Abstract

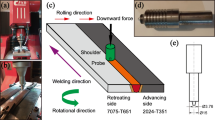

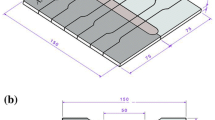

The search for lighter and more resistant structures contributed to the development of effective welding methods. Among them, friction stir welding, a recent technique patented in 1991, in which welding is performed by the friction between a rotating tool and the materials to be welded, has widely been studied in the last decades. Among the advantages the technique provides, are the possibility of welding aluminum alloys series 2xxx and 7xxx, and the possibility of welding materials of different chemical compositions. The industry is still cautious about using this technique, yet several studies have been performed to improve knowledge on it. This research investigated the three dissimilar junctions between aluminum alloys 2024-T4 and 7475-T6 with titanium alloy Ti6Al4V. The aluminum alloys were positioned on the top portion of the welding creating a butt weld. The titanium alloy was placed on the bottom portion of the weld creating a lap welding with the aluminum alloy. The parameters of rotation, welding speed, and tilt were varied, following a central composite experimental design. Through the response surface analysis, it was possible to identify the correlation between the input and output parameters. This correlation is used to identify main influence between the parameters and can be used to optimization of the process. The influences of these parameters were evaluated on the welding surface by measuring residual stress and microhardness. The residual stress was analyzed by the hole drilling method on the aluminum side and by X-ray diffraction on the titanium side. The microhardness was analyzed by the Vickers test. On the aluminum side, residual stress and microhardness show a strong relation; high value of residual stress resulted in low value of microhardness. On the titanium side, residual stress shows a relation with temperature; the high value of temperature resulted in low value of stress. The tensile test was used to compare joint efficiency between different welding parameters and the base metal. It was possible to reach parameters in which the welding ultimate tensile stress exceeded the AA2024 value.

Similar content being viewed by others

References

Akinlabi, E.T., Andrews, A., Akinlabi, S.A., 2014. Effects of processing parameters on corrosion properties of dissimilar friction stir welds of aluminium and copper. Trans. Nonferrous Metals Soc

Cavaliere, A., De Santis, F., Panella, A., Squillace, (2009). Effect of welding parameters on mechanical and microstructural properties of dissimilar AA6082eAA2024 joints produced by friction stir welding. Materials and Design

Chen, Y. C., Nakata, K., 2009. Microstructural characterization and mechanical properties in friction stir welding of aluminum and titanium dissimilar alloys. Materials and Design

European Aluminium Association, 2017. Aluminium in Cars - Unlocking the Light-Weighing Potential, p. 6. Brussels - Belgium

Guo, J.F., Chen, H.C., Sun, C.N. Bi, G., Sun, Z., Wei, J.(2014) Friction stir welding of dissimilar materials between AA6061 and AA7075 al alloys effects of process parameters. Materials and Design

Hiller, D. D. J., 2007. Estudo de parâmetros e percursos no processo de soldagem de mistura por atrito (FSW) da liga de alumínio 505. Dissertação, Universidade Federal do Rio de Janeiro, Rio de Janeiro

Hussein, S. A. et al., 2014. The joining of three dissimilar metallic alloys by a single pass friction stir welding. International symposium on research in innovation and sustainability, Malacca—Malaysia

Khodir, S.A., Shibayanagi, T. (2008) Friction stir welding of dissimilar AA2024 and AA7075 aluminum alloys. Mater. Sci. Eng. B

Kim YG et al (2006) Three defect in friction stir welding of aluminum die casting alloy. In: Material Science and Engineering A

Kusuda, Y., 2013. Honda develops robotized FSW technology to weld steel and aluminum and applied it to a mass-production vehicle. Industrial Robot: An International Journal

Li, B., Zhang, Z., Shen, Y., Hu, W., Luo, L., 2014 Dissimilar friction stir welding of Tie6Al4V alloy and aluminum alloy employing a modified butt joint configuration: influences of process variables on the weld interfaces and tensile properties. Materials and Design

Liu, X., Lan, S. Ni, J., 2014. Analysis of process parameters effects on friction stir welding of dissimilar aluminum alloy to advanced high strength steel. Materials and Design

Mishra, R. S., Ma, Z. Y., 2005. Friction stir welding and processing. Mater Sci Eng: R: Reports, 50, n. 1–2, p. 1–78

Najafkhani, A., Zangeneh-Madar, K., Abbszadeh, H., 2010. Evaluation of microstructure and mechanical properties of friction stir welded copper/316L stainless steel dissimilar metals. International Journal of Iron & Steel Society of Iran

Prater T (2014) Friction stir welding of metal matrix composites for use in aerospace structures. Acta Astronautica 93:366–373

Rodriguez, R.I, Jordon, J.B., Allison, P.G., Rushing, T., Garcia, L., 2015. Microstructure and mechanical properties of dissimilar friction stir welding of 6061-to-7050 aluminum alloys. Materials and Design

Shah, S., Tosunoglu S 2012. Friction stir welding: current state of the art and future prospects. The 16th world multi-conference on cybernetics and informatics

Salih, A. S. et al., 2015 A review of friction stir welding of aluminium matrix composites. Materials and Design

Song Y. et al., (2014) Defect features and mechanical properties of friction stir lap welded dissimilar AA2024eAA7075 aluminum alloy sheets. Materials and Design

Thomas, W. M. et al. 1991. Patent Application No. 9123978.8

Zapata J., Toro M., Lopez D., 2016 Residual stresses in friction stir dissimilar welding of aluminum alloys. Journal of Materials Processing Technology

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Delijaicov, S., Yakabu, D.Y., De Macedo, B. et al. Characterization of the surface and mechanical properties of the friction stir welding in tri-dissimilar joints with aluminum alloys and titanium alloy. Int J Adv Manuf Technol 95, 1339–1355 (2018). https://doi.org/10.1007/s00170-017-1306-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1306-x