Abstract

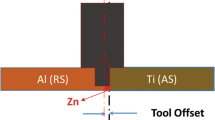

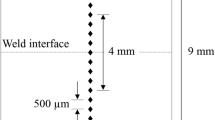

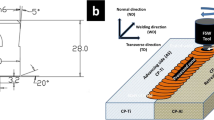

In dissimilar friction stir welding (FSW), the weld nugget is composed of two elements, which are mechanically mixed. This microstructure helps enhance the mechanical properties when they are homogeneously mixed, and the particles are sub-micron in size. Therefore, it is important to understand the mechanism of the particle formation and their distribution for engineering the mechanical properties of the weld. In the present investigation, dissimilar FSW between commercial purity Al and Ti has been carried out. The weld nugget consisted of distributed Ti particles in an Al matrix. The distribution of the Ti particles in the weld nugget was characterized using X-ray micro-computed tomography (XCT). Microstructural evolution in Ti and Al was examined using a scanning electron microscope (SEM) equipped with an energy dispersive spectrometer (EDS), X-ray diffraction and electron back-scattered diffraction (EBSD). Hardness and tensile tests were carried out to determine the integrity of the welds. The XCT result shows that the weld nugget contains Ti particles of variable size. The finer particles of Ti are distributed homogeneously in the weld nugget, unlike large particles. The deformation mechanisms and microstructural evolution of the Ti interface and Al matrix are investigated using EBSD. It is observed that the microstructure of both Ti and Al is substantially refined. However, for a given grain in Al, the boundary is of mixed character, namely low- and high-angle boundaries. Hardness data of the weld indicate large variation within the nugget region. The tensile test sample revealed that the failure of the sample occurs on the Al side of the weld. The fractograph indicates ductile and brittle modes of fracture with a bimodal distribution of dimples at the surface. Lack of twining and fine grains (40 to 5 µm) at the Ti interface indicates high-temperature deformation. Deformation of Ti at low temperature and high strain rate is caused by adiabatic shear banding (ASB). In these shear bands, a high level of grain refinement is observed and is a path for easy crack propagation. It is proposed that the ASB-controlled deformation of Ti leads to a recrystallized microstructure at the interface and fragmentation of Ti. These Ti particles undergo further fragmentation to form smaller particles. On the other hand, microstructural evolution in Al is gradual because of the high stacking fault energy, which leads to continuous dynamic recrystallization (CDRX) through the dynamic recovery (DRV) mechanism. The mechanical properties of the weld depend on the characteristics of particles in the Al matrix. Proper control of the fragmentation and distribution of Ti particles and interface property can lead to superior mechanical properties of the weld.

Similar content being viewed by others

References

B.J. Wilden and S. Herz: in: Proceedings of The 3rd International Brazing and Soldering Conference, April 24–26, 2006, Crown Plaza Riverwalk Hotel, San Antonio, TX, 2006, pp. 338–43.

A. Fuji, Science and Technology of Welding and Joining, 2002, vol. 7, pp. 413-416.

A.F. Y.C. Kim, Science and Technology of Welding and Joining, 2002, vol. 7 pp. 149-154.

C.Q. Zhang, J.D. Robson, O. Ciuca, P.B. Prangnell, Materials Characterization, 2014, vol. 97 pp. 83-91.

T.S. Thomas Lienert, S. Babu, and V. Acoff: Welding Fundamentals and Processes, ASM International, Materials Park, OH, 2011.

R. Jiangwei, L. Yajiang, F. Tao, Microstructure characteristics in the interface zone of Ti/Al diffusion bonding, Materials Letters, 2002, vol. 56, pp. 647-652.

W. Liu, L. Long, Y. Ma, L. Wu, Journal of Alloys and Compounds, 2015, vol. 643, pp.34-39.

D.-f. Mo, T.-f. Song, Y.-j. Fang, X.-s. Jiang, C.Q. Luo, M.D. Simpson, Z.-p. Luo, Advances in Materials Science and Engineering, 2018, vol. 2018, pp. 15-16.

F.J.J. Van Loo, G.D. Rieck, Acta Metallurgica, 1973, vol. 21, pp. 61-71.

D. Bakavos, P.B. Prangnell, Materials Science and Engineering: A, 2010, vol. 527, pp. 6320-6334.

A. Panteli, J.D. Robson, Y.-C. Chen, P.B. Prangnell, Metallurgical and Materials Transactions A, 2013, vol. 44, pp. 5773-5781.

F. Balle, J. Magin, Materials Science Forum, 2014, vol. 794-796, pp. 345-350.

N. Tsuji, Y. Saito, S.-H. Lee, Y. Minamino, Advanced Engineering Materials, 2003, vol. 5, pp. 338-344.

H. Yu, A.K. Tieu, C. Lu, A. Godbole, Metallurgical and Materials Transactions A, 2014, vol. 45, pp. 4038-4045.

A. Azushima, R. Kopp, A. Korhonen, D.Y. Yang, F. Micari, G.D. Lahoti, P. Groche, J. Yanagimoto, N. Tsuji, A. Rosochowski, and A. Yanagida: CIRP Annu. Manuf. Technol., 2008, vol. 57, pp. 716–35.

M. Kimura, S. Nakamura, M. Kusaka, K. Seo, A. Fuji, Science and Technology of Welding and Joining, 2005, vol. 10, pp. 666-672.

L. Kumar, K.U. Yazar, S. Pramanik, Materials Science and Engineering: A, 2019, vol. 754, pp. 400-410.

V. Buchibabu, G.M. Reddy, D. Kulkarni, A. De, Journal of Materials Engineering and Performance, 2016, vol. 25, pp. 1163-1171.

B. Vicharapu, H. Liu, H. Fujii, K. Narasaki, N. Ma, and A. De: Modeling of residual stresses in stationary shoulder friction stir welding, in: The National Meeting of JWS, 2019, vol. 2019s, pp. 52–55.

A. Kar, S.K. Choudhury, S. Suwas, S.V. Kailas, Materials Characterization, 2018, vol. 145, pp. 402-412.

A. Kar, S.V. Kailas, S. Suwas, Journal of Materials Engineering and Performance, 2018, vol. 27, pp. 6016–6026.

A. Kar, S. Suwas, S.V. Kailas, Materials Science and Engineering: A, 2018, vol. 733, pp. 199-210.

R.S. Mishra and H. Sidhar: Chapter 5—friction stir welding of Al–Li Alloys, in: Friction Stir Welding of 2XXX Aluminum Alloys Including Al-Li Alloys, ed. R.S. Mishra and Sidhar, Butterworth-Heinemann, Oxford, 2017, pp. 79–95.

R.S. Mishra and H. Sidhar: Chapter 4—FSW of Al–Cu and Al–Cu–Mg Alloys, in: Friction Stir Welding of 2XXX Aluminum Alloys Including Al-Li Alloys, ed. R.S. Mishra and Sidhar, Butterworth-Heinemann, Elsevier Science, Oxford, 2016, pp. 79–95.

N. Kumar, R.S. Mishra, and W. Yuan: Friction Stir Welding of Dissimilar Alloys and Materials, Elsevier Science, 2015, pp. 15–114.

R.S. Mishra, Z.Y. Ma, Friction stir welding and processing, Materials Science and Engineering: R: Reports, 2015, vol. 50, pp. 1-78.

J.-W. Choi, H. Liu, H. Fujii, Materials Science and Engineering: A, 2018, vol. 730, pp. 168-176.

A. Kar, S. Suwas, S.V. Kailas, JOM, 2019, vol. 79, pp. 444–451.

A. Shyam, S. Suwas, S. Bhargava, Practical Metallography, 1997, vol. 34, pp. 264-277.

Y. Li, L. Murr, J. McClure, Scripta Materialia, 1999, vol. 40, pp. 1041-1046.

Y. Li, L.E. Murr, J.C. McClure, Materials Science and Engineering: A, 1999, vol. 271, pp. 213-223.

Z. Zhang, D.E. Eakins, F.P.E. Dunne, International Journal of Plasticity, 2016, vol. 79, pp. 196-216.

U. Dressler, G. Biallas, and U. Alfaro Mercado: Mater. Sci. Eng. A, 2009, vol. 526, pp. 113–17.

K.S. Suresh, N. Kumar, R. S. Mishra, S. Suwas, Materials Science Forum, 2013, vol. 753, pp. 247-250.

N. Nadammal, S.V. Kailas, J. Szpunar, S. Suwas, JOM, 2015, vol. 67, pp. 1014-1021.

N. Nadammal, S.V. Kailas, J. Szpunar, S. Suwas, Materials Characterization, 2018, vol. 140, pp. 134-146.

H.C. Madhu, P. Ajay Kumar, C.S. Perugu, and S.V. Kailas: J. Mater. Eng. Perform., 2018, vol. 27, pp. 1318–26.

A. Kumar, D. Yadav, C.S. Perugu, S.V. Kailas, Materials & Design, 2017, vol. 113, pp. 99-108.

A. Kar, S.V. Kailas, and S. Suwas: Trans. Indian Inst. Met., 2019, vol. 72 (6), 1533–36.

A. Kar, S. Suwas, S.V. Kailas, The International Journal of Advanced Manufacturing Technology, 2018, vol. 100, pp. 435–443 .

Y. Wei, J. Li, J. Xiong, F. Huang, F. Zhang, S.H. Raza, Materials Characterization, 2012, vol. 71, pp. 1-5.

M. Sadeghi-Ghogheri, M. Kasiri-Asgarani, K. Amini, Kovove Mater, 2016, vol. 54, pp. 71-75.

K.-S. Bang, K.-J. Lee, H.-S. Bang, H.-S. Bang, MATERIALS TRANSACTIONS, 2011, vol. 52, pp. 974-978.

Z. Song, K. Nakata, A. Wu, J. Liao, L. Zhou, Materials & Design, 2014, vol. 57, pp. 269-278.

M. Meisnar, J.M. Bennett, D. Andrews, S. Dodds, R. Freeman, R. Bellarosa, D. Adams, A.F. Norman, T. Rohr, T. Ghidini, Materials Characterization, 2019, vol. 147, pp. 286-294.

H. Zhao, M. Yu, Z. Jiang, L. Zhou, X. Song, Journal of Alloys and Compounds, 2019, vol. 789, pp. 139-149.

C.L. Yuhua Chen, Geping Liu, The Open Materials Science Journal, 2011, vol. 5, pp. 256-261.

Y.-h. Chen, Q. Ni, L.-m. Ke, Transactions of Nonferrous Metals Society of China, 2012, vol. 22, pp. 299-304.

Y.C. Chen, K. Nakata, Materials & Design, 2009, vol. 30, pp. 469-474.

K. Kumar, S. V. Kailas, Science and Technology of Welding and Joining, 2010, vol. 15, pp. 305-311.

A. Wu, Z. Song, K. Nakata, J. Liao, L. Zhou, Materials & Design, 2015, vol. 71, pp. 85-92.

A. Slipenyuk, V. Kuprin, Y. Milman, V. Goncharuk, J. Eckert, Acta Materialia, 2006, vol. 54, pp. 157-166.

A. Slipenyuk, V. Kuprin, Y. Milman, J.E. Spowart, D.B. Miracle, Materials Science and Engineering: A, 2004, vol. 381, pp. 165-170.

B. Derby, C. Lawrence, P. Mummery, Intrinsic and extrinsic fracture mechanisms in inorganic composite systems, TMS, Warrendale, USA, 1995, pp. 39.

A.P. Kumar, R. Raj, S.V. Kailas, Materials & Design, 2015, vol. 85, pp. 626-634.

Y.B. Liu, S.C. Lim, L. Lu, M.O. Lai, Journal of Materials Science, 1994, vol. 29, pp. 1999-2007.

V. Goyal, R. Ravi, S.R. Bakshi, P.R. Soni, Journal of Materials Engineering and Performance, 2019, vol. 28, pp. 117-122.

S.-L. Kuo, Y.-C. Chen, M.-D. Ger, W.-H. Hwu, Materials Chemistry and Physics, 2004, vol. 86, pp. 5-10.

R.S. Mishra and M.W. Mahoney: Friction Stir Welding and Processing, ASM International, 2007, pp. 10–212.

H. Schmidt, J. Hattel, Modelling and Simulation in Materials Science and Engineering, 2005, vol. 13, pp. 77.

A. Kar, S. Suwas, S.V. Kailas, JOM, 2019, vol. 71, pp. 444-451.

S. Dixit, S. Kashyap, S.V. Kailas, K. Chattopadhyay, Journal of Alloys and Compounds, 2018, vol. 767, pp. 1072-1082.

S. Nemat-Nasser, W.G. Guo, J.Y. Cheng, Acta Materialia, 1999, vol. 47, pp. 3705-3720.

P.G. Partridge, Metallurgical Reviews, 1967, vol. 12, pp. 169-194.

H. Conrad, Progress in Materials Science, 1981, vol. 26, pp. 123-403.

N.P. Gurao, R. Kapoor, S. Suwas, Acta Materialia, 2011, vol. 59, pp. 3431-3446.

E. Yu, I. Kim, D.H. Shin, J. Kim, Materials Transactions, 2008, vol. 49, pp. 38-40.

A.M. Garde, E. Aigeltinger, R.E. Reed-Hill, Metallurgical Transactions, 1973, vol. 4, pp. 2461-2468.

J. Hodowany, G. Ravichandran, A.J. Rosakis, P. Rosakis, Experimental Mechanics, 2000, vol. 40, pp. 113-123.

S.V. Kailas, Y.V.R.K. Prasad, S.K. Biswas, Metallurgical Transactions A, 1993, vol. 24, pp. 2513-2520.

Y.V.R.K. Prasad, T. Seshacharyulu, Materials Science and Engineering: A, 1998, vol. 243, pp. 82-88.

N. Ranc, L. Taravella, V. Pina, P. Herve, Mechanics of Materials, 2008, vol. 40, pp. 255-270.

Y. Yang, B.F. Wang, Materials Letters, 2006, vol. 60, pp. 2198-2202.

H.A. Grebe, H.-R. Pak, M.A. Meyers, Metallurgical Transactions A, 1985, vol. 16, pp. 761-775.

M.A. Meyers, H.-R. Pak, Acta Metallurgica, 1986, vol. 34, pp. 2493-2499.

W.J. Kim, S.J. Yoo, J.B. Lee, Scripta Materialia, 2010, vol. 62, pp. 451-454.

S.K. Biswas, S.V. Kailas, Tribology International, 1997, vol. 30, pp. 369-375.

S.V. Kailas, Y.V.R.K. Prasad, S.K. Biswas, Metallurgical and Materials Transactions A, 1994, vol. 25, pp. 2173-2179.

E. Illeková, J.-C. Gachon, A. Rogachev, H. Grigoryan, J.C. Schuster, A. Nosyrev, P. Tsygankov, Thermochimica Acta, 2008, vol. 469, pp. 77-85.

S. Suwas, G. Upadhyaya, Metals Materials and Processes, 1996, vol. 7, pp. 225-250.

D.V. Lazurenko, V.I. Mali, I.A. Bataev, A. Thoemmes, A.A. Bataev, A.I. Popelukh, A.G. Anisimov, N.S. Belousova, Metallurgical and Materials Transactions A, 2015, vol. 46, pp. 4326-4334.

D. Yadav, R. Bauri, Materials Science and Engineering: A, 2012, vol. 539, pp. 85-92.

K. Vijayaraju, E.S. Dwarakadasa, T.S. Panchapagesan, Journal of Materials Science Letters, 1986, vol. 5, pp. 1000-1002.

P. Xue, B.L. Xiao, Z.Y. Ma, Materials Science and Engineering: A, 2012, vol. 532, pp. 106-110.

B. Li, Z. Zhang, Y. Shen, W. Hu, L. Luo, Materials & Design, 2014, vol. 53, pp. 838-848.

Z. Liu, Q. Han, J. Li, Powder Technology, 2013, vol. 247, pp. 55-59.

M. Sujata, S. Bhargava, S. Sangal, ISIJ International, 1996, vol. 36, pp. 255-262.

H. Bang, H. Bang, H. Song, S. Joo, Materials & Design, 2013, vol. 51, pp. 544-551.

Acknowledgments

The authors thank the Defense Research & Development Organization (DRDO), Department of Science and Technology (DST), Ministry of Human Resources Development (MHRD), India, for support and research funding. We also thank the Institute X-ray Facility and Advanced Facility for Microscopy and Microanalysis (AFMM) at the Indian Institute of Science (IISc), Bangalore, for providing the facilities. The authors thank Mr. V. Vijayan and Dr. Devinder Yadav, Department of Mechanical Engineering, IISc Bangalore, for their help in performing the friction stir welding (FSW) experiment.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 14, 2018.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kar, A., Suwas, S. & Kailas, S.V. Multi-Length Scale Characterization of Microstructure Evolution and Its Consequence on Mechanical Properties in Dissimilar Friction Stir Welding of Titanium to Aluminum. Metall Mater Trans A 50, 5153–5173 (2019). https://doi.org/10.1007/s11661-019-05409-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05409-4