Abstract

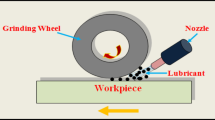

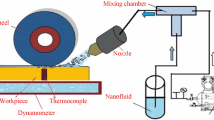

Conventional lubrication systems are used in grinding operations to reduce friction and defects produced during machining. Mineral-based oils, commonly used as conventional lubricants, were observed to produce greenhouse wastes that are hazardous to the environment. The minimum quantity lubrication (MQL) system, an eco-friendly, economical, and less hazardous lubrication technique, is affirmed to be an efficient substitute for these conventional lubricants. Nevertheless, the pure vegetable and synthetic oils used in MQL systems have lower tribological and thermal evacuation properties compared to conventional lubricants. Many adjustments and improvements have been introduced into the MQL system such as the introduction of nanofluids, cryogenic air, ionic fluids, and electrostatic atomization. This study aims to come up with an extensive review and analytical assessment of the trends and developments of the MQL system in grinding operations. Firstly, the different advances ranging from fluid types, additives, and redesigns of the MQL systems are discussed. Likewise, the results obtained from using different types of lubricants and nanofluids in the MQL system were discussed. Moreover, a detailed comparative assessment of the grinding performances between the MQL systems, dry grinding, and conventional lubrication was provided. It was found that the nanofluid MQL system produced 60% lower surface roughness and reduced the grinding forces by 30% compared to flood cooling systems. Lastly, the area of focus for research on grinding with MQL system for future advancements was proposed. The various advancements include the introduction of nanofluid varieties and the overall modification of the grinding system.

Similar content being viewed by others

Abbreviations

- CFL:

-

Conventional flood lubricant

- MQL:

-

Minimum quantity lubrication

- U :

-

Specific grinding energy

- NMQL:

-

Nano-biolubricant minimum quantity lubrication

- CC:

-

Cryogenic cooling

- Fn:

-

Normal grinding force

- Ft:

-

Tangential grinding force

- Ra:

-

Surface roughness

- CMQL:

-

Cryogenic minimum quantity lubrication

- ND:

-

Nano-diamond

- TEM:

-

Transmission electron microscopy

- FT-IR:

-

Fourier transform infrared spectroscopy

- TGA:

-

Thermogravimetric analysis

- CoF:

-

Coefficient of friction

- UAG:

-

Ultrasonic assisted grinding

- CBN:

-

Cubic boron nitride

- Ft/Fn:

-

Force ratio

- SEM:

-

Scanning electron microscope

- CNT:

-

Carbon nanotubes

- MWCNT:

-

Multi-walled carbon nanotubes

- ISO:

-

International organization for standardization

- 2D:

-

Two dimensional

- MRR:

-

Material removal rate

- XRD:

-

X-ray diffraction

- DLS:

-

Dynamic light scattering

- LN2:

-

Liquefied nitrogen

References

UNIDR (2018) Demand for manufacturing: driving inclusive and sustainable industrial development. United Nations Industrial Development Reports

UNIDR (2022) Industrial development report-the future of industrialization in a post-pandemic world. United Nations Industrial Development Organization

Pereira O, Rodríguez A, Barreiro J, Fernández-Abia AI, de Lacalle LNL (2017) Nozzle design for combined use of MQL and cryogenic gas in machining. Int J Precis Eng Manuf-Green Technol 4:87–95

Paul S, Ghosh A An experimental evaluation of solid lubricant based nanofluids in small quantity cooling and lubrication during grinding. In: Materials Science Forum 2017. Trans Tech Publ

Hamran NN, Ghani J, Ramli R, Haron CC (2020) A review on recent development of minimum quantity lubrication for sustainable machining. J Clean Prod 268:122165

Sharma AK, Tiwari AK, Dixit AR (2016) Effects of minimum quantity lubrication (MQL) in machining processes using conventional and nanofluid based cutting fluids: a comprehensive review. J Clean Prod 127:1–18

Zhou S, Wang D, Wu S, Gu G, Dong G, An Q, Guo H, Li C (2023) Minimum quantity lubrication machining nickel base alloy: a comprehensive review. Int J Adv Manuf Technol:1–39

Wang Y, Li C, Zhang Y, Yang M, Li B, Dong L, Wang J (2018) Processing characteristics of vegetable oil-based nanofluid MQL for grinding different workpiece materials. Int J Precis Eng Manuf-Green Technol 5:327–339

Dambatta YS, Sayuti M, Sarhan AA, Hamdi M, Manladan S, Reddy M (2019) Tribological performance of SiO2-based nanofluids in minimum quantity lubrication grinding of Si3N4 ceramic. J Manuf Process 41:135–147

Dambatta YS, Sarhan AA, Sayuti M, Hamdi M (2017) Ultrasonic assisted grinding of advanced materials for biomedical and aerospace applications—a review. Int J Adv Manuf Technol 92:3825–3858

Ding W, Zhang L, Li Z, Zhu Y, Su H, Xu J (2017) Review on grinding-induced residual stresses in metallic materials. Int J Adv Manuf Technol 88:2939–2968

Sanchez J, Pombo I, Alberdi R, Izquierdo B, Ortega N, Plaza S, Martinez-Toledano J (2010) Machining evaluation of a hybrid MQL-CO2 grinding technology. J Clean Prod 18(18):1840–1849

Wickramasinghe K, Sasahara H, Abd Rahim E, Perera G (2021) Recent advances on high performance machining of aerospace materials and composites using vegetable oil-based metal working fluids. J Clean Prod 310:127459

Zhang Y, Li C, Jia D, Zhang D, Zhang X (2015) Experimental evaluation of MoS2 nanoparticles in jet MQL grinding with different types of vegetable oil as base oil. J Clean Prod 87:930–940

Guo S, Li C, Zhang Y, Yang M, Jia D, Zhang X, Liu G, Li R, Bing Z, Ji H (2018) Analysis of volume ratio of castor/soybean oil mixture on minimum quantity lubrication grinding performance and microstructure evaluation by fractal dimension. Ind Crops Prod 111:494–505

Byers JP (2016) Metalworking fluids. Crc Press

Weinert K, Inasaki I, Sutherland JW, Wakabayashi T (2004) Dry machining and minimum quantity lubrication. CIRP Ann 53(2):511–537

Benedicto E, Carou D, Rubio E (2017) Technical, economic and environmental review of the lubrication/cooling systems used in machining processes. Proc Eng 184:99–116

Boubekri N, Shaikh V, Foster PR (2010) A technology enabler for green machining: minimum quantity lubrication (MQL). J Manuf Technol Manag 21(5):556–566

Xu X, Feng B, Huang S, Luan Z, Niu C, Lin J, Hu X (2019) Capillary penetration mechanism and machining characteristics of lubricant droplets in electrostatic minimum quantity lubrication (EMQL) grinding. J Manuf Process 45:571–578

Kalita P, Malshe AP, Kumar SA, Yoganath V, Gurumurthy T (2012) Study of specific energy and friction coefficient in minimum quantity lubrication grinding using oil-based nanolubricants. J Manuf Process 14(2):160–166

Rabiei F, Rahimi AR, Hadad MJ, Saberi A (2017) Experimental evaluation of coolant-lubricant properties of nanofluids in ultrasonic assistant MQL grinding. Int J Adv Manuf Technol 93:3935–3953

Tu HX, Jun G, Hien BT, Hung LX, Tung LA, Pi VN (2018) Determining optimum parameters of cutting fluid in external grinding of 9CrSi steel using Taguchi technique. SSRG Int J Mech Eng 5(6):1–5

Marksberry P, Jawahir I (2008) A comprehensive tool-wear/tool-life performance model in the evaluation of NDM (near dry machining) for sustainable manufacturing. Int J Mach Tools Manuf 48(7-8):878–886

Setti D, Ghosh S, Rao PV (2012) Application of nano cutting fluid under minimum quantity lubrication (MQL) technique to improve grinding of Ti–6Al–4V alloy. Int J Mech Mechatron Eng 6(10):2107–2111

Gupta MK, Sood P (2017) Machining comparison of aerospace materials considering minimum quantity cutting fluid: a clean and green approach. Proc Inst Mech Eng Part C: J Mech Eng Sci 231(8):1445–1464

Huang S, Lv T, Wang M, Xu X (2018) Effects of machining and oil mist parameters on electrostatic minimum quantity lubrication–EMQL turning process. Int J Precis Eng Manuf-Green Technol 5:317–326

Aoyama T (2002) Development of a mixture supply system for machining with minimal quantity lubrication. CIRP Ann 51(1):289–292

Brinksmeier E, Walter A, Janssen R, Diersen P (1999) Aspects of cooling lubrication reduction in machining advanced materials. Proc Inst Mech Eng Part B: J Eng Manuf 213(8):769–778

Klocke F, Eisenblätter G (1997) Dry cutting. Cirp Ann 46(2):519–526

Cui X, Li C, Yang M, Liu M, Gao T, Wang X, Said Z, Sharma S, Zhang Y (2023) Enhanced grindability and mechanism in the magnetic traction nanolubricant grinding of Ti-6Al-4 V. Tribol Int 186:108603

Sen B, Mia M, Krolczyk GM, Mandal UK, Mondal SP (2021) Eco-friendly cutting fluids in minimum quantity lubrication assisted machining: a review on the perception of sustainable manufacturing. Int J Precis Eng Manuf-Green Technol 8:249–280

Rao RV (2007) Cutting fluid selection for a given machining application. Decis Making Manuf Environ: Using Graph Theor Fuzzy Multiple Attribute Decis Making Methods:97–114

Sen B, Mia M, Krolczyk GM, Mandal UK, Mondal SP (2021) Eco-friendly cutting fluids in minimum quantity lubrication assisted machining: a review on the perception of sustainable manufacturing. Int J Precis Eng Manuf - Green Technol 8(1):249–280

Rabiei F, Rahimi A, Hadad M, Ashrafijou M (2015) Performance improvement of minimum quantity lubrication (MQL) technique in surface grinding by modeling and optimization. J Clean Prod 86:447–460

Silva LR, Corrêa EC, Brandao JR, de Avila RF (2020) Environmentally friendly manufacturing: behavior analysis of minimum quantity of lubricant-MQL in grinding process. J Clean Prod 256:103287

Barczak L, Batako A, Morgan M (2010) A study of plane surface grinding under minimum quantity lubrication (MQL) conditions. Int J Mach Tools Manuf 50(11):977–985

Rabiei F, Rahimi A, Hadad MJ (2017) Performance improvement of eco-friendly MQL technique by using hybrid nanofluid and ultrasonic-assisted grinding. Int J Adv Manuf Technol 93:1001–1015

Hadad M, Hadi M (2013) An investigation on surface grinding of hardened stainless steel S34700 and aluminum alloy AA6061 using minimum quantity of lubrication (MQL) technique. Int J Adv Manuf Technol 68(9-12):2145–2158

Kalita P (2013) Design and fundamental understanding of minimum quantity lubrication (MQL) assisted grinding using advanced nanolubricants. University of Arkansas

Hadad MJ, Tawakoli T, Sadeghi MH, Sadeghi B (2012) Temperature and energy partition in minimum quantity lubrication-MQL grinding process. Int J Mach Tools Manuf 54:10–17

Hegab H, Kishawy HA (2023) Heat transfer mechanisms of nano-cutting fluids: a comparative performance analysis model. Int J Adv Manuf Technol 124(5-6):1429–1435

Zhang JC, Li CH, Zhang YB, Yang M, Jia DZ, Liu GT, Hou YL, Li RZ, Zhang NQ, Wu QD, Cao HJ (2018) Experimental assessment of an environmentally friendly grinding process using nanofluid minimum quantity lubrication with cryogenic air. J Clean Prod 193:236–248

Mingzheng Liu CL, Yang M, Gao T, Wang X, Cui X, Zhang Y, Said Z, Sharma S (2023) Mechanism and enhanced grindability of cryogenic air combined with biolubricant grinding titanium alloy. Tribol Int 187:108704

Li B, Li C, Zhang Y, Wang Y, Yang M, Jia D, Zhang N, Wu Q, Ding W (2017) Numerical and experimental research on the grinding temperature of minimum quantity lubrication cooling of different workpiece materials using vegetable oil-based nanofluids. Int J Adv Manuf Technol 93(5-8):1971–1988

Shen B, Shih AJ, Tung SC (2008) Application of Nanofluids in Minimum Quantity Lubrication Grinding. Tribol Trans 51(6):730–737

Brinksmeier E, Heinzel C, Wittmann M (1999) Friction, cooling and lubrication in grinding. Cirp Annals 48(2):581–598

Saberi A, Rahimi A, Parsa H, Ashrafijou M, Rabiei F (2016) Improvement of surface grinding process performance of CK45 soft steel by minimum quantity lubrication (MQL) technique using compressed cold air jet from vortex tube. J Clean Prod 131:728–738

Cheng L (2009) Nanofluid heat transfer technologies. Recent Pat Eng 3(1):1–7

Dambatta YS, Sayuti M, Sarhan AA, Hamdi M (2018) Comparative study on the performance of the MQL nanolubricant and conventional flood lubrication techniques during grinding of Si 3 N 4 ceramic. Int J Adv Manuf Technol 96:3959–3976

Yang M, Li C, Luo L, Li R, Long Y (2021) Predictive model of convective heat transfer coefficient in bone micro-grinding using nanofluid aerosol cooling. Int Commun Heat Mass Transfer 125:105317

Dambatta YS, Sayuti M, Sarhan AA, Ab Shukor HB, Derahman NAB, Manladan SM (2019) Prediction of specific grinding forces and surface roughness in machining of AL6061-T6 alloy using ANFIS technique. Ind Lubr Tribol 71(2):309–317

Mao C, Zhang J, Huang Y, Zou H, Huang X, Zhou Z (2013) Investigation on the effect of nanofluid parameters on MQL grinding. Mater Manuf Process 28(4):436–442

Wang Y, Guan J, Wang J, Feng B, Xu X (2021) Electrical conductivity and wettability of nanofluids prepared by nanocomposite of MWCNTs and dialkyl pentasulfide. Curr Nanosci 17(1):151–161

Cho D-H, Kim J-S, Kwon S-H, Lee C, Lee Y-Z (2013) Evaluation of hexagonal boron nitride nano-sheets as a lubricant additive in water. Wear 302(1-2):981–986

Wang Y, Li C, Zhang Y, Yang M, Zhang X, Zhang N, Dai J (2017) Experimental evaluation on tribological performance of the wheel/workpiece interface in minimum quantity lubrication grinding with different concentrations of Al2O3 nanofluids. J Clean Prod 142:3571–3583

Setti D, Sinha MK, Ghosh S, Venkateswara Rao P (2015) Performance evaluation of Ti-6Al-4V grinding using chip formation and coefficient of friction under the influence of nanofluids. Int J Mach Tools Manuf 88:237–248

Li B, Li C, Zhang Y, Wang Y, Jia D, Yang M, Zhang N, Wu Q, Han Z, Sun K (2017) Heat transfer performance of MQL grinding with different nanofluids for Ni-based alloys using vegetable oil. J Clean Prod 154:1–11

Wang Y, Li C, Zhang Y, Li B, Yang M, Zhang X, Guo S, Liu G (2016) Experimental evaluation of the lubrication properties of the wheel/workpiece interface in MQL grinding with different nanofluids. Tribol Int 99:198–210

Lee PH, Nam JS, Li C, Lee SW (2012) An experimental study on micro-grinding process with nanofluid minimum quantity lubrication (MQL). Int J Precis Eng Manuf 13(3):331–338

Tawakoli T, Hadad MJ, Sadeghi MH, Daneshi A, Stöckert S, Rasifard A (2009) An experimental investigation of the effects of workpiece and grinding parameters on minimum quantity lubrication—MQL grinding. Int J Mach Tools Manuf 49(12-13):924–932

Cao Y, Yin J, Ding W, Xu J (2021) Alumina abrasive wheel wear in ultrasonic vibration-assisted creep-feed grinding of Inconel 718 nickel-based superalloy. J Mater Process Technol 297:117241

Cao Y, Zhu Y, Li HN, Wang C, Su H, Yin Z, Ding W (2020) Development and performance of a novel ultrasonic vibration plate sonotrode for grinding. J Manuf Process 57:174–186

Molaie MM, Akbari J, Movahhedy MR (2016) Ultrasonic assisted grinding process with minimum quantity lubrication using oil-based nanofluids. J Clean Prod 129:212–222

Jia D, Li C, Zhang Y, Yang M, Zhang X, Li R, Ji H (2019) Experimental evaluation of surface topographies of NMQL grinding ZrO2 ceramics combining multiangle ultrasonic vibration. Int J Adv Manuf Technol 100(1-4):457–473

Gao T, Zhang X, Li C, Zhang Y, Yang M, Jia D, Ji H, Zhao Y, Li R, Yao P, Zhu L (2020) Surface morphology evaluation of multi-angle 2D ultrasonic vibration integrated with nanofluid minimum quantity lubrication grinding. J Manuf Process 51:44–61

Essa F, Zhang Q, Huang X (2017) Investigation of the effects of mixtures of WS2 and ZnO solid lubricants on the sliding friction and wear of M50 steel against silicon nitride at elevated temperatures. Wear 374:128–141

Jiao D, Zheng S, Wang Y, Guan R, Cao B (2011) The tribology properties of alumina/silica composite nanoparticles as lubricant additives. Appl Surf Sci 257(13):5720–5725

Song W, Yan J, Ji H (2019) Fabrication of GNS/MoS2 composite with different morphology and its tribological performance as a lubricant additive. Appl Surf Sci 469:226–235

Zhang X, Li C, Zhang Y, Jia D, Li B, Wang Y, Yang M, Hou Y, Zhang X (2016) Performances of Al 2 O 3/SiC hybrid nanofluids in minimum-quantity lubrication grinding. Int J Adv Manuf Technol 86:3427–3441

Gupta MK, Khan AM, Song Q, Liu Z, Khalid QS, Jamil M, Kuntoğlu M, Usca ÜA, Sarıkaya M, Pimenov DY (2021) A review on conventional and advanced minimum quantity lubrication approaches on performance measures of grinding process. Int J Adv Manuf Technol 117:729–750

Li C, Wang S, Zhang Q, Jia D (2013) Evaluation of minimum quantity lubrication grinding with nano-particles and recent related patents. Recent Pat Nanotechnol 7(2):167–181

Adibi H, Hatami O, Rezaei SM (2023) Effects of minimum quantity lubrication (MQL) on grinding processes using eco-friendly nanofluids: a review. Adv Mater Process Technol 1–42. https://doi.org/10.1080/2374068X.2023.2198834

Wang X, Song Y, Li C, Zhang Y, Ali HM, Sharma S, Li R, Yang M, Gao T, Liu M (2023) Nanofluids application in machining: a comprehensive review. Int J Adv Manuf Technol 1–52. https://doi.org/10.1007/s00170-022-10767-2

Boswell B, Islam MN, Davies IJ, Ginting Y, Ong AK (2017) A review identifying the effectiveness of minimum quantity lubrication (MQL) during conventional machining. Int J Adv Manuf Technol 92:321–340

Osman KA, Ünver HÖ, Şeker U (2019) Application of minimum quantity lubrication techniques in machining process of titanium alloy for sustainability: a review. Int J Adv Manuf Technol 100:2311–2332

Wang Y, Li C, Zhang Y, Li B, Yang M, Zhang X, Guo S, Liu G, Zhai M (2017) Comparative evaluation of the lubricating properties of vegetable-oil-based nanofluids between frictional test and grinding experiment. J Manuf Process 26:94–104

Emami M, Sadeghi MH, Sarhan AAD, Hasani F (2014) Investigating the minimum quantity lubrication in grinding of Al2O3 engineering ceramic. J Clean Prod 66:632–643

Singh H, Sharma VS, Dogra M (2020) Exploration of graphene assisted vegetables oil based minimum quantity lubrication for surface grinding of TI-6AL-4V-ELI. Tribol Int 144

Li B, Li C, Zhang Y, Wang Y, Yang M, Jia D, Zhang N, Wu Q (2017) Effect of the physical properties of different vegetable oil-based nanofluids on MQLC grinding temperature of Ni-based alloy. Int J Adv Manuf Technol 89(9-12):3459–3474

Zhang Y, Li C, Jia D, Zhang D, Zhang X (2015) Experimental evaluation of the lubrication performance of MoS2/CNT nanofluid for minimal quantity lubrication in Ni-based alloy grinding. Int J Mach Tools Manuf 99:19–33

Alberts M, Kalaitzidou K, Melkote S (2009) An investigation of graphite nanoplatelets as lubricant in grinding. Int J Mach Tools Manuf 49(12-13):966–970

Shen B, Malshe AP, Kalita P, Shih AJ (2008) Performance of novel MoS2 nanoparticles based grinding fluids in minimum quantity lubrication grinding. Trans Namri/SME 36(357):357–364

Kalita P, Malshe AP, Rajurkar KP (2012) Study of tribo-chemical lubricant film formation during application of nanolubricants in minimum quantity lubrication (MQL) grinding. CIRP Ann 61(1):327–330

Mao C, Tang X, Zou H, Huang X, Zhou Z (2012) Investigation of grinding characteristic using nanofluid minimum quantity lubrication. Int J Precis Eng Manuf 13:1745–1752

Mao C, Zou H, Huang X, Zhang J, Zhou Z (2013) The influence of spraying parameters on grinding performance for nanofluid minimum quantity lubrication. Int J Adv Manuf Technol 64(9-12):1791–1799

Prabhu S, Vinayagam B (2010) Nano surface generation of grinding process using carbon nano tubes. Sadhana 35:747–760

Prabhu S, Vinayagam BK (2012) AFM investigation in grinding process with nanofluids using Taguchi analysis. Int J Adv Manuf Technol 60:149–160

Li M, Yu T, Zhang R, Yang L, Ma Z, Li B, Wang X, Wang W, Zhao J (2020) Experimental evaluation of an eco-friendly grinding process combining minimum quantity lubrication and graphene-enhanced plant-oil-based cutting fluid. J Clean Prod 244:118747

Sridharan U, Malkin S (2009) Effect of minimum quantity lubrication (MQL) with nanofluid on grinding behavior and thermal distortion. Trans NAMRI/SME 37:629–636

Vasu V, Kumar KM (2011) Analysis of nanofluids as cutting fluid in grinding EN-31 steel. Nano-Micro Lett 3:209–214

Zhang Y, Li C, Jia D, Li B, Wang Y, Yang M, Hou Y, Zhang X (2016) Experimental study on the effect of nanoparticle concentration on the lubricating property of nanofluids for MQL grinding of Ni-based alloy. J Mater Process Technol 232:100–115

Zhang Y, Li C, Yang M, Jia D, Wang Y, Li B, Hou Y, Zhang N, Wu Q (2016) Experimental evaluation of cooling performance by friction coefficient and specific friction energy in nanofluid minimum quantity lubrication grinding with different types of vegetable oil. J Clean Prod 139:685–705

Shao Y, Fergani O, Ding Z, Li B, Liang SY (2016) Experimental investigation of residual stress in minimum quantity lubrication grinding of AISI 1018 steel. J Manuf Sci Eng 138(1)

Tawakoli T, Hadad M, Sadeghi M (2010) Influence of oil mist parameters on minimum quantity lubrication–MQL grinding process. Int J Mach Tools Manuf 50(6):521–531

Tawakoli T, Hadad M, Sadeghi MH, Daneshi A, Sadeghi B (2011) Minimum quantity lubrication in grinding: effects of abrasive and coolant–lubricant types. J Clean Prod 19(17-18):2088–2099

Morgan M, Barczak L, Batako A (2012) Temperatures in fine grinding with minimum quantity lubrication (MQL). Int J Adv Manuf Technol 60:951–958

Sadeghi M, Haddad M, Tawakoli T, Emami M (2009) Minimal quantity lubrication-MQL in grinding of Ti–6Al–4V titanium alloy. Int J Adv Manuf Technol 44:487–500

Batako AD, Tsiakoumis V (2015) An experimental investigation into resonance dry grinding of hardened steel and nickel alloys with element of MQL. Int J Adv Manuf Technol 77:27–41

Balan A, Vijayaraghavan L, Krishnamurthy R (2013) Minimum quantity lubricated grinding of Inconel 751 alloy. Mater Manuf Process 28(4):430–435

De Oliveira D, Da Silva R, Gelamo R (2019) Influence of multilayer graphene platelet concentration dispersed in semi-synthetic oil on the grinding performance of Inconel 718 alloy under various machining conditions. Wear 426:1371–1383

de Paiva RL, de Souza Ruzzi R, de Oliveira LR, Bandarra Filho EP, Gonçalves Neto LM, Gelamo RV, da Silva RB (2020) Experimental study of the influence of graphene platelets on the performance of grinding of SAE 52100 steel. Int J Adv Manuf Technol 110:1–12

de Souza Ruzzi R, de Paiva RL, Gelamo RV, Machado AR, da Silva RB (2021) Study on grinding of Inconel 625 and 718 alloys with cutting fluid enriched with multilayer graphene platelets. Wear 476:203697

Jia D, Li C, Zhang D, Zhang Y, Zhang X (2014) Experimental verification of nanoparticle jet minimum quantity lubrication effectiveness in grinding. J Nanopart Res 16:1–15

ManojKumar K, Ghosh A (2015) Synthesis of MWCNT nanofluid and evaluation of its potential besides soluble oil as micro cooling-lubrication medium in SQL grinding. Int J Adv Manuf Technol 77:1955–1964

Sinha MK, Madarkar R, Ghosh S, Rao PV (2017) Application of eco-friendly nanofluids during grinding of Inconel 718 through small quantity lubrication. J Clean Prod 141:1359–1375

Singh H, Sharma VS, Singh S, Dogra M (2019) Nanofluids assisted environmental friendly lubricating strategies for the surface grinding of titanium alloy: Ti6Al4V-ELI. J Manufact Process 39:241–249

Gao T, Li C, Jia D, Zhang Y, Yang M, Wang X, Cao H, Li R, Ali HM, Xu X (2020) Surface morphology assessment of CFRP transverse grinding using CNT nanofluid minimum quantity lubrication. J Clean Prod 277:123328

Qu S, Gong Y, Yang Y, Wang W, Liang C, Han B (2020) An investigation of carbon nanofluid minimum quantity lubrication for grinding unidirectional carbon fibre-reinforced ceramic matrix composites. J Clean Prod 249:119353

Peng R, He X, Tong J, Tang X, Wu Y (2021) Application of a tailored eco-friendly nanofluid in pressurized internal-cooling grinding of Inconel 718. J Clean Prod 278:123498

Dambatta YS, Sarhan AAD, Sayuti MBAK, Shukor MHBA (2019) Fuzzy logic method to investigate grinding of alumina ceramic using minimum quantity lubrication. Int J Appl Ceram Technol 16(4):1668–1683

Azami A, Salahshournejad Z, Shakouri E, Sharifi AR, Saraeian P (2023) Influence of nano-minimum quantity lubrication with MoS2 and CuO nanoparticles on cutting forces and surface roughness during grinding of AISI D2 steel. J Manuf Process 87:209–220

Qu S, Yao P, Gong Y, Chu D, Yang Y, Li C, Wang Z, Zhang X, Hou Y (2022) Environmentally friendly grinding of C/SiCs using carbon nanofluid minimum quantity lubrication technology. J Clean Prod 366:132898

Pashmforoush F, Bagherinia RD (2018) Influence of water-based copper nanofluid on wheel loading and surface roughness during grinding of Inconel 738 superalloy. J Clean Prod 178:363–372

Lee PH, Nam TS, Li C, Lee SW (2010) Environmentally-friendly nano-fluid minimum quantity lubrication (MQL) meso-scale grinding process using nano-diamond particles. 2010 Proc Int Conf Manuf Autom, ICMA 2010

Manimaran G, Venkatasamy R (2014) Influence of cryogenic cooling on surface grinding of stainless steel 316. Cryogenics 59:76–83

Ghosh A (2021) On grinding force ratio, specific energy, G-ratio and residual stress in SQCL assisted grinding using aerosol of MWCNT nanofluid. Mach Sci Technol 25(4):585–607

Chakule RR, Chaudhari SS, Talmale PS (2020) Optimization of nanofluid minimum quantity lubrication (NanoMQL) technique for grinding performance using Jaya algorithm. In: Advances in Intelligent Systems and Computing, pp 211–221

da Silva LR, Bianchi EC, Fusse RY, Catai RE, Franca TV, Aguiar PR (2007) Analysis of surface integrity for minimum quantity lubricant—MQL in grinding. Int J Mach Tools Manuf 47(2):412–418

Etemadi Haghighi S, Shakouri E (2022) Evaluation the effect of adding CNT and CuO to the base fluid on the health and surface roughness of Inconel 718 MQL grinding. Modares Mech Eng 22(5):335–345

Guo S, Li C, Zhang Y, Wang Y, Li B, Yang M, Zhang X, Liu G (2017) Experimental evaluation of the lubrication performance of mixtures of castor oil with other vegetable oils in MQL grinding of nickel-based alloy. J Clean Prod 140:1060–1076

Javaroni RL, Lopes JC, Garcia MV, Ribeiro FSF, de Angelo Sanchez LE, de Mello HJ, Aguiar PR, Bianchi EC (2020) Grinding hardened steel using MQL associated with cleaning system and cBN wheel. Int J Adv Manuf Technol 107:2065–2080

Liu G, Li C, Zhang Y, Yang M, Jia D, Zhang X, Guo S, Li R, Zhai H (2018) Process parameter optimization and experimental evaluation for nanofluid MQL in grinding Ti-6Al-4V based on grey relational analysis. Mater Manuf Process 33(9):950–963

Lopes JC, Garcia MV, Volpato RS, de Mello HJ, Ribeiro FSF, de Angelo Sanchez LE, de Oliveira Rocha K, Neto LD, Aguiar PR, Bianchi EC (2020) Application of MQL technique using TiO2 nanoparticles compared to MQL simultaneous to the grinding wheel cleaning jet. Int J Adv Manuf Technol 106(5-6):2205–2218

Seyedzavvar M, Shabgard M, Mohammadpourfard M (2019) Investigation into the performance of eco-friendly graphite nanofluid as lubricant in MQL grinding. Mach Sci Technol 23(4)

Shabgard M, Seyedzavvar M, Mohammadpourfard M (2017) Experimental investigation into lubrication properties and mechanism of vegetable-based CuO nanofluid in MQL grinding. Int J Adv Manuf Technol 92:3807–3823

Said Z, Gupta M, Hegab H, Arora N, Khan AM, Jamil M, Bellos E (2019) A comprehensive review on minimum quantity lubrication (MQL) in machining processes using nano-cutting fluids. Int J Adv Manuf Technol 105(5-6):2057–2086

Emami M, Sadeghi MH, Sarhan A (2013) Minimum quantity lubrication in grinding process of zirconia (ZrO2) engineering ceramic. Int J Min Metall Mech Eng 1(3):1–4

Virdi RL, Chatha SS, Singh H (2022) Processing characteristics of different vegetable oil-based nanofluid MQL for grinding of Ni-Cr alloy. Adv Mater Process Technol 8(1):210–223

Dragičević M (2018) The application of alternative techniques for cooling, flushing and lubrication to improve efficiency of machining processes. Tehnički Vjesnik 25(5):1561–1568

Furness R, Stoll A, Nordstrom G, Martini G, Johnson J, Loch T and Klosinski R (2006) Minimum quantity lubrication (MQL) machining for complex powertrain components. in International Manufacturing Science and Engineering Conference

Daniel DM, Moraes DLD, Garcia MV, Lopes JC, Rodriguez RL, Ribeiro FSF, Sanchez LEDA, Bianchi EC (2023) Application of MQL with cooled air and wheel cleaning jet for greener grinding process. Int J Adv Manuf Technol 125(1-2):435–452

Dambatta YS, Sayuti M, Sarhan AAD, Hamdi M, Manladan SM, Reddy M (2019) Tribological performance of SiO 2 -based nanofluids in minimum quantity lubrication grinding of Si 3 N 4 ceramic. J Manuf Process 41:135–147

Emami M, Sadeghi M, Sarhan AA (2013) Investigating the effects of liquid atomization and delivery parameters of minimum quantity lubrication on the grinding process of Al2O3 engineering ceramics. J Manuf Process 15(3):374–388

Jia D, Li C, Zhang Y, Zhang D, Zhang X (2016) Experimental research on the influence of the jet parameters of minimum quantity lubrication on the lubricating property of Ni-based alloy grinding. Int J Adv Manuf Technol 82(1-4):617–630

Said Z, Gupta M, Hegab H, Arora N, Khan AM, Jamil M, Bellos E (2019) A comprehensive review on minimum quantity lubrication (MQL) in machining processes using nano-cutting fluids. Int J Adv Manuf Technol 105:2057–2086

Khan AM, Jamil M, Mia M, Pimenov DY, Gasiyarov VR, Gupta MK, He N (2018) Multi-objective optimization for grinding of AISI D2 steel with Al2O3 wheel under MQL. Materials 11(11):2269

Lee P-H, Nam JS, Li C, Lee SW (2012) An experimental study on micro-grinding process with nanofluid minimum quantity lubrication (MQL). Int J Precis Eng Manuf 13:331–338

Khan AM, Jamil M, Mia M, He N, Zhao W, Gong L (2020) Sustainability-based performance evaluation of hybrid nanofluid assisted machining: sustainability assessment of hybrid nanofluid assisted machining. J Clean Prod 257

Mao C, Zou H, Huang Y, Zhou Z (2014) Research on heat transfer mechanism in grinding zone for MQL surface grinding. China Mech Eng 25(6):826

Hafenbraedl D, Malkin S (2000) Environmentally-conscious minimum quantity lubrication (MQL) for internal cylindrical grinding. Transactions-North American Manufacturing Research Institution of SME 149–154

de Jesus Oliveira D, Guermandi LG, Bianchi EC, Diniz AE, de Aguiar PR, Canarim RC (2012) Improving minimum quantity lubrication in CBN grinding using compressed air wheel cleaning. J Mater Process Technol 212(12):2559–2568

Li K-M, Lin C-P (2012) Study on minimum quantity lubrication in micro-grinding. Int J Adv Manuf Technol 62:99–105

Lopes JC, Ventura CE, Rodriguez RL, Talon AG, Volpato RS, Sato BK, de Mello HJ, de Aguiar PR, Bianchi EC (2018) Application of minimum quantity lubrication with addition of water in the grinding of alumina. Int J Adv Manuf Technol 97:1951–1959

Rabiei F, Rahimi AR, Hadad MJ (2017) Performance improvement of eco-friendly MQL technique by using hybrid nanofluid and ultrasonic-assisted grinding. Int J Adv Manuf Technol 93(1-4):1001–1015

Iqbal A, Ning H, Khan I, Liang L, Dar NU (2008) Modeling the effects of cutting parameters in MQL-employed finish hard-milling process using D-optimal method. J Mater Process Technol 199(1-3):379–390

Marinescu, I.D., W.B. Rowe, B. Dimitrov, and H. Ohmori, Tribology of abrasive machining processes. 2012: William Andrew

Morshed A, Wu H, Jiang Z (2021) A comprehensive review of water-based nanolubricants. Lubricants 9(9):89

Wang Y, Li C, Zhang Y, Yang M, Li B, Jia D, Hou Y, Mao C (2016) Experimental evaluation of the lubrication properties of the wheel/workpiece interface in minimum quantity lubrication (MQL) grinding using different types of vegetable oils. J Clean Prod 127:487–499

Bai X, Jiang J, Li C, Dong L, Ali HM, Sharma S (2023) Tribological performance of different concentrations of Al2O3 nanofluids on minimum quantity lubrication milling. Chinese J Mech Eng 36(1):1–12

Lee P-H, Lee SW, Lim S-H, Lee S-H, Ko HS, Shin S-W (2015) A study on thermal characteristics of micro-scale grinding process using nanofluid minimum quantity lubrication (MQL). Int J Precis Eng Manuf 16:1899–1909

Paul S, Chattopadhyay A (1995) Effects of cryogenic cooling by liquid nitrogen jet on forces, temperature and surface residual stresses in grinding steels. Cryogenics 35(8):515–523

Busch K, Hochmuth C, Pause B, Stoll A, Wertheim R (2016) Investigation of cooling and lubrication strategies for machining high-temperature alloys. Proc CIRP 41:835–840

Sartori S, Ghiotti A, Bruschi S (2017) Hybrid lubricating/cooling strategies to reduce the tool wear in finishing turning of difficult-to-cut alloys. Wear 376:107–114

Pusavec F, Deshpande A, Yang S, M'Saoubi R, Kopac J, Dillon OW Jr, Jawahir I (2014) Sustainable machining of high temperature Nickel alloy–Inconel 718: part 1–predictive performance models. J Clean Prod 81:255–269

Pusavec F, Deshpande A, Yang S, M'Saoubi R, Kopac J, Dillon OW Jr, Jawahir I (2015) Sustainable machining of high temperature Nickel alloy–Inconel 718: part 2–chip breakability and optimization. J Clean Prod 87:941–952

Zhang J, Li C, Zhang Y, Yang M, Jia D, Hou Y, Li R (2018) Temperature field model and experimental verification on cryogenic air nanofluid minimum quantity lubrication grinding. Int J Adv Manufact Technol 97(1-4):209–228

Jia D, Li C, Liu J, Zhang Y, Yang M, Gao T, Said Z, Sharma S (2023) Prediction model of volume average diameter and analysis of atomization characteristics in electrostatic atomization minimum quantity lubrication. Friction 1–25. https://doi.org/10.1007/s40544-022-0734-2

Lv T, Xu X, Yu A, Hu X (2021) Oil mist concentration and machining characteristics of SiO2 water-based nano-lubricants in electrostatic minimum quantity lubrication-EMQL milling. J Mater Process Technol 290:116964

Wickramasinghe K, Sasahara H, Abd Rahim E, Perera G (2020) Green metalworking fluids for sustainable machining applications: a review. J Clean Prod 257:120552

Mannekote JK, Kailas SV (2012) The effect of oxidation on the tribological performance of few vegetable oils. J Mater Res Technol 1(2):91–95

Erhan SZ, Sharma BK, Perez JM (2006) Oxidation and low temperature stability of vegetable oil-based lubricants. Ind Crops Prod 24(3):292–299

Talib N, Jamaluddin NA, Sheng TK, Kiow LW, Abdullah H, Ahmad S, Saleh A (2021) Tribological study of activated carbon nanoparticle in nonedible nanofluid for machining application. Evergreen 8(2):454–460

Soltani R, Dincer I, Rosen MA (2015) Thermodynamic analysis and performance assessment of an integrated heat pump system for district heating applications. Appl Ther Eng 89:833–842

Brunner G (1998) Grinding with microcrystalline alumina, Dr. University of Hannover, Germany, Eng Dissertation

ManojKumar K, Ghosh A (2015) Synthesis of MWCNT nanofluid and evaluation of its potential besides soluble oil as micro cooling-lubrication medium in SQL grinding. Int J Adv Manuf Technol 77(9-12):1955–1964

Siniawski MT, Saniei N, Adhikari B, Doezema LA (2007) Influence of fatty acid composition on the tribological performance of two vegetable-based lubricants. J Synth Lubr 24(2):101–110

Kalita P, Malshe AP, Jiang W, Shih AJ (2010) Tribological study of nano lubricant integrated soybean oil for minimum quantity lubrication (MQL) grinding. Trans NAMRI/SME 38(313):137–144

Dupain X, Costa DJ, Schaverien CJ, Makkee M, Moulijn JA (2007) Cracking of a rapeseed vegetable oil under realistic FCC conditions. Appl Catal B: Environ 72(1-2):44–61

Lawal SA (2013) A review of application of vegetable oil-based cutting fluids in machining non-ferrous metals. Indian J Sci Technol 6(1)

Gu Y, Zhao X, Liu Y, Lv Y (2014) Preparation and tribological properties of dual-coated TiO2 nanoparticles as water-based lubricant additives. J Nanomater 2014:2–2

Rahman M, Kadirgama K (2014) Performance of water-based zinc oxide nanoparticle coolant during abrasive grinding of ductile cast iron. J Nanopart 2014:7. https://doi.org/10.1155/2014/175896

Huang S, Li X, Yu B, Jiang Z, Huang H (2020) Machining characteristics and mechanism of GO/SiO2 nanoslurries in fixed abrasive lapping. J Mater Process Technol 277:116444

Huang S, He A, Yun J-H, Xu X, Jiang Z, Jiao S, Huang H (2019) Synergistic tribological performance of a water based lubricant using graphene oxide and alumina hybrid nanoparticles as additives. Tribol Int 135:170–180

Wu H, Zhao J, Xia W, Cheng X, He A, Yun JH, Wang L, Huang H, Jiao S, Huang L (2017) Analysis of TiO2 nano-additive water-based lubricants in hot rolling of microalloyed steel. J Manufact Process 27:26–36

Esfe MH, Bahiraei M, Mir A (2020) Application of conventional and hybrid nanofluids in different machining processes: a critical review. Adv Colloid Interface Sci 282:102199

Choi SU, Eastman JA (1995) Enhancing thermal conductivity of fluids with nanoparticles. In: Argonne National Lab.(ANL). Argonne, IL (United States)

Choi S, Singer D, Wang H (1995) Developments and applications of non-Newtonian flows. Asme Fed 66:99–105

Kamyar A, Saidur R, Hasanuzzaman M (2012) Application of computational fluid dynamics (CFD) for nanofluids. Int J Heat Mass Transf 55(15-16):4104–4115

Das SK, Choi SU, Patel HE (2006) Heat transfer in nanofluids—a review. Heat Transf Eng 27(10):3–19

Hemmat Esfe M, Esfandeh S (2019) Rheological behavior of CuO/EG: W (20: 80 v/v) nanofluid from a thermal perspective: experimental study, development of new correlation, and sensitivity analysis. J Therm Anal Calorim 135:61–72

Urmi WT, Rahman M, Kadirgama K, Ramasamy D, Maleque M (2021) An overview on synthesis, stability, opportunities and challenges of nanofluids. Mater Today: Proc 41:30–37

Sundar LS, Hortiguela MJ, Singh MK, Sousa AC (2016) Thermal conductivity and viscosity of water based nanodiamond (ND) nanofluids: an experimental study. Int Commun Heat Mass Transf 76:245–255

Urmi WT, Rahman MM, Kadirgama K, Ramasamy D, Maleque MA (2020) An overview on synthesis, stability, opportunities and challenges of nanofluids. Mater Today: Proc 41:30–37

Khandekar S, Sankar MR, Agnihotri V, Ramkumar J (2012) Nano-cutting fluid for enhancement of metal cutting performance. Mater Manuf Process 27(9):963–967

Tadros T (2012) Electrostatic and steric stabilization of colloidal dispersions. Electric Phenomena Interface Biointerfaces. John Wiley & Sons, Inc, pp 153–172. https://doi.org/10.1002/9781118135440

Lahouij I, Vacher B, Martin J-M, Dassenoy F (2012) IF-MoS2 based lubricants: influence of size, shape and crystal structure. Wear 296(1-2):558–567

Yu W, Xie H (2012) A review on nanofluids: preparation, stability mechanisms, and applications. J Nanomater 2012:1–17

Hosseini SF, Emami M, Sadeghi MH (2018) An experimental investigation on the effects of minimum quantity nano lubricant application in grinding process of Tungsten carbide. J Manuf Process 35:244–253

Gao T, Li C, Yang M, Zhang Y, Jia D, Ding W, Debnath S, Yu T, Said Z, Wang J (2021) Mechanics analysis and predictive force models for the single-diamond grain grinding of carbon fiber reinforced polymers using CNT nano-lubricant. J Mater Process Technol 290:116976

Mao C, Tang X, Zou H, Huang X, Zhou Z (2012) Investigation of grinding characteristic using nanofluid minimum quantity lubrication. Int J Precis Eng Manuf 13(10):1745–1752

Zhang Y, Li C, Ji H, Yang X, Yang M, Jia D, Zhang X, Li R, Wang J (2017) Analysis of grinding mechanics and improved predictive force model based on material-removal and plastic-stacking mechanisms. Int J Mach Tools Manuf 122:81–97

Yang M, Li C, Luo L, Li R, Long Y (2021) Predictive model of convective heat transfer coefficient in bone micro-grinding using nanofluid aerosol cooling. Int Commun Heat Mass Transf 125

Jia D, Li C, Zhang Y, Yang M, Wang Y, Guo S, Cao H (2017) Specific energy and surface roughness of minimum quantity lubrication grinding Ni-based alloy with mixed vegetable oil-based nanofluids. Precis Eng 50:248–262

Kumar A, Ghosh S, Aravindan S (2017) Grinding performance improvement of silicon nitride ceramics by utilizing nanofluids. Ceramics Int 43(16):13411–13421

Cui X, Li C, Zhang Y, Jia D, Zhao Y, Li R, Cao H (2019) Tribological properties under the grinding wheel and workpiece interface by using graphene nanofluid lubricant. Int J Adv Manuf Technol 104:3943–3958

Karimipour A, Bagherzadeh SA, Goodarzi M, Alnaqi AA, Bahiraei M, Safaei MR, Shadloo MS (2018) Synthesized CuFe2O4/SiO2 nanocomposites added to water/EG: evaluation of the thermophysical properties beside sensitivity analysis & EANN. Int J Heat Mass Transf 127:1169–1179

Vishnu AV, Akhil J, Akhil A, Raju B, Praveen C, Pavan A (2017) Experimental investigation on effect of machining parameters of EN353 alloy steel using nano fluids. Int J Adv Res Innov Ideas Educ 2(2):20–27

Sidik NAC, Jamil MM, Japar WMAA, Adamu IM (2017) A review on preparation methods, stability and applications of hybrid nanofluids. Renew Sustain Energy Rev 80:1112–1122

Sajid MU, Ali HM (2018) Thermal conductivity of hybrid nanofluids: a critical review. Int J Heat Mass Transf 126:211–234

Kumar A, Ghosh S, Aravindan S (2019) Experimental investigations on surface grinding of silicon nitride subjected to mono and hybrid nanofluids. Ceram Int 45(14):17447–17466

Hamid K, Azmi W, Nabil M, Mamat R (2017) Improved thermal conductivity of TiO2–SiO2 hybrid nanofluid in ethylene glycol and water mixture. in IOP Conference series: materials science and engineering. IOP Publishing

Kursus M, Liew PJ, Che Sidik NA, Wang J (2022) Recent progress on the application of nanofluids and hybrid nanofluids in machining: a comprehensive review. Int J Adv Manuf Technol 121(3-4):1455–1481

Zhang X, Li C, Zhang Y, Wang Y, Li B, Yang M, Guo S, Liu G, Zhang N (2017) Lubricating property of MQL grinding of Al2O3/SiC mixed nanofluid with different particle sizes and microtopography analysis by cross-correlation. Precis Eng 47:532–545

Kumar DD, Arasu AV (2018) A comprehensive review of preparation, characterization, properties and stability of hybrid nanofluids. Renew Sustain Energy Rev 81:1669–1689

Lv T, Huang S, Hu X, Ma Y, Xu X (2018) Tribological and machining characteristics of a minimum quantity lubrication (MQL) technology using GO/SiO 2 hybrid nanoparticle water-based lubricants as cutting fluids. Int J Adv Manuf Technol 96:2931–2942

Ali ARI, Salam B (2020) A review on nanofluid: preparation, stability, thermophysical properties, heat transfer characteristics and application. SN Appl Sci 2(10):1636

Babu JR, Kumar KK, Rao SS (2017) State-of-art review on hybrid nanofluids. Renew Sustain Energy Rev 77:551–565

Botha SS, Ndungu P, Bladergroen BJ (2011) Physicochemical properties of oil-based nanofluids containing hybrid structures of silver nanoparticles supported on silica. Ind Eng Chem Res 50(6):3071–3077

Junankar AA, Purohit JK, Bhende NV (2022) A review on hybrid nanofluid: current research and sustainable development for turning operation. Int J Environ Sustain Dev 21(1-2):97–115

Wei B, Zou C, Yuan X, Li X (2017) Thermo-physical property evaluation of diathermic oil based hybrid nanofluids for heat transfer applications. Int J Heat Mass Transf 107:281–287

Qing SH, Rashmi W, Khalid M, Gupta T, Nabipoor M, Hajibeigy MT (2017) Thermal conductivity and electrical properties of hybrid SiO2-graphene naphthenic mineral oil nanofluid as potential transformer oil. Mater Res Express 4(1):015504

Bakthavatchalam B, Habib K, Saidur R, Saha BB, Irshad K (2020) Comprehensive study on nanofluid and ionanofluid for heat transfer enhancement: a review on current and future perspective. J Mol Liq 305:112787

Devendiran DK, Amirtham VA (2016) A review on preparation, characterization, properties and applications of nanofluids. Renew Sustain Energy Rev 60:21–40

Rakshit R, Das AK (2019) A review on cutting of industrial ceramic materials. Precis Eng 59:90–109

Chakule RR, Chaudhari SS, Chandratre KV, Patole PB, Talmale PS (2023) Nanofluids, micro-lubrications and machining process optimisations -a review. Manuf Rev 10

Shamray S, Azarhoushang B, Paknejad M, Buechler A (2022) Ductile-brittle transition mechanisms in micro-grinding of silicon nitride. Ceram Int 48(23):34987–34998

Ngoi BKA, Sreejith PS (2000) Ductile regime finish machining - a review. Int J Adv Manuf Technol 16(8):547–550

Bifano, T.G., T.A. Dow, and R.O. Scattergood, Ductile-regime grinding: a new technology for machining brittle materials. 1991

Lee P-H, Nam TS, Li C, Lee SW (2010) Environmentally-friendly nano-fluid minimum quantity lubrication (MQL) meso-scale grinding process using nano-diamond particles. In: 2010 international conference on manufacturing automation. IEEE

Sui M, Li C, Wu W, Yang M, Ali HM, Zhang Y, Jia D, Hou Y, Li R, Cao H (2021) Temperature of grinding carbide with castor oil-based MoS2 nanofluid minimum quantity lubrication. J Therm Sci Eng Appl 13(5)

Cao Y, Ding W, Zhao B, Wen X, Li S, Wang J (2022) Effect of intermittent cutting behavior on the ultrasonic vibration-assisted grinding performance of Inconel718 nickel-based superalloy. Precis Eng 78:248–260

Liu M, Li C, Zhang Y, Yang M, Gao T, Cui X, Wang X, Li H, Said Z, Li R (2023) Analysis of grain tribology and improved grinding temperature model based on discrete heat source. Tribol Int 180:108196

Dai W, Kheireddin B, Gao H, Liang H (2016) Roles of nanoparticles in oil lubrication. Tribol Int 102:88–98

Yang M, Li C, Said Z, Zhang Y, Li R, Debnath S, Ali HM, Gao T, Long Y (2021) Semiempirical heat flux model of hard-brittle bone material in ductile microgrinding. J Manuf Process 71:501–514

Cui X, Li C, Zhang Y, Jia D, Zhao Y, Li R, Cao H (2019) Tribological properties under the grinding wheel and workpiece interface by using graphene nanofluid lubricant. Int J Adv Manuf Technol 104(9-12):3943–3958

Zhou ZY, Di QQ, Liu B, Ma XY, Cai BH (2016) Experimental study on the surface tension of Al2O3-H2O nanofluid. In: Materials Science Forum. Trans Tech Publ

Fan J, Wang L (2011) Review of heat conduction in nanofluids. J Heat Transf 133(4)

Li B, Li C, Zhang Y, Wang Y, Yang M, Jia D, Zhang N, Wu Q (2017) Effect of the physical properties of different vegetable oil-based nanofluids on MQLC grinding temperature of Ni-based alloy. Int J Adv Manuf Technol 89:3459–3474

Virdi RL, Chatha SS, Singh H (2020) Performance evaluation of Inconel 718 under vegetable oils based nanofluids using minimum quantity lubrication grinding. Mater Today: Proc 33:1538–1545

Mao C, Huang Y, Zhou X, Gan H, Zhang J, Zhou Z (2014) The tribological properties of nanofluid used in minimum quantity lubrication grinding. Int J Adv Manuf Technol 71(5-8):1221–1228

Yang M, Li C, Zhang Y, Jia D, Li R, Hou Y, Cao H (2019) Effect of friction coefficient on chip thickness models in ductile-regime grinding of zirconia ceramics. Int J Adv Manuf Technol 102:2617–2632

Wu W, Li C, Yang M, Zhang Y, Jia D, Hou Y, Li R, Cao H, Han Z (2019) Specific energy and G ratio of grinding cemented carbide under different cooling and lubrication conditions. Int J Adv Manuf Technol 105:67–82

Zhang Z, Sui M, Li C, Zhou Z, Liu B, Chen Y, Said Z, Debnath S, Sharma S (2022) Residual stress of grinding cemented carbide using MoS2 nano-lubricant. Int J Adv Manuf Technol 119(9-10):5671–5685

Kogovšek J, Kalin M (2014) Various MoS 2-, WS 2-and C-based micro-and nanoparticles in boundary lubrication. Tribol Lett 53:585–597

Marinescu ID, Hitchiner MP, Uhlmann E, Rowe WB, Inasaki I (2006) Handbook of machining with grinding wheels. Crc Press

Mingzheng L, Changhe L, ZHANG Y, Min Y, Teng G, Xin C, Xiaoming W, Wenhao X, Zongming Z, Bo L (2022) Analysis of grinding mechanics and improved grinding force model based on randomized grain geometric characteristics. Chinese J Aeronaut. https://doi.org/10.1016/j.cja.2022.11.005

Hu M, Gao X, Wang P, Fu Y, Sun J, Weng L, Jiang D, Wang D (2019) Amorphous carbon films in situ formed from PTFE transfer layer in solid lubricated cryogenic turbopump bearings. Tribol Trans 62(4):603–613

Kalita P (2009) Testing of nano-engineered lubricants for minimum quantity lubrication (MQL) grinding: performance testing and fundamental understanding. University of Arkansas

Javaroni R, Lopes J, Sato B, Sanchez L, Mello H, Aguiar P, Bianchi E (2019) Minimum quantity of lubrication (MQL) as an eco-friendly alternative to the cutting fluids in advanced ceramics grinding. Int J Adv Manuf Technol 103:2809–2819

Adibi H, Esmaeili H, Rezaei S (2018) Study on minimum quantity lubrication (MQL) in grinding of carbon fiber-reinforced SiC matrix composites (CMCs). Int J Adv Manuf Technol 95:3753–3767

Virdi RL, Chatha SS, Singh H (2021) Experimental investigations on the tribological and lubrication behaviour of minimum quantity lubrication technique in grinding of Inconel 718 alloy. Tribol Int 153:106581

Virdi RL, Chatha SS, Singh H (2020) Machining performance of Inconel-718 alloy under the influence of nanoparticles based minimum quantity lubrication grinding. J Manuf Process 59:355–365

Rodriguez RL, Lopes JC, Mancini SD, de Ângelo Sanchez LE, de Almeida Varasquim FMF, Volpato RS, de Mello HJ, de Aguiar PR, Bianchi EC (2019) Contribution for minimization the usage of cutting fluids in CFRP grinding. Int J Adv Manuf Technol 103:487–497

Hong SY (2005) Investigation of liquid nitrogen lubrication effect in cryogenic machining. World Tribology Congress

Reddy PP, Ghosh A (2016) Some critical issues in cryo-grinding by a vitrified bonded alumina wheel using liquid nitrogen jet. J Mater Process Technol 229:329–337

Reddy PP, Ghosh A (2014) Effect of cryogenic cooling on spindle power and G-ratio in grinding of hardened bearing steel. Proc Mater Sci 5:2622–2628

de Moraes DL, Lopes JC, Andrioli BV, Moretti GB, da Silva AE, da Silva JMM, Ribeiro FSF, de Aguiar PR, Bianchi EC (2021) Advances in precision manufacturing towards eco-friendly grinding process by applying MQL with cold air compared with cooled wheel cleaning jet. Int J Adv Manuf Technol 113:3329–3342

Alonso U, Ortega N, Sanchez J, Pombo I, Izquierdo B, Plaza S (2015) Hardness control of grind-hardening and finishing grinding by means of area-based specific energy. Int J Mach Tools Manuf 88:24–33

Yang M, Li C, Zhang Y, Jia D, Li R, Hou Y, Cao H, Wang J (2019) Predictive model for minimum chip thickness and size effect in single diamond grain grinding of zirconia ceramics under different lubricating conditions. Ceram Int 45(12):14908–14920

Zhang D, Li C, Jia D, Zhang Y, Zhang X (2015) Specific grinding energy and surface roughness of nanoparticle jet minimum quantity lubrication in grinding. Chinese J Aeronaut 28(2):570–581

Wu W, Li C, Yang M, Zhang Y, Jia D, Hou Y, Li R, Cao H, Han Z (2019) Specific energy and G ratio of grinding cemented carbide under different cooling and lubrication conditions. Int J Adv Manuf Technol 105(1-4):67–82

Ibrahim AMM, Li W, Xiao H, Zeng Z, Ren Y, Alsoufi MS (2020) Energy conservation and environmental sustainability during grinding operation of Ti–6Al–4V alloys via eco-friendly oil/graphene nano additive and Minimum quantity lubrication. Tribol Int 150:106387

Huang X, Ren Y, Wu W, Li T (2019) Research on grind-hardening layer and residual stresses based on variable grinding forces. Int J Adv Manuf Technol 103:1045–1055

Shao Y, Fergani O, Li B, Liang SY (2016) Residual stress modeling in minimum quantity lubrication grinding. Int J Adv Manuf Technol 83:743–751

Sun C, Hong Y, Xiu S, Zhang P (2021) Investigation on the influence of dynamic characteristic on grinding residual stress. Int J Adv Manuf Technol 115(5-6):1853–1875

Zhang Z, Sui M, Li C, Zhou Z, Liu B, Chen Y, Said Z, Debnath S, Sharma S (2021) Residual stress of MoS2 nano-lubricant grinding cemented carbide. Int J Adv Manuf Technol 1:1–15

Miao Q, Ding W, Xu J, Cao L, Wang H, Yin Z, Dai C, Kuang W (2021) Creep feed grinding induced gradient microstructures in the superficial layer of turbine blade root of single crystal nickel-based superalloy. Int J Extreme Manuf 3(4):045102

Zhang Y, Yang X, Yuan S, Zhu J, Wang D (2021) Residual stress of high speed cylindrical grinding of 18CrNiMo7-6 steel. China Mech Eng 32(5):540

Wang R, Zhou K, Yang J, Ding H, Wang W, Guo J, Liu Q (2020) Effects of abrasive material and hardness of grinding wheel on rail grinding behaviors. Wear 454:203332

Ding Z, Sun J, Guo W, Jiang X, Wu C, Liang SY (2021) Thermal analysis of 3J33 grinding under minimum quantity lubrication condition. Int J Precis Eng Manuf-Green Technol 9:1247–1265

da Silva LR, da Silva DA, dos Santos FV, Duarte FJ (2019) Study of 3D parameters and residual stress in grinding of AISI 4340 steel hardened using different cutting fluids. Int J Adv Manuf Technol 100(1-4):895–905

Choi Y (2009) A comparative study of residual stress distribution induced by hard machining versus grinding. Tribol Lett 36:277–284

Hamdi H, Zahouani H, Bergheau J-M (2004) Residual stresses computation in a grinding process. J Mater Process Technol 147(3):277–285

Songyong L, Gang Y, Jiaqiang Z, Xiaohui L (2015) Numerical and experimental studies on grind-hardening cylindrical surface. Int J Adv Manuf Technol 76:487–499

Thampi AD, Prasanth M, Anandu A, Sneha E, Sasidharan B, Rani S (2021) The effect of nanoparticle additives on the tribological properties of various lubricating oils–review. Mater Today: Proc 47:4919–4924

Xiong S, Zhang B, Luo S, Wu H, Zhang Z (2021) Preparation, characterization, and tribological properties of silica-nanoparticle-reinforced BN-co-doped reduced graphene oxide as a multifunctional additive for enhanced lubrication. Friction 9:239–249

Sui M, Zhang N, Li C, Wu W, Zhang Y, Yang M (2020) Theoretical analysis and experiment on temperature field of nanofluid micro-lubrication grinding cemented carbide. Manuf Technol Mach Tool 693(3):81–87

Stachurski W, Krupanek K, Januszewicz B, Rosik R, Wojcik R (2018) An effect of grinding on microhardness and residual stress in 20MnCr5 following single-piece flow low-pressure carburizing. J Mach Eng 18

Soori M, Arezoo B (2022) Minimization of surface roughness and residual stress in grinding operations of Inconel 718. J Mater Eng Perform 1–10. https://doi.org/10.1007/s11665-022-07721-4

Silva L, Bianchi E, Catai R, Fusse R, França T, Aguiar P (2005) Study on the behavior of the minimum quantity lubricant-MQL technique under different lubricating and cooling conditions when grinding ABNT 4340 steel. J Braz Soc Mech Sci Eng 27:192–199

Ali ARI, Salam B (2020) A review on nanofluid: preparation, stability, thermophysical properties, heat transfer characteristics and application. SN Appl Sci 2(10)

Funding

The study was financially supported by the National Key Research and Development Program, China (2020YFB2010500), the National Natural Science Foundation of China (52105457 and 51975305), the Special Fund of Taishan Scholars Project (tsqn202211179), the Youth Talent Promotion Project in Shandong (SDAST2021qt12), and the Natural Science Foundation of Shandong Province, China (ZR2023QE057, ZR2022QE028, ZR2020KE027, and ZR2021QE116).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dambatta, Y., Li, C., Yang, M. et al. Grinding with minimum quantity lubrication: a comparative assessment. Int J Adv Manuf Technol 128, 955–1014 (2023). https://doi.org/10.1007/s00170-023-11962-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11962-5