Abstract

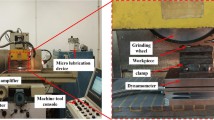

In nanofluid minimum quantity lubrication (NMQL) grinding of titanium (Ti) alloy, existing nanoparticles cannot solve the technical bottleneck of high surface integrity. Therefore, graphene (GR) nanoparticles, which have excellent lubrication performance, were applied in NMQL. The tribological properties of GR nanofluid on wheel–workpiece interface were studied by friction and wear test. In the experiment, 0.5–3 nm thick GR nanoparticles were used to prepare 3% vol. palm oil-based nanofluid. Ball-disc experiment under grinding conditions was carried out on the friction and wear tester. Grinding balls with SiC abrasive grains (to simulate the grinding wheel) and Ti-6Al-4V disc (to simulate the workpiece) were used. Load force was set for simulation of pressure boundary condition of the grinding wheel–workpiece interface. Stratiform nanoparticles (MoS2, MoO3, and HBN) were used as the comparison group. Results demonstrated that GR nanofluid achieved smaller friction coefficient (0.295), error bars (0.0029), and area of scratches (182,940 μm2). GR nanoparticles with small gravity and large specific surface area improved the viscosity of nanofluid and consequently the lubrication performance. The plane hexagonal honeycomb structure determines the strong lubrication stability and abrasive resistance of the GR nanoparticles. The scanning electron microscope (SEM) and energy dispersive spectrometer (EDS) images of the scratch surface also verified the above conclusions.

Similar content being viewed by others

Abbreviations

- NMQL:

-

Nanofluid minimum quantity lubrication

- GR:

-

Graphene

- HBN:

-

Hexagonal boron nitride

- SEM:

-

Scanning electron microscope

- EDS:

-

Energy dispersive spectrometer

- CNT:

-

Carbon nanotube

- APE-10:

-

Alkylphenol polyoxyethylene ether-10

- F r :

-

Force ratio

- μ :

-

Friction coefficient

- F n :

-

Normal force

- F n ’ :

-

Specific normal force

- F t :

-

Tangential force

- F mr :

-

Force of material removal

- F md :

-

Force of material deformation

- T R-F :

-

Critical time

- F L :

-

Load force

- G(z):

-

Matrix of protrusion height of grains

- G(d):

-

Matrix of grain size

- G(zg):

-

Matrix of axial position of generated grains

- λ :

-

Distance between two abrasive grains

- a gmax( n) :

-

Maximum undeformed chip thickness

- λ ( n~ n−1) :

-

Distance between the dynamic effective abrasive grain n and n − 1

- a p( n) :

-

Extruding height of the dynamic effective abrasive grain n

- a p( n−1) :

-

Extruding height the dynamic effective abrasive grain n − 1

- V s :

-

Peripheral speed of grinding wheel

- V w :

-

Feed speed

- F s :

-

Average normal action force of single abrasive grain

- b :

-

Grinding width

References

Hadad M, Sadeghi B (2012) Thermal analysis of minimum quantity lubrication-MQL grinding process. Int J Mach Tools Manuf 63:1–15

Shabgard M, Seyedzavvar M, Mohammadpourfard M (2017) Experimental investigation into lubrication properties and mechanism of vegetable-based CuO nanofluid in MQL grinding. Int J Adv Manuf Technol 92:3807–3823

Rabiei F, Rahimi AR, Hadad MJ (2017) Performance improvement of eco-friendly MQL technique by using hybrid nanofluid and ultrasonic-assisted grinding. Int J Adv Manuf Technol 93:1–15

Madarkar R, Agarwal S, Attar P, Ghosh S, Rao PV (2017) Application of ultrasonic vibration assisted MQL in grinding of Ti–6Al–4V. Mater Manuf Process 33:1–8

Setti D, Sinha MK, Ghosh S, Rao, PV (2015) Performance evaluation of Ti–6Al–4V grinding using chip formation and coefficient of friction under the influence of nanofluids. Int J Mach Tools Manuf 88:237–248

Deng ZH, Liu W, Wan LL, Tang H (2014) Experiment research progresses of single abrasive grain grinding. Key Eng Mater 589–590:470–474

Soepangkat BOP, Agustin HCK, Subiyanto H (2017) An investigation of force, surface roughness and chip in surface grinding of SKD 11 tool steel using minimum quantity lubrication-MQL technique. International Conference on Green Process

Wang YG, Li CH, Zhang YB, Yang M, Zhang XP, Zhang NQ, Dai JJ (2017) Experimental evaluation on tribological performance of the wheel/workpiece interface in minimum quantity lubrication grinding with different concentrations of Al2O3 nanofluids. J Clean Prod 142:3571–3583

Mia M, Gupta MK, Singh G, Krolczyk G, Pimenov DY (2018) An approach to cleaner production for machining hardened steel using different cooling-lubrication conditions. J Clean Prod 187:1069–1081

Mao C, Zhou X, Yin LR, Zhang MJ, Tang K, Zhang J (2016) Investigation of the flow field for a double-outlet nozzle during minimum quantity lubrication grinding. Int J Adv Manuf Technol 85:291–298

Yang M, Li CH,Zhang YB, Jia DZ, Zhang XP, Hou YL, Li RZ, Wang J (2017) Maximum undeformed equivalent chip thickness for ductile-brittle transition of zirconia ceramics under different lubrication conditions. Int J Mach Tools Manuf 122:55–65

Zhu LD, Yang ZC, Li ZB (2018) Investigation of mechanics and machinability of titanium alloy thin-walled parts by CBN grinding head. Int J Adv Manuf Techno 1–19

Li BK, Li CH, Zhang YB, Wang YG, Jia DZ, Yang M, Zhang NQ, Wu QD, Han ZG, Sun K (2017) Heat transfer performance of MQL grinding with different nanofluids for Ni-based alloys using vegetable oil. J Clean Prod 154:1–11

Jiang LL, Wang DZ (2019) Finite-element-analysis of the effect of different wiper tool edge geometries during the hard turning of AISI 4340 steel. Simul Model Pract Theory 94:250–263

Wang YG, Li CH, Zhang YB, Yang M, Li BK, Dong L, Wang J (2018) Processing characteristics of vegetable oil-based nanofluid MQL for grinding different workpiece materials. Int J Pr Eng Man-GT 5(2):327–339

Zhang YB, Li CH, Jia DZ, Zhang DK, Zhang XW (2015) Experimental evaluation of MoS2 nanoparticles in jet MQL grinding with different types of vegetable oil as base oil. J Clean Prod 87:930–940

Li HN, Yang Y, Zhao YJ, Zhang ZL, Zhu WQ, Wang WL, Qi H (2019) On the periodicity of fixed-abrasive planetary lapping based on a generic model. J Manuf Process 44:271–287

Ding WF, Zhu YJ, Zhang LC, Xu JH, Fu YC, Liu WD, Yang CY (2015) Stress characteristics and fracture wear of brazed CBN grains in monolayer grinding wheels. Wear 332–333:800–809

Sharma AK, Tiwari AK, Dixit AR (2016) Effects of Minimum Quantity Lubrication (MQL) in machining processes using conventional and nanofluid based cutting fluids: A comprehensive review. J Clean Prod 127:1–18

Tawakoli T, Hadad MJ, Sadeghi MH (2010) Influence of oil mist parameters on minimum quantity lubrication–MQL grinding process. Int J Mach Tools and Manuf 50:521–531

Yang M, Li CH, Zhang YB, Jia DZ, Li RZ, Hou YL, Cao HJ, Wang J (2019) Predictive model for minimum chip thickness and size effect in single diamond grain grinding of zirconia ceramics under different lubricating conditions. Ceram Int 45:14908–14920

Zhang YB, Li CH, Jia DZ, Li BK, Wang YG, Yang M, Hou YL, Zhang XW (2016) Experimental study on the effect of nanoparticle concentration on the lubricating property of nanofluids for MQL grinding of Ni-based alloy. J Mater Process Technol 232:100–115

Kalita P, Malshe AP, Kumar SA, Yoganath VG, Gurumurthy T (2012) Study of specific energy and friction coefficient in minimum quantity lubrication grinding using oil-based nanolubricants. J Manuf Process 14:160–166

Gao T, Li CH, Zhang YB, Yang M, Jia DZ, Jin T, Hou YL, Li RZ (2019) Dispersing mechanism and tribological performance of vegetable oil-based CNT nanofluids with different surfactants. Tribol Int 131:51–69

Li BK, Li CH, Zhang YB, Wang YG, Yang M, Jia DZ, Zhang NQ, Wu QD (2017) Effect of the physical properties of different vegetable oil-based nanofluids on MQLC grinding temperature of Ni-based alloy. Int J Adv Manuf Technol 89:3459–3474

Yang M, Li CH, Zhang YB, Wang YG, Li BK, Jia DZ, Hou YL, Li RZ (2017) Research on microscale skull grinding temperature field under different cooling conditions. Appl Therm Eng 126:525–537

Demas NG, Timofeeva EV, Routbort JL, Fenske GR (2012) Tribological effects of BN and MoS2 nanoparticles added to polyalphaolefin oil in piston skirt/cylinder liner tests. Tribol Lett 47:91–102

Zhang YB, Li CH, Jia DZ, Zhang DK, Zhang XW (2015) Experimental evaluation of the lubrication performance of MoS2/CNT nanofluid for minimal quantity lubrication in Ni-based alloy grinding. Int J Mach Tools Manu 99:19–33

Zhang JJ, Wang DZ (2019) Investigations of tangential ultrasonic vibration turning of Ti6Al4V using finite element method. Int J Mater Form 12:257–267

Ding WF, Zhao B, Xu JH, Yang CY, Fu YC, Su HH (2014) Grinding behavior and surface appearance of (TiCp+TiBw)/Ti-6Al-4V titanium matrix composites. Chin J Aeronaut 27:1334–1342

Wei L, Wang DZ (2019) Comparative study on drilling effect between conventional drilling and ultrasonic-assisted drilling of Ti-6Al-4V/Al2024-T351 laminated material. Int J Adv Manuf Technol 103:141–152

Mao C, Zhang YC, Peng XX, Zhang B, Hu YL, Bi ZM (2018) Wear mechanism of single cBN-WC-10Co fiber cutter in machining of Ti-6Al-4V alloy. J Mater Process Technol 259:45–57

Shang WJ, Cai T, Zhang YX, Liu D, Liu SG (2018) Facile one pot pyrolysis synthesis of carbon quantum dots and graphene oxide nanomaterials: All carbon hybrids as eco-environmental lubricants for low friction and remarkable wear-resistance. Tribol Int 118:373–380

Kuiliang G, Wu XH, Zhao GQ, Wang XB (2017) Nanosized MoS2 deposited on graphene as lubricant additive in polyalkylene glycol for steel/steel contact at elevated temperature. Tribol Int 110:1–7

Wu P, Chen XC, Zhang CH, Luo JB(2019) Synergistic tribological behaviors of graphene oxide and nanodiamond as lubricating additives in water. Tribol Int 132:177–184

Arenas MA, Ahuir-Torres JI, García I, Carvajal H, Damborenea J (2018) Tribological behaviour of laser textured Ti6Al4V alloy coated with MoS2 and grapheme. Tribol Int 128:240–247

Wang J, Guo XC, He Y, Jiang MJ, Gu KC (2018) Tribological characteristics of graphene as grease additive under different contact forms. Tribol Int 127:457–469

Li QY, Zhang S, Qi YZ, Yao QZ, Huang YH (2017) Friction of two-dimensional materials at the nanoscale: behavior and mechanisms. Chin J Solid Mech 38:189–214

Pu JB, Wang LP, Xue QJ (2014) Progress of tribology of graphene and graphene-based composite lubricating materials 34:93–112

Pavan RB, Gopal AV, Amrita M, Goriparthi BK (2019) Experimental investigation of graphene nanoplatelets-based minimum quantity lubrication in grinding Inconel718. P I Mech Eng B-J Eng 233:400–410

Zhang ST, Wang K, Hu ZX (2018) Effect of graphene additive on tribological properties of lube base oil. Pet Process Petrochem 49:91–95

Cheng JX, Xie F, Li B (2016) Application of nano-carbon lubricating oil additives. Contemp Chem Ind 45:843–846

Li ZJ, Zhang YZ, He Q, Du SM (2017) Research progress on the application of grapheme as additives in lubrication. Lubr Eng 42:133–140

Burton G, Goo CS, Zhang YQ, Jun MB (2014) Use of vegetable oil in water emulsion achieved through ultrasonic atomization as cutting fluids in micro-milling. J Manuf Process 16:405–413

Silva LR, Corrêa EC, Brandão JR, de Ávila RF (2013) Environmentally friendly manufacturing: behavior analysis of minimum quantity of lubricant-MQL in grinding process. J Clean Prod https://doi.org/10.1016/j.jclepro.2013.01.033

Emami M, Sadeghi MH, Sarhan AAD, Hasani F (2014) Investigating the minimum quantity lubrication in grinding of Al2O3 engineering ceramic. J Clean Prod 66:632–643

Liu W, Deng ZH, Huang YC (2017) Experimental on surface integrity of titanium alloy TC4 by high speed cylindrical grinding. Aerosp Mater Technol 47:66–70

Xu J, Lu WZ, Wang H, Zhu YS, Huang QC, Zuo DW (2014) Characteristics and wear properties of grinding surface of titanium alloy TC4-DT. Acta Aeron ET Astron Sin 35:567–573

Mao C, Zhou FJ, Hu YL, Cai PH, Jiang YF, Bi ZM, Peng GQ (2019) Tribological behavior of cBN-WC-10Co composites for dry reciprocating sliding wear. Ceram Int 45: 6447–6458

Wang YG, Li CH, Zhang YB, Yang M, Li BK, Jia DZ, Hou YL, Mao C (2016) Experimental evaluation of the lubrication properties of the wheel/workpiece interface in minimum quantity lubrication (MQL) grinding using different types of vegetable oils. J Clean Prod 127:487–499

Mao C, Ren YH, Gan HG, Zhang MJ, Zhang J, Tang K (2015) Microstructure and mechanical properties of cBN-WC-Co composites used for cutting tools. Int J Adv Manuf Technol 76:2043–2049

Zhang YB, Li CH, Ji HJ, Yang XH, Yang M, Jia DZ, Zhang XP, Li RZ, Wang J (2017) Analysis of grinding mechanics and improved predictive force model based on material-removal and plastic-stacking mechanisms. Int J Mach Tool Manu 122:81–97

Zhang JC, Li CH, Zhang YB, Yang M, Jia DZ, Hou YL, Li RZ (2018) Temperature field model and experimental verification on cryogenic air nanofluid minimum quantity lubrication grinding. Int J Adv Manuf Technol 97:209–228

Guo SM, Li CH, Zhang YB, Wang YG, Li BK, Yang M, Zhang XP, Liu GT (2017) Experimental evaluation of the lubrication performance of mixtures of castor oil with other vegetable oils in MQL grinding of nickel-based alloy. J Clean Prod 140:1060–1076

Zhang XP, Li CH, Zhang YB, Jia DZ, Li BK, Wang YG, Yang M, Hou YL, Zhang XW (2016) Performances of Al2O3/SiC hybrid nanofluids in minimum-quantity lubrication grinding. Int J Adv Manuf Technol 86:3427–3441

Peng XF, Yu XL, Xia LF, Zhong X (2007) Viscosity of low concentration nanofluids. T Chin Soc Agric Mach 38:138–141,150

Funding

This research was financially supported by the following foundations: the National Natural Science Foundation of China (51575290), the Major Research Project of Shandong Province (2017GGX30135 and 2018GGX103044), and the Shandong Provincial Natural Science Foundation, China (ZR2019PEE008).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cui, X., Li, C., Zhang, Y. et al. Tribological properties under the grinding wheel and workpiece interface by using graphene nanofluid lubricant. Int J Adv Manuf Technol 104, 3943–3958 (2019). https://doi.org/10.1007/s00170-019-04129-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04129-8