Abstract

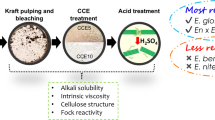

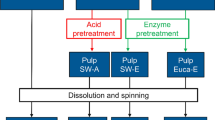

High purity cellulose from wood is an important raw material for many applications such as cellulosic fibers, films or the manufacture of various cellulose acetate products. Hitherto, multi-step refining processes are needed for an efficient hemicellulose removal, most of them suffering from severe cellulose losses. Recently, a novel method for producing high purity cellulose from bleached paper grade birch kraft pulp was presented. In this so called IONCELL process, hemicelluloses are extracted by an ionic liquid–water mixture and both fractions can be recovered without yield losses or polymer degradation. Herein, it is demonstrated that bleached Eucalyptus urograndis kraft pulp can be refined to high purity acetate grade pulp via the IONCELL process. The hemicellulose content could be reduced from initial 16.6 to 2.4 wt% while persevering the cellulose I crystal form by using an optimized 1-ethyl-3-methylimidazolium dimethylphosphate-water mixture as the extraction medium. The degree of polymerization was then reduced by a sulfuric acid treatment for subsequent acetylation of the pulp, resulting in a final hemicellulose content of 2.2 wt%. When pre-treating the pulp enzymatically with endoxylanase, the final hemicellulose content could be reduced even to 1.7 wt%. For comparison, the eucalyptus kraft pulp was also subjected to cold caustic extraction and the same subsequent acid treatment which led to 3.9 wt% of residual hemicelluloses. The performance in acetylation of all produced pulps was tested and compared to commercial acetate grade pulp. The endoxylanase-IONCELL-treated pulp showed superior properties. Thus, an ecologically and economically efficient alternative for the production of highest value cellulose pulp is presented.

Similar content being viewed by others

References

Berggren R, Berthold F, Sjöholm E, Lindström M (2003) Improved methods for evaluating the molar mass distributions of cellulose in kraft pulp. J Appl Polym Sci 88:1170–1179

Borrega M, Tolonen LK, Bardot F, Testova L, Sixta H (2013) Potential of hot water extraction of birch wood to produce high-purity dissolving pulp after alkaline pulping. Bioresour Technol 135:665–671

Brandt A, Gräsvik J, Hallett JP, Welton T (2013) Deconstruction of lignocellulosic biomass with ionic liquids. Green Chem 15:550–583

Christov L, Prior B (1993) Xylan removal from dissolving pulp using enzymes of Aureobasidium pullulans. Biotechnol Lett 15:1269–1274

Dinand E, Vignon M, Chanzy H, Heux L (2002) Mercerization of primary wall cellulose and its implication for the conversion of cellulose I to cellulose II. Cellulose 9:7–18

Froschauer C, Hummel M, Iakovlev M, Roselli A, Schottenberger H, Sixta H (2013) Separation of hemicellulose and cellulose from wood pulp by means of ionic liquid/cosolvent systems. Biomacromolecules 14:1741–1750

Gardner PE, Chang MY (1974) The acetylation of native and modified hemicelluloses. Tappi 57:71–75

Gehmayr V, Schild G, Sixta H (2011) A precise study on the feasibility of enzyme treatments of a kraft pulp for viscose application. Cellulose 18:479–491

Glegg RE, Ingerick D, Parmerter RR, Salzer JST (1968) Acetylation of cellulose I and II studied by limiting viscosity and X-ray diffraction. J Polym Sci Polym Phys Ed 6:745–773

Haemmerle F (2011) The cellulose gap. Lenzinger Ber 89:12–21

Hauru LK, Hummel M, King AW, Kilpeläinen I, Sixta H (2012) Role of solvent parameters in the regeneration of cellulose from ionic liquid solutions. Biomacromolecules 13:2896–2905

Hauru LK, Ma Y, Hummel M, Alekhina M, King AW, Kilpeläinen I, Penttilä PA, Serimaa R, Sixta H (2013) Enhancement of ionic liquid-aided fractionation of birchwood. Part 1: autohydrolysis pretreatment. RSC Adv 3:16365–16373

Hummel M, Laus G, Schwärzler A, Bentivoglio G, Rubatscher E, Kopacka H, Wurst K, Kahlenberg V, Gelbrich T, Griesser U (2010) Non-halide ionic liquids for solvation, extraction, and processing of cellulosic materials. In: Liebert TF, Heinze TJ, Edgar KJ (eds) Cellulose solvents: For analysis, shaping and chemical modification ACS symposium series, 1033:229–259

Ibarra D, Köpcke V, Larsson PT, Jääskeläinen A, Ek M (2010) Combination of alkaline and enzymatic treatments as a process for upgrading sisal paper-grade pulp to dissolving-grade pulp. Bioresour Technol 101:7416–7423

Janson J (1970) Calculation of the polysaccharide composition of wood and pulp. Pap Puu 52:323–329

Janzon R, Puls J, Saake B (2006) Upgrading of paper-grade pulps to dissolving pulps by nitren extraction: optimization of extraction parameters and application to different pulps. Holzforschung 60:347–354

Janzon R, Saake B, Puls J (2008) Upgrading of paper-grade pulps to dissolving pulps by nitren extraction: properties of nitren extracted xylans in comparison to NaOH and KOH extracted xylans. Cellulose 15:161–175

King AW, Zoia L, Filpponen I, Olszewska A, Xie H, Kilpeläinen I, Argyropoulos DS (2009) In situ determination of lignin phenolics and wood solubility in imidazolium chlorides using 31P NMR. J Agric Food Chem 57:8236–8243

Klemm D, Philipp B, Heinze T, Heinze U, Wagenknecht W (1998) Comprehensive cellulose chemistry: fundamentals and analytical methods, vol 1. Wiley-VCH, Weinheim

Kolpak FJ, Blackwell J (1967) Determination of the structure of Cellulose II. Macromolecules 9:273–278

Köpcke V, Ibarra D, Ek M (2008) Increasing accessibility and reactivity of paper grade pulp by enzymatic treatment for use as dissolving pulp. Nord Pulp Pap Res J 23:363–368

Lund K, Sjöström K, Brelid H (2012) Alkali extraction of kraft pulp fibres: influence on fibre and fluff pulp properties. J Eng Fiber Fabr 7:30–39

Mäki-Arvela P, Anugwom I, Virtanen P, Sjöholm R, Mikkola JP (2010) Dissolution of lignocellulosic materials and its constituents using ionic liquids—a review. Ind Crops Prod 32:175–201

Maloney T, Paulapuro H (1999) The formation of pores in the cell wall. J Pulp Paper Sci 25:430–436

Manninen M, Nieminen K, Maloney T (2013) Transactions of the 15th fundamental pulp and paper research symposium, Cambridge, UK, 2:765–785

Mazza M, Catana D, Vaca-Garcia C, Cecutti C (2009) Influence of water on the dissolution of cellulose in selected ionic liquids. Cellulose 16:207–215

Newman R, Hemmingson J (1997) Cellulose cocrystallization in hornification of kraft pulp. Presented at the 9th international symposium of wood and pulp chemistry, Montréal, Canada, June 9–12

Okano T, Sarko A (1985) Mercerization of cellulose. II. Alkali–cellulose intermediates and a possible mercerization mechanism. J Appl Polym Sci 30:325–332

Paice M, Jurasek L (1984) Removing hemicellulose from pulps by specific enzymic hydrolysis. J Wood Chem Technol 4:187–198

Penttilä PA, Kilpeläinen P, Tolonen L, Suuronen J, Sixta H, Willför S, Serimaa R (2013) Effects of pressurized hot water extraction on the nanoscale structure of birch sawdust. Cellulose 20:2335–2347

Pinkert A, Marsh KN, Pang S, Staiger MP (2009) Ionic liquids and their interaction with cellulose. Chem Rev 109:6712–6728

Puls J, Schöder N, Stein A, Janzon R, Saake B (2006a) Xylans from oat spelts and birch kraft pulp. Macromol Symp 232:85–92

Puls J, Janzon R, Saake B (2006b) Comparative removal of hemicelluloses from paper pulps using nitren, cuen, NaOH, and KOH. Lenzinger Ber 86:63–70

Röder T, Sixta H (2004) Thermal treatment of cellulose pulps and its influence to cellulose reactivity. Lenzinger Ber 83:79–83

Roselli A, Froschauer C, Hummel M, Sixta H (2013) IONCELL: Selective xylan extraction with ionic liquids. Proceedings of the 17th International Symposium of Wood, Fibre and Pulping Chemistry, Vancouver, Canada, June 12–14

Rydholm SA (1965a) Pulp properties and uses. Pulping processes. Wiley, New York, pp 1133–1185

Rydholm SA (1965b) Carbohydrate-removing methods. Pulping processes. Wiley, New York, pp 992–1023

Saka S, Matsumura H (2004) Wood pulp manufacturing and quality characteristics. In: Rustemeyer P (ed) Cellulose acetates: properties and applications. Macromolecular symposia. WILEY-VCH, Weinheim, pp 37–48

Shen L, Haufe J, Patel MK (2009) Product overview and market projection of emerging bio-based plastics; PRO-BIP 2009 Final report; Utrecht University

Sixta H (2006a) Pulp Properties and Applications. In: Sixta H (ed) Handbook of pulp, vol 2. WILEY-VCH, Weinheim, pp 1009–1067

Sixta H (2006b) Pulp purification. In: Sixta H (ed) Handbook of pulp, vol 2. WILEY-VCH, Weinheim, pp 933–966

Sixta H (2006c) Pulp properties and applications. In: Sixta H (ed) Handbook of pulp, vol 2. WILEY-VCH, Weinheim, pp 1009–1067

Sixta H, Schild G (2009) A new generation kraft process. Lenzinger Ber 87:26–37

Sixta H, Iakovlev M, Testova L, Roselli A, Hummel M, Borrega M, van Heiningen A, Froschauer C, Schottenberger H (2013) Novel concepts of dissolving pulp production. Cellulose 20:1547–1561

Sjöström E (1981) Cellulose derivatives. In: Wood chemistry, fundamentals and applications. Academic Press, pp 169–189

Steinmeier H (2004) Acetate manufacturing, process and technology. Macromol Symp 208:49–60

Sun N, Rahman M, Qin Y, Maxim ML, Rodríguez H, Rogers RD (2009) Complete dissolution and partial delignification of wood in the ionic liquid 1-ethyl-3-methylimidazolium acetate. Green Chem 11:646–655

Swatloski RP, Spear SK, Holbrey JD, Rogers RD (2002) Dissolution of cellose (sic) with ionic liquids. J Am Chem Soc 124:4974–4975

Testova L, Borrega M, Tolonen L, Penttilä PA, Serimaa R, Larsson P, Sixta H (2014) Dissolving-grade birch pulps produced under various prehydrolysis intensities: quality, structure and applications. Cellulose 21:2007–2021

The Fiber Year 2013—World Survey on Textiles & Nonwovens (2013) http://www.thefiberyear.com/. Accessed 20 December 2013

Welton T (1999) Room-temperature ionic liquids. Solvents for synthesis and catalysis. Chem Rev 99:2071–2084

Wilson JD, Tabke RS (1974) Influences of hemicelluloses on acetate processing in high catalyst systems. Tappi 57:77–80

Wollboldt RP, Zuckerstätter G, Weber HK, Larsson PT, Herbert S (2010) Accessibility, reactivity and supramolecular structure of E. globulus pulps with reduced xylan content. Wood Sci Technol 44:533–546

Zakrzewska ME, Bogel-Łukasik E, Bogel-Łukasik R (2010) Solubility of carbohydrates in ionic liquids. Energy Fuels 24:737–745

Acknowledgments

This research is part of the Future Biorefinery program financed by Finnish Bioeconomy Cluster (FIBIC) and Finnish Funding Agency for Technology and Innovation (TEKES). The authors thank Paavo A. Penttilä (Helsinki University) for WAXS analysis and Alistair King and Arno Parviainen (Helsinki University) for synthetizing [emim][DMP]. Armin Stein from Solvay-Rhodia is gratefully acknowledged for his help in the set-up of the acetylation system.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Roselli, A., Hummel, M., Monshizadeh, A. et al. Ionic liquid extraction method for upgrading eucalyptus kraft pulp to high purity dissolving pulp. Cellulose 21, 3655–3666 (2014). https://doi.org/10.1007/s10570-014-0344-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0344-x