Abstract

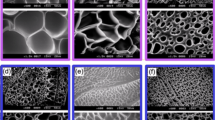

This work examines the addition of cationic polymers, cationic polyacrylamide (CPAM) and polyamide–amine–epichlorohydrin (PAE), to cellulose nanofibres to produce superior forming characteristics. The addition of 2 mg of high MW CPAM/g of nanofibres halved the drainage time to under 1 min at 0.1 wt% solids content due to increasing the floc size and the fibre forming a bulky and porous filter medium during drainage. The more open structure created in the wet state was partially preserved during the drying process, reducing the sheet density from 760 to 680 kg/m3, at the highest level of polymer addition. The addition of CPAM resulted in significant additional bridging between nanofibres, which then substantially increased the non-uniformity of the filter medium. PAE addition at 10 mg/g of micro fibrillated cellulose (MFC), also reduced drainage time, while increasing retention, but without changing the sheet uniformity. Wet strength increased continuously with PAE addition level, reaching 31.6 kN m/kg at the highest level of 20 mg of PAE/g of MFC.

Similar content being viewed by others

References

Ahola S, Österberg M, Laine J (2008) Cellulose nanofibrils—adsorption with poly (amideamine) epichlorohydrin studied by QCM-D and application as a paper strength additive. Cellulose 15(2):303–314. doi:10.1007/s10570-007-9167-3

Andresen M, Stenius P (2007) Water-in-oil emulsions stabilized by hydrophobized microfibrillated cellulose. J Dispers Sci Technol 28(6):837–844

Berglund LA, Peijs T (2010) Cellulose biocomposites—from bulk moldings to nanostructured systems. MRS Bull 35(03):201–207. doi:10.1557/mrs2010.652

Celzard A, Fierro V, Pizzi A (2008) Flocculation of cellulose fibre suspensions: the contribution of percolation and effective-medium theories. Cellulose 15(6):803–814

Fukuzumi H, Saito T, Iwata T, Kumamoto Y, Isogai A (2008) Transparent and high gas barrier films of cellulose nanofibers prepared by TEMPO-mediated oxidation. Biomacromolecules 10(1):162–165. doi:10.1021/bm801065u

Henriksson M, Berglund LA, Isaksson P, Lindstrom T, Nishino T (2008) Cellulose nanopaper structures of high toughness. Biomacromolecules 9(6):1579–1585. doi:10.1021/bm800038n

Hubbe MA, Heitmann JA (2007) Review of factors affecting the release of water from cellulosic fibers during paper manufacture. Bioresources 2(3):500–533

Jonoobi M, Mathew AP, Oksman K (2012) Producing low-cost cellulose nanofiber from sludge as new source of raw materials. Ind Crops Prod 40:232–238. doi:10.1016/j.indcrop.2012.03.018

Joutsimo OP, Asikainen S (2013) Effect of fiber wall pore structure on pulp sheet density of softwood kraft pulp fibers. BioResources 8(2):2719–2737

Li T-Q, Ödberg L (1996) Flow properties of cellulose fiber suspensions flocculated by cationic polyacrylamide. Colloids Surf A 115:127–135

Martinez DM, Buckley K, Jivan S, Lindstrom A, Thiruvengadaswamy R, Olson JA, Ruth TJ, Kerekes RJ (2001) Characterizing the mobility of papermaking fibres during sedimentation. In: Baker CF (ed) The Science of Papermaking, Transactions of the 12th Fundamental Reseach Symposium, Oxford. The Pulp and Paper Fundamental Research Society, Bury, Lancaster, pp 225–254

Nakagaito AN, Yano H (2005) Novel high-strength biocomposites based on microfibrillated cellulose having nano-order-unit web-like network structure. Appl Phys A Mater Sci Process 80(1):155–159. doi:10.1007/s00339-003-2225-2

Nogi M, Iwamoto S, Nakagaito AN, Yano H (2009) Optically transparent nanofiber paper. Adv Mater 21(16):1595–1598. doi:10.1002/adma.200803174

Norman RJ (1965) Dependence of sheet properties on formation and forming variables, in consolidation of the paper web. In: Bolam F (ed) Transactions of the Third Fundamental Research Symposium, Cambridge, pp 269–298

Operating manual—The Paper Perfect, OpTest, Canada 2005

Roberts JC (1996) The chemistry of paper. The Royal Society of Chemistry, Cambridge

Sehaqui H, Liu A, Zhou Q, Berglund LA (2010) Fast preparation procedure for large, flat cellulose and cellulose/inorganic nanopaper structures. Biomacromolecules 11(9):2195–2198. doi:10.1021/bm100490s

Seo YB, Choi CH, Jeon Y (2003) Effect of mechanical pretreatment on fibre properties. Appita J 56(5):371–375

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17(3):459–494. doi:10.1007/s10570-010-9405-y

Spence K, Venditti R, Rojas O, Habibi Y, Pawlak J (2010) The effect of chemical composition on microfibrillar cellulose films from wood pulps: water interactions and physical properties for packaging applications. Cellulose 17(4):835–848. doi:10.1007/s10570-010-9424-8

Su J, Mosse WJ, Sharman S, Batchelor W, Garnier G (2013) Effect of tethered and free microfibrillated cellulose (MFC) on the properties of paper composites. Cellulose 20:1925–1935. doi:10.1007/s10570-013-9955-x

Swerin A (1998) Rheological properties of cellulosic fibre suspensions flocculated by cationic polyacrylamides. Colloids Surf A 133(3):279–294. doi:10.1016/S0927-7757(97)00212-4

Syverud K, Stenius P (2009) Strength and barrier properties of MFC films. Cellulose 16(1):75–85. doi:10.1007/s10570-008-9244-2

Taipale T, Österberg M, Nykänen A, Ruokolainen J, Laine J (2010) Effect of microfibrillated cellulose and fines on the drainage of kraft pulp suspension and paper strength. Cellulose 17(5):1005–1020. doi:10.1007/s10570-010-9431-9

Varanasi S, Batchelor W (2013) Rapid preparation of cellulose nanofibre sheet. Cellulose 20(1):211–215. doi:10.1007/s10570-012-9794-1

Varanasi S, He R, Batchelor W (2013) Estimation of cellulose nanofibre aspect ratio from measurements of fibre suspension gel point. Cellulose 20(4):1885–1896. doi:10.1007/s10570-013-9972-9

Zhang L, Batchelor W, Varanasi S, Tsuzuki T, Wang X (2012) Effect of cellulose nanofiber dimensions on sheet forming through filtration. Cellulose 19(2):561–574. doi:10.1007/s10570-011-9641-9

Zhao YQ (2003) Correlations between floc physical properties and optimum polymer dosage in alum sludge conditioning and dewatering. Chem Eng J 92(1–3):227–235. doi:10.1016/S1385-8947(02)00253-X

Zimmermann T, Pöhler E, Geiger T (2004) Cellulose fibrils for polymer reinforcement. Adv Eng Mater 6(9):754–761. doi:10.1002/adem.200400097

Acknowledgments

The authors would like to acknowledge the facilities used at the Monash Center for Electron Microscopy and Xi-Ya Fang for her assistance on SEM. We would also like to acknowledge Jielong Su for experimental help and for providing the softwood sheet, as well as Scot Sharman and Hui Hui for providing the hardwood sheet. We would like thank Scot Sharman for providing information about PAE charge density. We would like to thank Jane Moodie for her assistance on manuscript preparation. We acknowledge the financial support of the Australian Research Council, Nopco Australasia, and Visy through Linkage Project Grants LP0990526. Swambabu Varanasi thanks Monash University for a MGS and FEIPRS Scholarship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Varanasi, S., Batchelor, W. Superior non-woven sheet forming characteristics of low-density cationic polymer-cellulose nanofibre colloids. Cellulose 21, 3541–3550 (2014). https://doi.org/10.1007/s10570-014-0370-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0370-8