Fig. 9i.

It has long been known that there are important differences in swelling behaviour between TMT modified under wet and dry conditions and that leaching of the wood after thermal modification reduces the ASE [7]. It was also reported that ‘heating wood in water-saturated atmospheres has no permanent effect upon the swelling and shrinking’ [7]. The possibility of crosslinking occurring during thermal modification was first posited as a mechanism explaining the reduction in hygroscopicity and improved dimensional stabilisation by Stamm and Hansen in 1937 [7]. They thought that the presence of excess water in the cell wall during thermal modification prevented crosslinking reactions occurring between adjacent OH groups, whereas the absence of moisture allowed for these dehydration reactions to occur, thereby forming ether crosslinks. This neatly explained the difference in swelling behaviour between TMT heated under HTdry and HTwet conditions. However, the existence of ether crosslinks was later tested by the use of swelling liquids on TMT, which showed that thermal modification only reduced the swelling in water [158]. This indicated that crosslinking could not be the explanation for the improved dimensional stability.

Seborg et al. [158] conducted studies where they heated wood in pressure bombs under dry conditions, where the wood had previously been equilibrated at 97% RH and where such equilibrated wood also had additional water placed in the bomb before it was sealed. After thermal modification, the specimens were leached with hot water to remove soluble degradation products. They did not observe any significant differences in dimensional stability or hygroscopicity between samples heated under dry or moist conditions. However, the samples were heated at 300 °C, considerably higher than the temperatures employed for commercial thermal modification reactions.

Wood heated under saturated steam in an initially dry state showed different properties compared to wood that contained moisture (conditioned at 65% or 95% RH at 20 °C) prior to modification [159]. Samples which contained moisture prior to thermal treatment showed higher mass losses, but larger swelling coefficients (and hence reduced ASE) compared to the samples which were oven-dried prior to thermal modification (180 °C, 10 bar). However, the S% was lower than the reference sample for all of the thermal modified samples. Only one water-soak/oven-dry cycle was employed in these experiments.