Abstract

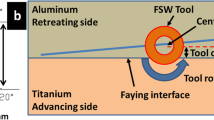

Friction stir welding (FSW) is a promising technology for joining dissimilar metal alloys, such as aluminum alloy (Al 2024) and titanium alloy (Ti-6Al-4V). However, optimizing FSW parameters to enhance joint strength and reliability remains a challenge. To address this, this manuscript presents a novel concept of using tool rotational speed as a key parameter to investigate joint formation mechanisms and associated mechanisms in FSW. The study found that tool rotational speed significantly affects the deformation and mechanical mixing of the two metals in the weld nugget. Optimal tool rotational speed produces a defect-free weld with superior mechanical properties. The fragmentation of joint interfaces and the formation of new particles of different sizes in titanium lead to deformation and fracture mechanisms. X-ray tomography results demonstrate that fine particles are evenly dispersed in the Al matrix compared to coarse particles. Moreover, the study provides valuable insights into the microstructural development in Al, attributed to dynamic recovery (DRV), continuous dynamic recrystallization (CDRX), and particle-stimulated nucleation (PSN). The type of intermetallic compounds (IMCs) formation is not affected by the tool rotational speed, and a proposed mechanism of IMCs formation is presented from a thermodynamic perspective. Overall, this study improvises the current understanding of joint formation mechanisms in FSW and suggests using tool rotational speed as a parameter for optimizing FSW parameters for enhanced joint strength and reliability.

Similar content being viewed by others

Data Availability Statement

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an on-going study. However, I am open to shear any data on request.

References

W.A.K.W. Zink and M. Peters, Advanced aerospace materials, DGLR, Munich, Germany, 25–32 (2000)

F. Möller, C. Thomy, and F. Vollertsen, Joining of titanium-aluminium seat tracks for aircraft applications—system technology and joint properties, Weld. World, 2012, 56(3–4), p 108–114. https://doi.org/10.1007/bf03321341

A. Fuji, In situ observation of interlayer growth during heat treatment of friction weld joint between pure titanium and pure aluminium, Sci. Technol. Weld. Join., 2002, 7(6), p 413–416. https://doi.org/10.1179/136217102225006903

J. Wilden, J.P. Bergmann, and S. Herz, Properties of diffusion welded hybrid joints titanium/aluminum. In Brazing and Soldering: Proceedings of The 3rd International Brazing and Soldering Conference, April 24–26, 2006, (Crown Plaza Riverwalk Hotel, San Antonio, Texas, USA, 2006), p. 338–343

Y.C. Kim and A. Fuji, Factors dominating joint characteristics in Ti-Al friction welds, Sci. Technol. Weld. Join., 2002, 7(3), p 149–154. https://doi.org/10.1179/136217102225004185

J.-G. Luo and V.L. Acoff, Using cold roll bonding and annealing to process Ti/Al multi-layered composites from elemental foils, Mater. Sci. Eng., A, 2004, 379(1–2), p 164–172. https://doi.org/10.1016/j.msea.2004.01.021

C.Q. Zhang, J.D. Robson, O. Ciuca, and P.B. Prangnell, Microstructural characterization and mechanical properties of high power ultrasonic spot welded aluminum alloy AA6111-TiAl6V4 dissimilar joints, Mater. Charact., 2014, 97, p 83–91. https://doi.org/10.1016/j.matchar.2014.09.001

L. Wan and Y. Huang, Friction stir welding of dissimilar aluminum alloys and steels: a review, Int. J. Adv. Manuf. Technol., 2018, 99(5), p 1781–1811. https://doi.org/10.1007/s00170-018-2601-x

R. Anbukkarasi and S.V. Kailas, Influences of shape of the new interfaces and morphology of the intermetallics on mechanical properties of aluminum AA2024–pure copper joints by friction stir welding, Int. J. Adv. Manuf. Technol., 2020, 106(11), p 5071–5083. https://doi.org/10.1007/s00170-019-04911-8

A. Kar, S.V. Kailas, and S. Suwas, Effect of zinc interlayer in microstructure evolution and mechanical properties in dissimilar friction stir welding of aluminum to titanium, J. Mater. Eng. Perform., 2018 https://doi.org/10.1007/s11665-018-3697-8

A. Kar, S. Suwas, and S.V. Kailas, Significance of tool offset and copper interlayer during friction stir welding of aluminum to titanium, Int. J. Adv. Manuf. Technol., 2018 https://doi.org/10.1007/s00170-018-2682-6

S. Delijaicov, D.Y. Yakabu, B. De Macedo, H.B. Resende, and M.H.F. Batalha, Characterization of the surface and mechanical properties of the friction stir welding in tri-dissimilar joints with aluminum alloys and titanium alloy, Int. J. Adv. Manuf. Technol., 2018, 95(1), p 1339–1355. https://doi.org/10.1007/s00170-017-1306-x

C.I. Chang, X.H. Du, and J.C. Huang, Producing nanograined microstructure in Mg-Al-Zn alloy by two-step friction stir processing, Scripta Mater., 2008, 59(3), p 356–359. https://doi.org/10.1016/j.scriptamat.2008.04.003

B. Li, Z. Zhang, Y. Shen, W. Hu, and L. Luo, Dissimilar friction stir welding of Ti–6Al–4V alloy and aluminum alloy employing a modified butt joint configuration: influences of process variables on the weld interfaces and tensile properties, Mater. Des., 2014, 53, p 838–848. https://doi.org/10.1016/j.matdes.2013.07.019

R. Palanivel, P. Koshy Mathews, N. Murugan, and I. Dinaharan, Effect of tool rotational speed and pin profile on microstructure and tensile strength of dissimilar friction stir welded AA5083-H111 and AA6351-T6 aluminum alloys, Mater. Des., 2012, 40, p 7–16. https://doi.org/10.1016/j.matdes.2012.03.027

K.-S. Bang, K.-J. Lee, H.-S. Bang, and H.-S. Bang, Interfacial microstructure and mechanical properties of dissimilar friction stir welds between 6061–T6 aluminum and Ti-6Al-4V alloys, Mater. Trans., 2011, 52(5), p 974–978. https://doi.org/10.2320/matertrans.L-MZ201114

Y. Li, L. Shi, C. Wu, S. Li, and Y. Jiang, Elucidation of welding speed on the microstructure and mechanical properties of medium-thick dissimilar Al/Ti double-side friction stir welded joint, Mater. Charact., 1964, 200, p 112910. https://doi.org/10.1016/j.matchar.2023.112910

W.J. McG. Tegart, Independent slip systems and ductility of hexagonal polycrystals, Philos. Mag., 1964, 9(98), p 339–341. https://doi.org/10.1080/14786436408229197

S.V. Kailas, Y.V.R.K. Prasad, and S.K. Biswas, Microstructural Features of Flow, Metall. Trans. A, 1993, 24(11), p 2513–2520. https://doi.org/10.1007/bf02646530

H.A. Grebe, H.-R. Pak, and M.A. Meyers, Adiabatic shear localization in titanium and Ti-6 pct Al-4 pct V alloy, Metall. Trans. A, 1985, 16(5), p 761–775. https://doi.org/10.1007/bf02814827

S.V. Kailas, Y.V.R.K. Prasad, and S.K. Biswas, Flow Instabilities and fracture in Ti-6Al-4V deformed in compression at 298 to 673 K, Metall. and Mater. Trans. A., 1994, 25(10), p 2173–2179. https://doi.org/10.1007/bf02652318

S.V. Kailas, Y.V.R.K. Prasad, and S.K. Biswas, Influence of initial texture on the microstructural instabilities during compression of commercial α-Titanium at 25 to 400 °C, Metall. and Mater. Trans. A., 1994, 25(7), p 1425–1434. https://doi.org/10.1007/bf02665475

N. Srinivasan and Y.V.R.K. Prasad, Microstructural control in hot working of IN-718 superalloy using processing map, Metall. and Mater. Trans. A., 1994, 25(10), p 2275–2284. https://doi.org/10.1007/bf02652327

S.K. Biswas and S.V. Kailas, Strain rate response and wear of metals, Tribol. Int., 1997, 30(5), p 369–375. https://doi.org/10.1016/S0301-679X(96)00066-7

M.A. Meyers and H.-R. Pak, Observation of an adiabatic shear band in titanium by high-voltage transmission electron microscopy, Acta Metall., 1986, 34(12), p 2493–2499. https://doi.org/10.1016/0001-6160(86)90152-5

A. Kar, S.K. Choudhury, S. Suwas and S.V. Kailas, Effect of niobium interlayer in dissimilar friction stir welding of aluminum to titanium, Mater. Charact., 2018, 145, p 402–412. https://doi.org/10.1016/j.matchar.2018.09.007

A. Kar, S. Suwas, and S.V. Kailas, Microstructural modification and high-temperature grain stability of aluminum in an aluminum-titanium friction stir weld with zinc interlayer, JOM, 2018 https://doi.org/10.1007/s11837-018-3152-1

M. Sujata, S. Bhargava, and S. Sangal, On the formation of TiAl3 during reaction between solid Ti and liquid Al, J. Mater. Sci. Lett., 1997, 16(13), p 1175–1178. https://doi.org/10.1023/A:1018509026596

A. Kar, S.V. Kailas, and S. Suwas, Effect of mechanical mixing in dissimilar friction stir welding of aluminum to titanium with zinc interlayer, Trans. Indian Inst. Met., 2019, 72, p 1533–1536. https://doi.org/10.1007/s12666-019-01643-x

A. Kar, S. Suwas, and S.V. Kailas, Two-pass friction stir welding of aluminum alloy to titanium alloy: a simultaneous improvement in mechanical properties, Mater. Sci. Eng. A, 2018, 733, p 199–210. https://doi.org/10.1016/j.msea.2018.07.057

A. Kar, S. Suwas, and S.V. Kailas, Multi-length scale characterization of microstructure evolution and its consequence on mechanical properties in dissimilar friction stir welding of titanium to aluminum, Metall. Mater. Trans. A., 2019, 50, p 5153–5173. https://doi.org/10.1007/s11661-019-05409-4

A. Kar, S. Kailas, and S. Suwas, Mechanism of variation in high-temperature grain stability of aluminum in dissimilar friction stir welds, Mater. Perform. Charact., 2020 https://doi.org/10.1520/MPC20190011

J.L. Murray, Phase diagrams of binary titanium alloys, ASM International, 1987, 1987, p 354.

J.L. Murray, Calculation of the titanium-aluminum phase diagram, Metall. Trans. A, 1988, 19(2), p 243–247. https://doi.org/10.1007/bf02652532

J.C. Rawers and W.R. Wrzesinski, Reaction-sintered hot-pressed TiAl, J. Mater. Sci., 1992, 27(11), p 2877–2886. https://doi.org/10.1007/BF01154095

J.C. Rawers, W.R. Wrzesinski, E.K. Roub, and R.R. Brown, TiAl–SiC composites prepared by high temperature synthesis, Mater. Sci. Technol., 1990, 6(2), p 187–191. https://doi.org/10.1179/mst.1990.6.2.187

J.C. Gachon, A.S. Rogachev, H.E. Grigoryan, E.V. Illarionova, J.J. Kuntz, D.Y. Kovalev, and P.A. Tsygankov, On the mechanism of heterogeneous reaction and phase formation in Ti/Al multilayer nanofilms, Acta Mater., 2005, 53(4), p 1225–1231. https://doi.org/10.1016/j.actamat.2004.11.016

Z. Liu, Q. Han, and J. Li, Fabrication of in situ Al3Ti/Al composites by using ultrasound assisted direct reaction between solid Ti powders and liquid Al, Powder Technol., 2013, 247, p 55–59. https://doi.org/10.1016/j.powtec.2013.07.005

Z.W. Liu, Q. Han, and J.G. Li, Formation of small blocky Al3Ti particles via direct reaction between solid Ti powders and liquid Al, Metall. and Mater. Trans. A., 2012, 43(12), p 4460–4463. https://doi.org/10.1007/s11661-012-1326-y

H.C. Yi, A. Petric, and J.J. Moore, Effect of heating rate on the combustion synthesis of Ti-Al intermetallic compounds, J. Mater. Sci., 1992, 27(24), p 6797–6806. https://doi.org/10.1007/BF01165971

A. Kar, S.V. Kailas, and S. Suwas, Formation sequence of intermetallics and kinetics of reaction layer growth during solid state reaction between titanium and aluminum, Materialia, 2020, 11, p 100702. https://doi.org/10.1016/j.mtla.2020.100702

A. Kar, S. Suwas, and S.V. Kailas, Microstructural modification and high-temperature grain stability of aluminum in an aluminum-titanium friction stir weld with zinc interlayer, JOM, 2019, 71(1), p 444–451. https://doi.org/10.1007/s11837-018-3152-1

Acknowledgment

Author would like to thank Professor Satish Vasu Kailas, Professor Satyam Suwas, and Advanced Facility for Microscopy and Microanalysis (AFMM) at Indian Institute of Science (IISc), Bangalore, and Indian Institute of Technology (Indian School of Mines), Dhanbad, for providing the facilities.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

The author contributed to the study conception and design. Material preparation, data collection, and analysis were performed by AK. The first draft of the manuscript was written by AK, and the author commented on previous versions of the manuscript. The author read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kar, A., Singh, K. & Kumar, L. Effect of Tool Rotational Speed and Mechanisms Associated with Microstructure Evolution and Intermetallics Formation in Friction Stir Welding of Aluminum Alloy to Titanium Alloy. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08407-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08407-1