Abstract

Background

Oxygenic photosynthetic microorganisms such as cyanobacteria and microalgae have attracted attention as an alternative carbon source for the next generation of biofuels. Glycogen abundantly accumulated in cyanobacteria is a promising feedstock which can be converted to ethanol through saccharification and fermentation processes. In addition, the utilization of marine cyanobacteria as a glycogen producer can eliminate the need for a freshwater supply. Synechococcus sp. strain PCC 7002 is a fast-growing marine coastal euryhaline cyanobacteria, however, the glycogen yield has not yet been determined. In the present study, the effects of light intensity, CO2 concentration, and salinity on the cell growth and glycogen content were investigated in order to maximize glycogen production in Synechococcus sp. strain PCC 7002.

Results

The optimal culture conditions for glycogen production in Synechococcus sp. strain PCC 7002 were investigated. The maximum glycogen production of 3.5 g L−1 for 7 days (a glycogen productivity of 0.5 g L−1 d−1) was obtained under a high light intensity, a high CO2 level, and a nitrogen-depleted condition in brackish water. The glycogen production performance in Synechococcus sp. strain PCC 7002 was the best ever reported in the α-polyglucan (glycogen or starch) production of cyanobacteria and microalgae. In addition, the robustness of glycogen production in Synechococcus sp. strain PCC 7002 to salinity was evaluated in seawater and freshwater. The peak of glycogen production of Synechococcus sp. strain PCC 7002 in seawater and freshwater were 3.0 and 1.8 g L−1 in 7 days, respectively. Glycogen production in Synechococcus sp. strain PCC 7002 maintained the same level in seawater and half of the level in freshwater compared with the optimal result obtained in brackish water.

Conclusions

We conclude that Synechococcus sp. strain PCC 7002 has high glycogen production activity and glycogen can be provided from coastal water accompanied by a fluctuation of salinity. This work supports Synechococcus sp. strain PCC 7002 as a promising carbohydrate source for biofuel production.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Background

Currently, biorefinery, including production of biofuels and bio-based chemicals, has received considerable attention. Additionally, environmental concerns and the depletion of oil reserves have resulted in promoting research on more environmentally benign and sustainable biofuels such as bioethanol.

Oxygenic photosynthetic microorganisms, including cyanobacteria and microalgae, have attracted attention as an alternative carbon source for biorefineries [1–3]. Cyanobacteria and microalgae convert solar energy to biomass more efficiently (0.5 to 2.0% efficiency) than energy crops such as switchgrass (0.2% efficiency) [4], and their α-polyglucans such as glycogen from cyanobacteria or starch from microalgae, can be converted to bioethanol by yeast fermentation [5–9]. In addition, they are capable of growing in aquatic environments, providing the additional benefit of whole-year cultivation using non-arable land. In particular, the cultivation of cyanobacteria and microalgae using seawater or brackish water eliminates the impact on freshwater resources [10]. These carbohydrate-producing species need to tolerate a wide salinity range because the salinity of coastal water fluctuates with changes in freshwater inflow by climate, weather, and diurnal tidal current. Therefore, in the current study, the euryhaline cyanobacteria Synechococcus sp. strain PCC 7002, which is well-suited for growing in a coastal region, was selected as a carbohydrate producer. Synechococcus sp. strain PCC 7002 is naturally transformable and its genome has been fully sequenced [11]. Based on these superior characteristics, Synechococcus sp. strain PCC 7002 is a model organism for research on cyanobacterial metabolites and is expected to be a platform for biotechnological applications by metabolic engineering [12–17].

According to definition, glycogen productivity is estimated from glycogen content and biomass productivity. To improve glycogen productivity in cyanobacteria, both the glycogen content and biomass productivity need to be enhanced. In general, glycogen is accumulated via nitrogen depletion in many cyanobacteria species, such as Synechococcus sp. strain PCC 7002, Synechocystis sp. strain PCC 6803, Arthrospira platensis, Arthrospira maxima, Anabaena variabilis, and Anacystis nidulans[16–23]. Unfortunately, high glycogen content is generated under nitrogen depletion which is associated with low biomass productivity [19, 23]. Hence, it is important to obtain a high biomass productivity with a satisfactory glycogen content. However, the integral effect of growth conditions on glycogen production in Synechococcus sp. strain PCC 7002 has not been fully investigated.

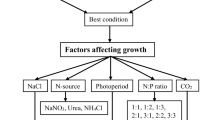

In the present study, the glycogen production activity of euryhaline cyanobacteria Synechococcus sp. strain PCC 7002 was examined under several combined growth conditions, including CO2 concentration, light intensity, salinity, and nitrate supply.

Results

Effect of light intensity and CO2 concentration on cell growth

Light intensity and CO2 concentration are the key environmental factors for cyanobacterial cell growth [1]. In this study, Synechococcus sp. strain PCC 7002 was cultivated on medium A for 7 days under a light intensity of 50 to 600 μmol photons m−2 s−1 with various CO2 concentrations as depicted in Figure 1 (for example, 0.04 to 4% CO2 in air). As shown in Figure 1a, cell growth in 0.04% CO2 in air (the atmospheric CO2 level) was not altered by an increase in light intensity. On the other hand, the cell density of Synechococcus sp. strain PCC 7002 tended to increase when increasing CO2 concentration from 0.04 to 2% and increasing light intensity from 50 to 600 μmol photons m−2 s−1. However, further increases in CO2 concentration to 4% resulted in no significant difference in cell growth under low and high light intensity, suggesting that excess CO2 supply (4%) would not provide a positive effect on cell growth. According to Figure 1, Synechococcus sp. strain PCC 7002 cultivated under conditions of high CO2 concentration (2 and 4% CO2) with high illumination (600 μmol photons m−2 s−1) reached the highest cell density of around 9 g L−1 after 7 days of cultivation. Thus, both enriched CO2 supply and high light intensity enhanced the cell growth of Synechococcus sp. strain PCC 7002.

Growth curve under different light intensities and CO 2 concentrations. (a) Growth curve under 0.04% CO2; (b), 1% CO2; (c), 2% CO2; and (d), 4% CO2. Light intensities are 50 (circles), 300 (squares), and 600 μmol photons m−2 s−1 (diamonds). Error bars indicate standard deviations (SD) of three replicated experiments. In some data points, error bars obtained by three replications are smaller than symbols.

Effect of light intensity and CO2 concentration on glycogen content and glycogen production

Light intensity and CO2 supply do not only influence the growth of photosynthetic organism but also alter their carbohydrate content [24–26]. Therefore, in this study, the effect of light intensity (50 to 600 μmol photons m−2 s−1) and CO2 concentration (such as 0.04 to 4% CO2) on glycogen content were explored, as shown in Figure 2a. Glycogen content increased with an increase in light intensity from 50 to 600 μmol photons m−2 s−1.

Glycogen content and glycogen production after 1 week under different light intensities and CO 2 concentrations. (a) Glycogen content; (b) glycogen production. Light intensities are 50 (white bars), 300 (gray bars), and 600 μmol photons m−2 s−1 (Black bars). Data points are mean values from three separate cultures with SD of triplicates.

As shown in Figure 2a, the glycogen content under 300 μmol photons m−2 s−1 increased from 0.8 to 19% as the CO2 concentration increased from 0.04 to 1%, and under the same range of CO2 concentrations at 600 μmol photons m−2 s−1, it increased from 9.4 to 31%. However, further increase in CO2 concentration to 2% under 300 or 600 μmol photons m−2 s−1 did not enhance glycogen content.

Glycogen production under 50 to 600 μmol photons m−2 s−1 in 0.04 to 4% CO2 after 7 days was calculated from biomass production and glycogen content, as shown in Figure 2b. The maximum glycogen production of 2.5 g L−1 was obtained under 600 μmol photons m−2 s−1 in 2% CO2. Hence, glycogen production in Synechococcus sp. strain PCC 7002 was significantly improved by the combined optimization of CO2 concentration and light intensity.

Effect of nitrate supply in different salinity media on glycogen production under high light and high CO2 conditions

The accumulation of glycogen occurs in many cyanobacteria, such as Synechococcus sp. strain PCC 7002, Synechocystis sp. strain PCC 6803, A. platensis, A. maxima, A. variabilis, and A. nidulans, under nitrogen-depleted conditions [16–23]. However, high levels of glycogen are generated under nitrogen depletion, which is associated with low biomass productivity [19, 23]. Therefore, in this study, the effect of nitrate supply on both glycogen content and biomass production in Synechococcus sp. strain PCC 7002 under 600 μmol photons m−2 s−1 and 2% CO2 was investigated. Additionally, in case of cultivation in brackish water or seawater at a coastal region, the salinity of medium was fluctuated according to climate, weather, and diurnal tidal current. Therefore, to estimate the glycogen productivity of Synechococcus sp. strain PCC 7002 under different salinity conditions, the glycogen content and biomass production in brackish water (Figure 3a), seawater (Figure 3b), and freshwater (Figure 3c) media were examined. The glycogen content of Synechococcus sp. strain PCC 7002 in all media increased with a drop of nitrate concentration from 27 to 9 mM, reaching 52, 50, or 62% of dry-cell weight in brackish water, seawater, or freshwater medium, respectively. Unfortunately, the biomass productions were suppressed below 21 mM in brackish water and below 15 mM in seawater (Figure 3a,b). Thus, in this study, the glycogen production of Synechococcus sp. strain PCC 7002 in each medium was calculated in order to optimize the nitrate concentration to obtain a suitable combination of biomass production and glycogen content, as shown in Figure 3d. The peak of glycogen production was 3.5 g L−1 in brackish water with 13 and 15 mM nitrate, 3.0 g L−1 in seawater with 15 mM nitrate, or 1.8 g L−1 in freshwater with 9 mM nitrate (Figure 3d). Glycogen production in Synechococcus sp. strain PCC 7002 maintained the same level in seawater and half of the level in freshwater compared with the level achieved in brackish water.

Biomass production, glycogen content, and glycogen production after 1 week under different salinity conditions. (a) Biomass production (circles) and glycogen content (squares) in brackish water; (b) in seawater; and (c) in freshwater; (d) glycogen production under different nitrate supplies in brackish water (circles), seawater (squares), and freshwater (diamonds). Cells were cultivated under 600 μmol photons m−2 s−1 and 2% CO2. Data points are mean values from three separate cultures with SD of triplicates.

Discussion

Cyanobacterial glycogen is remarkable carbon source for bioethanol production by yeast fermentation [5]. As shown in Figure 2a, glycogen accumulated under high light intensity and high CO2 concentration. In vitro and in situ kinetic experiments have revealed that cyanobacterial glycogen synthesis is regulated by adenosine diphosphate (ADP)-glucose pyrophosphorylase (AGPase) activity, which is enhanced by 3-phosphoglycerate (3-PG) accumulation and inhibited by inorganic phosphorus accumulation [27]. Therefore, 3-PG might be accumulated by the increase in light intensity and CO2 concentration, which would lead to glycogen accumulation in Synechococcus sp. strain PCC 7002.

The glycogen production of Synechococcus sp. strain PCC 7002 was examined under different nitrate additions in a brackish water medium (Figure 3a). As shown in Additional file 1: Figure S1, cell growth in brackish water media under 9 and 15 mM nitrate supplies were inhibited by nitrogen limitation. Under nitrogen-limiting conditions, biomass production would be strongly inhibited due to the relatively low photosynthesis efficiency, expecting that light-harvesting proteins (such as phycobiliproteins) would be degraded to compensate for the insufficient nitrogen availability [28]. On the other hand, the glycogen content in cyanobacteria is accumulated by nitrogen depletion [16–20]. Since lower initial nitrate supplies caused faster nitrate depletion (as shown in Additional file 2: Figure S2), glycogen content increased gradually with a decrease in initial supplied nitrate as shown in Figure 3a.

In addition, glycogen production was influenced by salinity in medium as shown in Figure 3a-d. Glycogen production in seawater was a little lower than brackish water, which was caused by the lower glycogen content (Figure 3a,b,d). Glycogen content in seawater would be reduced by the accumulation of osmolytes, such as glucosylglycerol, glucosylglycerate, and sucrose in Synechococcus sp. strain PCC 7002, with an increase in sodium chloride concentration [16, 17, 30]. Also, the decline of glycogen production in freshwater was due to lower biomass production (Figure 3a,c,d). High cell density in Synechococcus sp. strain PCC 7002 could not be obtained in the freshwater medium.

The biomass production and α-polyglucan production in various cyanobacteria and microalgae are summarized in Table 1. The highest biomass production (7.2 g L−1) and α-polyglucan production (3.5 g L−1) from Synechococcus sp. strain PCC 7002 under the optimal conditions with the brackish water medium are higher than that reported by other studies [19, 21, 22, 25, 30–36]. In addition, glycogen production of Synechococcus sp. strain PCC 7002 in a seawater and freshwater environment is greater than or similar with other cyanobacteria and microalgae as shown in Table 1. Therefore, Synechococcus sp. strain PCC 7002 would not only provide glycogen from coastal seawaters without the need for freshwater resources, but also can produce the highest level of α-polyglucan among microalgae and cyanobacteria in wide salinity conditions.

To further improve glycogen productivity in Synechococcus sp. strain PCC 7002, the glycogen accumulation rate should be accelerated through metabolic engineering. According to Kumaraswamy et al., the intracellular glycogen content in Synechococcus sp. strain PCC 7002 is positively correlated with the expression level of the NAD+-dependent glyceraldehyde 3-phosphate dehydrogenase (GAPDH-1) gene under photoautotrophic conditions [15]. Accordingly, glycogen productivity in Synechococcus sp. strain PCC 7002 may be further improved by a combination of the optimization of growth conditions and the overexpression of GAPDH-1. Glycogen produced by Synechococcus sp. strain PCC 7002 in this study was converted to ethanol by yeast fermentation (Additional file 3: Figure S3). The enhancement of glycogen production by Synechococcus sp. strain PCC 7002 would contribute to biofuel production.

Conclusions

Synechococcus sp. strain PCC 7002 which combines a wide salinity tolerance and high glycogen production capacity could become an important carbon source for the development of biofuels and bio-based chemicals production. The glycogen productivity of Synechococcus sp. strain PCC 7002 would be further enhanced through genetic engineering or metabolic engineering in the next step, which could accelerate the glycogen accumulation rate under nitrogen depletion.

Methods

Microorganism and growth conditions

The cyanobacteria Synechococcus sp. strain PCC 7002 was obtained from the Pasteur Culture Collection (Paris, France). Cells were pre-cultured in 500 mL Erlenmeyer flasks containing 250 mL of modified medium A (3.0 g L−1 NaNO3, 50 mg L−1 KH2PO4, 18 g L−1 NaCl, 5.0 g L−1 MgSO4•7H2O, 0.37 g L−1 CaCl2•2H2O, 0.60 g L−1 KCl, 32 mg L−1 Na2EDTA•2H2O, 8.0 mg L−1 FeCl3•6H2O, 34 mg L−1 H3BO3, 4.3 mg L−1 MnCl2•4H2O, 0.32 mg L−1 ZnCl2, 30 μg L−1 MoO3, 3.0 μg L−1 CuSO4•5H2O, 12 μg L−1 CoCl2•6H2O, 4.0 μg L−1 cobalamin, and 8.3 mM Tris aminomethane, all of which were purchased from Nacalai Teque, Inc., (Kyoto, Japan)) [37] with 100 rpm agitation under continuous illumination at 50 μmol photons m−2 s−1 for 7 days in air at 30 ± 2 °C in an NC350-HC plant chamber (Nippon Medical and Chemical Instruments, Osaka, Japan). Experiments were carried out in a closed double-deck flask, containing in the first stage 50 mL of 2 M NaHCO3/Na2CO3 buffer with the appropriate pH to obtain the desired CO2 concentration [38, 39], and containing in the second stage 70 mL of culture medium. NaHCO3/Na2CO3 buffer was exchanged after 4 days to maintain the desired CO2 concentration. Pre-cultured cells were inoculated into fresh medium at a dry-based biomass concentration of 0.01 g dry-cell weight L−1 (the optical density at 750 nm (OD750) value was 0.04) and cultivated for 7 days at 33 ± 3 °C with 80 rpm agitation. The effects of light intensity and CO2 concentration on glycogen production were examined under 50, 300, or 600 μmol photons m−2 s−1 at 0.04 (atmospheric level), 1, 2, or 4% (v/v) CO2 in air. Light intensity was measured in the middle of the medium using an LI-250A light meter (LI-COR, Lincoln, Nebraska, USA) equipped with an LI-190SA quantum sensor (LI-COR). To study the effect of nitrate supply in different salinity media under 600 μmol photons m−2 s−1 in 2% CO2 in air, pre-cultured cells were transferred into 3-types of media with 9 to 35 mM nitrate. : 1) medium A (brackish water medium; salinity at 2.7%), 2) medium A containing 0.075 g L−1 MgSO4•7H2O, 0.036 g L−1 CaCl2•2H2O, 0.04 g L−1 K2HPO4 without NaCl (freshwater medium; salinity at 0.3%), 3) medium A containing 29.2 g L−1 NaCl, 7 g L−1 MgSO4•7H2O, 4 g L−1 MgCl2•6H2O, 1.47 g L−1 CaCl2•2H2O, 0.6 g L−1 KCl, 0.05 g L−1 KH2PO4 (seawater medium; salinity at 4.0%). Medium salinity were measured with a refractometer (S/Mill-E; Atago Co. Ltd, Tokyo, Japan).

Analytical methods

Cell growth was monitored by measuring OD750 in a spectrophotometer (UVmini-1240, Shimadzu, Kyoto, Japan) [29]. Cell concentration was shown as dry-cell weight during cultivation and was converted using a pre-established calibration between dry-cell weight and optical density of cell suspension (1.0 OD750 equals approximately 0.32 g dry-cell weight L−1). Dry-cell weight was determined by centrifugation of serial diluted cell-suspension (6,300 × g for 2 minutes at 25 °C), washing the pellet once with 0.3 M ammonium carbonate and lyophilization.

Glycogen content and concentration were determined by high performance liquid chromatography (HPLC) (Shimadzu, Kyoto, Japan) using a size exclusion HPLC column (OHpak SB-806 M HQ; Shodex, Tokyo, Japan) and a reflective index detector (RID-10A; Shimadzu, Kyoto, Japan) [40]. Glycogen was extracted from the dried cells by the modified method of Ernst and Böger [22]. Glycogen productivity (g L−1 d−1) was estimated by dividing glycogen production by cultivation time. Experimental data were means of triplicate samples and error bars in the figures indicate the standard deviation.

Abbreviations

- 3-PG:

-

3-phosphoglycerate

- ADP:

-

Adenosine diphosphate

- AGPase:

-

ADP-glucose pyrophosphorylase

- HPLC:

-

High liquid chromatography

- OD:

-

Optical density

- SD:

-

Standard deviations.

References

Ducat DC, Way JC, Silver PA: Engineering cyanobacteria to generate high-value products. Trends Biotechnol 2011, 29: 95-103. 10.1016/j.tibtech.2010.12.003

Lopez PJ, Desclés J, Allen AE, Bowler C: Prospects in diatom research. Curr Opin Biotechnol 2005, 16: 180-186. 10.1016/j.copbio.2005.02.002

Rosenberg JN, Oyler GA, Wilkinson L, Betenbaugh MJ: A green light for engineered algae: redirecting metabolism to fuel a biotechnology revolution. Curr Opin Biotechnol 2008, 19: 430-436. 10.1016/j.copbio.2008.07.008

Melis A: Solar energy conversion efficiencies in photosynthesis: minimizing the chlorophyll antennae to maximize efficiency. Plant Sci 2009, 177: 272-280. 10.1016/j.plantsci.2009.06.005

Aikawa S, Joseph A, Yamada R, Izumi Y, Yamagishi T, Matsuda F, Kawai H, Chang JS, Hasunuma T, Kondo A: Direct conversion of Spirulina to ethanol without pretreatment or enzymatic hydrolysis processes. Energ Environ Sci 2013, 6: 1844-1849. 10.1039/c3ee40305j

Choi SP, Nguyen MT, Sim SJ: Enzymatic pretreatment of Chlamydomonas reinhardtii biomass for ethanol production. Bioresour Technol 2010, 101: 5330-5336. 10.1016/j.biortech.2010.02.026

Harun R, Jason WSY, Cherrington T, Danquah MK: Exploring alkaline pre-treatment of microalgal biomass for bioethanol production. Appl Energy 2011, 88: 3464-3467. 10.1016/j.apenergy.2010.10.048

Ho SH, Li PJ, Liu CC, Chang JS: Bioprocess development on microalgae-based CO2 fixation and bioethanol production using Scenedesmus obliquus CNW-N. Bioresour Technol 2013, 145: 142-149.

Miranda JR, Passarinho PC, Gouveia L: Pre-treatment optimization of Scenedesmus obliquus microalga for bioethanol production. Bioresour Technol 2012, 104: 342-348.

Dismukes GC, Carrieri D, Bennette N, Ananyev GM, Posewitz MC: Aquatic phototrophs: efficient alternatives to land-based crops for biofuels. Curr Opin Biotechnol 2008, 19: 235-240. 10.1016/j.copbio.2008.05.007

Stevens SE, Porter RD: Transformation in Agmenellum quadruplicatum . Proc Natl Acad Sci USA 1980, 77: 6052-6056. 10.1073/pnas.77.10.6052

Bennette NB, Eng JF, Dismukes GC: An LC-MS-based chemical and analytical method for targeted metabolite quantification in the model cyanobacterium Synechococcus sp. PCC7002. Anal Chem 2011, 83: 3808-3816. 10.1021/ac200108a

Ludwig M, Bryant DA: Synechococcus sp. strain PCC7002 transcriptome: acclimation to temperature, salinity, oxidative stress, and mixotrophic growth conditions. Front Microbiol 2012, 3: 1-14.

McNeely K, Xu Y, Bennette N, Bryant DA, Dismukes GC: Redirecting reductant flux into hydrogen production via metabolic engineering of fermentative carbon metabolism in a cyanobacterium. Appl Environ Microbiol 2010, 76: 5032-5038. 10.1128/AEM.00862-10

Kumaraswamy GK, Guerra T, Qian X, Zhang S, Bryant DA, Dismukes GC: Reprogramming the glycolytic pathway for increased hydrogen production in cyanobacteria: metabolic engineering of NAD+-dependent GAPDH. Energ Environ Sci 2013, 6: 3722-3731. 10.1039/c3ee42206b

Xu Y, Guerra LT, Li Z, Ludwig M, Dismukes GC, Bryant DA: Altered carbohydrate metabolism in glycogen synthase mutants of Synechococcus sp. strain PCC 7002: cell factories for soluble sugars. Metab Eng 2013, 16: 56-67.

Guerra LT, Xu Y, Bennette N, McNeely K, Bryant DA, Dismukes GC: Natural osmolytes are much less effective substrates than glycogen for catabolic energy production in the marine cyanobacterium Synechococcus sp. strain PCC 7002. J Biotechnol 2013, 166: 65-75. 10.1016/j.jbiotec.2013.04.005

Hasunuma T, Kikuyama F, Matsuda M, Aikawa S, Izumi Y, Kondo A: Dynamic metabolic profiling of cyanobacterial glycogen biosynthesis under conditions of nitrate depletion. J Exp Bot 2013, 64: 2943-2954. 10.1093/jxb/ert134

Aikawa S, Izumi Y, Matsuda F, Hasunuma T, Chang JS, Kondo A: Synergistic enhancement of glycogen production in Arthrospira platensis by optimization of light intensity and nitrate supply. Bioresour Technol 2012, 108: 211-215.

Aoyama K, Uemura I, Miyake J, Asada Y: Fermentative metabolism to produce hydrogen gas and organic compounds in a cyanobacterium, Spirulina platensis . J Ferment Bioeng 1997, 83: 17-20. 10.1016/S0922-338X(97)87320-5

De Philippis R, Sili C, Vincenzini M: Glycogen and poly-β-hydroxybutyrate synthesis in Spirulina maxima . J Gen Microbiol 1992, 138: 1623-1628. 10.1099/00221287-138-8-1623

Ernst A, Böger P: Glycogen accumulation and the induction of nitrogenase activity in the heterocyst-forming cyanobacterium Anabaena variabilis . J Gen Microbiol 1985, 131: 3147-3153.

Lehmann M, Wöber G: Accumulation, mobilization and turn-over of glycogen in the blue-green bacterium Anacystis nidulans . Arch Microbiol 1976, 111: 93-97. 10.1007/BF00446554

Ho SH, Chen CY, Chang JS: Effect of light intensity and nitrogen starvation on CO2 fixation and lipid/carbohydrate production of an indigenous microalga Scenedesmus obliquus CNW-N. Bioresour Technol 2012, 113: 244-252.

Sakamoto T, Bryant DA: Synergistic effect of high-light and low temperature on cell growth of the ∆12 fatty acid desaturase mutant in Synechococcus sp. PCC7002. Photosynth Res 2002, 72: 231-242. 10.1023/A:1019820813257

Webber AN, Nie GY, Long SP: Acclimation of photosynthetic proteins to rising atmospheric CO2. Photosynth Res 1994, 39: 413-425. 10.1007/BF00014595

Gómez-Casati DF, Dortassa S, Aon MA, Iglesias AA: Ultrasensitive behavior in the synthesis of storage polysaccharides in cyanobacteria. Planta 2003, 216: 969-975.

Boussiba S, Richmond AE: C-phycocyanin as a storage protein in the blue-green alga Spirulina platensis . Arch Microbiol 1980, 125: 143-147. 10.1007/BF00403211

Klähn S, Stglich C, Hess WR, Hagemann M: Glucosylglycerate: a secondary compatible solute common to marine cyanobacteria from nitrogen-poor environments. Environ Microbiol 2010, 12: 83-94. 10.1111/j.1462-2920.2009.02045.x

Friedman O, Dubinsky Z, Arad SM: Effect of light intensity on growth and polysaccharide production in red and blue-green rhodophyta unicells. Bioresour Technol 1991, 38: 105-110. 10.1016/0960-8524(91)90139-B

Yao C, Ai J, Cao X, Xue S, Zhang W: Enhancing starch production of a marine green microalga Tetraselmis subcordiformis through nutrient limitation. Bioresour Technol 2012, 118: 438-444.

Behrens PW, Bingham SE, Hoeksema SD, Cohoon DL, Cox JC: Studies on the incorporation of CO2 into starch by Chlorella vulgaris . J Appl Phycol 1989, 1: 123-130. 10.1007/BF00003874

Morsy FM: Acetate versus sulphur deprivation role in creating anaerobiosis in light for hydrogen production by Chlamydomonas reinhardii and Spirulina platensis : two different organisms and two different mechanisms. Photochem Photobiol 2011, 87: 137-142. 10.1111/j.1751-1097.2010.00823.x

Serebryakova LT, Sheremetieva M, Tsygankov AA: Reversible hydrogenase activity of Gloeocapsa alpicola in continuous culture. FEMS Microbiol Lett 1998, 166: 89-94. 10.1111/j.1574-6968.1998.tb13187.x

Huesemann MH, Hausmann TS, Cater BM, Gerschler JJ, Benemann JR: Hydrogen generation through indirect biophotolysis in batch cultures of the nonheterocystous nitrogen-fixing cyanobacterium Plectonema boryanum . Appl Biochem Biotechnol 2010, 162: 208-220. 10.1007/s12010-009-8741-6

Tandeau de Marsac N, Castets AM, Cohen-Bazire G: Wavelength modulation of phycoerythrin synthesis in Synechocystis sp. 6701. J Bacteriol 1980, 142: 310-314.

Stevens SE, Pat Patterson CO, Myers J: The production of hydrogen peroxide by blue-green algae: a survey. J Phycol 1973, 9: 427-430.

Flores E, Romero JM, Guerrero MG, Losada M: Regulatory interaction of photosynthetic nitrate utilization and carbon dioxide fixation in the cyanobacterium Anacystis nidulans . Biochim Biophys Acta 1983, 725: 529-532. 10.1016/0005-2728(83)90193-7

Deng Y, Ye J, Mi H: Effects of low CO2 on NAD(P)H dehydrogenase, a mediator of cyclic electron transport around photosystem I in the cyanobacterium Synechocystis PCC6803. Plant Cell Physiol 2003, 44: 534-540. 10.1093/pcp/pcg067

Izumi Y, Aikawa S, Matsuda F, Hasunuma T, Kondo A: Aqueous size-exclusion chromatographic method for the quantification of cyanobacterial native glycogen. J Chromatogr B 2013, 930: 90-97.

Association APH: Standard Methods for the Examination of Water and Wastewater. 17th edition. Edited by Clesceri LS, Greenberg AE, Trussell RR. Washington DC: American Public Health Association; 1989.

Acknowledgements

The authors thank Dr Hiroshi Teramura and Dr Ancy Joseph for their valuable comments. This work was supported by the Core Research for Evolutional Science and Technology (CREST) of Promoting Globalization on Strategic Basic Research Programs of the Japan Science and Technology Agency. The study was also partially supported by a National Cheng Kung University project, as part of a second-phase 5-year 50 billion dollar grant from the Taiwanese government to JSC, and a Grant-in-Aid for Kurita Water and Environment Foundation to SA (Number 13A021).

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

SA designed the study and wrote the manuscript. AN performed the experiments and analyzed the data. SHH revised manuscript. TH designed the study and revised manuscript. JSC and AK coordinated the study. All authors read and approved the final manuscript.

Shimpei Aikawa, Atsumi Nishida contributed equally to this work.

Electronic supplementary material

13068_2013_489_MOESM1_ESM.pdf

Additional file 1: Figure S1: Growth curve under different nitrate supplies in brackish water medium. Cells were cultivated under 600 μmol photons m−2 s−1 and 2% CO2 condition with 9 to 27 mM nitrate supplies. Error bars indicate standard deviations (SD) of three replicated experiments. In some data points, error bars obtained by three replications are smaller than symbols. (PDF 72 KB)

13068_2013_489_MOESM2_ESM.pdf

Additional file 2: Figure S2: Nitrate consumption under different nitrate supplies in brackish water medium. Nitrate concentrations were determine according to method proposed by American Public Health Association [41]. Cells were cultivated under 600 μmol photons m−2 s−1 and 2% CO2 from 35 to 9 mM nitrate supplies. Error bars indicate standard deviations (SD) of three replicated experiments. In some data points, error bars obtained by three replications are smaller than symbols. (PDF 84 KB)

13068_2013_489_MOESM3_ESM.pdf

Additional file 3: Figure S3: Ethanol production from glycogen extracts of Synechococcus sp. strain PCC 7002 following yeast fermentation. Ethanol was produced from glycogen extracts of Synechococcus sp. strain PCC 7002 by Saccharomyces cerevisiae MT8-1 in the presence of 0.3 U L−1 α-amylase and 0.1 U L−1 glucoamylase. Glycogen extracts of Synechococcus sp. strain PCC 7002 were prepared as described in Methods and then adjusted to pH 7.0 using 98% H2SO4 (w/w). S. cerevisiae MT8-1 cells were grown aerobically in 1-L Erlenmeyer flasks containing 500 mL YPD medium (10 g L−1 yeast extract, 20 g L−1 peptone, and 20 g L−1 glucose) at 30°C with 150 rpm agitation for 48 hours, and then collected by centrifugation at 5,000 × g for 3 minutes at 25°C, washed twice with distilled water, and then inoculated into 50 mL YPG medium (10 g L−1 yeast extract, 20 g L−1 peptone, 0.1 M phosphate buffer adjusted to pH 6.0, 10 mM disodium EDTA, and 10 g L−1Synechococcus sp. strain PCC 7002 glycogen extract). Ethanol production was performed at 30°C and an agitation speed of 500 rpm in 100-mL closed bottles equipped with a bubbling CO2 outlet and a stir bar under oxygen-limited conditions. Agitation speed was maintained with a magnetic stirrer (VARIOMAG Telesystem; Thermo Fisher Scientific, Waltham, Massachusetts, United States). (PDF 56 KB)

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

This article is published under an open access license. Please check the 'Copyright Information' section either on this page or in the PDF for details of this license and what re-use is permitted. If your intended use exceeds what is permitted by the license or if you are unable to locate the licence and re-use information, please contact the Rights and Permissions team.

About this article

Cite this article

Aikawa, S., Nishida, A., Ho, SH. et al. Glycogen production for biofuels by the euryhaline cyanobacteria Synechococcus sp. strain PCC 7002 from an oceanic environment. Biotechnol Biofuels 7, 88 (2014). https://doi.org/10.1186/1754-6834-7-88

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/1754-6834-7-88