Abstract

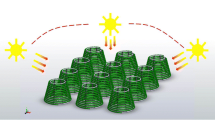

Two-tier vessels, developed for culturing of microalgae and cyanobacteria at high cell density on a shaken platform, were assembled from a flat lower chamber to be filled with a CO2 buffer and an upper flat sterile chamber for the culture that was separated from the lower chamber by a porous polypropylene membrane. Diffusive gas exchange with the atmosphere was controlled by the O2 outlet channel. Referred to surface area, rates of CO2 transfer to a shaken weakly alkaline buffer solution across the membrane were higher than those reached on the conventional pathway through the free upper liquid surface. Membrane-mediated CO2 supply enabled rapid growth of Synechocystis sp. PCC 6803 and Synechococcus sp. PCC 7002 up to ultrahigh cell density. The biomass (dry weight) concentration of Synechococcus cultures reached more than 30 g L−1 on a buffered medium with adequate concentrations of mineral nutrients. An increase of 15 to 20 g L−1 was observed during repeated two-day cycles. Separate pathways for CO2 supply and oxygen outlet prevented significant loss of CO2. Convective gas flow through the oxygen outlet channel enabled the estimation of the O2 generation rate. The permeability of the channel for diffusive O2/N2 exchange limited the O2 concentration to a moderate value. It is concluded that shaken flat cultures using CO2 supply through a porous hydrophobic membrane and diffusive release of O2 through a separate pathway are promising for research on microalgae and cyanobacteria.

Similar content being viewed by others

References

Aikawa S, Nishida A, Ho S-H, Chang J-S, Hasunuma T, Kondo A (2014) Glycogen production for biofuels by the euryhaline cyanobacteria Synechococcus sp. strain PCC 7002 from an oceanic environment. Biotechnol Biofuels 7:88. doi:10.1186/1754-6834-7-88

Bähr L (2013) Wachstum von Cyanobakterien bei extrem hoher Zelldichte in Starklicht-Photobioreaktoren mit membranvermitteltem Eintrag von anorganischem Kohlenstoff in Kulturmedien mit hohen Konzentrationen von HCO3 − und mineralischen Nährstoffen. Diploma thesis, Humboldt-University Berlin, Germany 55 pp

Beardall J, Raven JA (2013) Limits to phototrophic growth in dense culture: CO2 supply and light. In: Borowitzka MA, Moheimani NR (eds) Algae for biofuels and energy. Springer, Dordrecht, pp 91–97

Bilad MR, Arafat HA, Vankelecom IFJ (2014) Membrane technology in microalgae cultivation and harvesting. Biotechnol Adv 32:1283–1300

Dankwerts PV (1965) The absorption of gases in liquids. Pure Appl Chem 10:625–864

Doucha J, Livansky K (2009) Outdoor open thin-layer microalgal photobioreactor: potential productivity. J Appl Phycol 21:111–117

Drexler IL, Yeh DH (2014) Membrane applications for microalgae cultivation and harvesting: a review. Rev Environ Sci Biotechnol 13:487–504

Edsall JT (1969) Carbon dioxide, carbonic acid and bicarbonate ion: physical properties and kinetics of interconversion. In: Forster E, Edsall J T, Otis AB, Roughton F J W (eds.) CO2: chemical, biochemical and physiological aspects. NASA SP-188, pp. 15–34

Ehwald R, Bähr L, Wüstenberg A, Soh J H (2014) Method, photobioreactor and photosynthesis layer for the culture of photoautotrophic microorganisms. USA patent application US 20140315280 A1

Ehwald R, Bähr L, Wüstenberg A (2015) Research Photobioreactor. USA patent application US 20150087049 A1

Fontes G, Moreno AG, Vargas MA (1989) Analysis of biomass quality and photosynthetic efficiency of a nitrogen-fixing cyanobacterium grown outdoors with two agitation systems. Biotechnol Bioeng 34:819–824

Gitelson A, Hu Q, Richmond A (1996) Photic volume in photobioreactors supporting ultrahigh population densities of the photoautotroph Spirulina platensis. Appl Environ Microbiol 62:1570–1573

Hagemann M (2011) Molecular biology of cyanobacterial salt acclimation. FEMS Microbiol Rev 35:87–123

Hu Q, Richmond A (1996) Productivity and photosynthetic efficiency of Spirulina platensis as effected by light intensity, algal density and rate of mixing in a flat pane photobioreactor. J Appl Phycol 8:139–145

Hu Q, Guterman H, Richmond A (1996) A flat inclined modular photobioreactor (FIMP) for outdoor mass cultivation of photoautotrophs. Biotechnol Bioeng 51:51–60

Hu Q, Kurano N, Kawachi M, Iwasaki I, Miyachi S (1998a) Ultrahigh-cell-density culture of a marine green alga Chlorococcum littorale in a flat-pane photobioreactor. Appl Microbiol Biotechnol 49:655–662

Hu Q, Zarmi Y, Richmond A (1998b) Combined effects of light intensity, light-path and culture density on output rate of Spirulina platensis (Cyanobacteria). Eur J Phycol 33:165–171

Hüseman W, Barz W (1977) Photoautotrophic growth and photosynthesis in cell suspension cultures of Chenopodium rubrum. Physiol Plant 40:77–81

Kang LJ, Chen XJ, Pan XJ, Chang FY, Liu YD (2009) Effect of elevated bicarbonate concentration on growth, chlorophyll A fluorescence and ultrastructure of Microcystis aeruginosa (cyanobacterium). Fresenius Environ Bull 18:687–693

Lehr F, Posten C (2009) Closed photo-bioreactors as tools for biofuel production. Curr Opin Biotechnol 20:280–285

Long SP, Humphries MS, Falkowski PG (1994) Photoinhibition of photosynthesis in nature. Annu Rev Plant Physiol Plant Mol Biol 45:633–662

Ludwig M, Bryant DA (2011) Transcription profiling of the model cyanobacterium Synechococcus sp. strain PCC 7002 by Next-Gen (SOLIDTM). Front Microbiol 2:41. doi:10.3389/fmicb.2011.00041

Ludwig M, Bryant DA (2012) Acclimation of the global transcriptome of the cyanobac- terium Synechococcus sp. strain PCC 7002 to nutrient limitations and different nitrogen sources. Front Microbiol 3:145. doi:10.3389/fmicb.2012.00145

Moheimani NR (2013) Inorganic carbon and pH effect on growth and lipid productivity of Tetraselmis suecica and Chlorella sp (Chlorophyta) grown outdoors in bag photobioreactors. J Appl Phycol 25:387–398

Moheimani N, Borowitzka MA (2011) Increase CO2 and the effect of pH on growth and calcification of Pleurochrysis carterae and Emiliania huxleyi (Haptophyta) in semicontuous cultures. Appl Microbiol Biotechnol 90:1399–1407

Pörs Y, Wüstenberg A, Ehwald R (2010) A batch culture method for microalgae and cyanobacteria with CO2 supply through polyethylene membranes. J Phycol 46:825–830

Richmond A (2003) Growth characteristics of ultrahigh density microalgal cultures. Biotechnol Bioprocess Eng 8:349–353

Richmond A, Zou N (1999) Efficient utilization of high photon irradiance for mass production of photoautotrophic micro-organisms. J Appl Phycol 11:123–127

Rippka R, Derulles J, Waterbury JB, Herdman M, Stanier RY (1979) Generic assignments, strain histories and properties of pure cultures of cyanobacteria. J Gen Microbiol 111:1–61

Sawdon A, Peng C-A (2014) Internal deoxygenation of tubular photobioreactor for mass production of microalgae by perfluorcarbon emulsion. J Chem Technol Biotechnol B. doi:10.1002/jctb.4444

Souza C, Compadre A, Vermue MH, Wijffels RH (2013) Effect of oxygen at low and high light intensities on the growth of Neochloris oleoabundans. Algal Res 2:122–126

Tripathi U, Sarada R, Ravishhankar GA (2001) A culture method for microalgal forms using two-tier vessel providing carbon-dioxide environment: studies on growth and carotenoid production. World J Microbiol Biotechnol 17:325–329

Tsoglin LN, Gabel BV, Falkovich TN, Semenenko VE (1996) Closed photobioreactors for microalgal cultivation. Russ J Plant Physiol 43:131–136

Warburg O, Krippahl G (1960) Weiterentwicklung der manometrischen Methoden (Carbonatgemische). Z Naturforsch C 15b:364–367

Warburg O, Geissler W, Lorenz S (1961) CO2 - Drucke über Bicarbonat-Carbonatgemischen. Z Naturforsch C 16b:283

Wüstenberg A, Pörs Y, Ehwald R (2011) Culturing of stoneworts and submersed angiosperms with phosphate uptake exclusively from an artificial sediment. Freshw Biol 56:1531–1539

Zou N, Richmond A (2000) Light-path length and population density in photoacclimation of Nannochloropsis sp. (Eustigmatophyceae). J Appl Phycol 12:349–354

Zou N, Zhang CW, Cohen Z, Richmond A (2000) Production of cell mass and eicosapentaenoic acid (EPA) in ultrahigh cell density cultures of Nannochloropsis sp. (Eustigmatophyceae). Eur J Phycol 35:127–133

Acknowledgments

Authors are grateful to Prof. Dr. T. Buckhout and Dr. R. Steuer, Institute of Biology, Humboldt-University, for improving the language and critical comments.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendices

Appendix 1: Maximum O2 concentration in the culture vessel as dependent on the rate of oxygen production and the design of the oxygen outlet channel

The maximum rate of convective O2 flow through the channel (r o ) obtained with Synechococcus cultures of ultrahigh cell density at a PFD of 900 μmol photons m−2 s−1 was 1.3 mm3 s−1. The chosen cross sectional area (A = 3.14 mm2) and maximum length (l = 10 mm) of the oxygen outlet channel ensured that the gas volume flux (J v = r o /A = 0.36 mm s−1) through the channel obtained at an even higher rate (r o = 2 mm3s−1) was smaller than the mean velocity (permeability) of O2 diffusion in the gas flowing through the channel (P = D/l = 2.2 mm s−1). Under this condition the rate of O2 loss from the culture chamber (r l ) can be regarded as the sum of a convective loss rate (r c ) and a diffusive loss rate (r d ).

When O2 concentrations are expressed as volume fraction of O2 in the gas phase, the rate of diffusional loss of O2 by exchange with N2, (r d ), depends on the concentration difference (∆C) across the oxygen outlet channel by

The O2 concentration in the culture chamber (C) and the mean concentration in the O2 outlet channel \( \left(\overline{C}\right) \) may be derived from the concentration in the atmosphere (0.2) and the concentration difference across the channel:

The rate of convective O2 loss, r c , is the product of the volume flow rate (r o ) and the mean O2 concentration \( \left(\overline{C}\right) \) within the channel.

When the O2 concentration in the gas phase of both chambers is still increasing at a given value of r o ; r l is smaller than r o . A stationary maximum value of the O2 concentration in the culture chamber (C’) is reached when r l approximates to r 0:

C’ can be obtained by combining Eq. (3) with Eq. (7):

Using Eq. (8), stationary O2 concentrations at rates of O2 generation r o < 2 AD/l can be derived from the diffusion coefficient of O2 in air D (0.22 cm2s−1) and outlet dimensions A and l.

Appendix 2: Effect of CO2 consumption in the culture chamber on the CO2 buffer in the basal chamber

In the experiments documented in Fig. 7 and Table 2 the DWC of Synechococcus sp. strain PCC 7002 increased by 15 to 20 g L−1 in a volume of 20 mL during a batch cycle. In the culture vessel used (Fig. 1c), two culture chambers were combined with one basal chamber containing a CO2 buffer obtained by mixing 3 M KHCO3 with 3 M K2CO3 in the ratio 9:1 (540 mmol HCO3 − and 60 mmol CO3 in 200 mL). If the DWC increased by 20 g L−1 in both culture chambers (culture volume 40 mL), 800 mg of dry biomass were produced. Assuming a carbon content of 50 % in the dry mass (Fontes et al. 1989), this required transfer of c. 400 mg C or 33 mmol CO2 from the basal chamber to the culture chamber. According to the reaction 2 HCO3 −↔CO2 + CO3 2−, absorption of 33 mmol CO2 in the culture chamber induced the formation of 33 mmol CO3 2− in the CO2 buffer, thus reducing the amount of HCO3 − by 66 mmol. Hence, the amount of HCO3 − in the basal chamber was reduced from initially 540 mmol to c.474 mmol, while the amount of CO3 2−increased from initially 60 mmol to finally 93 mmol. The ratio between KHCO3 and K2CO3 within the basal chamber changed from initially 9:1 to finally c. 5:1 corresponding to a decrease in the CO2 concentration from initially c. 10 % to c. 5 % at 30 °C.

Rights and permissions

About this article

Cite this article

Bähr, L., Wüstenberg, A. & Ehwald, R. Two-tier vessel for photoautotrophic high-density cultures. J Appl Phycol 28, 783–793 (2016). https://doi.org/10.1007/s10811-015-0614-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-015-0614-5