Abstract

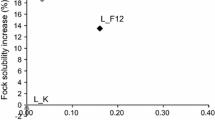

A fully bleached commercial acid dissolving pulp was treated with two endoglucanases, one obtained from Paenibacillus barcinonensis (B) and the other one produced from Cerrena unicolor (F) with the intention to improve cellulose reactivity and processability in the viscose process. B cellulase was tested under 120 U/g oven dry pulp (odp) and the F cellulase under two conditions, 12 and 60 U/g odp. In addition, a purification stage, consisting in a cold caustic extraction (CCE) of 9 % w/v NaOH, was applied before or after the enzymatic treatment in order to reduce the amount of hemicellulose and improve the action of enzymes. The treated pulps were evaluated in terms of brightness, viscosity, water retention value, fibre morphology, carbohydrate composition, Fock solubility and NMR. In general, results revealed that both endoglucanases improved cellulose reactivity, albeit in a different way; thus, B caused no scissions in the cellulose chain and no significant reduction in fibre length, whereas F strongly decreased viscosity, shortened fibre length and increased considerably the amount of fines. The result of applying two different doses of F cellulase was reflected on Fock solubility and fibre morphology. F60 treatment was found to give the highest value of Fock solubility and the biggest reduction of fibre length. The effect of both endoglucanases on Fock solubility was increased by introducing an earlier CCE stage. Finally, a CCE_B120 pulp with 3 % of hemicellulose and 69 % of Fock solubility was obtained.

Similar content being viewed by others

Abbreviations

- B120:

-

B endoglucanase at 120 U/g

- B120_CCE:

-

B endoglucanase at 120 U/g + cold caustic extraction

- CCE:

-

Cold caustic extraction

- CCE_B120:

-

Cold caustic extraction + B endoglucanase at 120 U/g

- CCE_F12:

-

Cold caustic extraction + F endoglucanase at 12 U/g

- CS:

-

Chain scission

- DP:

-

Degree of polymerization

- EG:

-

Endoglucanase

- F60:

-

F endoglucanase at 60 U/g

- F12:

-

F endoglucanase at 12 U/g

- K:

-

Control treatment

- K_CCE:

-

Control treatment + cold caustic extraction

- PO:

-

Hydrogen peroxide reinforced with pressurized oxygen

- TCF:

-

Totally chlorine free

- n.d.:

-

Not determined

- odp:

-

Oven dried pulp

- WRV:

-

Water retention value

- 13C-CP/MAS NMR:

-

Solid state cross polarization/magic angle spinning carbon 13 nucelar magnetic resonance

References

Arnoul-Jarriault B, Lachenal D, Chirat C, Heux L (2014) Upgrading softwood bleached kraft pulp to dissolving pulp by cold caustic treatment and acid-hot caustic treatment. Ind Crops Prod. doi:10.1016/j.indcrop.2014.09.051

Atalla RH (1979) Conformational effects of the hydrolysis of cellulose. Adv Chem Ser 181:55–69

Bouchard J, Morelli E, Berry RM (2000) Gas phase addition of solvent to ozone bleaching of kraft pulp. J Pulp Pap Sci 26:30–35

Cadena EM, Chriac AI, Javier Pastor FI et al (2010) Use of cellulases and recombinant cellulose binding domains for refining TCF kraft pulp. Biotechnol Prog 26:960–967. doi:10.1002/btpr.411

Chiriac AI, Cadena EM, Vidal T et al (2010) Engineering a family 9 processive endoglucanase from Paenibacillus barcinonensis displaying a novel architecture. Appl Microbiol Biotechnol 86:1125–1134. doi:10.1007/s00253-009-2350-8

Chiriac AI, Pastor FIJ, Popa VI et al (2013) Changes of supramolecular cellulose structure and accessibility induced by the processive endoglucanase Cel9B from Paenibacillus barcinonensis. Cellulose 21:203–219. doi:10.1007/s10570-013-0118-x

Ciolacu D, Pitol-Filho L, Ciolacu F (2011) Studies concerning the accessibility of different allomorphic forms of cellulose. Cellulose 19:55–68. doi:10.1007/s10570-011-9620-1

Engström A-C, Ek M, Henriksson G (2006) Improved accessibility and reactivity of dissolving pulp for the viscose process: pretreatment with monocomponent endoglucanase. Biomacromolecules 7:2027–2031

Evans R, Wallis AFA (1987) Comparison of cellulose molecular weights determined by high performance size exclusion chromatography and viscometry. In: 4th International symposium wood pulping chemistry, pp 201–205

Fock W (1959) A modified method for determining the reactivity of viscose-grade dissolving pulps. Papier 13:92–95

Garcia-Ubasart J, Torres AL, Vila C et al (2013) Biomodification of cellulose flax fibers by a new cellulase. Ind Crops Prod 44:71–76. doi:10.1016/j.indcrop.2012.10.019

Gehmayr V, Sixta H (2012) Pulp properties and their influence on enzymatic degradability. Biomacromolecules 13:645–651

Gehmayr V, Schild G, Sixta H (2011) A precise study on the feasibility of enzyme treatments of a kraft pulp for viscose application. Cellulose 18:479–491. doi:10.1007/s10570-010-9483-x

Gurnagul N, Page D, Paice M (1992) The effect of cellulose degradation on the strength of wood pulp fibres. Nord Pulp Pap Res J 7:152–154

Henriksson G, Christiernin M, Agnemo R (2005) Monocomponent endoglucanase treatment increases the reactivity of softwood sulphite dissolving pulp. J Ind Microbiol Biotechnol 32:211–214. doi:10.1007/s10295-005-0220-7

Ibarra D, Köpcke V, Ek M (2010a) Behavior of different monocomponent endoglucanases on the accessibility and reactivity of dissolving-grade pulps for viscose process. Enzyme Microb Technol 47:355–362. doi:10.1016/j.enzmictec.2010.07.016

Ibarra D, Köpcke V, Larsson PT et al (2010b) Combination of alkaline and enzymatic treatments as a process for upgrading sisal paper-grade pulp to dissolving-grade pulp. Bioresour Technol 101:7416–7423. doi:10.1016/j.biortech.2010.04.050

Janzon R, Puls J, Bohn A et al (2008a) Upgrading of paper grade pulps to dissolving pulps by nitren extraction: yields, molecular and supramolecular structures of nitren extracted pulps. Cellulose 15:739–750. doi:10.1007/s10570-008-9224-6

Janzon R, Saake B, Puls J (2008b) Upgrading of paper-grade pulps to dissolving pulps by nitren extraction: properties of nitren extracted xylans in comparison to NaOH and KOH extracted xylans. Cellulose 15:161–175. doi:10.1007/s10570-007-9154-8

Klemm D, Philipp B, Heinze T et al (1998) General considerations on structure and reactivity of cellulose. Compr Cellul Chem 1:9–29

Köpcke V (2010) Conversion of wood and non-wood paper-grade pulps to dissolving-grade pulps. Doctoral Thesis, KTH Chemical Science and Engineering

Köpcke V, Ibarra D, Ek M (2008) Increasing accessibility and reactivity of paper grade pulp by enzymatic treatment for use as dissolving pulp. Nord Pulp Pap Res J 23:363–368

Krässig HA (1993) Cellulose-structure, accessibility and reactivity, vol 11. Gordon and Breach Science, New York

Kvarnlöf N, Germgård U, Jönsson LJ, Söderlund C-A (2006) Enzymatic treatment to increase the reactivity of a dissolving pulp for viscose preparation. Appita J 59:242–246

Langan P, Nishiyama Y, Chanzy H (2001) X-ray structure of mercerized cellulose II at 1 Å resolution. Biomacromolecules 2:410–416. doi:10.1021/bm005612q

Langan P, Sukumar N, Nishiyama Y, Chanzy H (2005) Synchrotron X-ray structures of cellulose Iβ and regenerated cellulose II at ambient temperature and 100 K. Cellulose 12:551–562. doi:10.1007/s10570-005-9006-3

Mozdyniewicz DJ, Nieminen K, Sixta H (2013) Alkaline steeping of dissolving pulp. Part I: cellulose degradation kinetics. Cellulose 20:1437–1451. doi:10.1007/s10570-013-9926-2

Nishiyama Y, Langan P, Chanzy H (2002) Crystal structure and hydrogen-bonding system in cellulose Iβ from synchrotron X-ray and neutron fiber diffraction. J Am Chem Soc 124:9074–9082. doi:10.1021/ja0257319

Nishiyama Y, Kim U-J, Kim D-Y et al (2003) Periodic disorder along ramie cellulose microfibrils. Biomacromolecules 4:1013–1017. doi:10.1021/bm025772x

Patrick K (2011) Dissolving pulp gold rush in high gear. Paper360 8–12. http://www.tappi.org/Hide/The-Dissolving-Pulp-Gold-Rush.aspx

Pönni R, Pääkkönen T, Nuopponen M et al (2014) Alkali treatment of birch kraft pulp to enhance its TEMPO catalyzed oxidation with hypochlorite. Cellulose 21:2859–2869. doi:10.1007/s10570-014-0278-3

Rahkamo L, Viikari L, Buchert J et al (1998) Enzymatic and alkaline treatments of hardwood dissolving pulp. Cellulose 5:79–88. doi:10.1023/A:1009268713757

Sixta H (2006) Handbook of pulp. Wiley-VCH Verlag GmbH & Co, KGaA, Weinheim

Spiro R (1966) Analysis of sugars found in glycoproteins. Methods Enzymol 566:7–9

Teleman LPT (2001) On the accessibility and structure of xylan in birch kraft pulp. Cellulose 8:209–215. doi:10.1023/A:1013195030404

Testova L, Borrega M, Tolonen LK et al (2014) Dissolving-grade birch pulps produced under various prehydrolysis intensities: quality, structure and applications. Cellulose 21:2007–2021. doi:10.1007/s10570-014-0182-x

Van de Weyenberg I, Chi Truong T, Vangrimde B, Verpoest I (2006) Improving the properties of UD flax fibre reinforced composites by applying an alkaline fibre treatment. Compos Part A Appl Sci Manuf 37:1368–1376. doi:10.1016/j.compositesa.2005.08.016

Wada M, Chanzy H, Nishiyama Y, Langan P (2004) Cellulose III I crystal structure and hydrogen bonding by synchrotron X-ray and neutron fiber diffraction. Macromolecules 37:8548–8555. doi:10.1021/ma0485585

Acknowledgments

The authors thank the "Ministerio de Economía y Competitividad" of Spain for their support in this work under the projects BIOSURFACEL CTQ2012-34109 (funding also from the "Fondo Europeo de Desarrollo Regional FEDER”) and BIOPAPμFLUID CTQ2013-48995-C2-1-R. The authors are grateful to the consolidated group with the Universitat de Barcelona (UB) AGAUR 2014 SGR 534. The authors would like to thank DÖMSJO (Sweden) for providing the starting pulp, Fungal Bioproducts (Spain) for kindly supplying the F cellulase and the Department of Microbiology (University of Barcelona, Spain) for warmly providing the B cellulase.

Conflict of interest

The authors declare no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Quintana, E., Valls, C., Vidal, T. et al. Comparative evaluation of the action of two different endoglucanases. Part I: On a fully bleached, commercial acid sulfite dissolving pulp. Cellulose 22, 2067–2079 (2015). https://doi.org/10.1007/s10570-015-0623-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0623-1