Abstract

Foam formation is a massive challenge in submerged aerated bioprocesses, e.g., in beer fermentation. While the use of antifoam may easily overcome foaming at laboratory scale, it is often an unattractive solution since the challenge remains in future upscaling, as reduced mass transfer and extra steps in product purification and analytics result in increased costs. Interestingly, the number of studies tackling this challenge is relatively low, although literature suggests a range of alternatives, from avoiding foaming to means of controlling or even using foaming as an in situ product removal. Here we give an overview of the topic in five subsections. (1) We argue that a sound understanding of the molecular origin of foaming can facilitate solutions for overcoming the challenge while introducing some long-known challenges (i.e., in beer fermentation). We then review in (2) the apparent avoidance of foam formation before we in (3) summarize possibilities to reduce and control foam after its formation. Subsequently, in (4), we discuss possible solutions that take advantage of foam formation, for example, via foam fractionation for in situ product removal. Finally, in (5), we provide an overview of microbial strain engineering approaches to cope with some aspects of foaming in fermentations. With this review, we would like to sensitize and inform the interested reader while offering an overview of the current literature for the expert, particularly with regard to the foam special issue in Discover Chemical Engineering.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Foams are a type of dispersion (Table 1) in which the dispersed phase is a gas in a liquid continuous phase. Foam in microbiology and biotechnology is hence common, where gas is present in water, with the prominent example of aerated fermentations. The stabilization of the foam by surface-active agents (surfactants)—molecules that are amphiphilic and thus decrease surface tension—makes foaming an important topic in biotechnology. Such different molecules as lipids, proteins, or natural products (e.g., saponins, glycolipids) with surface-active properties are produced on purpose or are side products of the fermentation.

This review builds on previous reviews (e.g., [1]) and provides a comprehensive overview of the strategies employed to tackle foam-related issues in biotechnology, including using antifoam agents, bubble-free fermentation techniques, and biofilm formation. Furthermore, we explore the potential of engineering microbial strains to harness foam utilization and enhance foam control. In the introduction, we briefly cover some physical basics, showcase an example in biotechnology (i.e., beer brewing), and finally, motivate why we think foam formation requires more investigation and will receive more attention in the near future.

By consolidating recent advancements in foam management and highlighting the potential future research directions, this review aims to contribute to developing innovative and sustainable solutions for optimizing biotechnological processes. Through a deeper understanding of foam behavior and effective foam control strategies, biotechnologists can improve process efficiency, productivity, and product quality while minimizing energy consumption and operational challenges.

Considering the multifaceted nature of foam formation and its consequences, it is essential to delve deeper into understanding the physical properties of liquid foam and the mechanisms governing its behavior.

1.1 Physical properties of foam

Liquid foam is a complex gas structure surrounded by a liquid film, with a gas holdup Φ varying between 0.52 and 0.97 [2]. Depending on the shape and distribution of the foam bubbles monodisperse and ordered foam, a differentiation is made between the spherical bubble foam or so-called “Kugelschaum” with 0.52 ≤ Φ ≤ 0.74 and the polyhedral foam with Φ ≥ 0.74 [3, 4]. In polydisperse foam, even higher gas holdup can be achieved for both foam structures. The changes occurring within the foam structure and its stability are driven by different simultaneous stabilizing and destabilizing effects.

However, a prerequisite for foam to occur in the first place is the presence of surface-active molecules with amphiphilic character in the liquid phase. Also, increased viscosity can help stabilize the foam. When gas bubbles enter the liquid via aeration or gas bubbles build up via chemical reactions and/or pressure release, the surface-active molecules adsorb at the gas–liquid interfaces surrounding the gas bubbles, forming an amphiphile-enriched layer that stabilizes the foam [2, 5]. The stabilized foam bubbles ascend to the liquid’s surface due to density gradients. At the same time, liquid drainage from the foam phase to the bulk liquid due to gravity and capillary forces leads to an increased gas holdup. As a result, polyhedral foam is formed, in which the liquid lamellae intersect at angles of 120° to fill up the void space caused by liquid drainage, forming the so-called Plateau borders (Fig. 1). Four edges of these foam bubbles intersect at 109°, forming Plateau border channels [6].

The pressure difference between the gas bubbles and the Plateau channels is the driving force for drainage. The drainage velocity is a function of the physical properties of the liquid (density, viscosity), the geometry and size of the gas bubbles and the Plateau channels, the existing interfacial tension, the foam height, as well as the gravity field [3]. With drainage, the lamellae become thinner; thus, the distance between two adjacent bubbles and their amphiphile-enriched layers decreases. Interactive effects between the adsorption layers occur. Depending on the dominating effects, the foam lamellae remain stable or rupture due to thinning, thus destabilizing the foam. In addition to drainage, evaporation of the liquid may occur at the top of the foam, thus leading to further film thinning and, eventually, foam rupture.

In these thin films, attractive and repulsive forces occur due to the decreased distance between the amphiphile-enriched layers, as described by the DLVO theory (named after Boris Derjaguin, Lev Landau, Evert Verwey, and Theodoor Overbeek) [7]. Attractive van der Waals forces between adjacent amphiphilic layers lead to the compression of the lamellae and, thus, further drainage and film thinning [8]. Repulsive electrostatic forces, on the other hand, and short-range steric repulsion of the adsorbed amphiphiles counteract film thinning and lead to film stabilization [2].

Film thinning caused by drainage additionally leads to locally enlarged surfaces, which in turn leads to an increased gradient in amphiphile concentrations compared to the bulk liquid and higher surface tension. The amphiphiles diffuse to the thin spot, dragging liquid along and thus balancing the thinned area. This phenomenon is called film “healing” and is described as the Gibbs-Marangoni effect [2]. Similar effects can further occur due to evaporation to the gas phase, caused by temperature and humidity gradients [9].

On the other hand, when the lamella between two adjacent bubbles ruptures, the bubbles coalesce and form bigger ones. These bigger bubbles result in a decrease in the number of bubbles and an increase in the mean bubble volume [8]. In polydisperse foams, the so-called disproportionation, or Ostwald ripening, occurs. Due to higher gas pressure, according to Young–Laplace, gas diffuses from smaller bubbles through the bulk liquid to larger bubbles. As a result, small bubbles shrink while bigger bubbles grow in size [2]. A detailed overview of theoretical considerations of the occurring foam decay and generation mechanisms is given in [8].

In addition to the aforementioned effects, particles in the culture broth, such as biomass agglomerates, may also affect foam stability. Depending on their size, they may rupture foam lamellae and thus destabilize the foam, or act as dams in the plateau borders, thus slowing liquid drainage and foam coalescence [10]. Furthermore, temperature gradients and mechanical forces that may occur within the reactors can also affect the foam rupture [8].

In general, the different foam stabilizing and destabilizing effects are dynamic and specific to each liquid system and the surrounding conditions in the reactor. Therefore, each biotechnological process in which foaming occurs shows different foaming behavior and bears challenges for the process.

1.2 Foam challenges in biotechnology

Foaming in fermentations has been a serious operational issue for at least the last seventy years, as stated multiple times [11]. Nevertheless, as has been declared already over a decade ago, foaming in bioprocesses has received little attention [12], and foam control is not firmly founded on scientific insights [5]. Foaming in aerated fermentations is caused by surface-active molecules, which adhere to and stabilize air bubbles. The nature of the responsible compounds has been summarized before [12].

Foaming in fermentations causes various problems, as reviewed before [13]. The main problem is an uncontrolled and spontaneous crossing of the sterile barrier of a reactor system. Moreover, another big challenge is reactor design since traditional bioreactors are typically designed to handle liquids and not foams. Since foams behave differently, the reactor design might not be suited to sustain fermentation during heavy foaming (caused by, e.g., insufficient mixing or clogging), leading to a reduction in product and biomass concentrations, productivity, and product purity. Inhibiting the proper functioning of probes and gas supply and removal can be additional challenges. Furthermore, foaming can change the medium composition by discharging components that adsorb to the foam. In addition, the rising foam can block sterile filters, which endangers sterility and can lead to overpressure in the reactor [12, 14, 15]. Finally, foaming can also directly affect the microorganisms. In contrast to mammalian cells, microorganisms are not mechanically challenged by bursting bubbles. They can be entrained in the foam and thus leave the fermenter with the discharged foam. Minimizing this effect is discussed at the end of this review.

Although foam mitigation is a critical aspect of biotechnological processes, processes in which foaming is desired are also known, e.g., in the food industry [16]. One example in which proteins lead to excessive foaming is beer brewing.

1.3 Foaming during beer production

All beers have four ingredients as their basis: cereals, yeast, hops, and water. This is even a written rule in Germany: the Reinheitsgebot from 1516, according to which only barley is an accepted grain [17]. For many countries and master brewers, this is still the only starting point for brewing a beer. A master brewer’s definition of a beer could be formulated as follows: “A beer is normally an alcoholic, hop-containing beverage produced via an enzymatic conversation of starch into fermentable sugars, where the sugars are converted to alcohol via a fermentation”. The starch source depends on local conditions but is primarily based on starchy cereals, usually with a high proportion of malted barley dependent on the beer type to be produced. The cereals used can be kilned in many ways, resulting in a non-enzymatic browning mechanism (Maillard reactions), creating darker cereals giving more color and flavors to the beer.

The first part of brewing happens in the brewhouse, where the starch-containing raw materials are converted into a liquid called sweet wort. Next, the wort is boiled with hops resulting in a bitter-tasting wort, which is fermented with a specific yeast strain, matured, later stabilized (colloidally stable), and optionally filtered to produce a clear beer.

Beer fermentation is a biochemical process in which yeast, usually a Saccharomyces yeast, degrades sugar under anaerobic conditions. The higher the fermentation temperature, the faster the process and rate of fermentation. During fermentation, the yeast converts the fermentable sugars into alcohol, flavor compounds, and carbon dioxide, not to mention the extra biomass and heat also being produced. A bottom-fermenting yeast (e.g., Saccharomyces pastorianus) usually ferments at colder temperatures (typically 6–18 °C) than a top-fermenting yeast (e.g., Saccharomyces cerevisiae, generally above 20 °C).

The carbon dioxide produced will cause excessive foaming in the fermenter, especially during the filling and primary fermentation stage (krausen and high krausen), where the rate of carbon dioxide production is highest. The amount of foam produced depends on the process and if, e.g., top pressure or circulation/stirring is applied.

Excessive foaming in a fermenter typically requires enough headspace in the vessel (normal fill levels of approximately 80%) to ensure that the developed foam (and hop components) is not ending up in the pipework or carbon dioxide recovery systems and is not expelling yeast and beer to the drain causing loss and potential microbiological challenges.

As fermenter capacity (steel and equipment) is expensive, it might sometimes be favorable to fill fermenters to a higher level and add antifoam agents to the beer wort to avoid spillage and reduce foaming. In addition, yeast also adsorbs much bitterness from the hops, and as the yeast heads rise (foaming), bitterness can be lost through foam residues clinging onto the fermenter walls.

A surface-active foaming agent is crucial for foam to form—in beer, this is protein. Bubble formation begins when the carbon dioxide in beer reaches and exceeds the solubility limit under the given conditions. It is known that yeast secretes carbon dioxide as nano bubbles—tiny invisible carbon dioxide bubbles. The bubbles grow while ascending to the surface, primarily due to the diffusion of more carbon dioxide into the bubble. The surface tension in the beer film around the carbon dioxide bubble tends to keep the bubble as spherical as possible to occupy as little space as possible.

Excessive foaming in a fermenter can potentially lead to product loss. Loss of wort/beer can be avoided by controlling, e.g., the fill level of the fermenter, the initial fermentation temperature, the yeast strain, the yeast pitching level, the applied head-space pressure, the installed fermenter cooling system, and the wort composition (the level of glucose compared to maltose and maltotriose). If the start of the fermentation is “explosive”, the level of foaming can be excessive, and wort can be expelled through the pipework/safety valves, meaning product loss.

When wort/beer is expelled, this can also lead to microbiological challenges like the growth of bacteria in the pipework, which is detrimental to product quality. Bacteria in the pipework, e.g., Lactobacillus or Pediococcus, can be re-introduced due to, e.g., pressure fluctuations leading to contamination of the fermenter, which can cause off-flavors in the beer. In larger breweries, with or without carbon dioxide recovery, product loss and over-foaming are not necessarily noticed before inspection of the fermenter top and safety valves unless carefully monitoring the process.

1.4 Biosurfactants

Surfactants play an important role in foam formation in biotechnology, as they actively modulate the surface tension and interfacial properties and thus influence the stability and properties of the foam. Biosurfactants are surface-active compounds produced by microorganisms. With commercially relevant applications in the fields of detergents, cosmetics, pharmaceuticals, lubricants, etc., they have a high value in our daily life. Different biosurfactants have been reported to have foaming properties, including rhamnolipids, sophorolipids, mannosylerythritol lipids, cellobiose lipids, and surfactin.

Rhamnolipids, produced by Pseudomonas spp., are known to be potent foaming agents [18, 19]. They were first isolated and characterized in the 1940s [20], and research on their production, purification, and application has been ongoing since [21, 22]. Small-scale production for research and development purposes has also been performed for several decades [23]. However, the commercial production of rhamnolipids on a larger scale is a more recent development. The German company Evonik began commercial production of rhamnolipids in 2019.Footnote 1

Sophorolipids, produced by Starmerella bombicola and other yeasts, have good foaming properties but not as pronounced as rhamnolipids [24]. They have been commercially produced for at least a decade [25]. Mannosylerythritol lipids (MELs) have also been reported to have foaming properties [26], but they are less well-studied compared to rhamnolipids and sophorolipids. In Japan, the application of MELs in cosmetics is reported [27]. Cellobiose lipids produced by various Ustilaginaceae species are another kind of glycolipids also characterized as excessively foaming during their production in fermentations [28]. Finally, surfactin is a cyclic lipopeptide produced by different Bacillus species that has been extensively studied for its surface-active and antimicrobial properties [29]. However, both cellobiose lipids and surfactin are not produced on an industrial scale.

It is worth noting that the foaming capability of biosurfactants depends on various factors, such as the molecular structure and concentration of the biosurfactant, the pH and temperature of the fermentation broth, and the presence of other compounds that can affect foam stability. Depending on the production details, their foaming capabilities can be seen as a challenge but also as a feature for the process development.

1.5 Countermeasures against foam in fermentations

Various foam mitigation strategies have been developed and applied in research and industry to address this issue. In this study, we review the different foam mitigation strategies for reducing the adverse effects of foaming.

In the late 1950s, researchers first began studying the mechanisms behind foaming and how it impacts various biotechnological processes [30, 31]. In the following decades, several foam control strategies were developed and applied in various industries, including the chemical, pharmaceutical, and brewing industries. These strategies range from physical methods, such as mechanical defoaming, to chemical methods, such as the use of antifoam agents [32, 33]. Today, foam control remains an important area of research and development in biotechnology.

Two fundamentally different strategies exist to cope with foaming in fermentations. (1) Measures can be taken to avoid foam formation in the first place, and (2) foam whose formation could not be avoided can be disrupted. Examples of chemical foam mitigation strategies are antifoam agents and defoaming agents or defoamers. Both are used against foaming in industrial processes. However, their mode of action differs, and so do their applications. Antifoam agents are additives that are used to prevent the formation of foam. They work by reducing the surface tension of the liquid, which prevents the formation of the thin films of liquid that are necessary for the foam to form. Antifoam agents are typically used when foaming is a potential problem, such as in the early stages of fermentation. Defoamers, on the other hand, are used to eliminate existing foam. They also reduce the foam’s surface tension, causing the bubbles to collapse. Therefore, defoamers are typically used when foaming has already occurred and needs to be eliminated. However, it is worth noting that some defoamers can also act as antifoams, collapsing the existing foam while simultaneously preventing its reformation.

2 Avoiding foam formation

Avoiding the formation of foam in fermentations is an effective measure against the negative impacts of foam. In this section, the various approaches to preventing foam formation in biotechnological fermentations are described.

2.1 Antifoam agents

Usually, antifoam agents are applied to the aqueous phase before foam formation to prevent foam formation from within the aqueous medium. Examples show that antifoam agents have been successfully applied in the production of rhamnolipids [34] and biohydrogen [35] and in various fermentation processes [36], demonstrating their potential as beneficial for fermentations with excessive foaming. Sometimes, they are also named foam inhibitors [37]. In some cases, they are surface-active substances that lower the liquids’ surface tension and counteract foam-forming components [38, 39]. By stirring, the antifoam agents are dispersed and destroy the foam via bubble coalescence, which reduces the availability of surface area for gas–liquid mass transfer [5]. Antifoam droplets work via four steps: (i) entering the liquid film around the foam bubble, (ii) bridging the width of the liquid film, (iii) draining by causing the liquid film to thin where the antifoam is present, and (iv) rupture of the liquid film [40,41,42]. In addition, some antifoams contain insoluble substances that reduce the foam lamellae viscosity. As a result, the lamellae thin and drain in this fashion due to bubble production. This severely decreases the stability of the foam [42].

There are many different types of antifoams; however, the silicone type is used widely in the bioprocess industry [43]. In the food industry, silicon-based varieties of antifoam agents are commonly used to fulfill customer expectations. Silicone-based antifoam agents are poly(dialkylsiloxanes). Most commonly, they are in the form of poly(dimethylsiloxanes). Their average molecular weight is 27,000 g/mol, and their typical viscosity is 60 Pa s at room temperature [44]. They are virtually insoluble in water, possessing a low volatility. These properties translate into low spreading coefficients and low dispersion in foaming systems, making them less effective when used in their pure form [45]. Consequently, silicone-based antifoams contain finely divided solids, specifically silicas, creating high surface areas and an emulsifying agent to aid component distribution. According to some authors, highly dispersed, hydrophobic, solid silica are the main active ingredient and must be present for silicone antifoams to break foam [46]. Pure silicone-based materials are much stronger than water-based silicone emulsions to control foam, because they contribute a higher quantity of active silicone compared to the same weight of silicone/water emulsion. However, the prepared emulsions can be directly added to fermentations [47]. It is difficult to determine the effectiveness of antifoam agents due to variations in their drop sizes. The size distribution and aggregation state of the drops are unpredictable [48].

Food specialists see the specific antifoams in preparing deep-fried food like chicken nuggets, chips, and fries. Antifoams become important when foam disturbs filling operations, causes volume measurement errors, or negatively affects the composition of food products. Control of processing is the first solution to stop foam, but food manufacturers cannot do this without adding antifoams in some cases [49]. After saffron, the most popular flavoring agent is vanillin. It is an important product and, in addition, used as an antifoam agent [50, 51].

Various approaches have been applied to prevent severe foaming during surfactin production. The high energy consumption and mechanical stress on the cells limit the use of mechanical foam disruptors or breakers [52, 53]. Antifoam agents with desired chemical composition can be used in the culture medium to lower or prevent foam formation; however, they are not cost-effective, can interfere with the physiology of the cells, and are hard to eliminate in downstream processing [54, 55]. In another example, the combination of calcium stearate and corn oil, which was used because of their effectiveness as anti-oxidative and antifoam agents, could avoid foaming entirely, and surfactin production was 1.5 times higher compared to conventional antifoam agents used [56].

Polyethers typically are composed exclusively of ethylene or propylene oxides or random and block copolymers of ethylene and propylene oxides to achieve a broader range of surface activities [45]. Polyalkylene glycols are polyethers of molecular weights typically in the range of 400–2500 g/mol, which is suited for low solubility and can thus be applied to control foam effectively. Introducing a soluble substance into a foaming system that can integrate into the interface may reduce dynamic foam stability. This reduction may occur through any combination of the following actions: (i) an increase in surface tension, (ii) a decrease in surface elasticity, (iii) a decrease in surface viscosity, or (iv) a decrease in surface potential. Such effects can result from a co-solubilization impact on the interface or the partial or complete replacement of the original surfactants present. Certain branched, relatively high molecular mass alcohols can be employed for this purpose. Due to their limited solubility in water, they tend to be adsorbed at the gas–liquid interface, displacing foam-promoting surfactants and causing the foam to break or be inhibited [57]. Higher molecular weights generally lead to lower solubilities, a prerequisite for effective antifoaming. Poly(propylene glycol), for example, has a solubility in water (at 20 °C) of 15.5 g/L, while the solubility of the polypropylene/polyethylene copolymer in water is 3.4 g/L [58]. Poly(propylene glycol), thus, like other lower molecular weight polymers, features a water solubility too high for efficient foam control [45].

Natural plant oils are the earliest antifoams [45], used since they form a second organic phase in aqueous systems [59]. These oils are generally esters of glycerol with long-chain saturated or unsaturated monobasic acids (triglycerides) and some free fatty acids. Lard oil, composed mainly of glycerides of oleic and stearic acids, is one frequently used natural oil antifoam [60]. Unfortunately, oils used as antifoams tend to oxidize, forming aldehydes, carboxylic acids, peroxides, and other compounds with adverse effects on fermentation performance, necessitating co-addition of non-toxic antioxidants or the implementation of short expiry dates [61]. The best oils for antifoam applications feature high activity at low concentrations resulting in reasonably rapid foam collapse. However, foam suppression (preventing/inhibiting foam) as well as foam collapse must be considered [59]. All natural oils suppress foam formation to some degree, depending partly on the difference between their surface tension and that of the broth [62].

Aliphatic alcohols, such as n-octanol, act as antifoams and are attractive to use in fundamental studies since they are comprised of a single molecular species rather than a mixture; however, they are more volatile than higher molecular weight polymers [63]. Higher molecular weight alcohols such as octadecyl alcohol (also known as 1-octadecanol or stearyl alcohol) also possess antifoam properties but require a carrier since they are waxy solids [47].

Commercial antifoam agents PPG2000, B5600, and G832 have been commonly used in fermentation processes. B5600 was found to be the optimum antifoam agent in one study regarding membrane performance and defoaming efficiency [64]. Examples of the synergistic behavior operating in an SDS stabilized foam system using mixed antifoams are iDMPS-5X silicone oil, T-500, hydrophobic silica, and T-500 + DMPS-5X (1:40) [39].

2.2 Bubble-free fermentation by membrane aeration

Membrane aeration technology uses a membrane to introduce oxygen into an aqueous phase. The membrane is semi-permeable and is made of a material that allows oxygen to pass through while preventing water penetration. This technology creates an artificial environment for aerobic processes within a bioreactor and wastewater treatment plants. It furthermore reduces the energy needed to aerate the medium or wastewater and increases the system’s efficiency.

Membrane aeration offers several advantages for bioprocesses, like prevention of foam formation [65, 66], high energy efficiency [67], high and uniform gas distribution [67, 68], linear process scale-up by numbering-up of membrane area [69, 70], total shear stress reduction as no bubbles flow past the microorganism [71], and mitigation of evaporation of volatile organic compounds [69].

Despite the noted advantages, the scalability of in situ membrane aeration processes is challenging due to the declining surface-to-volume ratio at enlarged volumes [72]. Also, a precise cost model is necessary before considering the integration of membrane aeration. Being a rather costly equipment, low-price products are likely excluded from this aeration method. As biotechnology is multifaceted in products and organisms, the consideration of membrane aeration is highly case-dependent.

Knazek et al. [73] demonstrated membrane aeration for a mammalian cell culture in 1972 for the first time. For this, they utilized an extracorporeal membrane oxygenation device for an ex situ gas exchange system. This aeration technology pioneered the way to modern applications in producing biopharmaceuticals via cell culture. Since then, membrane oxygenators have become a solution for the bubble-free aeration of cell-culture media [74, 75]. Even though external membrane modules have high volumetric efficiency, gas supply for bioreactors is critical, as high flow rates of fermentation broth through the external loop are necessary to exchange the oxygen-poor medium in the vessel. Transferring the medium in and out of the external loop complicates process design and operation. Furthermore, the external loop increases the chance of contamination. Because of the limited gas transfer performance of these systems, membrane aeration was limited to cell cultivation [76], as mammalian cells tend to have a significantly lower oxygen consumption than microbes [77]. In the late 1980s, two parties of inventors filed patents for in situ cell culture (media) aeration (in Europe Lehmann et al. in 1984 [78], and in the US Miyamori et al. in 1989 [79]). The respective publication of Lehmann, Piehl, and Schulz [80] highlights the advantage of the bubble-free aeration process. The former Bayer Technology Services GmbH (BTS; now Engineering and Technology, Bayer AG, Leverkusen, Germany) started to develop a membrane aeration technology for cell cultivation in the millennial years, leading to a patent cluster [81, 82]. Despite the proof of principle, this technology did not find its way into broad application. Today, just the company bbi-biotech GmbH (Berlin, Germany) offers a commercially available static “aeration basket” for one- and two-liter bench top bioreactors. This basket contains silicone hoses connected to a steel frame that stabilizes and connects the hoses to the gas entry and outlet of the system. The silicone hoses can be considered membranes so that this installation can be regarded as an in situ membrane module. However, this product leads to a niche existence, most probably because of its low gas transfer performance. Our own measurements show that the aeration basket reaches an oxygen transfer rate (OTR) of approx. 1.25 mmol L−1 h−1 (supplied with air, 300 rpm stirring rate, and a trans-membrane pressure between 600 and 750 mbar, data provided in the SI). With the determined performance, the aeration basket could only support cell cultivations with comparably low oxygen demands.

In situ membrane aeration as one way to avoid an external loop is barely applied in industrial biotechnology but has been commonly used in wastewater treatment plants, for example, as membrane-aerated biofilm reactors [83, 84]. The utilization of hollow-fiber membranes for aeration in this field uses the tendency of biofouling of membrane systems for the process. By a sophisticated process operation, the membranes are used for the accumulation of biomass and parallel metabolic conversion of solved ingredients of the wastewater. Today, most wastewater facilities use this technology. A challenge in industrial membrane bioreactor usage for production is the potential formation of an undesired biofilm on the membrane surface. This physical barrier essentially reduces the mass transfer performance and necessitates frequent and extensive cleaning or expensive modifications of the utilized membranes [85]. Generally, biofilm formation can be controlled by diafiltration [86], the module design [87], and/or biosynthesis of surface-active products [88].

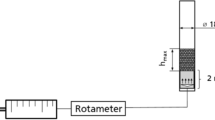

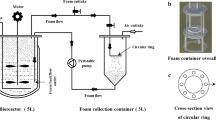

An early example of a rotating in situ membrane aeration in cell cultivation is the “Lehmann-Reaktor” [89] and its later application by Heidemann et al. [90]. A more recent approach with alternating membranes is the “dynamic membrane aeration” presented by Frahm et al. [82]. Nevertheless, oxygen transfer performance by the utilized membranes and module design is insufficient for operating a microbial process. Apart from cell cultivation, bubble-less membrane aeration is of interest for production processes with intense foam formation, e.g., biosurfactant synthesis. To overcome foaming, Kronemberger et al. [66] produced biosurfactants with Pseudomonas aeruginosa by utilizing an external membrane-aeration module. Coutte et al. [65] conducted membrane-aeration in three different settings (two with external modules and one with a submerged membrane contactor). During the fermentation of Bacillus subtilis, they synthesized surfactin (by external aeration) or fengymcyin (by submerged aeration). However, in both studies, the membrane modules were in ex situ approaches or not integrated into the specific reactor and stirrer configuration. A module design that directly leads to the mitigation of the boundary layer via the flow over the membrane significantly improves the overall oxygen transfer [69, 91] and, consequently, the process efficiency. Recently Bongartz et al. developed static [92, 93] and dynamic [94] membrane aeration systems (see Fig. 2), solving intense foam formation in biosurfactant production with Pseudomonas putida and Alcanivorax borkumensis with an unreached maximum oxygen transfer rate (OTRmax) of 175 mmol L−1 h−1. This technology opens the door for foam-free fermentation in industrial bioprocesses, even though further performance increases must be reached to support oxygen-demanding (high cell density) fermentations.

Pictures of the dynamic membrane aeration system [94] with the computer-aided design (CAD) model (left), the implemented prototype (middle), and the running rhamnolipid production process without foam (right)

2.3 Exploiting biofilm formation for foam-free fermentation

An emergent foam control strategy uses fixed instead of suspended biomass in bioprocess production. It is hypothesized that the production of soluble microbial products within a biofilm as opposed to the bulk liquid will reduce the release of soluble microbial products such as surface-active substances due to increased resistance at the biofilm-liquid boundary. In contrast to most bioprocess platforms which utilize suspended solutions of bacteria, bacteria rarely exist as single-cell suspensions but rather in complex communities termed a “biofilm” [95]. Biofilms are interface-associated microbial communities (e.g., liquid–air, solid–liquid) that exist as suspended flocs and/or dense aggregates [95, 96]. Within the biofilm, microbial cells are embedded in a surrounding matrix of self-produced extracellular polymeric substances (EPS), collectively forming a semi-permeable structure that allows diffusional exchange of solutes between the biofilm and bulk liquid [97]. The prevailing advantage for biofilms as an emergent bioprocess platform technology is the potential for operation with high solids retention time [98]. This invites the use of biofilms as an immobilized catalyst. For whole cells, physical entrapment is ultimately enabled by the adhesion of the biofilms EPS to suitable support (e.g., plastic carrier, membrane surface) [98]. Indeed, biofilm reactor technology is widely used by the water industry for the removal of organic pollutants from municipal and industrial waste streams, ranging from the use of trickling filters to suspended biofilm granules termed aerobic granular sludge [99]. The potential has also been demonstrated for the use of biofilm reactor technology in the production of bio-based chemicals from a defined chemical feedstock or an unwanted waste stream, leading to the definition of “productive” or catalytic biofilms [100, 101]. Yet, the use of productive biofilm processes as a platform technology remains limited at the level of system integration and full-scale production. On the one hand, this may be due to a greater understanding of suspended culture-based approaches and a limited fundamental understanding of long-term process operation required to design and maintain process stability. Arguably, the majority of biotechnological processes could exploit biofilm techniques as a continuous platform technology that would aid the separation of the biomass from the target product. However, to enable ubiquitous adoption of biofilm production technology, Edel et al. [98] proport the need to develop online monitoring solutions to help engineer biofilm thickness to ensure rapid transport of the end-products from the biofilm back to the medium stream. Biofilm membrane hybrid systems invite the opportunity to combine biofilms with process intensification platforms such as membrane contactors to improve system energetics and potentially reduce foam formation [102]. Recent application of membrane contactors for bubble-less oxygen delivery into culture media invites the combined use of an integrated biofilm process to avoid unwanted foam formation [92]. Retention of a biofilm on the surface of an oxygen transfer membrane facilitates direct transport of the electron acceptor to the biofilm-membrane interface biomass [103]. This is anticipated to help avoid foam formation for two reasons: (i) direct aeration of the surface attached biomass will lower the aeration of the culture media and decrease foaming potential, and (ii) low concentration of soluble microbial products derived from utilization associated products and biomass associated products [104]. The high diffusional resistance at the biofilm-liquid layer will retain solutes within the biofilm structure for recycling as an electron donor. In this way, released soluble microbial products, which would otherwise stabilize liquid lamellas, can be restricted in the cultural media.

2.4 Bubble-free fermentation by engineering a micro-aerophilic lifestyle

A completely different approach to avoid foam formation involves the engineering of lifestyles that do not require the presence of oxygen as terminal electron acceptor. P. putida, which has been used to produce highly foaming rhamnolipids, is an obligate aerobic organism. It utilizes the cellular process of aerobic respiration to release energy, as ATP, from glucose or other organic substrates in a stepwise manner via the electron transport chain. The terminal step in aerobic respiration entirely relies on the electronegative molecule oxygen, which releases energy from the organic compound to form carbon dioxide and water. In order to circumvent the strict requirement of oxygen sparged into the reactor and thereby prevent foaming, alternative metabolic processes to aerobic respiration have been engineered to adjust P. putida’s metabolism. Three strategies compromising the metabolic process of fermentation (i), anaerobic respiration (ii), and electrode respiration (iii) have been applied toward a microaerobic or anaerobic lifestyle of P. putida.

In the first strategy (i), P. putida was engineered toward a fermentative metabolism. In the metabolic process of fermentation, energy is released in the absence of oxygen. Just as in aerobic respiration, glycolysis produces pyruvate, thereby generating ATP. The reducing equivalent NAD+ needs to be regenerated to keep this process running. This is achieved by producing organic acids or alcohols (e.g., lactate, ethanol) from pyruvate and NADH. However, the ATP yield of fermentation is significantly lower than that of aerobic respiration. Therefore, a study by Sohn et al. [105] suggested that anaerobic growth of P. putida is not feasible due to a lack of ATP production, which a genome-scale model predicted. To overcome this hurdle, Sohn et al. expressed an acetate kinase gene (ackA) natively derived from Escherichia coli in P. putida. The native enzyme set of P. putida can already convert pyruvate over acetyl-coenzyme A to acetyl-phosphate, which is then further metabolized by the engineered acetate kinase (AckA) to acetate. Thereby, an additional ATP is generated. The introduced AckA enabled P. putida to prolonged anaerobic survival of 8 days on glucose as a carbon source. In 2013, Nikel et al. [106] suggested that not only is ATP limited under anoxic conditions in P. putida, but NADH regeneration is not possible due to the lack of oxygen. Therefore, Nikel et al. expressed, in addition to ackA from E. coli also a pyruvate decarboxylase (pdc), and an alcohol dehydrogenase II (adhB) gene from Zymomonas mobilis in P. putida. Pyruvate is then converted to acetaldehyde via the pyruvate decarboxylase and further to ethanol and NAD+ via alcohol dehydrogenase II. The additional genes enabled the engineered P. putida to maintain metabolic activity under anaerobic conditions. Here, the engineered P. putida strain survived for 7 days under anoxic conditions; ten-times longer than the wild type. Also, in terms of viability, the growth rate was increased by 58% and 37% for strains producing Pdc-AdhB or AckA, respectively.

In the second strategy (ii), anaerobic respiration via nitrate and nitrite reduction was engineered in P. putida. In the process of anaerobic respiration, energy is also released in a stepwise manner using the electrode transport chain. However, electrons are not shuttled to oxygen as terminal electron acceptor but rather to a less electronegative acceptor, e.g., nitrate, which results in a lower ATP yield compared to aerobic respiration. Natively, P. putida does not harbor the necessary genes to reduce nitrate or nitrite. At the same time, its close relatives, P. aeruginosa and P. stutzeri, can utilize nitrate or nitrite as terminal electron acceptors. Steen et al. [107] expressed the genes encoding for the anaerobic respiration machinery compromising all structural, maturation, and regulatory elements of P. aeruginosa for both nitrate and nitrite respiration in P. putida. Engineered P. putida strains harboring the nitrate reductase (pNAR) or nitrite- and nitric oxide reductase (pNIR-NOR) could reduce nitrate and nitrite, respectively, under anoxic conditions. Expressing the nar operon enabled P. putida to survive under anoxic conditions for 5 days with a 50-fold increase in colony-forming units compared to the wild type. The nor operon even resulted in an 80-fold increase in survival after 5 days of anoxic cultivation. However, while, anaerobic survival could be shown, anaerobic growth was not observed with the engineered strains.

Another strategy (iii) to enable oxygen-limited cultivation is to utilize an external poised electrode as a final electron acceptor replacing oxygen. In contrast to the reducing molecules utilized in anaerobic respiration, a poised electrode can provide the required electronegativity of oxygen. However, the challenge is to connect the external electrode to the central metabolism of the microorganism. The anode of a bioelectrochemical system (BES) can be used as an electron sink for the metabolically derived electrons. To connect the cells and the external electrode, so-called electron shuttles or mediators can be applied. In 2015, Schmitz et al. [108] engineered P. putida to produce redox-active phenazines natively derived from P. aeruginosa. Therefore, the seven gene core phenazine operon of P. aeruginosa PA01 for phenazine-carboxylic acid (PCA) synthesis and the two specific phenazine genes phzS and phzM for pyocyanin production were expressed from two inducible plasmids. Indeed, the engineered P. putida produced phenazines that could facilitate electron discharge on the poised electrode. Due to the phenazine production, P. putida could sustain oxygen-limited metabolism for up to 2 weeks. Also, Lai et al. [109] investigated the effect of mediators on the anaerobic survival of P. putida. Externally, Lai et al. added the redox-active mediators thionine chloride, tris(2,2′-bipyridine) cobalt(II) diperchlorate, or potassium hexacyano-ferrate(III) to the culture medium. These externally provided mediators helped P. putida to discharge electrons to a poised electrode in a BES and enabled P. putida to survive under anoxic conditions for almost 2 weeks with an increased adenylate energy charge indicating an energy generation using the electrode. In a follow-up study on electrode discharge via phenazines by Askitosari et al. [110], PCA generation by P. putida was successfully combined with rhamnolipid production. Indeed, a strain producing the phenazine PCA (26 mg/L) could generate 31 mg/L rhamnolipids in an electrode containing standard 1 L bioreactors under oxygen-limited conditions for 25 days. Hence, a BES could be successfully applied to enable an oxygen-limited production process of rhamnolipids. Since oxygen supply was not required, foam formation could completely be prevented.

Thus, several strategies, from fermentation over anaerobic respiration with nitrate or nitrite to respiration using an electrode as a terminal electron acceptor, have been successfully established in P. putida. All studies have in common that anaerobic survival of P. putida was enabled. However, anoxic growth using one of these strategies was not shown yet. Still, several studies have successfully combined improved anaerobic survival with product synthesis, e.g., rhamnolipid production. All tested strategies bear the potential to be applied to prevent reactor foaming during surfactant production.

2.5 Headspace aeration and pressurized conditions

One further possibility to circumvent foaming in bioprocesses is to eliminate or reduce the origin of foam formation. Since foaming occurs by the interaction of surface-active substances like biosurfactants at the gas–liquid-surface, submerged aeration enhances foaming because the small air bubbles provide main gas–liquid surface in the system. Headspace (surface) aeration can be realized in every bioreactor system without any modifications and is, therefore, the simplest technical solution to prevent almost any foam formation presented in this article. This huge advantage should always be kept in mind since it might outweigh the following listed disadvantages. Neglecting shaken culture systems like Erlenmeyer flasks and microtiter plates, only a minority of bioprocesses were established with headspace aeration since gas transfer rates are tremendously reduced in comparison to submerged aerated bioreactor systems [111]. Without sparging, two possible effects dominate the gas supply of the culture broth depending on the bioreactor setup (e.g., power input by stirring, impeller type and position, baffles): diffusion and surface gas entrainment. Diffusion does not form any bubbles; hence, it does not contribute to foam formation. Surface gas entrainment is caused by vortices near the liquid surface, followed by air entrapment [112]. Therefore, the turbulent kinetic energy needs to be larger than the surface tension and gravity effects of the bioreactor’s liquid volume [112]. Bioreactors equipped with baffles, high stirring rates, and an impeller close to the liquid surface promote the gas entrainment effect [112, 113]. However, it is expected that this additional gas–liquid surface displays only a small fraction compared to active sparging. Moreover, microbially generated carbon dioxide accumulates in the liquid phase. This can be a critical issue since many bacterial and yeast-based processes show inhibitions due to elevated dissolved carbon dioxide tension (pCO2) [114]. Therefore, headspace aeration is only applicable to avoid foam formation if a high tolerance or even demand for carbon dioxide is known [115,116,117,118]. Furthermore, gas formation by microorganisms displays another potential source for bubble and foam formation. For example, as described above, yeast can produce carbon dioxide nanobubbles in the beer brewery process (see Sect. 1.2). Another drawback is the limited scalability of headspace aeration in conventional stirred tank reactors because of the inversed proportionality of surface area/filling volume ratio to bioreactor scale. Therefore, large-scale processes will be oxygen-limited in a shorter time frame, and, moreover, higher pCO2 values will occur due to a higher hydrostatic pressure. Theoretically, choosing the surface area/filling volume ratio as the constant scale-up criterion is possible, but this would result in very low filling volumes in large reactors.

To at least overcome the oxygen limitation, overpressure can be applied to linearly increase the gas solubilities and thus also the oxygen transfer rate. For foaming bioprocesses, it is recommended to keep the pressure at a constant level because a pressure decrease would lead to sudden gas supersaturation, resulting in bubble formation and foaming. In case of low overpressures up to 900 mbar, pressurization is another simple technical solution that can be realized in every in situ sterilizable reactor system. For more efficient usage of overpressure, pressure-stable reactor systems can be used [119]. These bioreactors can be pressurized up to approx. 10 bar (depending on the scale), and their scalability was discussed by Knoll et al. [120]. Up to now, pressure bioreactors are no standard equipment in conventional pilot and industrial plants, but reactor numbers and scales are increasing due to their multipurpose usage. Despite the advantageous effect of elevated gas transfer in strongly foaming bioprocesses provided with headspace aeration and high cell density cultivations, highly viscous culture broths and anaerobic autotrophic processes can also benefit from overpressure application [121,122,123]. However, the combination of headspace aeration and elevated pressure also increases the solubility of carbon dioxide, which again might inhibit microbial activity.

3 Foam disruption and foam control

While preventing foam formation is an effective countermeasure in biotechnological fermentations, there may be situations where foam has already formed and needs to be eliminated. Mechanical defoaming is often used as an emergency treatment once foaming occurs. High-frequency stirring and high-pressure water jetting are the most commonly used methods [124]. Generally, shear force is applied to the foam, resulting in the breakdown of the lamellae. If surfactants are present, this process causes detachment of part of the surfactants attached to the lamellae. The detachment of these surfactants from the lamellae promotes the collapse of the foam structure. Ultrasonic or thermal methods are also commonly used [125, 126]. On these methods, a mini-review has recently been published [127], which is why these topics are not covered here. This section reviews the various approaches developed for eliminating foam in biotechnological fermentations.

3.1 Defoaming agents

Defoamers are additives used in liquid systems when foaming has already occurred and needs to be eliminated. They are often used in paper making since the kraft process is particularly susceptible to a foamy pulp. Many chemicals, such as liquid surfactants as well as solid particles, which help reduce surface tension and thus rupture bubbles, are utilized. The prominent examples of defoaming agents are oleic acid, 2-octanol, amide waxes, sulfonated oils, paraffinic waxes, silicone oils, mineral oils, organic phosphates, and dimethylpolysiloxane. The defoamers are mainly added to remove the stable foam in a liquid phase by a shock effect. Although foams are thermodynamically unstable, under practical conditions, they can remain fairly stable for a considerable period of time, and it is often necessary to add chemicals to prevent foaming or destroy the foam. However, this distinction is confusing today since most chemical additives cover several roles, and the nomenclature varies according to the industry where they are used. In fact, they are often referred to as foam-controlling agents, foam inhibitors, foam suppressants, and air release agents [39].

Defoaming agents are used in different industries, such as the bioprocess industry [15], as well in mammalian cell cultures as well as in microbial fermentations [36, 128], anaerobic digestors [129], and biogas production [130]. While defoaming agents are sometimes essential for upstream processing, they might pose significant challenges in downstream processing. During filtration, for example, the concentration of antifoaming agents (silicon-type) in the solution increases, thus significantly increasing the backpressure across the filter. In examples, the flux rate over the filter decreased by 32–68%. These findings emphasize the concentration-dependent, adverse impact of defoaming agents on filtration efficiency, highlighting the necessity for precise control in industrial processes [131].

Furthermore, defoaming methods are further subdivided into mechanical, chemical, and biological methods. To maximize the efficacy of defoaming, several methods are typically used [132]. Chemical defoaming methods mainly include adding defoaming agents. This method is commonly used for foam control in anaerobic digestion plants. Defoaming agents exert their effect by removing the stabilizing factors that promote foam formation. Biological defoaming methods refer to defoaming technology based on the application of microbes. Once foaming microorganisms are identified, the use of biological methods to regulate the functional microorganisms will eliminate foam and prevent foam formation. For example, in the field of wastewater treatment, scientists have proposed that bacteriophages can be used to infect and eliminate filamentous bacteria to lower the foaming potential of activated sludge [133]. Table 2 shows commercially available defoaming agents.

Foam trapping is another method for the disruption of foam. In this method, the antifoams are not used in the fermenter but in the foam trap [135]. Heyd et al. increase foam disruption using citric acid during rhamnolipid fermentation. Changes in the pH value of culture broths containing proteins are usually known to affect the stability of foam because of the pH-dependent solubility of proteins and the capacity of foam formation [136]. Shifting the pH value in the foam trap or using antifoam agents makes chemical disruption of foam possible, with no changes in the culture composition. However, this application is only implemented where there is no recirculation of foam back to the fermenter [137].

3.2 Mechanical foam destruction

3.2.1 Motivating mechanical foam destruction in biotechnology

In many bioreactors, the addition of liquid antifoam agents (see Sect. 1.2) is chosen to reduce foam formation. However, this measure has some disadvantages, as it decreases gas mass transfer and can cause issues in downstream processing. With mechanical foam breakers, foam is managed exclusively by mechanical principles. The liquid remains in the system, and the gas is released into the exhaust gas system. The applicability of mechanical foam handling depends on many parameters, the most important of which are the foam formation and drainage characteristic of the medium, the stability of the biological catalyst, technical implementability, and economics.

An aerated liquid’s foamability can be estimated by measuring the physicochemical properties density, surface tension, and viscosity and correlating the data in dimensionless numbers [138]. However, the experimental measurement of foamability, e.g., in laboratory bubble columns, and the determination of the foam decay behavior is essential to get a more detailed picture for designing and sizing mechanical foam destruction systems. It will be shown later that there are several types of mechanical defoamers with distinct characteristics in terms of mechanical principles. Therefore, the gravimetrical foam decay can be used for centrifugal-type foam breakers but is limited to other types of mechanical systems. Even in centrifugal foam breakers, additional forces during foam inlet, internal flow pattern, and foam discharge/return will occur. Currently, there is no direct theoretical correlation between physicochemical liquid/gas properties and foam breaker efficiency. Therefore, application and scale-up of mechanical foam breakers must be carried out from small-scale test benches with laboratory foam breakers using the same principle and having a defined geometry. Two fundamental problems with applications in the fermentation industry remain: first, the lack of representative fermentation broth (without antifoam agent) when a mechanical defoamer should be applied for the first time, and second, the time course of changes of foamability and other characteristics during discontinuous fermentation runs. Both aspects lead to the conclusion that empirical trials as a basis for a scale-up have to be made in fully equipped laboratory bioreactors running under similar process conditions compared to the large-scale units. Based on these empirical trials, typical scaling methods can be used.

3.2.2 Technical designs of mechanical foam breaker

A number of different mechanical systems have been proposed in the last decades:

-

Rotating disc-, blade-, needle- and brush defoamer (Fig. 3a)

-

Rotating foam breaker with inclined channels (Fig. 3b)

-

Bladed wheel foam separator

-

Disc stack defoamer (Fig. 3c)

-

Foam centrifuge of solid bowl type (Fig. 3d)

-

Stirring as foam disruption

-

Others

A technical comparison of some mechanical foam breakers, including systems with membranes, ultrasonic, cyclones, and rinsing, can be found in [3].

The typical configuration of a bioreactor with rotating mechanical foam breakers can be distinguished into two general types: an “open” and a “closed” configuration (Fig. 4). The hydraulic part of the foam breaker in the “open” configuration is located in the bioreactor’s headspace, and the foam concentrate with enhanced liquid content will be released directly into the bioreactor head. Examples of this type are rotating discs [139], needles, brushes, or paddles [140], either installed on the stirrer shaft or with a separate higher-speed drive. Also, disc stack defoamers [141] can work directly in the headspace. Solid bowl foam breakers [142, 143] are typically applied as “closed” system with foam concentrate discharge and return via a separate foam return pipe. Bladed wheel defoamers [144], foam breakers with inclined channels [145], and other types can be designed accordingly.

“Open” and “closed” configuration of mechanical foam breakers for industrial bioreactors. Left: “Open” defoamer with rotating disc stack to be located directly in the bioreactor headspace. Right: “closed” solid bowl-type defoamer with a rotating bowl with blades and a foam concentrate return line connected to a separate housing (to be attached to the bioreactor dome or in the exhaust gas pipe). Both systems are derived from workshop photographs at Frings, Germany

“Closed” systems typically are more efficient and have the advantage that they can easily be retrofitted to existing bioreactors. The mechanical foam breaker is then not laboriously integrated into the headspace of the bioreactor but installed into the exhaust pipe. This can also take place at some distance from the bioreactor so that there are hardly any space limitations. The liquefied foam-fraction is either free-flowing or actively pumped back into the bioreactor vessel through a return pipe. The gas leaves the device through a gas pipe to the exhaust gas. This general configuration is shown in Fig. 5 for a pilot bioreactor.

3.2.3 Design approaches

Depending on the type of mechanical foam breakers, the mechanical principles contain foam shear, pressure swing, impact, centrifugal forces, and other mechanical or hydrodynamical effects. In most foam breaker designs, a combination of effects is responsible for foam disruption and liquefaction.

The radial centrifugal acceleration of the liquid mass in a foam centrifuge correlates to the radius r in [m] and the angular velocity ω in [rad/s] squared. The dimensionless Froude-number

with g = 9.81 m/s2 in combination with the tip speed vTip [m/s], the foam inlet velocity vF [m/s], respectively, the mean resistance time τ [s] can be correlated with experimental data to basically scale mechanical defoamer. According to Furchner and Mersmann [146], a minimum tip speed of 10–12 m/s is necessary to liquefy the foam to at least 500 kg/m3, which is a prerequisite for it to flow freely.

Zlokarnik [147] has used a dimensionless Froude-number definition

with the diameter d [m] and the gas flow rate q [m3/s], and a gas flow number.

with the minimum rotational speed nmin [1/s]. It was shown that a foam centrifuge consisting of a rotating body with obliquely drilled holes/extended pipes could be scaled up even with variable concentrations of the foaming agent Mersolat H in the model liquid.

More deterministic approaches to calculate the efficiency of foam destruction have been proposed by Vetoshkin [148]. The basis for a theoretical approach was the calculation of the critical value for the shear stress arising in the foam flow, e.g., in disc stack foam breakers, in nozzles, and at plates.

3.2.4 The influence of bioreactor stirrer design on foam formation and foam destructibility

Besides the foam destruction above the liquid level, there are some possibilities for design optimizations of the bioreactor itself to avoid foam formation before gas leaves the liquid into the headspace [12]. The potential of optimizing the stirrer design of aerated bioreactors to avoid foam formation has been shown for down- and upward-pumping axial flow impellers in scale-down trials of industrial-type bioreactors [149]. However, many modern fed-batch processes are characterized by significant changes in filling volume, while the “stirring as foam disruption” approach is suitable in small volume variations only. If the liquid surface is at the level of the upper stage of a multistage stirrer, this can significantly increase the foam formation.

The surface flow regime of a bioreactor can be directed with self-aspirating hollow stirrers so that foam will be sucked back into the liquid via a central draft tube. This technology can be used for continuous operations with constant liquid levels only but is highly effective. It was developed several decades ago for the production of single-cell protein/fodder yeasts in non-sterile large-scale fermentation systems that are nowadays still in operation [150]. Comparable technologies are applied in aerobic wastewater treatment plants with floating devices that draw foam from the surface into a draft tube [151].

3.2.5 Foam disruption in the headspace

An important aspect of any kind of foam management in bioreactors besides the foam handling itself is the residence time distribution of liquid in the foam and the fractioning of broth components and biomass in the foam. A long residence time of fermentation broth in the foam can cause a lack of media components or gas transfer and therefore changes in the metabolic state, production of byproducts, cell death, or even the production of more foam by the release of proteins or harmful metabolites back into the bulk broth [12, 152]. Kar et al. have shown with flow cytometry that an “stirring as foam disruption” approach-controlled foam layer caused segregation of microbial cells of Yarrowia lipolytica in an intermediate layer between the liquid and foam phase resulting in decreased lipase production compared to a classical antifoam approach without this layer [153].

The use of a mechanical defoamer can significantly decrease the mean residence time of liquid in the headspace [154]. The prerequisite for this is that the foam concentrate is fed back into the bulk broth via the inner wall of the fermenter or an external line. If the headspace volume is low and the defoamer is adequately sized, the potential increase in working volume and oxygen transfer rate in this “foam fermentation mode” can overcompensate for the additional energy consumption of the foam breaker.

A reactor mass balance model for the liquid based on lab trial data of foam decay in [kg/m3/s] and representative samples for primary foam density and foam concentrate density [kg/m3] can be used to determine the steady state inside the bioreactor. For the mass balance, it is important to consider that the internal recirculation of air and liquid is causing higher flow rates through a mechanical foam breaker than balanced with the amount at the in- and outlet of the bioreactor.

3.2.6 Mechanical foam destruction versus chemical antifoam agents

There are certain advantages of mechanical foam centrifuges in comparison to other methods of foam destruction. One of the major advantages is that no or less additional chemical components like antifoam agents have to be added. This reduces the efforts in downstream processing and purification of the fermentation product. Documentation and qualification issues can be avoided by this method as well.

Another advantage of using solely mechanical foam treatment is the enhancement of oxygen transfer in microbial fermentations, whose productivity is rather often limited by the availability of dissolved oxygen in the broth. According to the well-known equation for the oxygen transfer rate.

The oxygen transfer rate strongly depends on the mass transfer coefficient kLa [1/h]. The specific surface area a is inversely proportional to the Sauter diameter d32 of the rising bubbles containing the required oxygen. Oxygen must be transported through the interface between the bubble surface and liquid bulk. Antifoam agents are rather often influencing the bubble size and causing a direct decrease of the OTR at higher aeration rates, as usual in bioreactors [155]. It was shown by Kawase and Moo-Young [156] that the kL value decreases by adding antifoam agents, whereby the mass transfer is additionally limited.

The effects of the reduction of antifoam agent by mechanical foam destruction methods have not been well studied. Further systematic studies are needed. Empirical data from industry shows that several foaming fermentation systems could be optimized by mechanical foam destruction, while in other foaming fermentations, antifoam addition is the method of choice. This must be defined based on bioprocess data but also considering cost factors for consumables, investment into mechanical defoaming equipment, energy demand, regulatory restrictions, and other influencing parameters.

Using mechanical defoamers and systems with chemical antifoams lead to different problems when cleaning bioreactors using cleaning-in-place (CIP). While the antifoam dosing unit within the bioreactor itself consists only of a foam electrode and a dip tube, a mechanical foam breaker is a complex device with many hydraulic parts that come into contact with the product. A corresponding CIP installation [141] is required for cleaning, and a series of cleaning sequences must be carried out. This does not mean that CIP would always be less expensive when using chemical antifoam systems. Here, an antifoam reservoir and a dosing pump must also be cleaned and sterilized using CIP and sterilization-in-place. In addition, considerable cleaning problems can arise due to the adhesion of antifoam agents in the headspace of the bioreactor.

3.2.7 Mechanical stress and applications of mechanical foam breakers

Mechanical foam destruction exposes the cell-containing liquid in the foam to mechanical stress. The application of this technology is, therefore, limited to biological systems that can resist mechanical forces to a certain threshold. There is a lack of scientific data regarding the effects on whole-cell biocatalysts. Industrial applications have shown that these forces do not have a negative impact on most microbial cells that are not mycelium-forming. Mechanical foam breakers are widely used in certain areas of the fermentation industry with numerous biological systems like strains of Komagataeibacter, Gluconobacter, Escherichia, Pichia, Saccharomyces, Pseudomonas, Bacillus, and others. However, mechanical foam destruction should be very carefully applied for production systems that need complex and fragile morphological structures. In most of these cases, this technology is unsuited for foam recycling.

3.2.8 Application examples

It could be shown in aerobic fermentation of polyhydroxybutyrate with Cupriavidus necator in 10 m3 scale that the application of a solid bowl-type foam breaker in “closed” configuration allows the increase of working volume by 5% and the overall increase of productivity by > 10%. Industrial scale production of the compatible solute ectoine with Halomonas elongata is operated with a similar type of foam breaker and without the use of antifoam agent. The technology was successfully scaled up from pilot scale. Industrial baker’s yeast production under the regulation of “bio” respectively “organic” doesn’t allow the use of highly effective chemical antifoam agents as used in conventional yeast fermentation. The implementation of “closed” solid bowl foam breakers into large-scale bioreactors (75 m3) enables to run aerobic fermentation with high productivity and without losses of fermentation broth via the exhaust line. The industrial application with the highest amount of installed mechanical foam breakers is acetic acid fermentation with more than a thousand production plants (ACETATOR) in scales from 1 to 150 m3 [157]. The mechanical defoamer in this application provides that no foam flows out of the fermenter, but that concentrated liquid with cell debris and fermentation-inhibiting metabolites can be removed from the reaction system [142]. Organic acid bases that are produced with acetic acid bacteria for the beverage industry, with gluconic acid as the major acidic component, are produced with mechanical foam breakers of the solid bowl type as well up to 75 m3. Super large fermenters for amino acid fermentation with Corynebacterium glutamicum > 400 m3 are typically not equipped with separate drives for mechanical foam breakers but with an additional blade or brush-type foam breaker installed on the stirrer shaft. However, this type of installation supports the foam rupture and drainage but cannot be as effective as a separate mechanical foam breaker with high centrifugal and shear forces. On the other hand, the additional energy demand is negligible, so that the application makes sense when antifoam agent can be used, but the amount used is minimized.

Numerous applications of mechanical foam breakers can be found in the field of GMP-regulated biopharmaceutical fermentation with microbial expression systems in aerobic processes. An application in the pharmaceutical industry where the foam concentrate is not recirculated into the broth is the use of a mechanical foam breaker for exhaust gas filter protection in mammalian cell culture. This measure ensures that no liquid enters the sterile exhaust filter and compromises the filter integrity so that the full containment of the bioreactor can be validated.

3.3 Organic solvents as a second liquid phase in fermentations

The usage of organic solvents to avoid and disrupt foam has been described before (antifoam and defoaming agents). We here describe two more approaches that exploit additional characteristics of the solvents used in addition to controlling foaming. It is worth noting that in the cases described here, adding organic solvents serves more as a foam control method than a foam disruption technique, as it reduces foam formation rather than breaking up already formed foam.

3.3.1 Oils as carbon source

Oils, applied as carbon sources in microbial cultivations, can simultaneously act as antifoam agents, thus diminishing the need to add antifoam agents. The oil droplets destabilize the foam in three different ways: (i) as hydrophobic bridges between the two surfaces, (ii) by displacing the adsorbed surfactant species on the film surface, or (iii) by spreading rapidly on the film surface, pushing the liquid away and causing the film to thin and collapse [158]. This beneficial property has been known for decades, making natural oils such as rapeseed and linseed oil one of the first antifoam agents used [159].

Currently, plant oils are rarely used as antifoam agents. Instead, the trend is moving towards commercially available antifoam agents, which are usually a combination of oils, surfactants, and hydrophilic particles [33, 160]. However, a few studies (e.g., [32]) have described oil as an antifoam agent. For example, sunflower and rapeseed oil have been used to reduce foam formation in manure-biogas reactors to reduce foam formation. In addition, it was shown that natural oils were as efficient in foam suppression and reduction as the commercially available antifoam agents [161]. A second example is the use of soybean oil in fed-batch fermentation of Pseudozyma aphidis as a carbon source and antifoam agent to produce mannosylerythritol lipids [162]. The simultaneous use of oil as a carbon source and antifoam agent is challenging because of the dynamic behavior of the antifoam agent as its amount decreases during fermentation. Another challenge in producing biosurfactants with oils as a carbon source in stirred tank reactors is the formation of emulsions. Since the formation of stable emulsions is desired in upstream processing, leading to high interface area and, thus, high mass transfer rates [163, 164], downstream processing concepts often fail to process the resulting stable emulsion [165, 166]. While intensive centrifugation can break the emulsion at a small scale, resulting in sufficient phase separation, this may not be feasible for large volumes in large-scale cultivation. Especially when surfactants are produced and/or the cell count is high. This requires other phase separation methods, such as catastrophic phase inversion, the addition of de-emulsifiers, filtration, or membrane separation involving higher costs and time or different reactor designs like the multi-phase loop reactor [167,168,169], which is discussed in Sect. 3.3.2. Oils currently used as carbon sources include vegetable oils, such as sunflower oil [170], olive oil [171], and soybean oil [172], as well as waste oil, such as waste frying canola oil [173], waste frying coconut oil [174], and waste frying soybean oil [175]. Further studies have used the by-products of oil production, namely oil cakes, as a carbon source [176]. Overall, in addition to increasing the product yield, the focus is on minimizing the production costs to increase the economic efficiency of the fermentations. Therefore, the trend is moving towards waste and low-cost oil substrates.

The majority of studies over the last years focused on the screening of various microorganisms for their ability to grow on oily substrates and produce valuable substances simultaneously, including but not limited to Auerobasidum melanogenum on vegetable oil [177], Y. lipolytica for astaxanthin production [178], P. putida KT2440 on waste frying vegetable oil [179], Burkholderia thailandensis on used cooking oil [180] and the production of polyhydroxyalkanoates using various microorganisms like C. necator [181].

The last process is intriguing because a low-value waste product is converted into a biodegradable, high-value biomaterial [182]. Nevertheless, the primary carbon source for the industrial production of polyhydroxyalkanoates today is carbohydrates such as corn and sucrose, independent of the manufacturer or organism used [183]. This trend can also be observed for other processes and shows that oil has become the preferred carbon source for only a handful of fermentation processes. One of the main reasons for this is the accessibility of the carbon source to microorganisms. Most microorganisms obtain their substrate from the surrounding medium, but when oil is the carbon source, bioavailability is limited to the interface of oil and water [184]. Moreover, hydrophobic substrates are usually more expensive than sugar-based substrates. This is a clear disadvantage, especially if a process competes with low-cost, well-established production processes [185]. At the same time, plant oils are more reduced substrates with a higher degree of reduction than sugars, which likely allows for higher production titers due to the higher energy content per carbon atom.

The production of various biosurfactants can avoid one of these problems and profits from the use of oil as carbon source. The produced biosurfactants increase the bioavailability of oil for microorganisms [186]. In addition, biosurfactant production in natural producers has been reported to be induced by the presence of hydrophobic compounds for various biosurfactants throughout the years [187,188,189]. The combination of these advantages makes oil an ideal carbon source for biosurfactant production and makes the production of biosurfactants currently the only fermentation process that uses oil as their preferred carbon source.

Rhamnolipids are glycolipids and currently implemented in the chemical industry. Nowadays, they account for a large share of biosurfactants production [190] and are already used in hand washing detergent, toothpaste, and cleaning products. However, future applications in other fields like the food, cosmetic, and biodegradation industry seem possible [191]. Positive characteristics include low toxicity and high biodegradability [192]. Pseudomonas aeruginosa, the primary producer of these glycosylated lipids, uses various types of oil [193,194,195]. A disadvantage of Pseudomonas aeruginosa is its intrinsic pathogenic nature [196]. Thus, it would be highly beneficial to integrate the rhamnolipid production pathway into nonpathogenic organisms. Research is therefore conducted to use, for example, Pseudomonas putida KT2240 for rhamnolipid production [196, 197].