Abstract

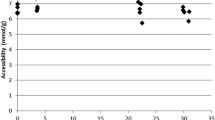

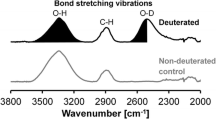

Deuterium exchange in a deuterium oxide (D2O) atmosphere (95 % relative humidity), quantified by a dynamic vapor sorption (DVS) apparatus, was applied for assessing the accessibility of hydroxyl groups in birch kraft pulps. Achieving the maximum deuteration level exhibited slower kinetics than was earlier reported for experiments with ground wood and bacterial cellulose. The deuterium exchange process followed two parallel phenomena. Applying multiple drying and rewetting cycles gave kinetic information also on the hornification phenomenon occurring during these cycles. Dry birch pulps treated with sodium hydroxide solution of varying alkalinities at elevated temperatures were assessed for their accessible hydroxyl groups by DVS with deuterium exchange. This method was evaluated against deuteration combined with Fourier transform infra-red spectroscopy and water retention value (WRV). DVS measurements were in correlation with WRV and both the methods indicated that an alkaline treatment of dry birch pulp improves cellulose accessibility. The level of irreversible deuteration also decreased as the alkalinity was increased. DVS was shown to provide quantitative information on the accessibility but to be a time-consuming method for the pulp samples. A potential means to decrease the duration of the measurement is increased D2O exposure by excluding the drying phases.

Similar content being viewed by others

References

Berthold J, Salmén L (1997) Inverse size exclusion chromatography (ISEC) for determining the relative pore size distribution of wood pulps. Holzforschung 51:361–368

Billosta V, Brändström J, Cochaux A, Joseleau J-P, Ruel K (2006) Ultrastructural organization of the wood cell wall can explain modifications caused in fibers during the pulping process. Cell Chem Technol 40:223–229

Dinand E, Vignon M, Chanzy H, Heux L (2002) Mercerization of primary wall cellulose and its implication for the conversion of cellulose I → cellulose II. Cellulose 9:7–18

Fahlén J, Salmén L (2003) Cross-sectional structure of the secondary wall of wood fibers as affected by processing. J Mater Sci 38:119–126

Fahlén J, Salmén L (2005) Pore and matrix distribution in the fiber wall revealed by atomic force microscopy and image analysis. Biomacromolecules 6:433–438

Fernandes Diniz JMB, Gil MH, Castro JAAM (2004) Hornification—its origin and interpretation in wood pulps. Wood Sci Technol 37:489–494

Frilette VJ, Hanle J, Mark H (1948) Rate of exchange of cellulose with heavy water. J Am Chem Soc 70:1107–1113

Gane PAC, Ridgway CJ, Lehtinen E, Valiullin R, Furó I, Schoelkopf J, Paulapuro H, Daicic J (2004) Comparison of NMR cryoporometry, mercury intrusion porosimetry, and DSC thermoporosimetry in characterizing pore size distributions of compressed finely ground calcium carbonate structures. Ind Eng Chem Res 43:7920–7927

Higgins HG, McKenzie AW (1963) The structure and properties of paper XIV. Effects of drying on cellulose fibres and the problem of maintaining pulp strength. Appita 16:145–164

Hill CAS, Norton A, Newman G (2009) The water vapor sorption behavior of natural fibers. J Appl Polym Sci 112:1524–1537

Hill CAS, Norton A, Newman G (2010) The water vapour sorption properties of Sitka spruce determined using a dynamic vapour sorption apparatus. Wood Sci Technol 44:497–514

Hill CAS, Ramsay J, Keating B, Laine K, Rautkari L, Hughes M, Constant B (2012) The water vapour sorption properties of thermally modified and densified wood. J Mater Sci 47:3191–3197

Hishikawa Y, Togawa E, Kataoka Y, Kondo T (1999) Characterization of amorphous domains in cellulosic materials using a FTIR deuteration monitoring analysis. Polymer 40:7117–7124

Hofstetter K, Hinterstoisser B, Salmén L (2006) Moisture uptake in native cellulose—the roles of different hydrogen bonds: a dynamic FT-IR study using Deuterium exchange. Cellulose 13:131–145

Howard RC (1990) The effects of recycling on paper quality. J Pulp Pap Sci 16:J143–J149

Hult E-L, Larsson PT, Iversen T (2001) Cellulose fibril aggregation—an inherent property of kraft pulps. Polymer 42:3309–3314

Jayme G (1944) Micromeasurements of the swelling of pulps. Papierfabr Wochenbl Papierfabr 6:187–194

Jayme G (1958) Properties of wood celluloses. II. Determination and significance of water-retention value. Tappi 41:180A–183A

Jeffries R (1963) An infra-red study of the deuteration of cellulose and cellulose derivatives. Polymer 4:375–389

Kachrimanis K, Noisternig MF, Griesser UJ, Malamataris S (2006) Dynamic moisture sorption and desorption of standard and silicified microcrystalline cellulose. Eur J Pharm Biopharm 64:307–315

Klemm D, Philipp B, Heinze U, Heinze W (1998) Comprehensive cellulose chemistry. Vol. 1. Fundamentals and analytical methods, vol 1. Wiley-VCH, Weinheim

Kljun A, Benians TAS, Goubet F, Meulewaeter F, Knox JP, Blackburn RS (2011) Comparative analysis of crystallinity changes in cellulose I polymers using ATR-FTIR, X-ray diffraction, and carbohydrate-binding module probes. Biomacromolecules 12:4121–4126

Klungness JH (1974) Recycled fiber properties as affected by contaminants and removal processes. Tappi 57:71–75

Kohler R, Dück R, Ausberger B, Alex R (2003) A numeric model for the kinetics of water vapor sorption on cellulosic fibers. Compos Interfaces 10:255–276

Laivins GV, Scallan AM (1993) The mechanism of hornification of wood pulps. Products of papermaking, transactions of the Xth fundamental research symposium, Oxford, 1235–1260

Lee JM, Heitmann JA, Pawlak JJ (2007) Technique for the measurement of dimensional changes of natural microfibril materials under variable humidity environments. Mater Sci Eng A 445–446:632–640

Lee K-Y, Quero F, Blaker JJ, Hill CAS, Eichhorn SJ, Bismarck A (2011) Surface only modification of bacterial cellulose nanofibres with organic acids. Cellulose 18:595–605

Lindström T (1992) Chemical factors affecting the behaviour of fibres during papermaking. Nord Pulp Pap Res J 4:181–192

Lindström T, Carlsson G (1982) The effect of carboxyl groups and their ionic form during drying on the hornification of cellulose fibers. Sven Papperstidn 85:R146–R151

Maloney TC, Paulapuro H (2000) The effect of drying conditions on the swelling and bonding properties of bleached kraft hardwood pulp. Appita Annu Conf Proc 1:41–46

Maloney TC, Paulapuro H, Stenius P (1998) Hydration and swelling of pulp fibers measured with differential scanning calorimetry. Nord Pulp Pap Res J 13:31–36

Maloney TC, Laine JE, Paulapuro H (1999) Comments on the measurement of cell wall water. Tappi J 82:125–127

Mann J, Marrinan HJ (1956) The reaction between cellulose and heavy water. Part 1. Qualitative study by infra-red spectroscopy. Trans Faraday Soc 52:481–487

McKenzie AW, Higgins HG (1958) The structure and properties of paper. Part II. The influence of alkali on the infra-red spectra, bonding capacity and beating response of wood and cotton fibres. Sven Papperstidn 61:893–901

Mercer J (1851) Improvement in chemical processes for fulling vegetable and other textures. US Patent 8303

Minor JL (1994) Hornification—its origin and meaning. Progr Pap Recycl 3:93–95

Morrison JL (1960) Deuterium–hydrogen exchange between water and macromolecules: accessibility of cellulose. Nature 185:160–161

Nazhad M, Paszner L (1994) Fundamentals of strength loss in recycled paper. Tappi J 77:171–179

Nishiyama Y, Kuga S, Okamo T (2000) Mechanism of mercerization revealed by X-ray diffraction. J Wood Sci 46:452–457

Oksanen T, Buchert J, Viikari L (1997) The role of hemicelluloses in the hornification of bleached kraft pulps. Holzforschung 51:355–360

Okubayashi S, Griesser UJ, Bechtold T (2004) A kinetic study of moisture sorption and desorption on lyocell fibers. Carbohydr Polym 58:293–299

Okubayashi S, Griesser UJ, Bechtold T (2005) Moisture sorption/desorption behavior of various manmade cellulosic fibers. J Appl Polym Sci 97:1621–1625

Östlund Å, Köhnke T, Nordstierna L, Nydén M (2010) NMR cryoporometry to study the fiber wall structure and the effect of drying. Cellulose 17:321–328

Park S, Venditti RA, Jameel H, Pawlak JJ (2006) Changes in pore size distribution during the drying of cellulose fibers as measured by differential scanning calorimetry. Carbohydr Polym 66:97–103

Philipp B, Lehmann R, Ruscher C (1959) Zum Einfluß des Cellulosematerials auf den Verlauf der Alkalicellulosebildung. Faserforschung und Textiltechnik 10:22–35

Pönni R, Vuorinen T, Kontturi E (2012) Proposed nano-scale coalescence of cellulose in chemical pulp fibers during technical treatments. BioResources 7:6077–6108

Pönni R, Kontturi E, Vuorinen T (2013) Accessibility of cellulose: structural changes and their reversibility in aqueous media. Carbohydr Polym 93:424–429

Pönni R, Galvis L, Vuorinen T (2014) Changes in accessibility of cellulose during kraft pulping of wood in deuterium oxide. Carbohydr Polym 101:792–797

Rautkari L, Hill CAS, Curling S, Jalaludin Z, Ormondroyd G (2013) What is the role of the accessibility of wood hydroxyl groups in controlling moisture content? J Mater Sci 48:6352–6356

Saito G (1939) Das Verhalten der Zellulose in Alkalilösungen. Kolloid-Beih 49:365–454

Scallan AM (1974) The structure of the cell wall of wood—a consequence of anisotropic inter-microfibrillar bonding? Wood Sci 6:266–271

Sepall O, Mason SG (1961) Hydrogen exchange between cellulose and water II. Interconversion of accessible and inaccessible regions. Can J Chem 39:1944–1955

Sharratt V, Hill CAS, Jalaludin Z, Kint DPR (2011) The influence of photodegradation and weathering on the water vapour sorption kinetic behavior of scots pine earlywood and latewood. Polym Degrad Stab 96:1210–1218

Siroká B, Manian AP, Noisternig MF, Henniges U, Kostic M, Potthast A, Griesser UJ, Bechtold T (2012) Wash-dry cycle induced changes in low-ordered parts of regenerated cellulosic fibers. J Appl Polym Sci 126:E396–E407

Sjöström E, Enström B (1967) Characterization of acidic polysaccharides isolated from different pulps. Tappi 50:32–36

Stone JE, Scallan AM (1967) The effect of component removal upon the porous structure of the cell wall of wood. II. Swelling in water and the fiber saturation point. Tappi 50:496–501

Stone JE, Scallan AM (1968) A structural model for the cell wall of water-swollen wood pulp fibres based on their accessibility to macromolecules. Cell Chem Technol 2:343–358

Suchy M, Kontturi E, Vuorinen T (2010a) Impact of drying on wood ultrastructure: similarities in cell wall alteration between native wood and isolated wood-based fibers. Biomacromolecules 11:2161–2168

Suchy M, Virtanen J, Kontturi E, Vuorinen T (2010b) Impact of drying on wood ultrastructure observed by deuterium exchange and photoacoustic FT-IR spectroscopy. Biomacromolecules 11:515–520

Taniguchi T, Harada H, Nakato K (1978) Determination of water adsorption sites in wood by a hydrogen–deuterium exchange. Nature 272:230–231

Tsuchikawa S, Siesler HW (2003a) Near-infrared spectroscopic monitoring of the diffusion process of deuterium-labeled molecules in wood. Part I: softwood. Appl Spectrosc 57:667–674

Tsuchikawa S, Siesler HW (2003b) Near-infrared spectroscopic monitoring of the diffusion process of deuterium-labeled molecules in wood. Part II: Hardwood. Appl Spectrosc 57:675–6681

Wang X, Maloney TC, Paulapuro H (2003) Internal fibrillation in never-dried and once-dried chemical pulps. Appita J 56:455–459

Weise U (1998) Hornification—mechanisms and terminology. Pap Puu 80:110–115

Weise U, Hiltunen E, Paulapuro H (1998) Verhornung von Zellstoff und Maßnahmen zu ihrer Reversion. Das Papier 52:V14–V19

Wistara N, Young RA (1999) Properties and treatments of pulps from recycled paper. Part I. Physical and chemical properties of pulps. Cellulose 6:291–324

Xie Y, Hill CAS, Jalaludin Z, Curling SF, Anandjiwala RD, Norton AJ, Newman G (2011) The dynamic water vapour sorption behavior of natural fibres and kinetic analysis using the parallel exponential kinetics model. J Mater Sci 46:479–489

Acknowledgments

Financial support from Academy of Finland and UPM are acknowledged. Mrs. Mirja Reinikainen is gratefully acknowledged for her help in experimental work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pönni, R., Rautkari, L., Hill, C.A.S. et al. Accessibility of hydroxyl groups in birch kraft pulps quantified by deuterium exchange in D2O vapor. Cellulose 21, 1217–1226 (2014). https://doi.org/10.1007/s10570-014-0166-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0166-x