Abstract

Bleached kraft pulps from Eucalyptus benthamii, E. globulus, E. nitens and E. nitens × E. globulus hybrid were prepared in laboratory scale and upgraded to dissolving-grade via cold caustic extraction (CCE) and dilute acid hydrolysis. The CCE reduced the alkali solubility (S18) of bleached kraft pulps from 11.8–16.4% to 4.5–6.3% after extraction with 5% (w/v) NaOH, and to 0.9–1.7% after extraction with 10% (w/v) NaOH. The dilute acid hydrolysis with 3% H2SO4 reduced the intrinsic viscosity of CCE-treated kraft pulps from 800–900 to 110–450 ml/g. E. nitens and E. benthamii displayed the most contrasting values for S18 and intrinsic viscosity after CCE and acid hydrolysis treatments. The X-ray diffraction results showed that the crystallinity index of bleached kraft pulps followed the order: E. benthamii > E. globulus > En × Eg > E. nitens. Regarding cellulose reactivity, the Fock reactivity of the bleached kraft pulps was in the range of 34.7–41.3%. After CCE, the pulps reactivity was reduced to 13.7–25.4%, whereas after acid hydrolysis it was increased to 40.7–87.5%. E. benthamii and E. nitens pulps showed to be the less reactive pulps after pulp activation via acid hydrolysis, whereas E. globulus and the hybrid showed to be the most reactive pulps towards xanthation. It was observed that different Eucalyptus species can lead to kraft pulps with different requirements towards xanthation, and that the inherent features of wood and how they are processed are of outmost importance for the final use of kraft-based dissolving pulp from a given wood species.

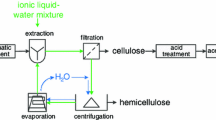

Graphical Abstract

Similar content being viewed by others

References

Agarwal UP, Ralph SA, Baez C, Reiner RS, Verrill SP (2017) Effect of sample moisture content on XRD-estimated cellulose crystallinity index and crystallite size. Cellulose 24:1971–1984

Ahvenainen P, Kontro I, Svedstrom K (2016) Comparison of sample crystallinity determination methods by X-ray diffraction for challenging cellulose I materials. Cellulose 23:1073–1086

Arnoul-Jarriault B, Lachenal D, Chirat C, Heux L (2015) Upgrading softwood bleached kraft pulp to dissolving pulp by cold caustic treatment and acid-hot caustic treatment. Ind Crops Prod 65:565–571

Carrillo I, Valenzuela S, Elissetche JP (2017) Comparative evaluation of Eucalyptus globulus and E. nitens wood and fibre quality. IAWA J 38:105–116

Carrillo I, Mendonça RT, Ago M, Rojas OJ (2018a) Comparative study of cellulosic components isolated from different Eucalyptus species. Cellulose 25:1011–1029

Carrillo I, Vidal C, Elissetche JP, Mendonça RT (2018b) Wood anatomical and chemical properties related to the pulpability of Eucalyptus globulus: a review. South For 80:1–8

Carrillo-Varela I, Pereira M, Mendonça RT (2018) Determination of polymorphic changes in cellulose from Eucalyptus spp. fibres after alkalization. Cellulose 25:6831–6845

Chen C, Duan C, Li J, Liu Y, Ma X, Zheng L, Stavik J, Ni Y (2016) Cellulose (dissolving pulp) manufacturing processes and properties: a mini-review. BioResources 11:5553–5564

Christov LP, Akhtar M, Prior BA (1998) The potential of biosulfite pulping in dissolving pulp production. Enzyme Microb Technol 23:70–74

Dou X, Tang Y (2017) The influence of cold caustic extraction on the purity, accessibility and reactivity of dissolving-grade pulp. Chem Sel 2:11462–11468

Duan C, Jianguo L, Ma X, Chen C, Liu Y, Stavik J, Ni Y (2015a) Comparison of acid sulfite (AS)- and prehydrolysis kraft (PHK)-based dissolving pulps. Cellulose 22:4017–4026

Duan C, Long Y, Li J, Ma X, Ni Y (2015b) Changes of cellulose accessibility to cellulase due to fiber hornification and its impact on enzymatic viscosity control of dissolving pulp. Cellulose 22:2729–2736

Duan C, Verma SK, Li J, Ma X, Ni Y (2016a) Combination of mechanical, alkaline and enzymatic treatments to upgrade paper-grade pulp to dissolving pulp with high reactivity. Bioresour Technol 200:458–463

Duan C, Verma SK, Li J, Ma X, Ni Y (2016b) Viscosity control and reactivity improvements of cellulose fibers by cellulase treatment. Cellulose 23:269–276

Duchemin B, Thuault A, Vicente A, Rigaud B, Fernandez C, Eve S (2012) Ultrastructure of cellulose crystallites in flax textile fibres. Cellulose 19(6):1837–1854

Dutt D, Tyagi GH (2011) Comparison of various Eucalyptus species for their morphological, chemical: pulp and paper making characteristics. Indian J Chem Technol 18:145–151

Engstrom AC, Ek M, Henriksson G (2006) Improved accessibility and reactivity of dissolving pulp for the viscose process: pretreatment with monocomponent endoglucanase. Biomacromolecules 7:2027–2031

Fock W (1959) A modified method for determining the reactivity of viscose-grade dissolving pulps. Papier 13:92–95

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896

Gehmayr V, Sixta H (2012) Pulp properties and their influence on enzymatic degradability. Biomacromol 13:645–651

Gehmayr V, Schild G, Sixta H (2011) A precise study on the feasibility of enzyme treatments of a kraft pulp for viscose application. Cellulose 18(2):479–491

Gronqvist S, Hakala TK, Kamppuri T, Vehvilainen M, Hanninen T, Liitia T, Maloney T, Suurnakki A (2014) Fibre porosity development of dissolving pulp during mechanical and enzymatic processing. Cellulose 21:3667–3676

Hakansson H, Ahlgren P (2005) Acid hydrolysis of some industrial pulps: effect of hydrolysis conditions and raw material. Cellulose 12:177–183

Hakansson H, Germgard U, Sens D (2005) Influence of xylan on the degradability of laboratory kraft pulps from hardwood and reed canary grass in acid hydrolysis. Cellulose 12:621–628

Hubbe MA, Venditti RA, Rojas OJ (2007) What happens to cellulosic fibers during papermaking and recycling? A review. BioResources 2:739–788

Ibarra D, Kopcke V, Larsson PT, Jaeaeskelaeinen AS, Ek M (2010) Combination of alkaline and enzymatic treatments as a process for upgrading sisal paper-grade pulp to dissolving-grade pulp. Bioresour Technol 101:7416–7423

Isogai A, Atalla RH (1998) Dissolution of cellulose in aqueous NaOH solutions. Cellulose 5:309–319

Kohnke T, Lund K, Westman (2010) Kraft pulp hornification: a closer look at the preventive effect gained by glucuronoxylan adsorption. Carbohydr Polym 81:226–233

Kopcke V, Ibarra D, Ek M (2008) Increasing accessibility and reactivity of paper grade pulp by enzymatic treatment for use as dissolving pulp. Nord Pulp Pap Res J 23:363–368

Kopcke V, Ibarra D, Larsson PT, Ek M (2009) Optimization of treatments for the conversion of Eucalyptus kraft pulp to dissolving pulp. Polym Renew Resour 1:17–34

Kopcke V, Ibarra D, Larsson PT, Ek M (2010) Optimization of treatment sequences for the production of dissolving pulp from birch kraft pulp. Nord Pulp Pap Res J 25(1):31–38

Kumar H, Christopher LP (2017) Recent trends and developments in dissolving pulp production and application. Cellulose 24:2347–2365

Li J, Liu Y, Duan C, Zhang H, Ni Y (2015) Mechanical pretreatment improving hemicelluloses removal from cellulosic fibers during cold caustic extraction. Bioresour Technol 136:501–506

Li H, Legere S, He Z, Zhang H, Li J, Yang B, Zhang S, Zhang L, Zheng L, Ni Y (2018a) Methods to increase the reactivity of dissolving pulp in the viscose rayon production process: a review. Cellulose 25:3733–3753

Li J, Zhang S, Li H, Ouyang X, Huang L, Ni Y, Chen L (2018b) Cellulase pretreatment for enhancing cold caustic extraction-based separation of hemicelluloses and cellulose from cellulosic fibers. Bioresour Technol 251:1–6

Mendonça RT, Jara J, González V, Elissetche J, Freer J (2008) Evaluation of the white-rot fungi Ganoderma austral and Ceriposipsis subvermispora in biotechnological applications. J Ind Microbiol Biotechnol 35:1323–1330

Miao Q, Tian C, Chen L, Huang L, Zheng L, Ni Y (2015) Combined mechanical and enzymatic treatments for improving the Fock reactivity of hardwood kraft-based dissolving pulp. Cellulose 22:803–809

Nam S, French AD, Condon BD, Concha M (2016) Segal crystallinity index revisited by the simulation of X-ray diffraction patterns of cotton cellulose Ib and cellulose II. Carbohydr Polym 135:1–9

Newman RH (2004) Carbon-13 NMR evidence for cocrystal- lization of cellulose as a mechanism for hornification of bleached kraft pulp. Cellulose 11:45–52

Palme A, Theliander H, Brelid H (2016) Acid hydrolysis of cellulosic fibres: comparison of bleached kraft pulp, dissolving pulps and cotton textile cellulose. Carbohydr Polym 136:1281–1287

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulose performance. Biotechnol Biofuels 3:10

Popescu CM, Singurel G, Popescu MC, Vasile C, Argyropoulos DS, Willfor S (2009) Vibrational spectroscopy and X-ray diffraction methods to establish the differences between hardwood and softwood. Carbohydr Polym 77:851–857

Quintana E, Valls C, Vidal T, Roncero MB (2015) Comparative evaluation of the action of two different endoglucanases, part I: on a fully bleached, commercial acid sulfite dissolving pulp. Cellulose 22:2067–2079

Roselli A, Hummel M, Monshizadeh A, Maloney T, Sixta H (2014) Ionic liquid extraction method for upgrading Eucalyptus kraft pulp to high purity dissolving pulp. Cellulose 21:3655–3666

Scherrer P (1918) Bestimmung der Grösse und der inneren Struktur von Kolloidteilchen mittels Röntgenstrahlen. Nachrichten von der Gesellschaft der Wissenschaften, Göttingen

Schild G, Sixta H (2011) Sulfur-free dissolving pulps and their application for viscose and lyocell. Cellulose 18:1113–1128

Shi Z, Yang Q, Kuga S, Matsumoto Y (2015) Dissolution of wood pulp in aqueous NaOH/urea solution via dilute acid pretreatment. J Agric Food Chem 63:6113–6119

Sixta H (2006) Handbook of pulp. Weiley-Vch Verlag, Weinheim

Sixta H, Iakovlev M, Testova L, Roselli A, Hummel M, Borrega M, Heiningen A, Froschauer C, Schottenberger H (2013) Novel concepts of dissolving pulp production. Cellulose 20:1547–1561

Strunk P, Eliasson B, Hagglund C, Agnemo R (2011) The influence of properties in cellulose pulps on the reactivity in viscose manufacturing. Nord Pulp Pap Res J 26:81–89

Tian C, Zheng L, Miao Q, Nash C, Cao C, Ni Y (2013) Improvement in the Fock test for determining the reactivity of dissolving pulp. Tappi J 12:19–24

Tian C, Zheng L, Miao Q, Cao C, Ni Y (2014) Improving the reactivity of kraft-based dissolving pulp for viscose rayon production by mechanical treatments. Cellulose 21:3647–3654

Treiber E, Rehnstroem J, Ameen C, Kolos F (1962) Über die Laboratoriumsviskosekleinstanlage zur Testung von Chemiefaserzellstoffen—a small scale laboratory viscose plant for testing rayon grade pulps. Das Papier 16:85–94

Wada M, Okano T, Sugiyama J (1997) Synchrotron-radiated X-ray and neutron diffraction study of native cellulose. Cellulose 4:221–232

Wada M, Okano T, Sugiyama J (2001) Allomorphs of native crystalline cellulose I evaluated by two equatorial d-spacings. J Wood Sci 47:124–128

Wollboldt RP, Zuckerstaetter G, Weber HK, Larsson PT, Sixta H (2010) Accessibility, reactivity and supramolecular structure of E. globulus pulps with reduced xylan content. Wood Sci Technol 44:533–546

Yang S, Wen Y, Zhang H, Li J, Ni Y (2018) Enhancing the Fock reactivity of dissolving pulp by the combined prerefining and poly dimethyl diallyl ammonium chloride-assisted cellulase treatment. Bioresour Technol 260:135–140

Yu L, Lin J, Tian F, Li X, Bian F, Wang J (2014) Cellulose nanofibrils generated from jute fibers with tunable polymorphs and crystallinity. J Mater Chem A 2:6402–6411

Zhao L, Yuan Z, Kapu NS, Chang XF, Beatson R, Trajano HL, Martinez DM (2017) Increasing efficiency of enzymatic hemicellulose removal from bamboo for production of high-grade dissolving pulp. Bioresour Technol 223:40–46

Acknowledgments

The authors are grateful for the financial support from FONDECYT (Grant 1160306) and the provision of facilities and technical support by Instituto GEA-UdeC for XRD analysis. Isabel Carrillo-Varela thanks CONICYT-PFCHA/Doctorado Nacional/2018-21180299.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Carrillo-Varela, I., Retamal, R., Pereira, M. et al. Structure and reactivity of cellulose from bleached kraft pulps of different Eucalyptus species upgraded to dissolving pulp. Cellulose 26, 5731–5744 (2019). https://doi.org/10.1007/s10570-019-02491-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-019-02491-0