Abstract

Gas, which is trapped in either solid or liquid pockets, results in foam formation. Foam formation is common in many industries, i.e., in detergents, food and beverage, cosmetics, and fire-fighting. Foam formation in excess causes biotechnology fermentation instabilities, including material loss and the danger of contaminating the fermentation and the environment. Many foam-controlling measures have been reported, including thermal, enzymatic, mechanical, ultrasound pretreatments, steam explosion, reducing digester mixing, and surface sludge spray. Using antifoaming agents for foam control in fermentation is the most common method, sometimes supported by mechanical foam breakers. However, antifoam can be costly and can complicate product purification. Indeed, effective foam control can significantly impact the economics of the whole process. This mini-review summarizes some unconventional foam destruction techniques, including their various challenges.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

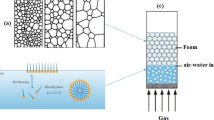

Foam formation is a very interesting phenomenon and has been the subject of research for more than two centuries. In most fermentation processes in which foaming is observed, the product yield and overall performance are significantly reduced. Simply, foam is a complex structure composed of gas bubbles separated by liquid membranes [1,2,3,4]. Living cells could be adversely affected by physical methods of foam destruction, such as thermal, electrical, and ultrasound [5]. In fermentations, product formation and cell growth could be inhibited due to severe foam formation by reducing the bioavailability of the substrates, working volume, oxygen transfer rate, and many other biological and physical adverse effects [6]. Furthermore, excessive overflowing of the foam through gas outlets of the bioreactor would have many harmful impacts on the fermentation process, including culture medium loss, loss of cells and product, and a higher risk of contamination [7].

To overcome foaming, chemical and physical foam destruction methods are commonly used. Chemical methods include antifoaming agents, which can act as cell inhibitors, depending on the process stage [8, 9]. Physical methods used for foam destruction include the mechanical transmission of shear stress through contact with a blade of the destruction element [8, 9]. Ultrasound is another physical method of foam destruction, which has been discussed in detail [10,11,12,13]. Antifoaming agents, otherwise known as defoamers, have been widely used in biotechnology, including the improvement of cell cultures and fermentations. Additionally, research findings claim that antifoaming agents have many advantages, such as preventing foam formation or increasing the rate of foam decay. The antifoam agent’s function is to weaken the foam’s liquid film stability. Furthermore, it can boost the liquid discharge rate, thereby increasing the decay rate of the foam [4, 14]. Although manufacturers claim that antifoaming agents pose no risk to health and preserve the nutritional value of the food, there is an increasing preference for physical methods of foam destruction, especially in the food industry. Specifically, this is true among small food manufacturers, who can then present their products as natural and healthy. However, there are several drawbacks to using physical methods. For instance, the performance of upscaled devices decreases while energy consumption increases. Furthermore, while the produced foam is removed during the production process, the tendency of the liquid to foam formation is not eliminated [15].

This review highlights recent advances in thermal methods and ultrasound foam destruction that might be applicable in the industry.

2 Foam destruction

Defoamers or antifoaming agents are chemical preservatives that reduce foam production and destroy formed foam in industrial process liquids. There are two methods of using chemical agents for foam control: 1) They are applied before foam production to control foaming (antifoaming agents), or they are applied to the solution after the production of foam in order to control foaming (defoamers) [4, 16]. They are also used extensively in biotechnology, such as cell culturing and microbial fermentation [17, 18], bioprocess industries [19], biogas production [20], and anaerobic digesters [21]. However, the antifoam agents’ biological effects are poorly understood because of a wide range of molecular structures and insufficient data about their composition [22]. Antifoaming agents are often added to the fermentation process despite having little knowledge about their impact on cell viability and productivity. However, antifoaming agents can affect the growth of both eukaryotic and prokaryotic organisms, changing surface properties, i.e., lipid contents, which results in permeability changes. These results emphasize the importance of understanding and optimizing the addition of an antifoam to the bioprocess [19]. Furthermore, the negative and positive effects of the antifoaming agents on the oxygen transfer in bioprocesses have been observed, for instance, silicone-based antifoaming agents were shown to have an adverse impact on mass transfer co-efficient, velocity, and hold up of gas inside the medium [23]. Koch et al. found that antifoaming agents without silicone oil did not significantly affect the oxygen transfer rate, while silicone oil significantly affected the process at the beginning, which gradually decreased with time [18]. In addition, some of the defoamers used in fermentations can significantly affect the membranes in downstream processing, i.e., reduction of the flux [17].

In order to limit the adverse effects of foams, a range of foam control technologies are discussed or are already in industrial fermentation. For example, adjusting media components and culture conditions can facilitate control of the foam formation [3, 24]. Using defoaming agents or mechanical equipment is the most common strategy to destroy pre-existing foams, thereby effectively avoiding foam accumulation [25, 26]. Additionally, it has been reported by Zaky et al. that in biofuel production, foam formation can be controlled using seawater [27, 28]. Although these methods of preventing foam have achieved positive results, there is still a need to optimize resource use (e.g., energy, chemicals) without compromising on foam control in industrial fermentation processes resulting in, i.e., final titer, high carbon yield, and productivity [29]. Here, thermal methods and ultrasound foam destruction, two unconventional physical defoaming procedures, are reviewed.

2.1 Thermal methods

Thermal defoaming, by increasing or lowering the temperature, may collapse foam. The foam will collapse at high temperatures as surface viscosity decreases and the solvent evaporates or because of chemical degradation of the foam-producing materials. Foam instability occurs by lowering the temperature due to a reduction in surface elasticity or freezing. Methods for foam destruction by temperature changes that have been used include the following: The foam has been collapsed through a hot wire placed in the foam or a heating tape wrapped around a glass column filled with foam [30], by passing steam or hot water through a condenser attached to the top of a foam column, and by reducing the temperature [30]. Thermal methods often function by using thermal stress to destroy the bubbles. The bubbles are compressed and expended by cooling and heating the foam, which eventually destroying them [31]. The disappearance of yield stress at high temperatures could be attributed to the liquid phase’s thermal thinning, which weakens the bubble structure’s strength [32]. The increase in temperatures reduced the consistency index of foam more than that of the base fluid. Consequently, the normalized consistency index of foam mainly decreased with the temperature [32]. Thermal methods have minimal applications in fermentations and may have drawbacks. For instance, the product cost increases due to high energy consumption, and the viscosity is decreased, affecting the texture and product [33,34,35,36]. Furthermore, the proper mechanism of action is not well known. For example, the potential of thermal foam control is reported by Wang et al. [37] and Junker et al. [2]. Table 1 lists some thermal methods used for foam destruction at various temperatures.

2.2 Ultrasonic defoaming

Ultrasonic methods of foam control were reported. Using a powerful ultrasonic transducer directly in the headspace of a foaming solution generates a shearing force on the surface of a bubble, which is produced due to the high acoustic pressure [43]. Airborne ultrasonic plate transducers have been used for defoaming by Rodriguez et al. [13]. Defoaming efficiency positively correlates with increasing ultrasonic intensity (at 10 W/cm2 to 5 cm3) and the treatment time. Ultrasonic treatment of two different types of foam was reported: a light and dry foam containing 0.71 g/L of surfactants and bubble sizes ranging from 0.2 to 10 mm, and a stable foam having 2.85 g/L of surfactants and bubble sizes ranging from 0.2 to 2 mm. The volume ratios were 0.02 and 0.005 liquid to foam, respectively. After the ultrasonic treatment with the applied intensity of 10 W/cm2 for 98 milliseconds, the heavier foam (2.85 g/l) had a defoaming volume of 5 cm3, compared to 13 cm3 for the lighter foam (0.71 g/l). The main benefit of airborne ultrasonic defoaming is that the device has no contact with the foam, thus keeping the product sterile and ensuring that the foam is clear of adjunct materials such as flammable liquids [43].

Furthermore, it is already well known that ultrasound treatment changes the foam’s properties by adjusting the molecular forces among EWP (Egg white protein) to form clusters because of protein aggregates jamming in the fluid interstices between bubbles and/or to the higher viscosity of the aqueous phase [44]. The static foam structure was destabilized using a higher intensity of ultrasound vibrations. The supply of ultrasound vibrations periodically was found to be more efficient than supplying continuously in terms of energy costs [45]. Up to now, several studies have been conducted to study the ultrasound effect on foaming during fermentation processes. Due to lacking quantitative data, the commercial use of ultrasound as a defoaming method has previously been limited, although it is an elegant alternative to mechanical and chemical foam breaking (e.g., for sterility reasons). Ultrasound has been used during fermentation for controlling foam, degassing, and jet fuel oil pumping [46].

As the source of ultrasound vibrations, an ultrasonic horn was also used for foam destruction. The ultrasonic horn generates ultrasonic vibrations that produce surface waves leading to high rates of local drainage at the foam surface, causing bubble collapse and foam destruction [45]. For the destruction of higher volumes of foam, the ultrasonic horn is very efficient, but the tip position of the horn plays a vital role. Periodic pulses of ultrasound vibrations would be a good step in the right direction in achieving significant savings in the operation cost and energy for the destruction of foam [45]. For nearly 70 years, ultrasound has been used as a method for defoaming (destruction of existing foam) and antifoaming (foam prevention). An ultrasonic vibration generator, most often piezoelectric, is used in this method which is placed in the air above the foam. The generated waves destroy the existing foams or work as an antifoam, which helps prevent foam formation. Foams constituted by large bubbles easily and quickly collapse at low-power ultrasound, whereas fine bubbles need a much higher intensity [47]. If the ultrasonic vibration source is placed inside the liquid, there will be only a little ultrasonic energy transfer to the foam. Therefore, this method is ineffective for foam destruction [47].

The ultrasound-based mechanisms for foam destruction still need to be better understood and studied, especially in non-aqueous foam [12]. The destruction of foam using ultrasound is attributed to the pressure of sound vibrations, the vibration resonance in bubbles, the turbulence produced by the sound vibrations, and the efficient drainage from capillary waves [36, 48]. By adjusting the power and acoustic intensity, the efficacy of ultrasound defoaming/antifoaming can be optimized [10]. Additionally, the variable frequency can be optimized, as bubbles resonance vibration could help in defoaming [10, 12]. In some cases, such as old foam, there is a foam boosting and stabilizing effect by the ultrasound vibrations, but it is still being determined when destabilizing and stabilizing occurs [31]. These unknown effects, combined with a general need for understanding ultrasound’s first principles on non-aqueous foam, make optimization difficult. As foam destabilization based on ultrasound is non-contaminating and non-invasive, this method is commonly used in food processing to prevent non-aqueous and aqueous foams [31]. See Table 2 for more details.

Whether used alone or in combination with other procedures, ultrasound processing can significantly improve food quality, e.g., to improve microbial inactivation in liquid foods, ultrasound is combined with other treatments such as pressure (manosonic), heat (thermosonic) or both [49,50,51].

The main applications of ultrasonic pretreatments in the food industry are freezing, cutting, homogenization, drying, defoaming and foaming, emulsification, filtration, and extraction. Ultrasonic defoaming methods are powerful because they do not interfere with production procedures and can easily be sterilized and cleaned, thus fulfilling industry food safety requirements [51]. However, ultrasonic defoaming systems have significant drawbacks related to noise (usually operating at a frequency in the hearing range), higher air generation capacity, controlled airflow, contamination, and energy consumption. Furthermore, ultrasound that uses high intensity and high power uses an intensity higher than 1 W/cm2 at a frequency range between 20 and 500 kHz, which is very disruptive and affects the chemical, mechanical, physical, and biochemical properties of the food fermentation process. For these reasons, physical foam breakers are preferred over chemical antifoaming agents to overcome the drawbacks (i.e., reaction inhibition, mass transfer rate reduction, toxicity, and effects on downstream processing). In stirred tank reactors, mechanical foam control significantly reduces the need for agitation power by the increase in the gas hold-up. Additionally, the ultrasonic method helps in the enzymatic hydrolysis reaction due to having the advantage of being a short-term measure, easy to use, and effectuating lower temperature changes [52,53,54].

3 Outlook and future perspectives

The increase in temperature shows a decrease in fluid viscosity, which affects the foam solution’s stability, and foamability. The viscosity reduction due to the thermal thinning of the liquid phase aggravates the drainage in the plateau borders and hence reduces the foaming. However, industrial application of thermal defoaming is limited due to high energy consumption and its effect on product yield. Antifoaming agents can also be added to the aqueous phase before the production process. However, this may also affect the product yield by reacting with the product. Furthermore, Progress in mechanical defoaming is mainly confined to new insights concerning the use of ultrasound. We here argue that defoaming using an ultrasonic technique can efficiently overcome challenges caused by excess foam formation in industry. The advantages of sonication are the ease of tool cleaning and effective non-contact operation. However, this technology needs further industrial trials to adapt to a broader range of applications. In addition, for further optimization, it is a prerequisite to deepen the basic knowledge about defoaming mechanisms and to quantify their influence on the overall process. Ultrasonic parameters used in defoaming should be adjusted to specific requirements. For instance, a comprehensive range of operating frequencies and energy inputs for current ultrasonic defoaming technology should be available to provide a more versatile solution to industrial problems. Future developments of this technology will depend on pursuing basic and applied research studies of the mechanisms of ultrasonic defoaming, and, as a result of these advancements, optimized ultrasonic systems may be developed catering to specific requirements. The future of ultrasonic defoaming relies on fundamental research on the triggering parameters of foam collapse. In addition, close collaboration between industrial end users and manufacturers of ultrasonic technology will be much welcome.

Data availability

All data analyzed during this review paper is within the article.

References

Höhler R, Cohen-Addad S. Rheology of Liquid Foam. J Phys Condens Matter. 2005;17:R1041. https://doi.org/10.1088/0953-8984/17/41/R01.

Junker B. Foam and its mitigation in fermentation systems. Biotechnol Prog. 2007;23:767–84. https://doi.org/10.1021/bp070032r.

Vardar-Sukan F. Foaming. Consequences, prevention and destruction. Biotechnol Adv. 1998;16:913–48. https://doi.org/10.1016/S0734-9750(98)00010-X.

Mohamad Pauzi S, Ahmad N, Yahya MF, Arifin MA. The effects of antifoam agent on dead end filtration process. IOP Conf Ser Mater Sci Eng. 2018;358:012038. 10.1088/1757-899X/358/1/012038.

Vardar-Sukan F. Effects of natural oils on foam collapse in bioprocesses. Biotechnol Lett. 1991;13:107–12. https://doi.org/10.1007/BF01030460.

Chayabutra C, Wu J, Ju LK. Rhamnolipid production by Pseudomonas aeruginosa under denitrification: effects of limiting nutrients and carbon substrates. Biotechnol Bioeng. 2001;72:25–33. https://doi.org/10.1002/1097-0290(20010105)72:1<25::AID-BIT4>3.0.CO;2-J

Sodagari M, Ju LK. Cells were a more important foaming factor than free rhamnolipids in fermentation of Pseudomonas aeruginosa E03-40 for high Rhamnolipid production. J Surfactants Deterg. 2014;17:573–82. https://doi.org/10.1007/s11743-013-1535-4.

Pelton RA. Review of antifoam mechanisms in fermentation. J Ind Microbiol Biotechnol. 2002;29:149–54. https://doi.org/10.1038/sj.jim.7000293.

Koop J, Merz J, Wilmshöfer R, Winter R, Schembecker G. Influence of thermally Induced structure changes in diluted β-Lactoglobulin solutions on their surface activity and behavior in foam fractionation. J Biotechnol. 2020;319:61–8. https://doi.org/10.1016/j.jbiotec.2020.05.011.

Pugh RJ, Foaming. Foam films, antifoaming and defoaming. Adv Colloid Interface Sci. 1996;64:67–142. https://doi.org/10.1016/0001-8686(95)00280-4.

Winterburn J. Sound methods of breaking foam. 2007; 65.

Garrett PR. Defoaming. Antifoams and mechanical methods. Curr Opin Colloid Interface Sci. 2015;20:81–91. https://doi.org/10.1016/j.cocis.2015.03.007.

Rodríguez G, Riera E, Gallego-Juárez JA, Acosta VM, Pinto A, Martínez I, Blanco A. Experimental study of defoaming by air-borne power ultrasonic technology. Phys Procedia. 2010;3:135–9. https://doi.org/10.1016/j.phpro.2010.01.019.

Winterburn JB, Martin PJ. Foam mitigation and exploitation in biosurfactant production. Biotechnol Lett. 2012;34:187–95. https://doi.org/10.1007/s10529-011-0782-6.

Tomtas P, Skwiot A, Sobiecka E, Obraniak A, Ławińska K, Olejnik TP. Bench tests and CFD simulations of liquid–gas phase separation modeling with simultaneous liquid transport and mechanical foam destruction. Energies. 2021;14:1740. https://doi.org/10.3390/en14061740.

Denkov ND. Mechanisms of foam destruction by oil-based antifoams. Langmuir. 2004;20:9463–505. https://doi.org/10.1021/la049676o.

Routledge SJ, Hewitt CJ, Bora N, Bill RM. Antifoam addition to shake flask cultures of recombinant pichia pastoris increases yield. Microb Cell Fact. 2011;10:1–11. https://doi.org/10.1186/1475-2859-10-17.

Koch V, Rüffer HM, Schügerl K, Innertsberger E, Menzel H, Weis J. Effect of antifoam agents on the medium and microbial cell properties and process performance in small and large reactors. Process Biochem. 1995;30:435–46. https://doi.org/10.1016/0032-9592(94)00029-8.

Routledge SJ. Beyond de-foaming. The effects of antifoams on bioprocess productivity. Comput Struct Biotechnol J. 2012;3:e201210001. https://doi.org/10.5936/csbj.201210014.

Kougias PG, Boe K, Tsapekos P, Angelidaki I. Foam suppression in overloaded manure-based biogas reactors using antifoaming agents. Bioresour Technol. 2014;153:198–205. https://doi.org/10.1016/j.biortech.2013.11.083.

Subramanian B, Miot A, Jones B, Klibert C, Pagilla KR. A full-scale study of mixing and foaming in Egg-Shaped anaerobic digesters. Bioresour Technol. 2015;192:461–70. https://doi.org/10.1016/j.biortech.2015.06.023.

Ganidi N, Tyrrel S, Cartmell E. Anaerobic digestion foaming causes—a review. Bioresour Technol. 2009;100:5546–54. https://doi.org/10.1016/j.biortech.2009.06.024.

Al-Masry WA. Effects of antifoam and Scale-up on operation of bioreactors. Chem Eng Process Process Intensif. 1999;38:197–201. https://doi.org/10.1016/S0255-2701(99)00014-8.

Wang H, Hu B, Liu J, Qian H, Xu J, Zhang W. Co-production of lipid, exopolysaccharide and single-cell protein by Sporidiobolus Pararoseus under ammonia nitrogen-limited conditions. Bioprocess Biosyst Eng. 2020;43:1403–14. https://doi.org/10.1007/s00449-020-02335-3.

Akter MM, Theary K, Kalkornsurapranee E, Prabhakar CS, Thaochan N (2021) The Effects of Methyl Eugenol, Cue Lure and Plant Essential Oils in Rubber Foam Dispenser for Controlling Bactrocera Dorsalis and Zeugodacus Cucurbitae. Asian J Agric Biol. 221: 1–11 doi: https://doi.org/10.35495/ajab.2020.10.530.

Jin Y, Li J, Wu S, Zhou F. Comparison of polyurethane foam dressing and hydrocolloid dressing in patients with pressure ulcers: a Randomized Controlled Trial Protocol. Medicine (Baltimore). 2021;100:e24165. https://doi.org/10.1097/MD.0000000000024165.

Zaky AS. Introducing a marine biorefinery system for the integrated. Processes. 2021;9:1841.

Zaky AS, Carter CE, Meng F, French CE. A preliminary life cycle analysis of bioethanol production using seawater in a coastal biorefinery setting. Processes. 2021;9:1399. https://doi.org/10.3390/pr9081399.

Guo YF, Wang MQ, Wang YL, Wang HT, Xu JZ. Controlling the formation of Foams in Broth to promote the co-production of microbial oil and Exopolysaccharide in Fed-Batch fermentation. Fermentation. 2022;8:68. https://doi.org/10.3390/fermentation8020068.

Lapja MK, Mechanical foam B. 1965; 6: 195–200.

Mawson R, Tongaonkar J, Bhagwat SS, Pandit AB. Airborne ultrasound for enhanced defoaming applications. Amsterdam: Elsevier Ltd; 2016. ISBN 9780081002988.

Sinha V, Ahmed R, Akhtar T, Shah S, Amani M. Rheology and hydraulics of polymer-based foams at elevated temperatures. J Pet Sci Eng. 2019;180:330–46. https://doi.org/10.1016/j.petrol.2019.05.047.

Bazukova ER, Politova TO, Khaziakhmetova ER, Medyakov AA, Kolcunova I. Destruction of thermal insulation and effectiveness of the thermal energy transfer system. E3S Web Conf 2019; 124:0–3. https://doi.org/10.1051/e3sconf/201912401030.

Vardar-Sukan F. Foaming and its control in Bioprocesses. In: Recent Advances in Biotechnology. Springer, Dordrecht. 1992; pp. 113–46. https://doi.org/10.1007/978-94-011-2468-3_6.

Takesono S, Onodera M, Yamagiwa K, Ohkawa A. Design and operation of rotating-disk foam‐breakers fitted to Tower fermenters. J Chem Technol Biotechnol. 1993;57:237–46. https://doi.org/10.1002/jctb.280570307.

Gallego-Juárez JA, Rodríguez G, Riera E, Cardoni A. Ultrasonic defoaming and debubbling in food processing and other applications. Power Ultrason Appl High Intensity Ultrasound. 2015; 793–814. https://doi.org/10.1016/B978-1-78242-028-6.00026-0.

Wang J, Cao P, Yin K. Structure design of and Experimental Research on a two-stage Laval Foam Breaker for Foam Fluid Recycling. J Environ Biol. 2015;36(Spec):829–36.

Alfaro N, Cano R, Fdz-Polanco F. Effect of thermal hydrolysis and ultrasounds pretreatments on foaming in anaerobic digesters. Bioresour Technol. 2014;170:477–82. https://doi.org/10.1016/j.biortech.2014.08.013.

Affes R, Palatsi J, Flotats X, Carrère H, Steyer JP, Battimelli A. Saponification pretreatment and solids recirculation as a new anaerobic process for the treatment of Slaughterhouse Waste. Bioresour Technol. 2013;131:460–7. https://doi.org/10.1016/j.biortech.2012.12.187.

Barjenbruch M, Kopplow O, Enzymatic. Mechanical and thermal pre-treatment of surplus sludge. Adv Environ Res. 2003;7:715–20. https://doi.org/10.1016/S1093-0191(02)00032-1.

Pal P, Shittu I, Oladunni J, Banat F. Defoaming of industrial lean methyldiethanolamine solution using ultrasonic waves and their kinetic studies. J Nat Gas Sci Eng. 2020;81:103478. https://doi.org/10.1016/j.jngse.2020.103478.

Joshi KS, Jeelani SAK, Blickenstorfer C, Naegeli I, Windhab EJ. Influence of fatty alcohol antifoam suspensions on foam stability. Colloids Surf Physicochem Eng Asp. 2005;263:239–49. https://doi.org/10.1016/j.colsurfa.2005.01.004.

Villamiel M, Riera E, García-Pérez JV. The use of ultrasound for drying, degassing and defoaming of foods. Innov Food Process Technol A Compr Rev. 2020; 415–38. https://doi.org/10.1016/b978-0-08-100596-5.22957-0.

Manzocco L, Panozzo A, Nicoli MC. Effect of ultraviolet processing on selected properties of egg white. Food Chem. 2012;135:522–7. https://doi.org/10.1016/j.foodchem.2012.05.028.

Dedhia AC, Ambulgekar PV, Pandit AB. Static foam destruction: role of ultrasound. Ultrason Sonochem. 2004;11:67–75. https://doi.org/10.1016/S1350-4177(03)00134-2.

Kordosky GA. Chemical processing. Min Eng. 1984;36:477–8. https://doi.org/10.1201/9780429288326-15.

Calhoun SGK, Chandran Suja V, Fuller GG. Foaming and antifoaming in non-aqueous liquids. Curr Opin Colloid Interface Sci. 2022;57. https://doi.org/10.1016/j.cocis.2021.101558.

Dollet B, Raufaste C. Rheology of aqueous foams. Comptes Rendus Phys. 2014;15:731–47. https://doi.org/10.1016/j.crhy.2014.09.008.

Earnshaw RG, Ultrasound. A new opportunity for food preservation. Ultrasound food Process. 1998. https://doi.org/10.1002/anie.201916748.

Lee DU, Heinz V. Effects of combination treatments of Nisin and high-intensity ultrasound with high pressure on the microbial inactivation in liquid whole egg. Science. 2003;4:395–402. https://doi.org/10.1016/S1466-8564.

Chavan P, Sharma P, Sharma SR, Mittal TC, Jaiswal AK. Application of high-intensity ultrasound to improve food processing efficiency: a review. Foods. 2022;11:122. https://doi.org/10.3390/foods11010122.

Cui P, Yang X, Liang Q, Huang S, Lu F, owusu J, Ren X, Ma H. Ultrasound-assisted preparation of ACE inhibitory peptide from milk protein and establishment of its in-situ real-time infrared monitoring model. Ultrason Sonochem. 2020;62:104859. https://doi.org/10.1016/j.ultsonch.2019.104859.

Gallego-Juárez JA, Rodriguez G, Acosta V, Riera E. Power ultrasonic transducers with extensive radiators for industrial processing. Ultrason Sonochem. 2010;17:953–64. https://doi.org/10.1016/j.ultsonch.2009.11.006.

Awad TS, Moharram HA, Shaltout OE, Asker D, Youssef MM. Applications of ultrasound in analysis, processing and quality control of food: a review. Food Res Int. 2012;48:410–27. https://doi.org/10.1016/j.foodres.2012.05.004.

Allen CH, Rudnick IA. Powerful high frequency. Siren. 1947; 19.

Dorsey AE. Control of foam during fermentation by the application of ultrasonic energy. J Biochem Microbiol Technol Eng. 1959;1:289–95. https://doi.org/10.1002/jbmte.390010305.

Boucher RMG, Weiner AL. Foam control by acoustic and aerodynamic means. Br Chem Eng. 8: 80–812. Pressure air. 1963, 599.

Sandor N, Stein HN. Foam destruction by ultrasonic vibrations. J Colloid Interface Sci. 1993;161:265–7.

Barigou M. Foam rupture by mechanical and vibrational methods. Chem Eng Technol. 2001;24:659–63. https://doi.org/10.1002/1521-4125(200106)24:6<659::AID-CEAT659>3.0.CO;2-1.

Ghildyal NP, Lonsane BK, Karanth NG. Foam control in submerged fermentation: state of the art. Adv Appl Microbiol. 1988;33:173–222. https://doi.org/10.1016/S0065-2164(08)70207-7.

Thünnesen J, Gatternig B, Delgado A. Ultrasonic effects on foam formation of fruit juices during bottling. Eng. 2021;2:356–71. https://doi.org/10.3390/eng2030023.

Funding

This work was supported by the national natural science China (Grant number 31961133017, 52073022). These Grants are part of the MIX-UP Project, which received funding within the framework of a joint NSFC and EU H2020 collaboration. In Europe, MIX-UP has received funding from the European Union’s Horizon 2020 research and innovation program under Grant Agreement No. 870294.

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Khan, S.S., Ullah, I., Wang, Q. et al. Thermal and ultrasound foam control in biotechnology: a mini-review. Discov Chem Eng 2, 7 (2022). https://doi.org/10.1007/s43938-022-00016-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43938-022-00016-z