Abstract

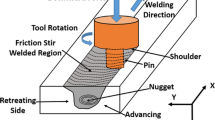

The present paper is focused on friction stir welding (FSW) of dissimilar aluminum alloys and steels, an area that is getting great concern recently. The promise of FSW joints lies in low welding heat input and its ability to minimize the extent of the formation of intermetallic compound (IMC) in dissimilar metals. The present paper assessed the status of FSW process of dissimilar aluminum alloys and steels, and to identify the opportunities and challenges for the future. The essential reason for the formation of the dissimilar Al/steel FSW joints with high quality is explained by super diffusion behavior. This paper will provide basis to designers and engineers to consider FSW for a wider range of dissimilar aluminum alloys and steels.

Similar content being viewed by others

References

Kochan A (2002) A time of change for welding. Assembly Autom 22(1):29–35

Michalos G, Makris S, Papakostas N, Mourtzis D, Chryssolouris G (2010) Automotive assembly technologies review: challenges and outlook for a flexible and adaptive approach. CIRP J Manuf Sci Technol 2(2):81–91

Ermolaeva NS, Castro MBG, Kandachar PV (2004) Materials selection for an automotive structure by integrating structural optimization with environmental impact assessment. Mater Des 25(8):689–698

Coelho RS, Kostka A, dos Santos JF, Kaysser-Pyzalla A (2012) Friction-stir dissimilar welding of aluminum alloy to high strength steels: mechanical properties and their relation to microstructure. Mater Sci Eng A 556:175–183

Coelho RS, Kostka A, dos Santos JF, Pyzalla AR (2008) EBSD technique visualization of material flow in aluminum to steel friction-stir dissimilar welding. Adv Eng Mater 10(12):1127–1133

Tanaka T, Morishige T, Hirata T (2009) Comprehensive analysis of joint strength for dissimilar friction stir welds of mild steel to aluminum alloys. Scr Mater 61:756–759

Watanabe T, Takayama H, Yanagisawa A (2006) Joining of aluminum alloy to steel by friction stir welding. J Mater Process Tech 178:342–349

Chen CM, Kovacevic R (2005) Joining of Al 6061 alloy to AISI 1018 steel by combined effects of fusion and solid state welding. Int J Mach Tools Manuf 44:1205–1214

Uzun H, Donne CD, Argagnotto A, Ghidini T, Gambaro C (2005) Friction stir welding of dissimilar Al 6013-T4 to X5CrNi18-10 stainless steel. Mater Des 26:41–46

Won-Bae L, Martin S, Ulises AM, Gerhard B, Seung-Boo J (2006) Interfacial reaction in steel–aluminum joints made by friction stir welding. Scr Mater 55:355–358

Springer H, Kostka A, dos Santos JF, Raabe D (2011) Influence of intermetallic phases and Kirkendall-porosity on the mechanical properties of joints between steel and aluminum alloys. Mater Sci Eng A 528:4630–4642

Dilthey U, Stein L (2006) Multimaterial car body design: challenge for welding and joining. Sci Technol Weld Joi 11:135–142

Sajan SG, Meshram M, Pankaj S, Dey SR (2013) Friction stir welding of aluminum 6082 with mild steel and its joint analyses. Int J Adv Mater Manuf Charact 3:1–6

Ghosh M, Kar A, Kumar K, Kailas S (2012) Structural characterization of reaction zone for friction stir welded aluminum-stainless steel joint. Mater Technol Adv Perform Mater 27:169–172

Saida K, Song W, Nishimoto K (2005) Diode laser brazing of aluminum alloy to steels with aluminium filler metal. Sci Technol Weld Join 10(2):227–235

Dong HG, Liao CQ, Chen GQ, Dong C (2012) Butt joining of aluminum to steel by arc brazing process. Mater Manuf Process 27(12):1392–1396

Cai W, Wang P, Yang W (2005) Assembly dimensional prediction for selfpiercing riveted aluminum panels. Int J Mach Tools Manuf 45:695–704

Abe Y, Kato T, Mori K (2006) Joinability of aluminum alloy and mild steel sheets by self-piercing rivet. J Mater Process Technol 177:417–421

Yan WM, Xie ZQ, Yu C, Song LL, He HX (2017) Experimental investigation and design method for the shear strength of self-piercing rivet connections in thin-walled steel structures. J Construc Steel Res 133:231–240

Chen SH, Ma K, Huang JH, Xia J, Zhang H, Zhao XK (2011) Microstructure and mechanical property of joint by TIG welding brazing with dual weld pools for steel/aluminum dissimilar metals. Chin J Nonfer Metals 21(12):3076–3081

He H, Yang C, Lin S, Fan C, Chen Z, Chen Z (2014) Flux modification for AC-TIG braze welding of aluminum to stainless steel. Sci Technol Weld Join 19:527–533

Saida K, Ohnishi H, Nishimoto K (2010) Fluxless laser brazing of aluminum alloy to galvanized steel using a tandem beam-dissimilar laser brazing of aluminum alloy and steels. Weld Int 24(3):161–168

Jácome LA, Weber S, Leitner A, Arenholz E, Bruckner J, Hackl H, Pyzalla AR (2009) Influence of filler composition on the microstructure and mechanical properties of steel-aluminum joints produced by metal arc joining. Adv Eng Mater 11(5):350–358

Geiger M, Duflou J, Kals HJJ, Shirvani B, Singh UP (2005) Joining of steel-aluminum hybrid structures with electron beam on atmosphere. Adv Mater Res 6:143–150

Wang T, Zhang YY, Li XP, Zhang BG, Feng JC (2017) Influence of beam current on microstructures and mechanical properties of electron beam welding-brazed aluminum-steel joints with an Al5Si filler wire. Vacuum 141:281–287

Ye Z, Huang JH, Gao W, Zhang YF, Cheng Z, Chen SH, Yang J (2017) Microstructure and mechanical properties of 5052 aluminum alloy/mild steel butt joint achieved by MIG-TIG double-sided arc welding-brazing. Mater Des 123:69–79

Huang JK, He J, Yu XQ, Li CL, Fan D (2017) The study of mechanical strength for fusion-brazed butt joint between aluminum alloy and galvanized steel by arc-assisted laser welding. J Manuf Proces 25:126–133

Dong HG, Yang LQ, Dong C, Kou SD (2012) Improving arc joining of Al to steel and Al to stainless steel. Mater Sci Eng A 534:424–435

Shi Y, Zhang G, Huang Y, Lu L, Huang J, Shao Y (2014) Pulsed double electrode GMAW brazing for joining of aluminum to steel. Weld J 93:216–224

Movahedi M, Kokabi AH, Reihani SMS, Najafi H (2012) Effect of tool travel and rotation speeds on weld zone defects and joint strength of aluminum-steel lap joints made by friction stir welding. Sci Technol Weld Join 17:162–167

Thomas WM, Nicholas ED, Needham JC, Murch MG, Templesmith P, Dawes CJ (1991) G B Patent Application No. 9125978.8

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R 50:1–78

Nandan R, DebRoy T, Bhadeshia HKDH (2008) Recent advances in friction stir welding-process, weldment structure and properties. Prog Mater Sci 53:980–1023

Singh KV, Hamilton C, Dymek S (2010) Developing predictive tools for friction stir weld quality assessment. Sci Tech Weld Join 15:142–148

Teimournezhad J, Masoumi A (2010) Experimental investigation of onion ring structure formation in friction stir butt welds of copper plates produced by non-threaded tool pin. Sci Tech Weld Join 15:166–170

Moraitis GA, Labeas GN (2010) Investigation of friction stir welding process with emphasis on calculation of heat generated due to material stirring. Sci Tech Weld Join 15:177–184

Yadava MK, Mishra RS, Chen YL, Carlson B, Grant GJ (2010) Study of friction stir joining of thin aluminum sheets in lap joint configuration. Sci Tech Weld Join 15:70–75

Thomas WM, Threadgill PL, Nicholas ED (1999) Feasibility of friction stir welding steel. Sci Tech Weld Join 4(6):365–372

Bhadeshia H, DebRoy T (2009) Critical assessment: friction stir welding of steels. Sci Tech Weld Join 14(3):193–196

Cam G (2011) Friction stir welded structural materials: beyond Al-alloys. Int Mater Rev 56(1):1–48

Jiang WH, Kovacevic R (2004) Feasibility study of friction stir welding of 6061-T6 aluminum alloy with AISI1018 steel. Eng Manuf 218:1323–1331

Rafiei R, Moghaddam AO, Hatami MR, Khodabakhshi F, Abdolahzadeh A, Shokuhfar A (2017) Microstructural characteristics and mechanical properties of the dissimilar friction-stir butt welds between an Al–Mg alloy and A316L stainless steel. Int J Adv Manuf Technol 90:2785–2801

Chen T (2009) Process parameters study on FSW joint of dissimilar metals for aluminum-steel. J Mater Sci 44(10):2573–2580

Kimapong K, Watanabe T (2005) Effect of welding process parameters on mechanical property of FSW lap joint between aluminum alloy and steel. Mater Trans 46(10):2211–2217

Elrefaey A, Gouda M, Takahashi M, Ikeuchi K (2005) Characterization of aluminum/steel lap joint by friction stir welding. J Mater Eng Perform 14(1):10–17

Ogura T, Nishida T, Tanaka Y, Nishida H, Yoshikawa S, Fujimoto M (2013) Microscale evaluation of mechanical properties of friction stir welded A6061 aluminium alloy/304 stainless steel dissimilar lap joint. Sci Tech Weld Join 18:108–113

Elrefaey A, Takahashi M, Ikeuhi K (2005) Friction stir welded lap joint of aluminum to zinc-coated steel. Proc Jpn Weld Soc 23(2):186–193

Merklein M, Giera A (2008) Laser assisted friction stir welding of drawable steel-aluminum tailored hybrids. Int J Mater Form 1:1299–1302

Xing L, Ke LM, Huang CP (2007) Weld appearances and mechanical properties of friction stir welded joint of Al alloy and mild steel. Trans China Weld Instit 28(1):29–32

Habibnia M, Shakeri M, Nourouzi S, Givi MKB (2015) Microstructural and mechanical properties of friction stir welded 5050 Al alloy and 304 stainless steel plates. Int J Adv Manuf Technol 76:819–829

Ghosh M, Gupta RK, Husain MM (2014) Friction stir welding of stainless steel to Al alloy: effect of thermal condition on weld nugget microstructure. Metal Mater Trans A 45:854–863

Liu X, Lan SH, Ni J (2014) Analysis of process parameters effects on friction stir welding of dissimilar aluminum alloy to advanced high strength steel. Mater Des 59:50–62

Fukumoto M, Tsubaki M, Yasui T, Shimoda Y (2005) Joining of ADC12 and SS400 by means of friction stir welding. Weld Intern 19:364–369

Shen Z, Chen Y, Haghshenas M, Gerlich AP (2015) Role of welding parameters on interfacial bonding in dissimilar steel/aluminum friction stir welds. Eng Sci Technol Int J 18:270–277

Yasui T, Tsubaki M, Fukumoto M, Shimoda Y, Ishii T (2006) High-speed weldability between 6063 and S45C by friction stir welding. Weld Intern 20(4):284–289

Kundu S, Roy D, Bhola R, Bhattacharjee D, Mishra B, Chatterjee S (2013) Microstructure and tensile strength of friction stir welded joints between interstitial free steel and commercially pure aluminum. Mater Des 50:370–375

Fei XJ, Jin XZ, Peng NX, Ye Y, Wu SG, Dai HF (2016) Effects of filling material and laser power on the formation of intermetallic compounds during laser-assisted friction stir butt welding of steel and aluminum alloys. Appl Phys A Mater Sci Process 122:936

Leitao C, Arruti E, Aldanondo E, Rodrigues DM (2016) Aluminum-steel lap joining by multipass friction stir welding. Mater Des 106:153–160

Xiong JT, Li JL, Qian JW, Zhang FS, Huang WD (2012) High strength lap joint of aluminium and stainless steels fabricated by friction stir welding with cutting pin. Sci Technol Weld Join 17:196–201

Chen ZW, Yazdanian S, Littlefair G (2013) Effects of tool positioning on joint interface microstructure and fracture strength of friction stir lap Al-to-steel welds. J Mater Sci 48:2624–2634

Haghshenas M, Abdel-Gwad A, Omran AM, Gökçe B, Sahraeinejad S, Gerlich AP (2014) Friction stir weld assisted diffusion bonding of 5754 aluminum alloy to coated high strength steels. Mater Des 55:442–449

Liyanage T, Kilbourne J, Gerlich AP, North TH (2009) Joint formation in dissimilar Al alloy/steel and mg alloy/steel friction stir spot welds. Sci Tech Weld Join 14:500–508

Bozzi S, Helbert-Etter AL, Baudin T, Criqui B, Kerbiguet JG (2010) Intermetallic compounds in Al 6016/IF-steel friction stir spot welds. Mater Sci Eng A 527:4505–4509

Pourali M, Abdollah-zadeh A, Saeid T, Kargar F (2017) Influence of welding parameters on intermetallic compounds formation in dissimilar steel/aluminum friction stir welds. J Alloys Comp 715:1–8

Collier M, Steel R, Nelson T, Sorensen C, Packer S (2003) Grade development of polycrystalline cubic boron nitride for friction stir processing of ferrous alloys. Mater Sci Forum 426-432(4):3011–3016

Rai R, De A, Bhadeshia HKDH, DebRoy T (2011) Review: friction stir welding tools. Sci Tech Weld Join 16:325–342

Sawada YK, Nakamura M (2009) Lapped friction stir welding between ductile cast irons and stainless steels. J Jpn Weld Soc 27:176–182

Choi DH, Lee CY, Ahn BW, Yeon YM, Park SHC, Sato YS, Kokawa H, Jung SB (2010) Effect of fixed location variation in friction stir welding of steels with different carbon contents. Sci Tech Weld Join 15:299–304

Shamsujjoha M, Jasthi BK, West M, Widener C (2015) Friction stir lap welding of aluminum to steel using refractory metal pin tools. J Eng Mater Technol 137(2):1–8

Mahto RP, Bhoje R, Pal SK, Joshi HS, Das S (2016) A study on mechanical properties in friction stir lap welding of AA 6061-T6 and AISI304. Mater Sci Eng A 652:136–144

Tanaka T, Hirata T, Shinomiy N, Shirakawa N (2015) Analysis of material flow in the sheet forming of friction-stir welds on alloys of mild steel and aluminum. J Mater Proc Technol 226:115–124

Patterson EE, Hovanski Y, Field DP (2016) Microstructural characterization of friction stir welded aluminum-steel joints. Metal Mater Trans A 7:2815–2829

Wei YN, Li JL, Xiong JT, Huang F, Zhang FS, Raza SH (2015) Joining aluminum to titanium alloy by friction stir lap welding with cutting pin. Mater Charact 71:1–5

Wei Y, Li J, Xiong J, Huang F, Zhang F (2012) Microstructures and mechanical properties of magnesium alloy and stainless steel weld-joint made by friction stir lap welding. Mater Des 33:111–114

Sorger G, Wang H, Vilaça P, Santos TG (2017) FSW of aluminum AA5754 to steel DX54 with innovative overlap joint. Weld World 61:257–268

Sun YF, Fujii H, Takaki N, Okitsu Y (2013) Microstructure and mechanical properties of dissimilar Al alloy/steel joints prepared by a flat spot friction stir welding technique. Mater Des 47:350–357

Uematsu Y, Kakiuchi T, Tozaki Y, Kojin H (2012) Comparative study of fatigue behavior in dissimilar Al alloy/steel and Mg alloy/steel friction stir spot welds fabricated by scroll grooved tool without probe. Sci Tech Weld Join 17(5):348–356

Li WY, Li JF, Zhang ZH, Gao DL, Wang WB, Dong CL (2014) Improving mechanical properties of pinless friction stir spot welded joints by eliminating hook defect. Mater Des 62:247–254

Zhang GF, Su W, Zhang JX, Wei ZX (2011) Friction stir brazing: a novel process for fabricating Al/steel layered composite and for dissimilar joining of Al to steel. Metall Mater Trans A 42:2850–2861

Chen YC, Komazaki T, Kim YG, Tsumura T, Nakata K (2007) Int Weld Join Conf., Seoul, Korea, 435–436

Kimapong K, Watanabe T (2004) Friction stir welding of aluminum alloy to steel. Weld J 12:277–282

Yazdipour A, Heidarzadeh A (2016) Effect of friction stir welding on microstructure and mechanical properties of dissimilar Al 5083-H321 and 316L stainless steel alloy joints. J Alloys Comp 680:595–603

van der Rest C, Jacques PJ, Simar A (2014) On the joining of steel and aluminum by means of a new friction melt bonding process. Scr Mater 77:25–28

Evans W, Gibson B, Reynolds J, Strauss A, Cook G (2015) Friction stir extrusion: a new process for joining dissimilar materials. Manuf Lett 5:25–28

Huang YX, Wang JC, Wan L, Meng XC, Liu HB, Li H (2016) Self-riveting friction stir welding of aluminum alloy to steel. Mater Lett 185:181–184

Bang HS, Bang HS, Jeon GH, Oh IH, Ro CH (2012) Gas tungsten arc welding assisted hybrid friction stir welding of dissimilar materials Al6061-T6 aluminum alloy and STS304 stainless steel. Mater Des 37:48–55

Bang HS, Bang HS, Hong JH, Jeon GH, Kim GS, Kapla AFH (2016) Effect of tungsten-inert-gas preheating on mechanical and microstructural properties of friction stir welded dissimilar Al alloy and mild steel. Strength Mater 48:152–159

Liu X, Lan SH, Ni J (2015) Electrically assisted friction stir welding for joining Al 6061 to TRIP780 steel. J Mater Proc Technol 219:112–123

Dehghani M, Amadeh A, Mousavi SAAA (2013) Investigations on the effects of friction stir welding parameters on intermetallic and defect formation in joining aluminum alloy to mild steel. Mater Des 49:433–441

Derazkola HA, Aval HJ, Elyasi M (2015) Analysis of process parameters effects on dissimilar friction stir welding of AA1100 and A441 AISI steel. Sci Tech Weld Join 20(7):553–562

Chen Y, Komazaki T, Tsumura T, Nakata K (2008) Role of zinc coat in friction stir lap welding Al and zinc coated steel. Mater Sci Tech 24:33–39

Chen YC, Komazaki T, Kim YG, Tsumura T, Nakata K (2008) Interface microstructure study of friction stir lap joint of AC4C cast aluminum alloy and zinc-coated steel. Mater Chem Phys 111:375–380

Jiang WH, Kovacevic R (2004) Feasibility study of friction stir welding of 6061-T6 aluminium alloy with AISI1018 steel. Eng Manuf 218:1323–1331

Kittipong K, Takehiko W (2005) Lap joint of A5083 aluminum alloy and SS400 steel by friction stir welding. Mater Trans (4):835–841

Chen YC, Nakata K (2008) Effect of the surface state of steel on the microstructure and mechanical properties of dissimilar metal lap joints of aluminum and steel by friction stir welding. Metall Mater Trans A 39(8):1985–1992

Sato YS, Park SHC, Michiuchi M (2004) Constitutional liquation during dissimilar friction stir welding of Al and Mg alloys. Scr Mater 50(9):1233–1236

Movahedi M, Kokabi AH, Reihani SMS, Cheng WJ, Wang CJ (2013) Effect of annealing treatment on joint strength of aluminum/steel friction stir lap weld. Mater Des 44:487–492

Das H, Jana SS, Pal TK, De A (2014) Numerical and experimental investigation on friction stir lap welding of aluminum to steel. Sci Tech Weld Join 19:69–75

Danesh MH, Karimi TA (2003) Bond strength and formability of an aluminum–clad steel sheet. J Alloy Compd 361:138–143

Nishida T, Ogura T, Nishida H, Fujimoto M, Takahashi M, Hirose A (2014) Formation of interfacial microstructure in a friction stir welded lap joint between aluminum alloy and stainless steel. Sci Tech Weld Join 19:609–616

Ogura T, Saito Y, Nishida T, Nishida H, Yoshida T, Omichi N, Fujimoto M, Hirose A (2012) Partitioning evaluation of mechanical properties and the interfacial microstructure in a friction stir welded aluminum alloy/stainless steel lap joint. Scr Mater 66:531–534

Esmaeili A, Zareie RHR, Sharbati M, Besharati GMK, Shamanian M (2011) The role of rotation speed on intermetallic compounds formation and mechanical behavior of friction stir welded brass/aluminum 1050 couple. Intermetallics 19:1711–1719

Coelho RS, Kostka A, Sheikhi S, dos Santos JF, Pyzalla AR (2008) Microstructure and mechanical properties of an AA6181-T4 aluminum alloy to HC340LA high strength steel friction stir overlap weld. Adv Eng Mater 10:961–972

Das H, Ghosh RN, Pal TK (2014) Study on the formation and characterization of the intermetallics in friction stir welding of aluminum alloy to coated steel sheet lap joint. Metall Mater Trans A 45:5098–5106

Abbasi M, Dehghani M, Guim H, Kim D (2016) Investigation of Fe-rich fragments in aluminum-steel friction stir welds via simultaneous transmission Kikuchi diffraction and EDS. Acta Mater 117:262–269

Fei X, Jin X, Ye Y, Xiu T, Yang H (2016) Effect of pre-hole offset on the property of the joint during laser-assisted friction stir welding of dissimilar metals steel and aluminum alloys. Mater Sci Eng A 653:43–52

Potesser M, Schoeberl T, Antrekowitsch H, Bruckner J (2006) The characterization of the intermetallic Fe-Al layer of steel-aluminum weldings. In: EPD Congress 2006. Curran Associates Incorporated, New York, pp 167–176

Schmidt H, Hattel J, Wert J (2004) An analytical model for the heat generation in friction stir welding. Model Simul Mater Sci Eng 12(1):143–157

Ramachandran KK, Murugan N, Kumar SS (2015) Influence of tool traverse speed on the characteristics of dissimilar friction stir welded aluminium alloy, AA5052 and HSLA steel joints. Archives Civ Mech Eng 15(4):822–830

Ma ZY, Pilchak AL, Juhas MC, Williams JC (2008) Microstructural refinement and property enhancement of cast light alloys via friction stir processing. Scr Mater 58:361–366

Watanabe M, Feng KY, Nakamura Y, Kumai S (2011) Growth manner of intermetallic compound layer produced at welding interface of friction stir spot welded aluminum/steel lap joint. Mater Trans 52(5):953–959

Wang ZB, Lu J, Lu K (2005) Chromizing behaviors of a low carbon steel processed by means of surface mechanical attrition treatment. Acta Mater 53(7):2081–2089

Fukumoto S, Tsubakino H, Okita K, Aritoshi M, Tomita T (2000) Amorphization by friction welding between 5052 aluminum alloy and 304 stainless steel. Scr Mater 42(8):807–812

Su JY, Fujii H, Koji I, Sun YF, Yoshihiko Y, Hisamichi K, Akihisa I (2011) Fabrication of Fe based metallic glass particle reinforced Al-based composite materials by friction stir processing. Mater Trans 52:1634–1640

Tarasov SY, Rubtsov VE, Kolubaev EA (2014) A proposed diffusion-controlled wear mechanism of alloy steel friction stir welding (FSW) tools used on an aluminum alloy. Wear 318:130–134

ben-Avraham D, Havlin S (2000) Diffusion and reactions in fractals and disordered systems. Cambridge University Press

Havlin S, ben-Avraham D (2002) Diffusion in disordered media. Adv Phys 51:187–292

Balluffi RW, Ruoff AL (1963) On strain-enhanced diffusion in metals: I. Point defect models. J Appl Phys 34(6):1634–1647

Das D, Chatterjee PP, Manna I, Pabi S (1999) Measure of enhanced diffusion kinetics in mechanical alloying of Cu–18 at.% Al by planetary ball milling. Scr Mater 41(8):861–866

Li MY, Ji HJ, Wang CQ, Han SB, Bang HS (2006) Interdiffusion of Al–Ni system enhanced by ultrasonic vibration at ambient temperature. Ultrasonics 45(1–4):61–65

Sauvage X, Enikeev N, Valiev R, Nasedkina Y, Murashkin M (2014) Atomic-scale analysis of the segregation and precipitation mechanisms in a severely deformed Al–Mg alloy. Acta Mater 72(15):125–136

Sauvage X, Jessner P, Vurpillot F, Pippan R (2008) Nanostructure and properties of a Cu–Cr composite processed by severe plastic deformation. Scr Mater 58(12):1125–1128

Xiong JT, Zhang FS, Li JL, Qian JW, Huang WD (2010) In-situ synthesized Al3Ni-Al composites by friction stir processing. Rare Metal Mater Eng 39(1):139–143

Qian JW, Li JL, Xiong JT, Zhang FS, Lin X (2010) In-situ synthesized Al3Ti-Al surface composites by friction stir processing. Trans China Weld Ins 31(8):61–64

Sauvage X, Wetscher F, Pareige P (2005) Mechanical alloying of cu and Fe induced by severeplastic deformation of a Cu–Fe composite. Acta Mater 53(7):2127–2135

Acknowledgements

The work was jointly supported by the National Natural Science Foundation of China (No. 51575132) and the Fund of National Engineering and Research Center for Commercial Aircraft Manufacturing (No. COMAC-SFGS-2016-33214).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wan, L., Huang, Y. Friction stir welding of dissimilar aluminum alloys and steels: a review. Int J Adv Manuf Technol 99, 1781–1811 (2018). https://doi.org/10.1007/s00170-018-2601-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2601-x