Abstract

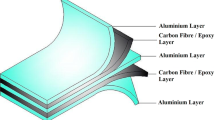

Natural fibre metal laminates are widely being researched for their mechanical properties and in the making of metal and polymer matrix composites. The hybrid metal–natural fibre laminate composites have largely improved mechanical properties and can withstand greater forces without failing. In this study, Aluminium 6082 is the metal chosen, and flax fibre is used to reinforce the Aluminium 6082. However, natural fibre and metal fibre have difficulty bonding with a polymer matrix to enhance their mechanical performance. Hence, alkaline surface treatment method is applied for flax and metal fibre to increase the adhesive strength of the material. Fabricate the treated and untreated samples using hand layup followed by compression moulding technique. The micromechanical performance including tensile strength and flexural strength of treated and untreated samples was investigated. It was found that untreated flax fibre-reinforced aluminium laminate does not have proper interfacial adhesion. The resulting fabricated sample with the treated exhibit there is an improvement in tensile and flexural properties and microstructural characterisation also examined and it showed the interfacial adhesion mechanism affected the improvement in the properties.

Similar content being viewed by others

Availability of Data and Materials

Not applicable.

References

M. Ramesh, Flax (Linum usitatissimum L.) fibre reinforced polymer composite materials: a review on preparation, properties and prospects. Prog. Mater. Sci. 102, 109–166 (2019)

K. Pickering, M.A. Efendy, T. Le, A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. S. 83, 98–112 (2016)

L.B. Vogelesang, A. Vlot, Development of fibre metal laminates for advanced aerospace structures. J. Mater. Process. Technol. 103, 1–5 (2016)

O. Faruk, A.K. Bledzki, H.P. Fink, M. Sain, Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 37(11), 1552–1596 (2012)

Q. Zehua, X. Pan, H. Xiaoyue, Y. Guo, Y. Shen, Evaluation of nano-mechanical behavior on flax fiber metal laminates using an atomic force microscope. MDPI Mater. 12, 3363 (2019). https://doi.org/10.3390/ma12203363

J.P. Singh, P. Gulati, R. Kumar, M. Singh, Flax fiber reinforced polymer composites: a review article in SSRN electronic journal. IJRAR 6, 1 (2019)

J. Zhu, H. Zhu, J. Njuguna, H. Abhyanka, Recent development of flax fibres and their reinforced composites based on different polymeric matrices. Materials (Basel) 6(11), 5171–5198 (2013)

I. Van de Weyenberg, J. Ivensa, A. De Costerb, B. Kinob, E. Baetensb, I. Verpoesta, Influence of processing and chemical treatment of flax fibres on their composites. Compos. Sci. Technol. 63(9), 1241–1246 (2003)

J. Gassan, A.K. Bledzki, Possibilities for improving the mechanical properties of jute/epoxy composites by alkali treatment of fibres. Compos. Sci. Technol. 59(9), 1303–1309 (1999)

M. Chandrasekar, M. Ishak, S. Sapuan, Z. Leman, M. Jawaid, R.M. Shahroze, Fabrication of fibre metal laminate with flax and sugar palm fibre based epoxy composite and evaluation of their fatigue properties. J. Polym. Mater. 35, 463–473 (2019). https://doi.org/10.32381/JPM.2018.35.04.5

Y. Shen, J. Zhong, S. Cai, H. Ma, Z. Qu, Y. Guo, Y. Li, Effect of temperature and water absorption on low-velocity impact damage of composites with multi-layer structured flax fiber. Materials 12(3), 453 (2019). https://doi.org/10.3390/ma12030453

M.N.M. Merzuki, M.R.M. Rejab, N.K. Romli, D. Bachtiar, J. Siregar, M.F. Rani, S. Mohd Salleh, Finite element simulation of aluminium/GFRP fibre metal laminate under tensile loading. IOP Conf. Ser. Mater. Sci. Eng. 318, 012072 (2018)

A. Shahzad, Investigation into fatigue strength of natural/synthetic fiber-based composite materials, in Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites Woodhead Publishing Series in Composites Science and Engineering (2019), pp. 215–239

N.M. Ishak, S.D. Malingam, M.R. Mansor, N. Razali, Z. Mustafa, A.F. Ab Ghani, Investigation of natural fibre metal laminate as car front hood. Mater. Res. Express 8(2), 025303 (2021)

P.M. Waghmare, P.G. Bedmutha, S.B. Sollapur, Investigation of effect of hybridization and layering patterns on mechanical properties of banana and kenaf fibers reinforced epoxy biocomposite. Mater. Today Proc. 46, 3220–3224 (2021)

D. Saravanan, Tribological properties of filler and green filler reinforced polymer composites. Mater. Today Proc. 50, 2065–2072 (2022)

S.H. Ghaffar, M. Al-Kheetan, P. Ewens, Investigation of the interfacial bonding between flax/wool twine and various cementitious matrices in mortar composites. Constr. Build. Mater. 239, 11783 (2020)

U.A. Khilare, S.B. Sollapur, Investigation of residual stresses and its effect on mechanical behaviour of AISI310. Int. J. Sci. Prog. Res. (Ijspr) 12, 035 (2015)

U.A. Khilare et al., Investigation of residual stresses in welding and its effect on mechanical behavior of stainless steel 310. J. Res. 2, 05 (2016)

K.O. Odesanya, R. Ahmadl, M. Jawaid, Natural fibre-reinforced composite for ballistic applications: a review. J. Polym. Environ. (2021). https://doi.org/10.1007/s10924-021-02169-4

G. R. Chate, et al., Ceramic material coatings: emerging future applications, in Advanced Ceramic Coatings for Emerging Applications (Elsevier, 2023), pp. 3–17.

M.S. Patil, S.P. Deshmukh, Experimental investigation of high precision XY mechanism. Int. J. Mech. Eng. Technol. 9(5), 43–50 (2018)

M. Ostapiuk, J. Bieniaś, Corrosion resistance in NaCl environment of fiber metal laminates based on aluminum and titanium alloys with carbon and glass fibers. Adv. Eng. Mater. 23(3), 2001030 (2021)

K.P. Toradmal, P.M. Waghmare, S.B. Sollapur, Three point bending analysis of honeycomb sandwich panels: experimental approach. Int. J. Eng. Tech. 3, 5 (2017)

M.S. Patil, S.P. Deshmukh, Design and development aspects of flexure mechanism for high precision application. AIP Conf. Proc. 1943(1), 020023 (2018)

S. Sun, Y. Pan, G. Wu, X. Wang, P. Zeng, L. Hei, L. Wang, Corrosion characteristics and protection of fiber metal laminates based on Mg–Li alloys. Mater. Res. Express 5(9), 096517 (2018)

Z. Qu, X. Pan, X. Hu, Y. Guo, Y. Shen, Evaluation of nano-mechanical behavior on flax fiber metal laminates using an atomic force microscope. Materials 12(20), 3363 (2019)

T. Shinde et al., Fatigue analysis of alloy wheel using cornering fatigue test and its weight optimization. Mater. Today Proc. 62, 1470–1474 (2022)

S. Sollapur, M.S. Patil, S.P. Deshmukh, Position estimator algorithm implementation on precision applications. Mater. Today Proc. 24, 333–342 (2020)

I. Van de Weyenberg, J. Ivens, A. De Coster, B. Kino, E. Baetens, I. Verpoest, Influence of processing and chemical treatment of flax fibres on their composites. Compos. Sci. Technol. 63(9), 1241–1246 (2003)

A. Shahzad, Investigation into fatigue strength of natural/synthetic fiber-based composite materials, in Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites (Woodhead Publishing, 2019), pp. 215–239

S.B. Sollpaur, M.S. Patil, S.P. Deshmukh, Evaluation of stiffness and parametric modelling of XY flexure mechanism for precision applications. J. Model. Simul. Mater. 1(1), 8–15 (2018)

P.M. Waghmare, P.G. Bedmutha, Review on mechanical properties of banana fiber biocomposite. Int. J. Res. Appl. Sci. Eng. Technol. 5(10), 847 (2017)

C. Durga Prasad, S. Kollur, C.R. Aprameya, T.V. Chandramouli, T. Jagadeesha, B.N. Prashanth, Investigations on tribological and microstructure characteristics of WC-12Co/FeNiCrMo composite coating by HVOF process. JOM J. Miner. Met. Mater. Soc. TMS (2023). https://doi.org/10.1007/s11837-023-06242-2

S. Gotagunaki, V.S. Mudakappanavar, R. Suresh, C. Durga Prasad, Studies on the mechanical properties and wear behavior of an AZ91D magnesium metal matrix composite utilizing the stir casting method. Metallogr. Microstruct. Anal. (2023). https://doi.org/10.1007/s13632-023-01017-2

P. Sangwan, R. Kumar, Y. Sharma, D.G. Bhosale, C. Durga Prasad, Application of computing in recognition of input design factors for vapour-grown carbon nanofibers through fuzzy cluster analysis. Int. J. Interact. Des. Manufact. (IJIDeM). (2023). https://doi.org/10.1007/s12008-023-01547-7

K.S. Lokesh, K. Shashank Kumar, N. Keerthan, R. Revanth, S. Sandeep, S.B. Lakkundi, V. Bharath, H. Hanumanthappa, C. Durga Prasad, B.K. Shanmugam, Experimental analysis of the rice husk and eggshell powder-based natural fibre composite. J. Inst. Eng. (India) Ser. D (2023). https://doi.org/10.1007/s40033-023-00557-9

G. Srinivasa Rao, U. Mukkamala, C. Harish Hanumanthappa, D. Prasad, H. Vasudev, B. Shanmugam, KCh.. Kishore Kumar, Evaluating and optimizing surface roughness using genetic algorithm and artificial neural networks during turning of AISI 52100 steel. Int. J. Interact. Des. Manuf. IJIDeM (2023). https://doi.org/10.1007/s12008-023-01549-5

C. Manjunatha, T.N. Sreenivasa, P. Sanjay, C. Durga Prasad, Optimization of friction stir welding parameters to enhance weld nugget hardness in AA6061-B4C composite material. J. Inst. Eng. (India) Ser. D (2023). https://doi.org/10.1007/s40033-023-00562-y

M. Arunadevi, R. Monisha Rani, M.K. Sibinraj, C.D. Chandru Prasad, Comparison of k-nearest neighbor and artificial neural network prediction in the mechanical properties of aluminum alloys. Mater. Today Proc. (2023). https://doi.org/10.1016/j.matpr.2023.09.111

H. Sharanabasava, M. Raviprakash, C. Durga Prasad, M.R. Ramesh, M.V. Phanibhushana, H. Vasudev, S. Kumar, Microstructure, mechanical and wear properties of SiC and Mo reinforced NiCr microwave cladding. Adv. Mater. Process. Technol. (2023). https://doi.org/10.1080/2374068X.2023.2257937

C. Durga Prasad, S. Kollur, M. Nusrathulla, G. Satheesh Babu, M.B. Hanamantraygouda, B.N. Prashanth, N. Nagabhushana, Characterisation and wear behaviour of SiC reinforced FeNiCrMo composite coating by HVOF process. Trans. IMF 1, 21 (2023). https://doi.org/10.1080/00202967.2023.2246259

M.A. Kattimani, P.R. Venkatesh, L.J. Kirthan, M.M. Math, A.C. Prapul Chandra, R. Hegde, C. Durga Prasad, M. Gupta, S. Kumar, Design and optimization of fatigue life studies on induction hardened IN718 alloy for gas turbine applications. Adv. Mater. Process. Technol. (2023). https://doi.org/10.1080/2374068X.2023.2256121

A.K.R. Tavadi, N. Nagabhushana, V.N. Vivek Bhandarkar, T. Jagadeesha, M.R. Kerur, S. Rudresha, C. Durga Prasad, A. Rajesh Kannan, D.G. Mohan, Investigation on mechanical and sliding wear behaviour of pongamia-oil-cake/basalt fibre reinforced epoxy hybrid composites. Arab. J. Sci. Eng. (2023). https://doi.org/10.1007/s13369-023-08207-8

M.A. Kattimani, P.R. Venkatesh, H. Masum, M.M. Math, V.N. Bahadurdesai, C. Syed Mustafkhadri, D. Prasad, H. Vasudev, Design and numerical analysis of tensile deformation and fracture properties of induction hardened Inconel 718 superalloy for gas turbine applications. Int. J. Interact. Des. Manuf. (IJIDeM) (2023). https://doi.org/10.1007/s12008-023-01452-z

A. Rajesh Kannan, C. Durga Prasad, V. Rajkumar, N. Siva Shanmugam, V. Rajkumar, W. Lee, J. Yoon, Hot oxidation and corrosion behaviour of boiler steel fabricated by wire arc additive manufacturing. Mater Charact 203, 113113 (2023). https://doi.org/10.1016/j.matchar.2023.113113

G.S. Kulkarni, N.G. Siddeshkumar, C. Durga Prasad, L. Shankar, R. Suresh, Drilling of GFRP with liquid silicon rubber reinforced with fine aluminium powder on hole surface quality and tool wear using DOE. J. Bio Tribo Corros. 9, 53 (2023). https://doi.org/10.1007/s40735-023-00771-8

S.D. Kulkarni, C.U. Manjunatha, K.V. Manjunath, C. Durga Prasad, H. Vasudev, Design and optimization of polyvinyl-nitride rubber for tensile strength analysis. Int. J. Interact. Des. Manuf. (IJIDeM) (2023). https://doi.org/10.1007/s12008-023-01405-6

M.M. Math, K.V.S. Rajeswara Rao, A.C. Prapul Chandra, M.N. Vijayakumar, B. Nandini, C. Durga Prasad, H. Vasudev, Design and modeling using finite element analysis for the sitting posture of computer users based on ergonomic perspective. Int. J. Interact. Des. Manuf. (IJIDeM) (2023). https://doi.org/10.1007/s12008-023-01383-9

G. Madhu Sudana Reddy, C. Durga Prasad, S. Kollur, A. Lakshmikanthan, R. Suresh, C.R. Aprameya, Investigation of high temperature erosion behaviour of NiCrAlY/TiO2 plasma coatings on titanium substrate. JOM J. Miner. Met. Mater. Soc. (TMS) (2023). https://doi.org/10.1007/s11837-023-05894-4

S. Pulla Nagabhushana, C.D. Ramprasad, H.V. Prasad, C. Prakash, Numerical investigation on heat transfer of a nano-fluid saturated vertical composite porous channel packed between two fluid layers. Int. J. Interact. Des. Manuf. (IJIDeM) (2023). https://doi.org/10.1007/s12008-023-01379-5

G. Anjaneya, S. Sunil, S. Kakkeri, M.M. Math, M.N. Vaibhav, C. Solaimuthu, C. Durga Prasad, H. Vasudev, Numerical simulation of microchannel heat exchanger using CFD. Int. J. Interact. Des. Manuf. (IJIDeM) (2023). https://doi.org/10.1007/s12008-023-01376-8

M. Poojari, C. Harish Hanumanthappa, D. Prasad, H.M. Jathanna, A.R. Ksheerasagar, P. Shetty, B.K. Shanmugam, H. Vasudev, Computational modelling for the manufacturing of solar-powered multifunctional agricultural robot. Int. J. Interact. Des. Manuf. (IJIDeM) (2023). https://doi.org/10.1007/s12008-023-01291-y

H. Sharanabasva, C. Durga Prasad, M.R. Ramesh, Characterization and wear behavior of NiCrMoSi microwave cladding. J. Mater. Eng. Perform. (2023). https://doi.org/10.1007/s11665-023-07998-z

C.J. Manjunatha, C. Durga Prasad, H. Hanumanthappa, A. Rajesh Kannan, D.G. Mohan, B.K. Shanmugam, C. Venkategowda, Influence of microstructural characteristics on wear and corrosion behaviour of Si3N4 reinforced Al2219 composites. Adv. Mater. Sci. Eng. 2023, 1120569 (2023). https://doi.org/10.1155/2023/1120569

H. Sharanabasva, C. Durga Prasad, M.R. Ramesh, Effect of Mo and SiC reinforced NiCr microwave cladding on microstructure, mechanical and wear properties”. J. Inst. Eng. (India) Ser. D (2023). https://doi.org/10.1007/s40033-022-00445-8

H.S. Nithin, K.M. Nishchitha, D.G. Pradeep, C. Durga Prasad, M. Mathapati, Comparative analysis of CoCrAlY coatings at high temperature oxidation behavior using different reinforcement composition profiles. Weld. World 67, 585–592 (2023). https://doi.org/10.1007/s40194-022-01405-2

D.C. Naveen, N. Kakur, B.S. Keerthi Gowda, G. Madhu Sudana Reddy, C. Durga Prasad, R. Shanmugam, Effects of polypropylene waste addition as coarse aggregate in concrete: experimental characterization and statistical analysis. Adv. Mater. Sci. Eng. 2022, 11 (2022). https://doi.org/10.1155/2022/7886722

G. Madhusudana Reddy, C. Durga Prasad, P. Patil, N. Kakur, M.R. Ramesh, Elevated temperature erosion performance of plasma sprayed NiCrAlY/TiO2 coating on MDN 420 steel substrate. Surf. Topogr. Metrol. Prop. 10, 025010 (2022). https://doi.org/10.1088/2051-672X/ac6a6e

V. Gowda, H. Hanumanthappa, B.K. Shanmugam, C. Durga Prasad, T.N. Sreenivasa, M.S. Rajendra Kumar, High-temperature tribological studies on hot forged Al6061-Tib2 in-situ composites. J. Bio Tribo-Corros. 8, 101 (2022). https://doi.org/10.1007/s40735-022-00699-5

G. Madhusudana Reddy, C. Durga Prasad, G. Shetty, M.R. Ramesh, T. Nageswara Rao, P. Patil, Investigation of thermally sprayed NiCrAlY/TiO2 and NiCrAlY/Cr2O3/YSZ cermet composite coatings on titanium alloys. Eng. Res. Express 4, 025049 (2022). https://doi.org/10.1088/2631-8695/ac7946

G. Madhusudana Reddy, C. Durga Prasad, G. Shetty, M.R. Ramesh, T. Nageswara Rao, P. Patil, High temperature oxidation behavior of plasma sprayed NiCrAlY/TiO2 and NiCrAlY /Cr2O3/YSZ coatings on titanium alloy. Weld. World (2022). https://doi.org/10.1007/s40194-022-01268-7

T. Naik, C. Mahantayya Mathapathi, D. Prasad, H.S. Nithin, M.R. Ramesh, Effect of laser post treatment on microstructural and sliding wear behavior of HVOF sprayed NiCrC and NiCrSi coatings. Surf. Rev. Lett. 29(1), 225000 (2022). https://doi.org/10.1142/S0218625X2250007X

G. Madhusudana Reddy, C. Durga Prasad, G. Shetty, M.R. Ramesh, T. Nageswara Rao, P. Patil, High temperature oxidation studies of plasma sprayed NiCrAlY/TiO2 and NiCrAlY /Cr2O3/YSZ cermet composite coatings on MDN-420 special steel alloy. Metallogr. Microstruct. Anal. 10, 642–651 (2021). https://doi.org/10.1007/s13632-021-00784-0

M. Mathapati, C. Kiran Amate, D. Prasad, M.L. Jayavardhana, T. Hemanth Raju, A review on fly ash utilization. Mater. Today Proc. 50(5), 1535–1540 (2022). https://doi.org/10.1016/j.matpr.2021.09.106

C. Durga Prasad, S. Lingappa, M.R. Sharnappa Joladarashi, S.B. Ramesh, Characterization and sliding wear behavior of CoMoCrSi+Flyash composite cladding processed by microwave irradiation. Mater. Today Proc. 46, 2387–2391 (2021). https://doi.org/10.1016/j.matpr.2021.01.156

G. Madhu, K.M. Mrityunjaya Swamy, D.A. Kumar, C. Durga Prasad, U. Harish, Evaluation of hot corrosion behavior of HVOF thermally sprayed Cr3C2–35NiCr coating on SS 304 boiler tube steel. Am. Inst. Phys. 2316, 030014 (2021). https://doi.org/10.1063/5.0038279

C. Durga Prasad, M.R. Sharnappa Joladarashi, M.S. Ramesh, Srinath, Microstructure and tribological resistance of flame sprayed CoMoCrSi/WC-CrC-Ni and CoMoCrSi/WC-12Co composite coatings remelted by microwave hybrid heating. J. Bio Tribo-Corros. 6, 124 (2020). https://doi.org/10.1007/s40735-020-00421-3

C. Durga Prasad, M.R. Sharnappa Joladarashi, Ramesh, Comparative investigation of HVOF and flame sprayed CoMoCrSi coating. Am. Inst. Phys. 2247, 050004 (2020). https://doi.org/10.1063/5.0003883

M.S. Reddy, C. Durga Prasad, M.R. Pradeep Patil, N.R. Ramesh, Hot corrosion behavior of plasma sprayed NiCrAlY/TiO2 and NiCrAlY/Cr2O3/YSZ cermets coatings on alloy steel. Surf. Interfaces 22, 100810 (2021). https://doi.org/10.1016/j.surfin.2020.100810

C. Durga Prasad, M.R. Akhil Jerri Ramesh, Characterization and sliding wear behavior of iron based metallic coating deposited by HVOF process on low carbon steel substrate. J. Bio Tribo-Corros. 6, 69 (2020). https://doi.org/10.1007/s40735-020-00366-7

R. Dinesh, S. Rohan Raykar, T.L. Rakesh, M.G. Prajwal, M. Shashank Lingappa, P.C. Durga, Feasibility study on MoCoCrSi/ WC-Co cladding developed on austenitic stainless steel using microwave hybrid heating. J. Mines Met. Fuels (2021). https://doi.org/10.18311/jmmf/2021/30113

C. Durga Prasad, M.R. Sharnappa Joladarashi, M.S. Ramesh, B.H. Srinath, Channabasappa, Comparison of high temperature wear behavior of microwave assisted HVOF sprayed CoMoCrSi-WC-CrC-Ni/WC-12Co composite coatings. SILICON 12, 3027–3045 (2020). https://doi.org/10.1007/s12633-020-00398-1

N. Praveen, U.S. Mallik, A.G. Shivasiddaramaih, R. Suresh, C. Durga Prasad, L. Shivaramu, Synthesis and wire EDM characteristics of Cu–Al–Mn ternary shape memory alloys using Taguchi method. J. Inst. Eng. (India) Ser. D (2023). https://doi.org/10.1007/s40033-023-00501-x

C. Durga Prasad, M.R. Sharnappa Joladarashi, M.S. Ramesh, B.H. Srinath, Channabasappa, Effect of microwave heating on microstructure and elevated temperature adhesive wear behavior of HVOF deposited CoMoCrSi-Cr3C2 composite coating. Surf. Coat. Technol. 374, 291–304 (2019). https://doi.org/10.1016/j.surfcoat.2019.05.056

K.G. Girisha, K.V. Sreenivas Rao, C. Durga Prasad, Slurry erosion resistance of martenistic stainless steel with plasma sprayed Al2O3–40%TiO2 coatings. Mater. Today Proc. 5, 7388–7393 (2018). https://doi.org/10.1016/j.matpr.2017.11.409

C. Durga Prasad, M.R. Sharnappa Joladarashi, M.S. Ramesh, B.H. Srinath, Channabasappa, Development and sliding wear behavior of Co–Mo–Cr–Si cladding through microwave heating. SILICON 11, 2975–2986 (2019). https://doi.org/10.1007/s12633-019-0084-5

C. Durga Prasad, M.R. Sharnappa Joladarashi, M.S. Ramesh, B.H. Srinath, Channabasappa, Microstructure and tribological behavior of flame sprayed and microwave fused CoMoCrSi/CoMoCrSi-Cr3C2 coatings. Mater. Res. Express 6, 026512 (2019). https://doi.org/10.1088/2053-1591/aaebd9

K.G. Girisha, R. Rakesh, C. Durga Prasad, K.V. Sreenivas Rao, Development of corrosion resistance coating for AISI 410 grade steel”. Appl. Mech. Mater. 813–814, 135–139 (2015). https://doi.org/10.4028/www.scientific.net/AMM.813-814.135

C. Durga Prasad, M.R. Sharnappa Joladarashi, M.S. Ramesh, B.H. Srinath, Channabasappa, Influence of microwave hybrid heating on the sliding wear behaviour of HVOF sprayed CoMoCrSi coating. Mater. Res. Express 5, 086519 (2018). https://doi.org/10.1088/2053-1591/aad44e

C. Durga Prasad, M.R. Sharnappa Joladarashi, A.S. Ramesh, High temperature gradient cobalt based clad developed using microwave hybrid heating. Am. Inst. Phys. 1943, 020111 (2018). https://doi.org/10.1063/1.5029687

K.G. Girisha, C. Durga Prasad, K.C. Anil, K.V. Sreenivas Rao, Dry sliding wear behaviour of Al2O3 coatings for AISI 410 grade stainless steel. Appl. Mech. Mater. 766–767, 585–589 (2015). https://doi.org/10.4028/www.scientific.net/AMM.766-767.585

Funding

Not applicable.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vinod, M., Kumar, C.A., Sollapur, S.B. et al. Study on Fabrication and Mechanical Performance of Flax Fibre-Reinforced Aluminium 6082 Laminates. J. Inst. Eng. India Ser. D (2023). https://doi.org/10.1007/s40033-023-00605-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40033-023-00605-4