Abstract

Cellulose nanofibre aspect ratio controls the properties of sheets made from nanofibres and processing conditions, but aspect ratio is very difficult to measure. In this paper, aspect ratio was estimated from the gel point of a cellulose nanofibre suspension, the solids concentration at which the transition from a dilute to a semi-dilute suspension occurs. Four batches of cellulose nanofibres were tested. Two were produced from softwood fibres using ball milling. Commercially produced microfibrillated cellulose material was also used, both in as supplied form and after removal of the larger fibres by filtering. The average diameter measured from SEM images of fibres ranged from 33 to 73 nm. One sample was too heavily treated and an average dimension could not be measured. The gel-point was measured both from the height of a layer of cellulose nanofibres sedimented from a dilute suspension or from the lowest solids concentration at which a yield stress could be measured using a vane rheometer. The two methods were closely in agreement for all samples. Aspect ratio was then calculated using either the effective medium (EMT) or crowding number (CN) theories. Aspect ratio calculated with an assumed fibre density of 1,500 kg/m3, using the CN theory ranged from 155 to 60. Use of the EMT theory reduced the calculated aspect ratio by between 11 and 23 %. Reducing the assumed density in suspension from 1,500 to 1,166 kg/m3 reduced the calculated aspect ratio by 12–14 %. The heavily treated sample had by far the lowest aspect ratio.

Similar content being viewed by others

References

Ahola S, Österberg M, Laine J (2008) Cellulose nanofibrils—adsorption with poly(amideamine) epichlorohydrin studied by QCM-D and application as a paper strength additive. Cellulose 15(2):303–314. doi:10.1007/s10570-007-9167-3

Celzard A, Marêché JF, Payot F (2000) Simple method for characterizing synthetic graphite powders. J Phys D Appl Phys 33(12):1556

Celzard A, Fierro V, Pizzi A (2008) Flocculation of cellulose fibre suspensions: the contribution of percolation and effective-medium theories. Cellulose 15(6):803–814. doi:10.1007/s10570-008-9229-1

Celzard A, Fierro V, Kerekes R (2009) Flocculation of cellulose fibres: new comparison of crowding factor with percolation and effective-medium theories. Cellulose 16(6):983–987. doi:10.1007/s10570-009-9314-0

Czaja WK, Young DJ, Kawecki M, Brown RM (2006) The future prospects of microbial cellulose in biomedical applications. Biomacromolecules 8(1):1–12. doi:10.1021/bm060620d

Dalpke B, Kerekes RJ (2005) The influence of fibre properties on the apparent yield stress of flocculated pulp suspensions. J Pulp Pap Sci 31(1):39–43

Derakhshandeh B, Kerekes RJ, Hatzikiriakos SG, Bennington CPJ (2011) Rheology of pulp fibre suspensions: a critical review. Chem Eng Sci 66(15):3460–3470. doi:10.1016/j.ces.2011.04.017

Dufresne A, Dupeyre D, Vignon MR (2000) Cellulose microfibrils from potato tuber cells: processing and characterization of starch-cellulose microfibril composites. J Appl Polym Sci 76(14):2080–2092

Dzuy NQ, Boger DV (1985) Direct yield stress measurement with the vane method. J Rheol 29(3):335–347

Eichhorn S, Dufresne A, Aranguren M, Marcovich N, Capadona J, Rowan S, Weder C, Thielemans W, Roman M, Renneckar S, Gindl W, Veigel S, Keckes J, Yano H, Abe K, Nogi M, Nakagaito A, Mangalam A, Simonsen J, Benight A, Bismarck A, Berglund L, Peijs T (2010) Review: current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45(1):1–33. doi:10.1007/s10853-009-3874-0

Henriksson M, Berglund LA, Isaksson P, Lindström T, Nishino T (2008) Cellulose nanopaper structures of high toughness. Biomacromolecules 9(6):1579–1585. doi:10.1021/bm800038n

Ishii D, Saito T, Isogai A (2011) Viscoelastic evaluation of average length of cellulose nanofibers prepared by TEMPO-mediated oxidation. Biomacromolecules 12(3):548–550. doi:10.1021/bm1013876

Jakob HF, Fengel D, Tschegg SE, Fratzl P (1995) The elementary cellulose fibril in picea abies: comparison of transmission electron microscopy, small-angle X-ray scattering, and wide-angle X-ray scattering results. Macromolecules 28(26):8782–8787. doi:10.1021/ma00130a010

Janarthanan S, Sain M (2006) Isolation of cellulose microfibrils—an enzymathic approach. Bioresources 1(2):176–188

Karppinen A, Vesterinen A-H, Saarinen T, Pietikäinen P, Seppälä J (2011) Effect of cationic polymethacrylates on the rheology and flocculation of microfibrillated cellulose. Cellulose 18(6):1381–1390. doi:10.1007/s10570-011-9597-9

Kerekes RJ, Schell CJ (1992) Characterization of fibre flocculation regimes by a crowding factor. J Pulp Pap Sci 18(1):J32–J38

Kerekes RJ, Soszynski RM, Tam Doo PA (1985) The flocculation of pulp fibres. In: Proceedings of the 8th fundamental research symposium, Oxford, England. Mechanical Engineering Publications, pp 265–310

Kropholler HW, Sampson WW (2001) The effect of fibre length distribution on suspension crowding. J Pulp Pap Sci 27(09):301–305

Lasseuguette E, Roux D, Nishiyama Y (2008) Rheological properties of microfibrillar suspension of TEMPO-oxidized pulp. Cellulose 15(3):425–433

Liddel PV, Boger DV (1996) Yield stress measurements with the vane. J Nonnewton Fluid Mech 63(2–3):235–261. doi:10.1016/0377-0257(95)01421-7

Malcolm Brown R Jr, Saxena IM, Kudlicka K (1996) Cellulose biosynthesis in higher plants. Trends Plant Sci 1(5):149–156. doi:10.1016/S1360-1385(96)80050-1

Martinez DM, Buckley K, Jivan S, Lindstrom A, Thiruvengadaswamy R, Olson JA, Ruth TJ, Kerekes RJ (2001) Characterizing the mobility of papermaking fibres during sedimentation. In: Baker CF (ed) The science of papermaking, transactions of the 12th fundamental research symposium, Oxford. The Pulp and Paper Fundamental Research Society, Bury, Lancaster, UK, pp 225–254

Mosse WKJ, Boger DV, Garnier G (2012a) Avoiding slip in pulp suspension rheometry. J Rheol 56(6):1517–1533

Mosse WKJ, Boger DV, Simon GP, Garnier G (2012b) Effect of cationic polyacrylamides on the interactions between cellulose fibers. Langmuir 28(7):3641–3649. doi:10.1021/la2049579

Nogi M, Iwamoto S, Nakagaito AN, Yano H (2009) Optically transparent nanofiber paper. Adv Mater 21(16):1595–1598. doi:10.1002/adma.200803174

Perkins EL, Batchelor WJ (2012) Water interaction in paper cellulose fibres as investigated by NMR pulsed field gradient. Carbohydr Polym 87:361–367. doi:10.1016/j.carbpol.2011.07.065

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17(3):459–494. doi:10.1007/s10570-010-9405-y

Taniguchi T, Okamura K (1998) New films produced from microfibrillated natural fibres. Polym Int 47(3):291–294. doi:10.1002/(sici)1097-0126(199811)47:3<291:aid-pi11>3.0.co;2-1

Varanasi S, Batchelor W (2013) Rapid preparation of cellulose nanofibre sheet. Cellulose 20(1):211–215. doi:10.1007/s10570-012-9794-1

Varanasi S, Chiam HH, Batchelor WJ (2012) Application and interpretation of zero and short-span testing on nanofibre sheet materials. Nord Pulp Pap Res J 27(2):343–352

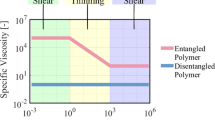

Xu J, Chatterjee S, Koelling KW, Wang Y, Bechtel SE (2005) Shear and extensional rheology of carbon nanofiber suspensions. Rheol Acta 44(6):537–562. doi:10.1007/s00397-005-0436-5

Zhang L, Batchelor W, Varanasi S, Tsuzuki T, Wang X (2012) Effect of cellulose nanofiber dimensions on sheet forming through filtration. Cellulose 19(2):561–574. doi:10.1007/s10570-011-9641-9

Acknowledgments

The authors would like to acknowledge the facilities used with the Monash Center for Electron Microscopy. The authors would like to thank Wade Mosse and Mae-Gene Yew for assisting us with rheological measurements and Liyuan Zhang and A.Prof. Takuya Tsuzuki for helping us to develop the method for separating nanofibres from MFC sample. We acknowledge the financial support of the Australian Research Council, Australian Paper, Nopco Australasia, Norske Skog, SCA Hygiene Australasia and Visy through Linkage Project Grants LP0989823 and LP0990526. Swambabu Varanasi thanks Monash University for a MGS and FEIPRS Scholarship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Varanasi, S., He, R. & Batchelor, W. Estimation of cellulose nanofibre aspect ratio from measurements of fibre suspension gel point. Cellulose 20, 1885–1896 (2013). https://doi.org/10.1007/s10570-013-9972-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-013-9972-9