Abstract

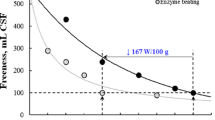

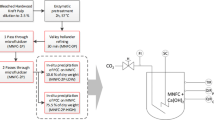

Different types of microfibrillated cellulose (MFC) and fines suspensions were produced, characterized, and then added to a papermaking pulp suspension. High and medium molar mass cationic polyelectrolytes were used as fixatives. The drainage behavior of the pulp suspensions with additives were evaluated against the strength properties of hand sheets made thereof. The effects of salt concentration, pH, fixative type, dosage and type of fibrillar material on drainage were examined. All the MFC and fines samples produced had clearly different properties due to their dissimilar production methods, and they also introduced specific responses on the measured drainage and paper strength. Generally, the addition of MFC decreased the drainage rate of pulp suspension and increased the strength of paper. However, it was shown that by optimum selection of materials and process conditions an enhancement of the strength properties could be achieved without simultaneously deteriorating the drainage.

Similar content being viewed by others

References

Aaltio EA (1962) The effect of highly beaten birch pulp fraction on the properties of kraft paper. Paperi Puu 44:217–222

Ahola S (2008) Properties and interfacial behaviour of cellulose nanofibrils. Doctoral dissertation, Helsinki University of Technology, TKK, Espoo, Finland

Ahola S, Österberg M, Laine J (2008a) Cellulose nanofibrils adsorption with poly(amide-amine) epichlorohydrin studied by QCM-D and application as a paper strength additive. Cellulose 15:303–314

Ahola S, Salmi J, Johansson L-S, Laine J, Österberg M (2008b) Model films from native cellulose nanofibrils, preparation, swelling, and surface interactions. Biomacromolecules 9:1273–1282

Alén R (2000) Structure and chemical composition of wood. In: Stenius P, Pakarinen H (eds) Papermaking science and technology, book 3 forest products chemistry. Fapet Oy, Helsinki, pp 12–57

Andersson K, Sandström A, Ström K, Barla P (1986) The use of cationic starch and colloidal silica to improve the drainage characteristics of kraft pulps. Nord Pulp Pap Res J 1:26–30

Andresen M, Johansson L-S, Tanem BS, Stenius P (2006) Properties and characterization of hydrophobized microfibrillated cellulose. Cellulose 13:665–677

Aulin C, Ahola S, Josefsson P, Nishino T, Hirose Y, Österberg M, Wågberg L (2009) Nanoscale cellulose films with different crystallinities and mesostructures-their surface properties and interaction with water. Langmuir 25:7675–7685

Berglund L (2005) Cellulose-based nanocomposites. In: Mohanty AK, Misra M, Drzal LT (eds) Natural fibers, biopolymers, and biocomposites. CRC Press LLC, Boca Raton, FL, USA, pp 807–832

Borsa J, Racz I, Obendorf SK, Bodor G (2000) Slight carboxymethylation of cellulose. Lenzinger Ber 79:18–24

Britt KW, Unbehend JE, Shridharan R (1986) Observations on water removal in papermaking. Tappi J 69:76–79

Buléon A, Colonna P, Planchot V, Ball S (1998) Starch granules: structure and biosynthesis. Int J Biol Macromol 23:85–112

Campbell WB (1959) The mechanism of bonding. Tappi 42:999–1001

Carlsson G, Kolseth P, Lindström T (1983) Polyelectrolyte swelling behavior of chlorite delignified spruce wood fibers. Wood Sci Technol 17:69–73

Cole CA, Hubbe MA, Heitmann JA (2008) Water release from fractionated stock suspensions. Part 1-effects of the amounts and types of fiber fines. Tappi J 7:28–32

Davies LM, Harris PJ (2003) Atomic force microscopy of microfibrils in primary cell walls. Planta 217:283–289

Ding S-Y, Himmel M (2006) The maize primary cell wall microfibril: a new model derived from direct visualization. J Agric Food Chem 54:597–606

Donnan FG, Harris AB (1911) The osmotic pressure and conductivity of aqueous solutions of Congo-red, and reversible membrane equilibria. J Chem Soc 99:1554–1577

Eichhorn SJ, Dufresne A, Aranguren M, Marcovich NE, Capadona JR, Rowan SJ, Weder C, Thielemans W, Toman M, Renneckar S, Gindl W, Veigel S, Keckes J, Yano H, Abe K, Nogi M, Nakagaito AN, Mangalam A, Simonsen J, Benight AS, Bismarck A, Berglund LA, Peijs T (2010) Review: current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45:1–33

Eklund D, Lindström T (1991) Paper chemistry an introduction. DT Paper Science, Grankulla, Finland

Eriksen Ø, Syverud K, Gregersen Ø (2008) The use of microfibrillated cellulose produced from kraft pulp as strength enhancer in TMP paper. Nord Pulp Pap Res J 23:299–304

Fors C (2000) The effect of fibre charge on web consolidation in papermaking. Licentiate thesis. Royal Institute of Technology, Stockholm, Sweden

Grignon J, Scallan AM (1980) Effect of pH and neutral salts upon the swelling of cellulose gels. J Appl Polym Sci 25:2829–2843

Henriksson M, Berglund LA, Isaksson P, Lindström T, Nishino T (2008) Cellulose Nanopaper Structures of High Toughness. Biomacromolecules 9:1579–1585

Herrick FW, Casebier RL, Hamilton JK, Sandberg KR (1983) Microfibrillated cellulose: morphology and accessibility. J App Polym Sci Symp (Proc Cellul Conf, 9th, 1982, Part 2) 37:797–813

Heux L, Dinand E, Vignon MR (1999) Structural aspects in ultrathin cellulose microfibrils followed by 13C CP-MAS NMR. Carbohydr Polym 40:115–124

Hubbe MA, Heitmann JA (2007) Review of factors affecting the release of water from cellulosic fibers during paper manufacture. Bioresourses 2:500–533

Jakob HF, Fengel D, Tschegg SE, Pratzl P (1995) The elementary cellulose fibril in picea abies: comparison of transmission electron microscopy, small-angle X-ray scattering, and wide-angle x-ray scattering results. Macromolecules 28:8782–8787

Kajanto I (1998) Structural mechanics of paper and board. In: Niskanen K (ed) Papermaking science and technology, book 16 paper physics. Fapet Oy, Helsinki, pp 193–221

Ketola H, Andersson T (1999) Dry strength additives. In: Neimo L (ed) Papermaking Science and Technology, Book 4 Papermaking Chemistry. Fapet Oy, Helsinki, pp 269–287

Krogerus B, Eriksson L, Sundberg A, Mosbye J, Ahlroth A, Östlund I, Sjöström L (2002) Fines in closed circuits—Final report. SCAN Forsk report 740. (http://www.nordicinnovation.net/_img/Fines-final_report.doc, in 23.02.2010)

Laine J, Lövgren L, Stenius P, Sjöberg S (1994a) Potentiometric titration of unbleached kraft cellulose fibre surfaces. Colloids Surf A 88:277–287

Laine J, Stenius P (1997) Effect of charge on the fiber and paper properties of bleached industrial kraft pulps. Paperi Puu 79:257–266

Laine J, Stenius P, Carlsson G, Ström G (1994b) Surface characterization of unbleached kraft pulps by means of ESCA. Cellulose 1:145–160

Lin T, Yin X, Retulainen E, Nazhad MM (2007) Effect of chemical pulp fines on filler retention and paper properties. Appita J 60:469–473

Lindström T (1992) Chemical factors affecting the behavior of fibers during papermaking. Nord Pulp Pap Res J 7:181–192

Lindström T, Carlsson G (1982) The effect of chemical environment on fiber swelling. Sven Papperstidn 85:R14–R20

Lindström T, Wågberg L (1983) Effects of pH and electrolyte concentration on the adsorption of cationic polyacrylamides on cellulose. Tappi J 66:83–85

Lobben T (1977) Effects of the fines on the paper strength properties of chemical pulps. Nor Skogind 31:93–97

Lobben T (1978) On the influence of the pulp components on the shrinkage and elongation of paper. Nor Skogind 32:80–84

Lumiainen J (1998) Refining of chemical pulp. In: Paulapuro H (ed) Papermaking science and technology, book 8 papermaking part 1, stock preparation and wet end. Fapet Oy, Helsinki

Manners DJ (1989) Recent developments in our understanding of amylopectin structure. Carbohydr Polym 11:87–112

Myllytie P (2009) Interactions of polymers with fibrillar structure of cellulose fibres: a new approach to bonding and strength in paper. Doctoral dissertation. Helsinki University of Technology, TKK, Espoo, Finland

Nagakaito AN, Yano H (2005) Novel high-strength biocomposites based on microfibrillated cellulose having nano-order-unit web-like network structure. Appl Phys A 80:155–159

Neale SM (1929) The swelling of cellulose and its affinity relations with aqueous solutions. J Textile Inst 20:T373–T400

Niskanen K, Kärenlampi P (1998) In-plane tensile properties. In: Niskanen K (ed) Papermaking science and technology, book 16 paper physics. Fapet Oy, Helsinki, pp 139–191

Norell M, Johansson K, Persson M (1999) Retention and drainage. In: Neimo L (ed) Papermaking science and technology, book 4 papermaking chemistry. Fapet Oy, Helsinki, pp 43–81

Pääkkö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O, Lindström T (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8:1934–1941

Pääkkö M, Vapaavuori J, Silvennoinen R, Kosonen H, Ankerfors M, Lindström T, Berglund LA, Ikkala O (2008) Long and entangled native cellulose I nanofibers allow flexible aerogels and hierarchically porous templates for functionalities. Soft Matter 4:2492–2499

Reid IJD, Daul GC (1947) The partial carboxymethylation of cotton to obtain swellable fibers. Text Res J 17:554–561

Retulainen E, Luukko K, Fagerholm K, Pere J, Laine J, Paulapuro H (2002) Papermaking quality of fines from different pulps—the effect of size, shape and chemical composition. Appita J 55:457–467

Retulainen E, Moss P, Nieminen K (1993a) Effect of fines on the properties of fibre networks. In: Baker CF (ed) Products of papermaking, Vol. 2, Transactions of the 10th fundamental research symposium September 1993. Pira Int, Oxford, pp 727–769

Retulainen E, Nieminen K (1996) Fibre properties as control variables in papermaking? Part 2. Strengthening interfibre bonds and reducing grammage. Paperi Puu 78:305–312

Retulainen E, Nieminen K, Nurminen I (1993b) Enhancing strength properties of kraft and CTMP fibre networks. Appita 46:33–38

Retulainen E, Niskanen K, Nilsen N (1998) Fibers and bonds. In: Niskanen K (ed) Papermaking science and technology, book 16 paper physics. Fapet Oy, Helsinki, pp 55–87

Reynolds WF (1980) Dry strength additives. Tappi press, Atlanta, GA, USA

Salmi J (2009) Surface interactions in polyelectrolyte-cellulose systems and their implications for flocculation mechanisms. Doctoral dissertation. Helsinki University of Technology, TKK, Espoo, Finland

Salmi J, Nypelö T, Österberg M, Laine J (2009) Layer structures formed by silica nanoparticles and cellulose nanofibrils with cationic polyacrylamide (C-PAM) on cellulose surface and their influence on interactions. Bioresourses 4:602–625

Scallan AM, Grignon J (1979) The effect of cations on pulp and paper properties. Sven Papperstidn 82:40–47

Shirazi M, Van de Ven TGM, Garnier G (2003) Adsorption of modified starches on pulp fibers. Langmuir 19:10835–10842

Sjöström E (1989) The origin of charge on cellulosic fibers. Nord Pulp Pap Res J 4:90–93

Somerville C, Bauer S, Brininstool G, Facette M, Hamann T, Milne J, Osborne E, Paredez A, Persson S, Raab T, Vorwerk S, Youngs H (2004) Toward a systems approach to understanding plant cell walls. Science 306:2206–2211

Swerin A, Ödberg L, Lindström T (1990) Deswelling of hardwood kraft pulp fibres by cationic polymers. The effect of wet pressing and sheet properties. Nord Pulp Pap Res J 5:188–196

Taniguchi T, Okamura K (1998) New films produced from microfibrillated natural fibers. Polym Int 47:291–294

Tatsumi D, Ishioka S, Matsumoto T (2002) Effect of fiber concentration and axial ratio on the rheological properties of cellulose fiber suspensions. J Soc Rheol Japan 30:27–32

Towers M, Scallan AM (1996) Predicting the ion-exchange of kraft pulps using Donnan theory. J Pulp Pap Sci 22:J332–J339

Turbak AF, Snyder FW, Sandberg KR (1983) Microfibrillated cellulose, a new cellulose product: properties, uses, and commercial potential. J Appl Polym Sci 37:815–827

Unbehend JE, Britt KW (1982) Retention, drainage, and sheet consolidation. Ind Eng Chem Prod Res Dev 21:150–153

Van de Steeg HGM (1992) Cationic starches on cellulose surfaces: a study of polyelectrolyte adsorption. Ph.D. thesis. University of Wageningen, The Netherlands

Van de Ven T (2000) A model for the adsorption of polyelectrolytes on pulp fibers: relation between fiber structure and polyelectrolyte properties. Nord Pulp Pap Res J 15:494–501

Wågberg L, Decher G, Norgren M, Lindström T, Ankerfors M, Axnäs K (2008) The build-up of polyelectrolyte multilayers of microfibrillated cellulose and cationic polyelectrolytes. Langmuir 24:784–795

Wågberg L, Winter L, Ödberg L, Lindström T (1987) On the charge stoichiometry upon adsorption of a cationic polyelectrolyte on cellulosic materials. Colloids Surf 27:163–173

Walecka JA (1956) An investigartion of low degree of substitution carboxymethylcelluloses. Tappi 39:458–463

Xu Y, Pelton R (2005) A new look at how fines influence the strength of filled papers. J Pulp Pap Sci 31:147–152

Yano H, Nakahara S (2004) Bio-composites produced from plant microfiber bundles with a nanometer unit web-like network. J Mater Sci 39:1635–1638

Zimmermann T, Bordeanu N, Strub E (2010) Properties of nanofibrillated cellulose from different raw materials and its reinforcement potential. Carbohydr Polym 79:1086–1093

Acknowledgments

The authors are grateful for the financial support from UPM-Kymmene Corporation. The work was a part of the Nanosellu I –project established by the Finnish Centre for Nanocellulosic Technologies. Dr. J. Campbell is thanked for his linguistic support. We also thank the laboratory staff and research colleagues at Aalto University School of Science and Technology and at VTT Technical Research Centre of Finland for their skilful assistance, observations and co-operation throughout the work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Taipale, T., Österberg, M., Nykänen, A. et al. Effect of microfibrillated cellulose and fines on the drainage of kraft pulp suspension and paper strength. Cellulose 17, 1005–1020 (2010). https://doi.org/10.1007/s10570-010-9431-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-010-9431-9