Abstract

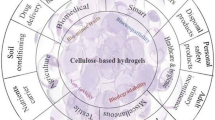

Cellulose is the most abundant polysaccharide on Earth. It can be obtained from a vast number of sources, e.g. cell walls of wood and plants, some species of bacteria, and algae, as well as tunicates, which are the only known cellulose-containing animals. This inherent abundance naturally paves the way for discovering new applications for this versatile material. This review provides an extensive survey on cellulose and its derivatives, their structural and biochemical properties, with an overview of applications in tissue engineering, wound dressing, and drug delivery systems. Based on the available means of selecting the physical features, dimensions, and shapes, cellulose exists in the morphological forms of fiber, microfibril/nanofibril, and micro/nanocrystalline cellulose. These different cellulosic particle types arise due to the inherent diversity among the source of organic materials or due to the specific conditions of biosynthesis and processing that determine the consequent geometry and dimension of cellulosic particles. These different cellulosic particles, as building blocks, produce materials of different microstructures and properties, which are needed for numerous biomedical applications. Despite having great potential for applications in various fields, the extensive use of cellulose has been mainly limited to industrial use, with less early interest towards the biomedical field. Therefore, this review highlights recent developments in the preparation methods of cellulose and its derivatives that create novel properties benefiting appropriate biomedical applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The increasing demand for bio-based materials is gaining more attention for immediate applications in biomedical fields such as tissue engineering, wound healing, and drug delivery. Polysaccharides, long-chain biopolymeric carbohydrate molecules primarily composed of monosaccharide units, are bio-based materials that combine immense potential in biomedical applications with the unique beneficial features of natural polymers in contrast with synthetic polymers. Among several kinds of polysaccharides, cellulose and chitin are the most important natural biopolymers based on their broad distribution in nature. Cellulose is synthesized mostly in wood and plants, whereas chitin is obtained from lower animals (Barikani et al. 2014; Moon et al. 2011). In this review paper, we focus on the characteristics, preparation methods, and application of cellulose and its derivatives in the biomedical field.

Cellulose is an unbranched, natural polymer composed of repeating glucose units (C6H10O5)n (French 2017), and is considered as the most profuse organic material and polysaccharide on Earth. This biodegradable polymer is mostly found in nature in the form of microfibrils in the cell walls of wood and plant, algae tissues, and membrane of epidermal cells of tunicate. It is also synthesized by bacteria in the form of nanofiber networks. Cellulosic materials exploit hierarchical structure design that spans from nanoscale to macroscopic dimensions in the form of fibril aggregates, fibrils, nanocrystallite, and nanoscale disordered domains (Fig. 1a,b). Cellulose features an intricate multi-level structure, built up of bundles/aggregates of superfine fibrils. The superfine fibril contains several cellulose chains (Fig. 1a). Each fibril is composed of repeating large ordered (crystalline) domains and small disordered (amorphous) domains with a cross-sectional dimension ranging from 2 to 20 nm, depending on the source of synthesis (Fig. 1b) (Ioelovich 2008). A single cellulose chain passes through many crystalline and disordered domains, while strong β 1 → 4 glycosidic bonds link single cellulose chain units. Cellulose chains are remarkably aligned in the crystalline domain of a cellulose fibril (Klemm et al. 2018, 2011).

Schematic illustration of the microstructure of a cellulosic fiber. a Plant/wood fiber, fibril aggregate, and nanofibril (containing cellulose chains) associated with lignin and hemicellulose. b Cross section and longitudinal section showing the crystalline and disordered regions of a cellulose nanofibril embedded in lignin and hemicellulose matrix

Cellulose and its derivatives, as biocompatible polymers, have attracted considerable attention for applications in the biomedical field due to suitable physical and mechanical properties. Cellulose naturally develops functionality, flexibility, and high specific strength by exploiting hierarchical structure (Ansari et al. 2015; Moon et al. 2011). It also has low density, low price, as well as biodegradability (Fidale et al. 2013). Cellulosic materials enable tuning of porosity and interconnectivity desirable for targeting biomedical applications (Sultan and Mathew 2018). Nevertheless, cellulose has several less favorable properties for application in the biomedical field like moisture sensitivity, insolubility in water and most common solvents, and low resistance against microbial attacks (Dumitriu et al. 2018; Tilki et al. 2010). However, cellulose can be chemically modified by substitution of its native hydroxyl groups with functional groups, such as specific acids, chlorides, and oxides, to address less favorable properties or to develop new desired characteristics.

Traditionally, cellulosic materials have been used in industries for developing paper and textile (Karmazsin 1987), while in the last decades, cellulosic materials have been used for a variety of applications, e.g. biomedical applications (Ates et al. 2020; Trache et al. 2020). Cellulosic materials especially show great promise as cost-effective forward-looking materials for biomedical applications because of their biocompatibility, biodegradability, and low cytotoxicity. Moreover, due to their chemical functionality, cellulosic materials can be easily modified to yield useful products. Cellulosic materials play an essential role in traditional disease control and health care. Meanwhile, many new application areas are also explored, such as tissue engineering (Ninan et al. 2013), wound treatment (Solway et al. 2011), and drug delivery (Gunduz et al. 2013). In the current review, the results of detailed studies on cellulose from various sources and the preparation of cellulose derivatives, as well as their applications as novel biomedical substances in the field of tissue engineering, wound dressing, and drug delivery systems are presented.

Cellulose structure

Cellulose is a high molecular weight unbranched chain, homo-biopolymer with repeating d-glucose units, linked together by β 1 → 4 glycosidic bonds (Brown et al. 1996; Habibi et al. 2010). One end of the cellulose chain is reduced to a hemiacetal functionality (Habibi et al. 2010; Moon et al. 2011). The structure of cellulose is complicated due to different packing and aggregation of the cellulose chains, which varies among cellulose producing organisms. Cellulose has three hydroxyl groups in each glucose residue with a degree of polymerization based on glucose units ranging from 1000 to 15,000, depending on the cellulose origin and treatments (Table 1). The intra-chain hydrogen bonding between hydroxyl groups and oxygen of the adjoining ring of cellulose molecules stabilizes the linkage and results in a unbranched conformation of cellulose chains (Agoda-Tandjawa et al. 2010).

Cellulose molecules assemble in the form of ordered parallel layers into elementary fibrils, either in plant cell walls, algae cell walls, tunicate epidermal cell membranes, or produced by bacteria. Linked by van der Waals forces and strong intra- and/or intermolecular hydrogen bonds, the cellulose chains are tightly aggregated together with a lateral dimension of 3–5 nm. Each elementary fibril is a bundle of cellulosic crystals along the fibril axis alternated with disordered domains. Bundles of elementary fibrils further constitute cellulose microfibrils with a cross-sectional width of 5–20 nm and a length of several micrometers, depending on their origin (Klemm et al. 2005).

Cellulose is a semi-crystalline material, and its degree of crystallinity depends on its origin, extraction method, and pretreatment. The degree of crystallinity of wood-based and plant-based cellulose usually ranges from 40 to 60%, while cellulose from other sources, like bacteria and tunicin, shows a higher degree of crystallinity ranging from 80 to 100% (Avolio et al. 2012; Moon et al. 2011; Müller et al. 2014). Crystalline cellulose exists in the allomorphs of cellulose I, II, III, and IV (Moon et al. 2011), which are discussed below.

Cellulose I, II, III, and IV

The different allomorphs of crystalline cellulose are cellulose I, II, III, and IV (Ishikawa et al. 1997). Cellulose I contains parallel chains in the crystalline structure and is naturally derived from a variety of sources (trees, plants, tunicates, algae, and bacteria) (Wada et al. 2010). Cellulose I forming sheets, which are stacked together by hydrogen bonds and Van der Waals interactions (Wada et al. 2010), contribute significantly to the stiffness and specific structure of cellulose.

The crystalline phase of cellulose I is composed of two metastable structures, i.e. triclinic (Iα) and monoclinic (Iβ). The ratio of Iα to Iβ structures depends on the source of cellulose. The Iα structure with a triclinic unit cell is the allomorph known for most algal and bacterial cellulose (Wada et al. 2010). The Iβ allomorph has a monoclinic unit cell containing two parallel chains, which is typically found in plant-based and tunicate-based cellulose (Yamamoto et al. 1996). The Iα structure can be partly converted into the Iβ structure (Debzi et al. 1991; Horikawa and Sugiyama 2009), through hydrothermal treatment in alkaline solution at 260 °C or through high-temperature treatment in helium gas and organic solvents (Debzi et al. 1991).

The thermodynamically metastable cellulose I can be converted into either cellulose II or III (Fig. 2). Up to now, cellulose II is considered to have the most stable structure, specifically a monoclinic structure, that provides technical relevance for its use. Conversion of cellulose I into cellulose II was discovered by John Mercer in 1844, during the treatment of cotton by an alkaline solution (Heines 1944). Cellulose II is typically obtained by regeneration (dissolution and recrystallization) or mercerization (aqueous sodium hydroxide treatment) of native cellulose (Wada et al. 2010). During this conversion, the parallel chain arrangement of cellulose I changes into a more stable antiparallel chain arrangement of cellulose II.

Cellulose III can be formed from cellulose I or II through liquid ammonia treatment, and is called cellulose IIII and IIIII, respectively (Fig. 2). Subsequent thermal treatments can be applied to form cellulose IV from both cellulose IIII and IIIII (Nishiyama et al. 2002; Wada et al. 2010) (Fig. 2).

Cellulose sources

Cellulose is categorized based on its source of origin, i.e. as wood-based cellulose (WC), plant-based cellulose (PC), bacteria-based cellulose (BC), algae-based cellulose, and tunicate-based cellulose (Fig. 3). In the long history of cellulose use, based on its abundance and cost-effectiveness, WC and PC became the most commonly known kinds of cellulose in contrast with BC, tunicate-based cellulose, and algae-based cellulose (Klemm et al. 2011).

Wood and plant cellulose

Cellulose has been extracted from softwood (such as pine (Bilbao et al. 1997), cedar (Shi et al. 2015), and spruce (Fernandes et al. 2011)) and hardwood (such as oak (Robertson et al. 1997), and beech (Uehara and Sakata 1990)). Furthermore, a wide variety of plant materials has been studied for the extraction of cellulose including cotton (Nam et al. 2020), flax (Yu et al. 2015), pineapple leaf (Balakrishnan et al. 2018a, b), corn (Gopi et al. 2017), hemp, jute, bagasse, ramie (Nishiyama et al. 2003), cereal straws (Vargas et al. 2012), potato peel waste (Chen et al. 2012), and oil palm biomass (Haafiz et al. 2013) (Fig. 3).

Fibers extracted from wood and plant show similarities in composition and structure, including biodegradable carbohydrate polymers, mainly cellulose, hemicellulose, and lignin (Table 2). Cellulose molecules in either wood or plant have a complex, multi-level structure (Fig. 4); they are linked to other biopolymers like hemicellulose and lignin (Bidlack and Buxton 1992; Herranz et al. 1981; Ramsden and Blake 1997) (Fig. 1a,b). Although cellulose from plants and wood has the same chemical structure as that from other sources, it has a different microstructural organization (Martínez-Sanz et al. 2011). In WC and PC, cellulose chains are packed in layers as nanofibrils, held together by hemicellulose and lignin matrix (Fig. 1a, b). Although cotton fiber is PC, it does not have lignin or hemicellulose to a significant extent. The cellulose content in plants is generally 30-75% and in wood 40-50% (Parveen Kumar 2009; Shahzadi et al. 2014; Sun and Cheng 2002) (Table 2). Softwood and hardwood differ in chemical composition, i.e. they differ in the content of cellulose, hemicellulose, and lignin (Table 2), and in structural organization.

Bacterial cellulose

The cellulose produced by bacteria is called “microbial cellulose”, “bacterial nanocellulose”, “biocellulose” or specifically “bacterial cellulose”. BC was first discovered by Brown in 1886 as a strong jelly membrane on the surface of a vinegar fermentation broth (Brown 1886). BC is synthesized by terminal complex in almost pure form (> 90%) without binding to any other polymer, e.g. lignin and hemicellulose (Fig. 5). Therefore, the isolation and purification of BC are quite simple and do not need extensive chemical or any other type of treatment, in contrast with WC and PC. Since its discovery, BC has attracted attention due to several advantages such as high purity, ultrafine fibers shapes, remarkably crystalline structure, high mechanical strength, biodegradability, biocompatibility, high water-holding capability, conducive chemical stability, and a high degree of polymerization (Campano et al. 2016). More importantly, BC is considered a non-cytotoxic, non-genotoxic, and highly biocompatible material, attracting interest in diverse areas with hallmarks in medicine (Gorgieva and Trček 2019).

BCs are mainly produced extracellularly by Gram negative bacteria such as Komagataeibacter xylinus, Agrobacterium, Achromobacter, Aerobacter, Azotobacter, Pseudomonas, and Rhizobium, and only one genus of Gram positive bacteria namely Sarcina (Fig. 3) (Hong and Qiu 2008; Jonas and Farah 1998) with oxygen supply (air) and a carbon source (mainly d-glucose), as well as a nitrogen source (Jozala et al. 2015; Klemm et al. 2011). Komagataeibacter xylinus (formerly Acetobacter xylinum) is the most widely used species of bacteria for producing BC since it produces relatively large amounts of BC from a wide range of carbon and nitrogen sources in liquid culture (Hong and Qiu 2008; Zhong et al. 2013). Carbon sources used for this purpose are commonly agro-industrial wastes, e.g. rotten fruit like pineapple peels juice and sugar as a medium (Castro et al. 2011; Jozala et al. 2015). The yield of BC synthesis is up to 40% in relation to the starting carbon source, although, generally, the large-scale production of BC is costly (Klemm et al. 2011).

The main characteristics of BC are the high degree of crystallinity (80–90%), the high degree of polymerization (in the range of 7000–16000 glucose residues; Table 1), and high mechanical strength associated with inherent single cellulose nanofibers (at the order of the specific strength of steel or Kevlar). BC can be processed into the morphological forms of fleeces, films, spheres, and hollow particles (Müller et al. 2014), which make it versatile for biomedical materials design. Although WC, PC, and BC have the same chemical building blocks, they differ in mechanical properties due to their difference in structural organization (Martínez-Sanz et al. 2011) (Table 4). Furthermore, the degradation rate of BC is slightly higher than that of WC and PC (Castro et al. 2011; Klemm et al. 2011). BC is synthesized in a variety of synthetic and non-synthetic media by a class of acetic acid-generating bacteria. During biosynthesis, BC forms a pellicle of a random nanofibrillar network of cellulose chains composed of crystalline and disordered regions (Koizumi et al. 2008) (Fig. 5). Moreover, BC takes up enormous amounts of water (in some cases, more than 99% water), and produces stable hydrogels. Well-separated BC nanofibers have large surface areas forming an extremely porous structure (Chen et al. 2009). BC consists of randomly assembled, < 100 nm wide ribbon-shaped fibrils, composed of 7–8 nm wide elementary nanofibrils aggregated in bundles (Gorgieva and Trček 2019; Li et al. 2016a). This unique nano-morphology results in a large surface area that can hold a large amount of water, and at the same time displays excellent elasticity, high wet strength, and conformability (Gorgieva and Trček 2019). The combination of the advantageous properties of BC has become an exciting feature for biomedical applications, especially in tissue engineering and in the pharmaceutical industry, as implants and scaffolds, emulsion and hydrogel stabilizers, drug-delivery systems, smart artificial skin or wound regeneration therapies, and enzyme and biomolecules immobilization for enhanced activity and higher stability in vivo.

Algal cellulose

Various types of algae, e.g. brown species (Posidonia Oceanica) (Tarchoun et al. 2019), green species (Cladophora) (Pan et al. 2016), and red species (Gelidium elegans) (Chen et al. 2016b) (Fig. 3), are other important sources of cellulose, with the algae cell walls made up of a large portion of cellulose. Red algae (like Gelidium elegans) have a rich content of carbohydrates, which are mainly composed of an energy-dense substrate (cellulose) and mucilaginous materials (agar). Algae are alternative renewable sources for cellulose production since they can receive nutrients from waste streams (i.e. wastewater, flue gas), and be cultivated at a large scale ultimately benefitting the environment (Aysu et al. 2016). Valonia- or Cladophora-derived cellulose has a remarkably high degree of crystallinity (> 95%) (Sugiyama et al. 1991). Algal cellulose is not pure, and is associated mainly with hemicellulose, protein, and lignin (Rabemanolontsoa and Saka 2013).

Cellulose extracted from green algae has unprecedented advantages over WC, PC, and BC because of its high crystallinity (> 70%) (Chen et al. 2016b), low moisture adsorption capacity, high porosity in the mesoporous range, and associated high specific surface area (Strømme et al. 2002; Zhou et al. 2019). Overall, algal nanocellulose has excellent potential for biomedical applications such as tissue engineering because of its nontoxicity, and facile chemical modification (Hua et al. 2016).

Tunicate cellulose

Tunicates are invertebrate animals living in the oceans in vast numbers and are the only known animal source of cellulose (Fig. 3). There are several enzyme complexes in the plasma membrane of tunicate epidermal cells responsible for cellulose synthesis. Tunicate-based cellulose is obtained from the outer tissue of tunicate, named “tunic”, from which a pure form of cellulose termed “tunicin” can be extracted (Zhu et al. 2018b). The purified extracted cellulose from tunic is called tunicate cellulose or tunicin. Most of the research in this field has focused on a class of tunicates known as Ascidiacea (sea squirts), which includes over 2300 species (Zhao and Li 2014).

Hundreds of cellulose nanofibrils are bundled in the tunic (Kimura et al. 2001). The shape and dimensions of a nanofibril bundle vary depending on the species. Nanofibril bundles are deposited in a multi-layered texture parallel to the surface of the epidermis. The length of tunicate cellulose nanofibrils ranges from 100 nm to several micrometers (typically > 2 µm), the width ranges from 10 to 30 nm (Table 3), and the aspect ratio ranges from 60 to 70 (Zhao et al. 2015b). Generally dry tunic contains approximately 60% cellulose and 27% nitrogen-containing components (Berrill 1947). However, after treatment and extraction, tunicate cellulose is highly crystalline (ca. 95%) composed of nearly pure cellulose in the morphological form of high aspect ratio fibrils (Zhao and Li 2014). Tunicate cellulose has a high specific surface area ranging from 150 to 170 m2/g (Sturcová et al. 2005). It also has a reactive surface due to hydroxyl groups (Šturcová et al. 2005). The degree of polymerization of tunicate cellulose has been reported to be in the range of 700–3500 (Table 1).

Various morphological forms of cellulosic particles

Cellulose naturally exists or is isolated from various sources in some predetermined dimension and shape, which can simply be classified into cellulose fibers, cellulose filaments, cellulose crystals, and cellulose micro/nanofibrils (Fig. 6). Each cellulosic particle type has a distinguished size, morphology, aspect ratio, crystallinity, and physiochemical properties. These cellulosic particles are discussed below.

Cellulose fibers

At the site of biosynthesis of wood or plants, cellulose is synthesized as microfibrils that are further organized to assemble cellulose fibers (Fig. 1a). Cellulosic fibers are typically found in three geometries, i.e. strand fibers (long fibers of 20-100 cm length), staple fibers (short fibers of < 60 mm length), and pulp fibers (very short fibers of 1–10 mm length) (Ardanuy et al. 2015). A staple fiber is an entire but single cell, while a strand fiber is composed of many cells. Cotton fibers are staple fibers, with a length of 25–45 mm. The length of cotton linters, i.e. the fibers that remain adhered to the cotton seed, is only a few millimeters. Strand and staple fibers are obtained from crop or wild plants directly after a water retting process. Pulp fibers are usually obtained as individual cells from wood and sometimes plant sources (like sisal, banana, fique, and cotton linters) by a pulping process. Pulping is an extensive treatment with solutions that remove the lignin between cells and result in individual plant cells that are just a few mm long (Ardanuy et al. 2015; Elhawary 2015).

Cellulose filaments

Cellulose nanofibers can be assembled into filament form by wet-extrusion (Walther et al. 2011), flow-focusing (Håkansson et al. 2014), or spinning (Iwamoto et al. 2011; Vuoriluoto et al. 2017) processes. These cellulose filaments may have different physicochemical aspects (e.g. allomorph, crystallinity), but all filaments are mechanically strong, ductile, and have very high aspect ratios (Fig. 6). Filaments are interesting as building blocks of materials for biomedical applications.

There is also a different type of cellulose filament, which is not obtained via the above-described processes but by peeling cellulose fibers from wood or plants (Tibolla et al. 2017). This peeling process is only mechanical and does not require chemicals or enzymes and has no released effluent, which makes the generated filaments appealing for biomedical applications.

Cellulose micro/nanofibrils

Cellulose microfibrils, also originally-called microfibrillated cellulose (MFC), have been developed first by Turbak et al. (Turbak et al. 1983) and Herrick et al. (Herrick et al. 1983) at ITT Rayonier Inc., USA, in the late 1970s. Cellulose fibers (mainly from wood) are mechanically disintegrated into micro- and nanofibrils, for example by passing through a homogenizer. Cellulose nanofibrils (CNFs; width < 100 nm) are mainly obtained at a low concentration from water suspensions of wood or plant pulps. CNFs are not always obtained as pure cellulose nanofibers; they can be disintegrated from sources that are still containing a considerable amount of hemicellulose and lignin (Abe et al. 2009; Kumagai and Endo 2018; Oliaei et al. 2020). Many attempts have been made to obtain individual fibrils, such as mechanical disintegration, including homogenization (Turbak et al. 1983; Wang et al. 2013) and micro-fluidization (Ferrer et al. 2012), as well as the application of enzymatic treatments (Tibolla et al. 2017; Wågberg et al. 2008). Some chemical treatments are also used to facilitate the disintegration of CNFs, such as TEMPO (2,2,6,6tetramethylpiperidinyloxyl)-catalyzed oxidation (Isogai et al. 2011), and carboxymethylation (Wågberg et al. 2008), which also introduce different functionalities to the cellulose fibrils. The width of CNFs is generally in the range of 2–100 nm depending on the source of cellulose, fibrillation process, and pretreatment (Table 3). The length of CNFs is typically > 1 μm (Dufresne 2013; Gumrah Dumanli 2017) (Table 3). CNFs are mostly comprised of alternating crystalline and disordered domains (Klemm et al. 2011). Principally, CNFs have typically an elastic modulus between 14 and 36 GPa (Lindström 2017; Supachok et al. 2012), and an ultimate tensile strength around 1 GPa (Ali and Gibson 2012; Lindström 2017) at ambient conditions, but even higher values have been reported (Bledzki and Gassan 1999; Henriksson et al. 2007; Sakurada et al. 1962).

Crystalline cellulose

When cellulose microfibrils are subjected to a proper combination of mechanical, chemical, and/or enzymatic treatments, the highly crystalline regions of the cellulose microfibrils can be extracted, resulting in the formation of microcrystalline cellulose (MCC; with a diameter in micron scale) or cellulose nanocrystals (CNCs; with a diameter in nano scale) (Trache et al. 2017). MCC and CNCs are stiff rod-like particles consisting of cellulose chain segments in a nearly perfect crystalline structure, which was first developed by Ranby (1949). MCC was first commercialized under the brand name Avicel® (Battista and Smith 1962). In 1964, the Food Machinery Corporation introduced Avicel® PH to the pharmaceutical industry as an ingredient for direct tableting (Dinand et al. 1996). The length of MCC from Avicel® PH is in the range of micrometers. Nowadays, MCC is produced by more than ten suppliers all around the world. The most common source of pharmaceutical MCC is wood cellulose (Thoorens et al. 2014).

MCC is a purified form of partially depolymerized alpha cellulose through hydrochloric acid hydrolysis (Schuh et al. 2013). The partial depolymerization of the disordered regions of cellulose by acid hydrolysis produces shorter and more crystalline particles like MCC due to its inclination to hydrolysis (Wardhono et al. 2020; Zhao et al. 2015a). MCC has broad compatibility with active pharmaceutical ingredients (APIs), due to its physiological inertness, ease of handling, biodegradability, as well as inherent security of supply (Nsor-Atindana et al. 2017). Commercial MCC has round or rod-like particles measuring 10–200 µm (Juban et al. 2015). Pharmaceutical MCC is produced from softwood, hardwood (Thoorens et al. 2014), and cotton (Shlieout et al. 2002; Suzuki and Nakagami 1999). MCC has several advantages, such as biodegradability, thermal stability, satisfying mechanical characteristics, high elastic modulus, high aspect ratio, and low density, making it an appropriate candidate to be used as a filler in biocomposites (Pei et al. 2010). Moreover, the large surface area and high internal porosity of MCC provide appropriate cohesiveness for wetted mass (Zolkefpeli and Wong 2013).

CNC particles are the extracted crystalline regions of the cellulose microfibrils (Moon et al. 2011; Shopsowitz et al. 2010; Siqueira et al. 2010). Purified CNCs are often made by sulfuric acid hydrolysis of native cellulose. Aggressive sulfuric acid hydrolysis and ultrasonic treatment of bulk cellulose results in disintegration of highly crystalline CNC particles, which are then extracted. CNCs exhibit exceptional characteristics, such as a high aspect ratio, large specific surface area, high specific strength and modulus, along with abundance, biodegradability, reactive surfaces, and the ability to make stable suspensions in various low-polarity solvents when a surfactant is used (Chang et al. 2009; Wu et al. 2010). The characteristics of nanocrystals, e.g. shape, length, and width, depend on the cellulose source and the extraction procedure, e.g. controlled time and temperature for acid hydrolysis, high-pressure homogenization conditions (Lu and Hsieh 2010) (Table 3), and further modifications, such as neutralization and dialysis (Martínez-Sanz et al. 2011).

CNCs can be prepared from different sources, including WC, PC, BC, algal, and tunicate cellulose (Le Goff et al. 2015; Martínez-Sanz et al. 2011; Siqueira et al. 2010). CNC particles can be isolated by breaking down MCC particles. After treatment of MCC particles with sulfuric acid, a stable dispersion of CNCs in water or organic solvents is prepared (Klemm et al. 2011). CNCs typically have a relatively broad length distribution because of the diffusion-controlled nature of the acid hydrolysis. Generally, the average length is a few hundred nanometers, and the width a few nanometers (Moon et al. 2011), with an aspect ratio between 10 for cotton (Ebeling et al. 1999), and 67 for tunicin (Angles and Dufresne 2000) and Capim dourado (golden grass) (Siqueira et al. 2010). Typically, CNCs derived from WC and PC have a length between 100–500 nm, and a width between 3-30 nm, while tunicate- and bacteria-based cellulose have a length of 100 nm to several microns, and a width of 5–50 nm (Table 3). The degree of polymerization of cellulose in CNCs is in the range of 500 to 15000. CNC has been reported to have an elastic modulus of 60–220 GPa, and a tensile strength of 7500–7700 MPa (Table 4). Compared to bulk cellulose, which has more significant disordered fractions, these nanocrystals exhibit very high specific strength, elastic moduli, high surface area, and unique liquid crystalline properties (Wu et al. 2013).

CNC as nanoparticle reinforcement has received much attention as it has attractive advantages, such as low density, very good uniformity and durability, and biodegradability. The high strength and elastic modulus, as well as the small dimensions of nanocrystalline cellulose, provide a far-reaching reinforcement effect on the overall matrix structure (Le Goff et al. 2015; Septevani et al. 2018). The versatility and adaptability of bionanocomposites enable these nanocrystalline cellulose-based materials to be utilized for biomedical applications, including medical implants, wound dressing, drug delivery, and scaffolds for tissue engineering and vascular grafts (Rudisill et al. 2015).

Cellulose properties

Cellulose solubility

A major limitation of cellulose in biomedical applications is its insolubility in water and other common solvents. This is due to the stabilization of cellulose molecules by intra- and intermolecular hydrogen bonds, as well as to electrostatics and hydrophobic interactions within the integrated fibrils, forming tough bundles with numerous hydroxyl groups, which are distributed on the backbone (Bergenstråhle et al. 2010; Lindman et al. 2017). The overall effects of the hydrogen bonding mechanism on stabilization are not completely understood; recently, electrostatics, and hydrophobic interactions have been suggested to play an important role (Lindman et al. 2017). As a result of the consequent tight connections between the entangled chains of cellulose, cellulose becomes insoluble in water and most common solvents. Therefore, it is essential to develop intricate solvents that create systems requiring minimum energy for dissolving cellulose. Ionic liquids are considered environmentally friendly solvents, and some of them dissolve cellulose. Besides, ionic liquids have low toxicity, thermal stability, negligible volatility, recyclability, and promote dissolvability for cellulosic particles (Li et al. 2016b). Ionic liquids, including 1-butyl-3-methylimidazolium formate (BMIMFmO) (Xu et al. 2010), 1-butyl-3-methylimidazolium chloride (BmimCl) (Erdmenger et al. 2007), N,N-dimethylacetamide/lithium chloride (DMAc/LiCl) (Potthast et al. 2002), NaOH/thiourea (Jiang et al. 2017), LiOH/urea, and NaOH-urea (Cai and Zhang 2005) are able to properly dissolve cellulose. 1-Ethyl-3-methylimidazolium diethyl phosphate ([EMIM] DEP), an ionic liquid solvent, is a favorable cellulose solvent since it has low viscosity with a corresponding low melting point (19–21 °C). A solution of cellulose in [EMIM] DEP-pyridine mixture is stable in time (Vitz et al. 2009).

Some ionic liquids can be used to dissolve cellulosic materials, but limitations exist regarding their usage such as high energy consumption, high cost, and inherent difficulty in solvent recovery (de Oliveira Ribeiro et al. 2018; Zhu et al. 2018a). N-methylmorpholine-N-oxide monohydrate (NMMO·H2O), an organic solvent, has also been used to dissolve cellulose. NMMO is a nontoxic solvent, of which more than 99% can be recycled after dissolution (Zhang et al. 2017). Thus, depending on the specific conditions required for application, there is continuous interest in developing innovative cellulose solvents with favorable properties to allow usage of cellulose in biomedical applications.

Mechanical properties of cellulose

Cellulose-based materials and their composites with inorganic materials and polymers are emerging for the design of high-performance mechanical and functional materials (Benitez and Walther 2017). The high intrinsic stiffness and strength of cellulose I crystals yield promising materials that exhibit extraordinary mechanical properties if they are assembled correctly, making them a suitable candidate for biomedical applications where high mechanical performance is desired. CNFs, for instance, feature outstanding intrinsic mechanical properties (high specific modulus and strength) due to high crystallinity (Benitez and Walther 2017), as well as order and intermolecular interactions such as hydrogen bonding between cellulose chains (Yu et al. 2012). The elastic modulus of crystalline cellulose I along the cellulose chain axis has been reported to be 124–155 GPa (Šturcová et al. 2005; Tanaka and Iwata 2006; Tashiro and Kobayashi 1991).

The rigid crystalline CNCs have specific moduli similar to Kevlar and steel (Eichhorn et al. 2010; Moon et al. 2011; Xiong et al. 2016). Moreover, BC in never-dried form has exceptional mechanical characteristics that resemble soft tissue (Hu and Catchmark 2011; Svensson et al. 2005). BC in the dried form also possesses exceptional mechanical properties. The elastic modulus of BC has been reported to be very high, i.e. 60–115 GPa (Benitez and Walther 2017; Guhados et al. 2005; Hsieh et al. 2008) (Table 4). The mechanical properties of BC and interactions with smooth muscle cells have been investigated, and it has been argued that the morphology of single nanofibrils, the network structures of BC, and the stress–strain response reveal similarities to that of a collagen network (Bäckdahl et al. 2006). It is worth mentioning that extensive research has been carried out to improve collagen-based constructs (Berglund et al. 2003; L’Heureux et al. 1993; Seliktar et al. 2000), as they have enormous potential for biomedical applications. This opens up opportunities for novel biomimetic scaffold design where BC replaces the collagen network of the extracellular matrix. Information about the mechanical properties of cellulosic forms from different sources is provided in Table 4. Based on the data in Table 4, and what has been discussed so far, it can be easily understood that the elastic modulus and tensile strength of cellulosic reinforcements are very impressive and promising for biomedical applications such as tissue engineering, wound healing, and drug delivery, where strong and stable structures are required.

Hygroscopic properties of cellulose

Despite impressive mechanical properties of cellulose in dry-state, the low wet-strength of this material is a limiting parameter for many applications (Mertaniemi et al. 2016). The reason for this problem is associated with the intrinsic hygroscopic properties of cellulose, which is considered a hygroscopic substance due to the tendency to form hydrogen bonding with water. The water molecules attract and hold in the structure of cellulose. Penetration of water in the structure of cellulose is mainly limited to the disordered domains. As a result, the percentage of disordered domains and fiber saturation point concur around 30% (Kolin and Janezic 1996). The water swelling of cellulose allows for favorable aqueous processing of cellulose and/or cellulose-based hybrid and composite materials. However, such materials as products are prone to significant swelling due to both adsorption of moist air or absorption of liquid water along the hydrophilic surface of the cellulose or within embedded hydrophilic polymers. Nanocellulose-based materials can thus take up water and swell much more compared with fiber-based materials due to their higher surface area (Benítez et al. 2013). Moreover, in chemically modified cellulose-based materials that carry charged groups, water uptake is elaborated by the osmotic swelling pressure generated by the charged groups (Walther et al. 2020). These hygroscopic properties of cellulose might determine whether cellulose can be used for a specific biomedical application.

Toxicity

Toxicity of materials is a concern for biomedical applications. Cellulosic particles are extracted from sources with no or low toxicity, but the dimension, surface modification, hydrophilization, hydrophobization, and aggregation might influence their cytotoxicity and biocompatibility. Generally, the nanoscale dimension of particles has been recognized as a potential factor generating toxicity of materials that are composed by these particles (Nel et al. 2006). Conflicting reports on in vitro research exist on cyto-, geno-, and immunotoxicity of cellulosic nanoparticles (Catalán et al. 2015; Coelho et al. 2018). Moreover, inflammation is often occurring after exposure to cellulosic nanoparticles as a normal biological response to a foreign material. It may disappear after a while. Attempts have been made to correlate the cellulosic nanoparticle size and rigidity (of a specific type and chemical function) to cell toxicity in acute tests, but no clear correlation has been documented. Therefore, more research is needed on the long-term in vivo effects of cellulose nanomaterials, since this may provide different results from those obtained by acute and in vitro studies.

Cellulose derivatives

For upgrading the value or expanding versatility of cellulose, and by using chemical treatment or functionalization, various cellulose derivatives have been developed and utilized in biomedical industries. The properties of cellulose derivatives are not only determined by the type and degree of substitution, but also by the functionalization pattern along the polymer chain. Regio-selective synthesis of cellulose derivatives is limited by cellulose’ poor solubility in organic solvents, and high steric hindrance due to the stiff and bulky cellulose main chain. The hydroxyl group is the most targeted reactive group on the cellulose chain. Cellulose hydroxyl groups are relatively poor nucleophiles, resulting in the requirement for fairly harsh reactions, so that taking advantage of the relatively small reactivity differences between the 2-, 3- and 6-OH groups is difficult (Zheng et al. 2014). Therefore, regio-selective substitution is one of the remaining challenges in the synthesis of cellulose derivatives. To synthesize cellulose derivatives under more general and practical conditions for commercial purposes, it is necessary to understand the relationship between cellulose derivatives’ regio-chemical structure and their properties (Zheng et al. 2014). The chemical derivatization of cellulose, based on the hydroxyl group, generally includes etherification and esterification. The derivatives may vary in terms of essential characteristics, e.g. chemical structure, moisture sorption, water interaction, surface activity, and solubility, which is discussed below in detail, and summarized in Table 5.

Cellulose ether

Cellulose hydroxyl groups can be partially or totally etherified by different reagents, e.g. epoxides, alpha halogenated carboxylic acids, and halogenoalkanes (Kamel et al. 2008). The solubility rate of cellulose ethers (CEs) is affected by the acidity or alkalinity of the solution. In acidic conditions, cellulose ether dissolves very slowly, while in alkaline conditions it dissolves rapidly. Cellulose ether can be water-soluble depending on the substituent chemical structure, as well as degree and pattern of substitution. Most water-soluble cellulose ethers have a degree of substitution of 0.4–2. Although many cellulose ether compositions have been synthesized since the early 1900s, only a few have gained commercial importance. Among all CEs, carboxymethyl cellulose (CMC), methyl cellulose, and hydroxyethyl cellulose are extensively used in the formulation of industrial biomedical products due to their nontoxic profile and appropriate rheological and mechanical properties. CEs high water retention capacity (Fidale et al. 2013) and thermo-gelling ability (Sanz et al. 2015) are known to accelerate wound healing. These important properties of CEs depend on the chemical structure of the substituent and degree of substitution. Despite the success of hydrated CEs in practical biomedical applications, rather few attempts have been made to investigate CEs water retention mechanism.

Methyl cellulose

Methyl cellulose is the most important commercial cellulose ether. Methyl cellulose is the simplest alkyl ether, which can be synthesized in an alkaline medium with a methylating agent, such as methyl chloride or dimethyl sulfate (Viera et al. 2007) (Fig. 7). A different degree of substitution can be obtained via altering the synthesis conditions, such as the reaction time or the methylating agent (Viera et al. 2007). Methyl cellulose dissolves in many organic solvents, depending on the degree of substitution. For instance, if the degree of substitution is between 1.4 and 2.0, methyl cellulose dissolves in water, and if this degree is between 2.4 and 2.8, it is generally soluble in water and some organic solvents (Table 5) (Vieira et al. 2012). Methyl cellulose has thermo-gelling ability. The degree of cellulose substitution, molecular weight, presence and concentration of additives are parameters affecting the methyl cellulose gel-formation temperature and the characteristics of the resulting gel (Sarkar 1979). Besides, methyl cellulose is an emulsifying additive (Içten et al. 2017), which is useful for drug delivery systems. Methyl cellulose is mostly used for biomedical applications such as tissue engineering, wound healing, and pharmaceutical formulations.

Carboxymethyl cellulose

CMC is one type of CEs, which is commercially available and has unique features like hydrophilicity, water solubility and stability, high chemical stability, nontoxicity, biocompatibility, and biodegradability. Also, it has no known side effects to human health (Sahoo and Jena 2018). However, it is insoluble in some organic solvents such as ethanol. The solubility of CMC depends on the degree of polymerization, the degree of substitution, and on the distribution of the substituent. CMC can be used as effective viscosity increasing agent, rheological control agent, binder, stabilizer, and film former in the biomedical field with particular attention to drug delivery and tissue engineering systems. CMC is formed by reaction of cellulose with monochloroacetic acid, where the hydroxyl groups are substituted by carboxymethyl groups in C2, C3, and C6 of each glucose residue, such that the substitution slightly prevails at the C2 position. No secondary OH groups are formed during the reaction (Heinze and Pfeiffer 1999; Xiquan et al. 1990). Therefore, CMC chemical structure is based on carboxymethyl groups (–CH2–COOH) bound to some of the hydroxyl groups of the cellulose backbone (Fig. 7) (Swamy and Yun 2015). The degree of substitution of commercial CMC grades for biomedical products is typically between 0.6 and 1.25 (Swamy and Yun 2015). CMC properties depend on its molecular weight, degree of substitution, and the distribution of carboxymethyl substituents along the polymer chains. CMC is often activated in aqueous sodium hydroxide, whereby it is transformed into its sodium form for further use.

Ethyl cellulose

Ethyl cellulose is another important commercial CE. The chemical structure of ethyl cellulose is based on converting some of the hydroxyl groups on the repeating glucose units into ethyl ether groups (Fig. 7) (Davidovich-Pinhas et al. 2015). Ethyl cellulose is prepared by reaction of alkali cellulose with ethyl chloride at about 60 °C for several hours (Rekhi and Jambhekar 1995). The complete etherification of cellulose yields triethyl cellulose, although normally ethyl cellulose with 2–2.6 degree of substitution is used for a range of commercial products (Koch 1937). The physical characteristic and performance of materials based on ethyl cellulose depend on the degree of etherification, molecular weight, and molecular uniformity. Solubility in most organic solvents is typically achieved with degree of substitution between 2.2 and 2.6 (Koch 1937).

Ethyl cellulose is a biodegradable substance that has no water-solubility, no toxicity, excellent film-forming capacity, water resistance, and barrier-forming characteristics (Yang et al. 2014). Ethyl cellulose has excellent strength at room temperature, but its strength decreases immediately with increasing temperature. Ethyl cellulose has potential for use in biomedical applications, especially drug delivery.

Hydroxyethyl cellulose

Another CE is hydroxyethyl cellulose, which is prepared from the reaction of alkali cellulose and ethylene oxide (Wang et al. 2015) (Fig. 7). The chemical structure of hydroxyethyl cellulose can be easily further modified due to its reactive hydroxyl groups. Hydroxyethyl cellulose is soluble in hot and cold water (Zhang and Chen 2002) and many organic solvents. Its ease of solubility makes it an appropriate candidate in many biomedical applications (Yang et al. 2016). Further, its non-toxic nature, ease of compression, ability to host nanoparticles, and capability to accommodate a high level of drug loading are critical factors for its biomedical usage (Yang et al. 2016). Also, hydroxyethyl cellulose can be mixed with cellulose, enabling solvent-free processing of cellulose, and making it more compatible with less-polar matrices (Hooshmand et al. 2017), which might further expand cellulose applications in the biomedical field.

Hydroxypropyl cellulose

Hydroxypropyl cellulose is a water-soluble (both in cold and hot medium) thermoplastic in the category of CEs. The chemical structure of hydroxypropyl cellulose is based on partial or complete substitution of free hydroxyls with hydroxypropyl groups. In the reaction with 1,2-propylene oxide, secondary OH groups are formed (Fig. 7). These secondary groups can further react. Therefore, the chemical structure of hydroxypropyl cellulose can be easily further modified due to its backbone reactive hydroxyl groups, which may provide new properties that are of interest for biomedical applications e.g. drug delivery and tissue engineering.

Cellulose ester

Cellulose ester is a commercially available class of thermoplastic biopolymers derived from cellulose (Moraïs et al. 2010). Unlike cellulose, cellulose esters have good solubility in common solvents and melt before decomposition (Edgar et al. 2001). Various morphological forms of cellulosic particles, e.g. fibers, fibrils, or crystals, can be esterified to form cellulose ester (Berlioz et al. 2009; Ramírez et al. 2017). Cellulose esters can be utilized in biomedical applications via less complicated production processes, which are further discussed below.

Cellulose acetate

Cellulose acetate (CA) was first discovered in 1865 by Schützenberger (Kulterer et al. 2011) as a thermoplastic biodegradable polymer. It is produced by the esterification of cellulosic sources such as cotton, wood, sugarcane, and even recycled paper (Rodrigues Filho et al. 2011). CA is relatively cheap since it is commonly obtained from agricultural by-products, like cotton burrs, cottonseed hulls, and sugarcane bagasse (Cheng et al. 2010). Also, the existing CA preparation techniques do not need further chemical or mechanical treatment to isolate remaining cellulose from other components, which is advantageous for some biomedical applications, e.g. tissue engineering (Vikingsson et al. 2015), wound healing (Schunck et al. 2005), and drug delivery systems (Mwesigwa and Basit 2016).

Generally, CA synthesis approaches include ring-opening esterification and transesterification under heterogeneous or homogeneous conditions (Khoshnevisan et al. 2018). CA is conventionally produced by acetylation of hydroxyl groups in cellulose with acetic anhydride (Clermont and Manery 1974), acetic acid (solvent), and sulfuric acid (catalyst) (Fig. 7).

N-ethyl-pyridinium chloride (Heinze et al. 2000), N,N-dimethylacetamide (DMAc)/lithium chloride (LiCl) (Morgado et al. 2013), and 1,3-dimethyl-2-imidazolidinone (DMI)/LiCl dissolve CA (Chen et al. 2016a). These solvent systems typically need prolonged pretreatment. Ionic liquids have also been used as efficient solvents of CA (Abbott et al. 2005), though their industrial application is limited due to their high cost (Chen et al. 2016a).

Cellulose nitrate

Cellulose nitrate, also known as nitrocellulose or celluloid, is considered the first semi-synthetic polymer in the advent of the plastic industry. Cellulose nitrate is a versatile polymer that has been widely used since the 1900s (Falkowitz and Piech 1956). Cellulose nitrate is commercially produced through the reaction of cellulose with nitric acid, by substituting cellulose hydroxyl groups with nitrate groups (Fig. 7). Cellulose nitrate is the polynitrate ester of cellulose with a typical 2.2–2.8 nitrate groups per glucose unit within the structure (Neves et al. 2019). Cellulose nitrate properties and applications depend on the degree of nitration. Cellulose nitrates are employed as explosives, plastics, or in coating and ink industries. By lowering the degree of nitration and adding a plasticizer, a workable plasticized material could be produced (Neves et al. 2019). Future studies may explore the possibilities of cellulose nitrate in biomedical applications.

Cellulose sulfate

Cellulose sulfate is a cellulose derivative with relatively simple chain structure and unique biological properties. The sulfation of cellulose is carried out using amongst others sulfuric acid, sulfur trioxide, and chlorosulfonic acid (Schweiger 1972). The reaction is carried out either directly on cellulose (under heterogeneous condition) or on partially substituted cellulose esters or ethers (mostly under homogeneous condition). Cellulose sulfate generally has water soluble, antiviral, antibacterial, and anticoagulant properties, which can be attributed to the presence of the sulfate groups and the broad degree of substitution. Apart from the simplicity in preparation, affordable cost, and large-scale production, cellulose sulfate’s excellent biocompatibility, film-forming ability, and biodegradability makes it a frontrunner for potential biomedical applications like tissue engineering (Palaninathan et al. 2018) and drug delivery (Su et al. 2019).

Cellulose in biomedical applications

For biomedical applications, it is an essential requirement to assess the biocompatibility of materials and verify their interaction with cells, especially for applications where the material needs to remain in contact with living tissue and should not cause any cytotoxic or other side effects. Cellulose offers unique features of biodegradability, biocompatibility, low production cost as compared to synthetic biopolymers, abundance, sustainable resources, nontoxicity, and excellent mechanical properties. These features offer potential as bioresorbable polymers that plays an increasingly important role in biomedical applications due to their unique ability to be resorbed entirely in pre-designed time frames ranging from months to a few years.

Tissue engineering

Tissue engineering is known as an interdisciplinary field that applies the principles of engineering and life sciences toward the development of smart biological substitutes that potentially restore, maintain, and improve tissue functions that have malfunctioned (Table 6). The tissue engineering field generally utilizes biomaterials to develop constructs for intended medical interventions. Such constructs are to be exposed to living biological entities in the human body, from biomolecules and physiological fluids to cells, up to tissues and organs. In terms of physical properties, regenerative tissue material must possess optimal strength, e.g. compressive strength for bone tissue engineering, or tensile strength for artificial blood vessels and other soft tissue repairs. On the other hand, chemical considerations such as the surface chemistry of the materials are crucial, and the selection of materials must be rendered for specific application purposes. For instance, it is possible to tune porosity, thickness, and interconnectivity of nanocellulosic materials without compromising the mechanical properties for tissue scaffold production (Bäckdahl et al. 2008). For tissue engineering, cellulose as an additive or as primary scaffold material should have mechanical properties matching real tissues (Farzamfar et al. 2018; Hasan et al. 2018), promote porous structures for scaffolds (Hoo et al. 2013), or provide anchoring sites for osteoblasts (Gouma et al. 2012), and fibroblasts (Taokaew et al. 2015). The most commonly used cellulose derivatives for tissue engineering include cellulose acetate (Farzamfar et al. 2018), hydroxyethyl cellulose (Zulkifli et al. 2017), hydroxypropyl cellulose (Hoo et al. 2013), cellulose sulfate (Palaninathan et al. 2018), carboxymethyl cellulose (Hasan et al. 2018), methyl cellulose (Zhuo et al. 2017), and ethyl cellulose (Mao et al. 2018a).

One of the ubiquitous usages of biomaterials in tissue engineering is in the production of a biologically compatible scaffold that will support the attachment, proliferation, and differentiation of living cells that contribute to the promotion of tissue regeneration in vitro and in vivo conditions. Mammalian cells are not able to attach to the cellulosic surfaces used in artificial tissue scaffolds due to their hydrophilic nature and low non-specific protein adsorption. However, cell adhesion to substrate surfaces in cellulosic materials can be improved by the addition of matrix ligands. For example, ionic charges can be added to the cellulose membranes to adsorb collagen on the membrane surfaces, which can promote cellular adhesion (Courtenay et al. 2017). The positively charged BC has been applied, in the absence of proteins, to enhance cell attachment (Courtenay et al. 2017). BC is a biomaterial with a huge potential in dental and oral applications (Canas-Gutierrez et al. 2020). Recently, cost-effective and user-friendly functional biopolymeric-based materials have been used as a promising tool for developing, repairing, and regenerating functional tissues and organs in the human body. The use of cellulosic composites has been proposed in developing scaffold constructs that can be implanted in patients to replace failing or malfunctioning organs. Moreover, the inclusion of the appropriate reinforcement material for tissue-engineered biocomposite scaffolds is a significant factor in improving its characteristics and sustained biocompatibility. The use of cellulosic materials as reinforcement in biocomposites is now a fast-growing field, on account of their property enhancing capabilities (Ao et al. 2017; Sajjad et al. 2019). For instance, cellulosic fibers have been demonstrated recently to improve the formidability of biocomposite scaffolds in bone tissue engineering applications due to their unique structure (Mao et al. 2018b). In addition, microfibrillated cellulose remarkably increases the surface area, and its interfibrillar hydrogen bonds facilitate network formation, which is desirable in bone tissue engineering (Ioniță et al. 2018). Moreover, CMC stimulates adhesion, spreading, and migration of mouse fibroblasts in vitro (Adachi et al. 1992; Aoshima and Jo 2013). Also, the presence of CMC decreases osteoclastogenesis by murine bone marrow progenitors (Agis et al. 2010), but increases osteoblast differentiation (Qi et al. 2018). Hydroxyethyl cellulose is a non-ionic, water-soluble polymer, and has a β-glucose linkage, which makes it a suitable candidate for tissue engineering applications. Hydroxyethyl cellulose increases cell viability and substantially stimulates cell growth (Tohamy et al. 2018). It also significantly enhances cell proliferation at high concentrations of hydroxyethyl cellulose (Chahal et al. 2016).

The appropriate mechanical properties of biomedical devices and materials are essential and very specific to the nature of the application area. For example, the elastic modulus of the material needs to be close to the medium and/or tissue that it is replacing or reinforcing. Nanocrystalline cellulose can be a promising material for cell attachment and proliferation due to its excellent mechanical properties and biocompatible nature. One particular advantage of using nanocrystalline cellulose is the fibrillar high aspect ratio building blocks, which construct a natural fiber network of fibrils or nanorods that is held together by hydrogen bonding and mechanical entanglement. Such a network could be even further reinforced mechanically by cross-linking the individual nanofibers. There are numerous cellular species cultured on nanocellulose biomaterials such as hydrogels, electrospun nanofibers, sponges, composites, and membranes (Luo et al. 2019). Among the sources of nanocellulose, bacterial nanocellulose is believed to be the most popular choice for cell culture due to its high porosity, biodegradability, and low toxicity (Halib et al. 2019). Usually, the rate of scaffold degradation under a given condition is an important issue as it should match the time of tissue formation to ensure the injured tissue is completely replaced by healthy tissue, and its function is restored.

Wound dressing

The wound healing process involves an elaborate series of biological phenomena to restore barrier functionality, prevent dehydration, and reduce the risk of bacterial infection. Burn wounds and skin grafting require the development of novel wound dressing materials. Cellulose-based polymers have a high potential for wound dressing applications (Table 6). As wound dressing material, they should promote water retention or high water absorption capacity (Wutticharoenmongkol et al. 2019) or promote porosity and dryness that abhors bacterial attachment (Henschen et al. 2016). Here, the cellulosic material must be shaped like a sheet and used as a cover on wounds. It is highly beneficial to make drug-loaded cellulose-based bandages (Fan et al. 2019). Nanocellulose has excellent potential for wound healing applications, based on its moisture absorption and water retention ability that can be implemented over the wound itself, to contribute towards lowering inflammatory responses and promoting fibroblast proliferation in the wound healing cascade (Wang et al. 2016). Nanofibrillar cellulose is an ideal matrix for wound healing due to its high surface area to volume ratio, high water-holding ability, and high porosity. Moreover, its structure allows to mimic the architecture of the extracellular matrix or tissue/organs. Nanofibrillar cellulose hydrogel is a novel material for controlling excessive wound contraction in vivo and in vitro (Nuutila et al. 2018). Nanofibrillar cellulosics such as CMC and CA are the most promising wound dressing cellulosic materials that have been used in the treatment of burns and ulcers due to biocompatibility with mucous membrane and skin, biodegradability, non-toxicity, low immunogenicity, high water bonding affinity, and swelling capacity (Gomaa et al. 2017; Hakkarainen et al. 2016). Oxidized cellulose nanofiber is also appropriate for wound healing applications because of its substantial water absorption capacity and well-dispersed cellulose fibrils (Shefa et al. 2017).

Using CMC in wound healing requires some modifications to decrease the consequent pain burden in patients. A low level of localized pain, postoperative bleeding, and synechia have been reported for dissolvable CMC foam dressing (Szczygielski et al. 2010). Dissolvable CMC foam can also be used as wound dressing after sinus surgery due to the observed low levels of postoperative bleeding and synechia formation during application (Szczygielski et al. 2010). Nanocomposites based on BC are prepared by the direct introduction of magnetic nanoparticles within the cellulose culture medium for efficient chronic wound healing. Bionanocomposites containing plant CNC have been reported to be suitable wound healing templates for accelerating tissue regeneration (Singla et al. 2017). CA is also a suitable candidate in biocomposites for wound healing scaffold upon developing electrospun nanofibers (Wutticharoenmongkol et al. 2019). Hydrophilicity and bioactivity of CA enables cellular interaction between CA and fibroblasts, which consequently promotes cell proliferation (Gomaa et al. 2017).

BC is an appealing candidate for wound healing applications based on its favorable characteristics, such as biocompatibility, nontoxicity, and mechanical stability. Furthermore, BC provides a moist environment for the wound, hence enhancing the healing process (Sulaeva et al. 2015; Zmejkoski et al. 2018). However, BCs provide a suitable environment on-site as wound dressing materials, but the pH conditions can affect their contribution to the healing process (Shao et al. 2015a). Different materials have been incorporated to develop BC-based biomaterials with enhanced properties to be suitable for wound dressing (Qiu et al. 2016). BC-montmorillonite-reinforced composites have been developed as wound dressing and regeneration materials for therapeutic applications without any side effects (Ul-Islam et al. 2013). BC-chitosan membranes show antibacterial activity and favorably low cytocompatibility for wound dressing (Lin et al. 2013). BC-based membranes show significant epithelialization and regeneration of the skin, faster than the commercial wound dressing product, Tegaderm™ (Lin et al. 2013). Besides, the BC membrane accelerates the wound healing process in a burn model system through the regulation of angiogenesis and connective tissue formation (Kwak et al. 2015). BC-based hydrogel microparticles have been used as a dressing material for coverage of partial-thickness burn wounds both in vitro and in vivo (Pandey et al. 2017). Oxidized BC is another kind of cellulosic materials, which is appropriate for wound healing since it possesses considerable water absorption capacity, antibacterial effect, and well-dispersed cellulose fibrils (Wu et al. 2018).

Drug delivery

A drug delivery system is defined as the release of drugs at an appropriate time, to specifically targeted organs in a specified amount. Drug delivery systems transfer drugs to the desired organs, tissues, or cells, where the transfer mechanism can be controlled to respond to environmental stimuli such as light, temperature, pH, chemical actions, and electric and magnetic fields. Cellulose has a long history of application in the pharmaceutical industry, where it has been used as a tablet-coating when blended with various excipients for oral administration. Despite an extended history of use in tableting, there is still ongoing research on the potential use of cellulose and its derivatives in advanced drug-loaded systems in terms of the rate of tablet dissolution as appropriate excipients or extended drug release as novel drug carriers (Table 6) (Abeer et al. 2014; Yan et al. 2019). As a drug delivery system, cellulosic materials should promote controllable diffusive properties and dissolvability. For instance, cellulose and its derivatives have been observed to exhibit definite drug delivery patterns by instant, controlled, or delayed-release in oral dosage forms (Godakanda et al. 2019; Jeddi and Mahkam 2019). Furthermore, the natural resistance of cellulosic materials to the acidic environment of the stomach makes them very practical to use as enteric coatings on capsules or tablets (Guo et al. 2002).

Extemporaneously, compounded medicines are used when a needed dose or dose form is commercially inaccessible, or when a particular dosing regime is required. Powdered cellulose and MCC are used as adsorbents, capsule diluents, and thickening stabilizing agents in compounded medicines (Marques-Marinho and Vianna-Soares 2013). MCC shows viscoelastic behavior and sensitivity to the strain rate. In high-speed tableting, the time for plastic deformation is limited, and hence, in this case, elastic effects are more significant (Roberts and Rowe 1985). Thus, in the formulation design and dosing, dependency of MCC to the strain rate should be considered (Thoorens et al. 2014).

CNFs possess a considerable potential in biomedicine as carrier for controlled drug delivery because of their suitable flexibility, conducive elasticity, low density, low toxicity, and relatively reactive surface, that can be used for grafting specific groups, in addition to being renewable and cheap. The rheological, barrier, and physicochemical characteristics of CNFs allow them to stabilize oil–water and air–water interfaces. Moreover, CNFs’ high surface area per unit mass provides stabilization of nanoparticles and a higher probability for positive molecular interaction with poorly soluble drugs. CNFs have been used as stabilizers for crystalline drug nanoparticles, as matrix former to obtain a long-lasting sustained drug release over several weeks, and as film former with immediate release properties for poorly soluble drug (Löbmann and Svagan 2017). CNFs can generally be converted into aerogel form during drug adsorption and subsequent freeze-drying (Bhandari et al. 2017). Plant-based CNFs have been successfully used as an injectable drug-releasing hydrogel in mice, demonstrating the potential application of CNFs as a matrix for controlled release or targeted local delivery of drug compounds in humans (Laurén et al. 2014).

CA nanofiber mats have been used mainly in diverse pharmaceutical applications due to their advantageous characteristics, like high shear strength and shear modulus, biocompatibility, regenerative properties, high affinity with other substances, biodegradability, and suitable flexural and tensile strength. In particular, CA-based drug-loaded nanofibers have received considerable attention in the development of topical and transdermal drug delivery systems (Yu et al. 2013). Besides, cellulose acetate phthalate is a novel material that provides the most efficient solution for pH-controlled drug release. One of the decisive applications of cellulose acetate phthalate is in microencapsulation, which is utilized in an aqueous or organic medium (Wan and Chui 1995). Cellulose acetate phthalate electrospun fibers facilitate resistance to HIV infections. These fibers, even after dissolution, are nontoxic for vaginal epithelial cells and vaginal lactobacilli. These fibers are suitable for loading anti-HIV drugs and in preventing HIV infection during sexual intercourse (Huang et al. 2012). Typically, microencapsulation with cellulose acetate phthalate has been done by coacervation phase separation, spray-drying, and extrusion methods (Wan and Chui 1995).

One of the most prevalent hydrophilic biodegradable polymers that has been used in controlled-release formulations and that has been approved by the United States Food and Drug Administration (FDA), is hydroxy propyl methyl cellulose (Hu et al. 2018). Injectable chitosan/glycerophosphate thermosensitive solutions containing vancomycin-loaded hydroxy propyl methyl cellulose microparticles are produced for the local treatment of osteomyelitis (Mahmoudian and Ganji 2017). The porous and spongy structure of a hydroxyl propyl methyl cellulose hydrogel allows for a long-term release profile in vitro, which provides excellent potential for usage in sustained antibiotic delivery (Mahmoudian and Ganji 2017).

Conclusions

Over the last decades, numerous studies have reported on the modification and utilization of cellulosic materials. This review summarized the preparation of cellulose and its derivatives from different sources, with a focus on specific properties that include structure at molecular and microscopic levels, solubility in certain liquids, and mechanical properties, with further emphasis on their versatility for applications in the biomedical field. Recent advances show that cellulosic materials prove to have inherent characteristics that can be tailored for a broad range of biomedical applications, in tissue engineering, and for the development of drug delivery and wound dressing systems. Several chemical derivatizations and/or modifications that are reported here have been utilized to alter specific cellulose properties for expanding the range of applications, especially biomedical applications. In particular, hydroxyethyl cellulose and CMC are used since they are ideal as versatile materials for tissue engineering. Further, CA, which promotes tissue regeneration in wound dressing preparations, provides patient comfort. BC and cellulose nanocrystals are used for encapsulation. Carboxymethyl cellulose, hydroxy propyl methyl cellulose, ethyl cellulose, and cellulose sulfate are used in drug delivery systems for controlled release. Therefore, although cellulosic materials are traditionally used in everyday household items as paper and textile, they exhibit the necessary qualities for developing novel materials for biomedical applications.

Future perspectives

Cellulose provides a sustainable resource satisfying the requirements as biomedical material; it has continuously inspired researchers to exploit cellulose-based materials with novel functionalities. Undoubtedly, cellulosic materials hold excellent promise for applications in biological implants and scaffolds for tissue engineering, wound and burn dressing material, medical implants, and drug delivery systems because of their excellent physical and biological properties, biocompatibility, biodegradability, and low cytotoxicity. The surface functionalization and the form of cellulose used for biomedical applications, e.g. hydrogel, solid film, scaffold, membrane, and nanomaterials, provides a useful and powerful tool to tune the interactions of biomaterials with living tissue. Preliminary studies on cellulosic materials have shown that they are favorable biomaterials compared to many other natural polymers in tissue engineering due to their durability and compatibility. The usefulness of cellulosic materials in wound-healing and organ replacement applications has been shown and commercialized, but more interdisciplinary research is still needed to further develop these materials. For instance, a wide variety of mammalian cells needs to be cultured on cellulosic materials to assess their viability and proliferation in vitro. In vivo studies will also be essential to prove its usefulness and functionality for future biomedical applications. Future applications of cellulose and its derivatives are already envisioned in the pharmaceutical industry to act as drug delivery systems, and/or smart artificial skin or wound regeneration therapies. Although cellulosic materials are not inherently toxic, more research is needed to evaluate the potential pharmaceutical side effects and cytotoxicity profile. Cellulose’ hydrophilic nature, leading to a poor dispersion in hydrophobic polymer matrices, together with its cytotoxicity, has led to the devotion of much effort on surface modification of cellulosic materials. Various surface and/or bulk modifications of cellulose offer new opportunities for developing unique functional materials. Meanwhile, modification results in alterations of physicochemical properties of materials, especially at the nanoscale. Therefore, the influence of foreign molecule incorporation on the cytotoxicity and/or biocompatibility of nanocellulose should be specifically addressed in future research. Clearly, despite the significant developments concerning biomedical nanocellulosic materials, this area is still in its infancy. We believe that there are still several areas that need to be addressed and plenty of possibilities to be explored on this topic.

Availability of data and material

Not applicable.

Code availability

Not applicable.

References

Abbott AP, Bell TJ, Handa S, Stoddart B (2005) O-Acetylation of cellulose and monosaccharides using a zinc based ionic liquid. Green Chem 7:705–707. https://doi.org/10.1039/b511691k

Abe K, Nakatsubo F, Yano H (2009) High-strength nanocomposite based on fibrillated chemi-thermomechanical pulp. Compos Sci Technol 69:2434–2437. https://doi.org/10.1016/j.compscitech.2009.06.015

Abeer MM, Amin MCIM, Lazim AM, Pandey M, Martin C (2014) Synthesis of a novel acrylated abietic acid-g-bacterial cellulose hydrogel by gamma irradiation. Carbohydr Polym 110:505–512. https://doi.org/10.1016/j.carbpol.2014.04.052

Abraham E, Weber DE, Sharon S, Lapidot S, Shoseyov O (2017) Multifunctional cellulosic scaffolds from modified cellulose nanocrystals. ACS Appl Mater Inter 9:2010–2015. https://doi.org/10.1021/acsami.6b13528

Adachi S, Ebi Y, Nishikawa S-i, Hayashi S-i, Yamazaki M, Kasugai T, Yamamura T, Nomura S, Kitamura Y (1992) Necessity of extracellular domain of W (c-kit) receptors for attachment of murine cultured mast cells to fibroblasts. Blood 79:650–656. https://doi.org/10.1182/blood.v79.3.650.650

Agis H, Beirer B, Watzek G, Gruber R (2010) Effects of carboxymethylcellulose and hydroxypropylmethylcellulose on the differentiation and activity of osteoclasts and osteoblasts. J Biomed Mater Res A 95:504–509. https://doi.org/10.1002/jbm.a.32842

Agoda-Tandjawa G, Durand S, Berot S, Blassel C, Gaillard C, Garnier C, Doublier J-L (2010) Rheological characterization of microfibrillated cellulose suspensions after freezing. Carbohydr Polym 80:677–686. https://doi.org/10.1016/j.carbpol.2009.11.045

Agubata CO, Okereke C, Nzekwe IT, Onoja RI, Obitte NC (2016) Development and evaluation of wound healing hydrogels based on a quinolone, hydroxypropyl methylcellulose and biodegradable microfibres. Eur J Pharm Sci 89:1–10. https://doi.org/10.1016/j.ejps.2016.04.017

Ahlfeld T, Köhler T, Czichy C, Lode A, Gelinsky M (2018) A methylcellulose hydrogel as support for 3D plotting of complex shaped calcium phosphate scaffolds. Gels 4:68. https://doi.org/10.3390/gels4030068

Ali ZM, Gibson LJ (2012) The structure and mechanics of nanofibrillar cellulose foams. Soft Matter 9:1580–1588. https://doi.org/10.1039/c2sm27197d

Angles MN, Dufresne A (2000) Plasticized starch/tunicin whiskers nanocomposites. 1. Structural analysis. Macromolecules 33:8344–8353. https://doi.org/10.1021/ma0008701

Ansari F, Sjöstedt A, Larsson PT, Berglund LA, Wågberg L (2015) Hierarchical wood cellulose fiber/epoxy biocomposites–Materials design of fiber porosity and nanostructure. Compos Part A-Appl Sci 74:60–68. https://doi.org/10.1016/j.compositesa.2015.03.024

Ao C, Niu Y, Zhang X, He X, Zhang W, Lu C (2017) Fabrication and characterization of electrospun cellulose/nano-hydroxyapatite nanofibers for bone tissue engineering. Int J Biol Macromol 97:568–573. https://doi.org/10.1016/j.ijbiomac.2016.12.091

Aoshima M, Jo Y (2013) Augmentation for cell spreading and migration by a soluble fraction of cotton-derived carboxymethyl cellulose. Kobunshi Ronbunshu 70:273–281. https://doi.org/10.1295/koron.70.273

Araki J, Kuga S (2001) Effect of trace electrolyte on liquid crystal type of cellulose microcrystals. Langmuir 17:4493–4496. https://doi.org/10.1021/la0102455

Ardanuy M, Claramunt J, Toledo Filho RD (2015) Cellulosic fiber reinforced cement-based composites: a review of recent research. Constr Build Mater 79:115–128. https://doi.org/10.1016/j.conbuildmat.2015.01.035

Ates B, Koytepe S, Ulu A, Gurses C, Thakur VK (2020) Chemistry, structures, and advanced applications of nanocomposites from biorenewable resources. Chem Rev 120:9304–9362. https://doi.org/10.1021/acs.chemrev.9b00553

Atila D, Keskin D, Tezcaner A (2016) Crosslinked pullulan/cellulose acetate fibrous scaffolds for bone tissue engineering. Mater Sci Eng C-Mater 69:1103–1115. https://doi.org/10.1016/j.msec.2016.08.015

Avolio R, Bonadies I, Capitani D, Errico ME, Gentile G, Avella M (2012) A multitechnique approach to assess the effect of ball milling on cellulose. Carbohydr Polym 87:265–273. https://doi.org/10.1016/j.carbpol.2011.07.047

Aysu T, Maroto-Valer MM, Sanna A (2016) Ceria promoted deoxygenation and denitrogenation of Thalassiosira weissflogii and its model compounds by catalytic in situ pyrolysis. Bioresour Technol 208:140–148. https://doi.org/10.1016/j.biortech.2016.02.050

Bäckdahl H, Helenius G, Bodin A, Nannmark U, Johansson BR, Risberg B, Gatenholm P (2006) Mechanical properties of bacterial cellulose and interactions with smooth muscle cells. Biomaterials 27:2141–2149. https://doi.org/10.1016/j.biomaterials.2005.10.026

Bäckdahl H, Esguerra M, Delbro D, Risberg B, Gatenholm P (2008) Engineering microporosity in bacterial cellulose scaffolds. J Tissue Eng Regen Med 2:320–330. https://doi.org/10.1002/term.97

Balakrishnan P, Gopi S, Geethamma V, Kalarikkal N, Thomas S (2018a) Cellulose nanofiber vs nanocrystals from pineapple leaf fiber: a comparative studies on reinforcing efficiency on starch nanocomposites. Macromol Symp 380:1800102. https://doi.org/10.1002/masy.201800102

Balakrishnan P, Gopi S, Sreekala MS, Thomas S (2018b) UV resistant transparent bionanocomposite films based on potato starch/cellulose for sustainable packaging. Starch-Stärke 70:1700139. https://doi.org/10.1002/star.201700139

Barikani M, Oliaei E, Seddiqi H, Honarkar H (2014) Preparation and application of chitin and its derivatives: a review. Iran Polym J 23:307–326. https://doi.org/10.1007/s13726-014-0225-z

Basu A, Celma G, Strømme M, Ferraz N (2018a) In vitro and in vivo evaluation of the wound healing properties of nanofibrillated cellulose hydrogels. ACS Appl Bio Mater 1:1853–1863. https://doi.org/10.1021/acsabm.8b00370