Abstract

The Multi-hollow Surface Dielectric Barrier Discharge (MSDBD) generated in ambient air at atmospheric pressure was used to treat maize, pea, wheat and parsley seeds. Plasma exposure was applied as a pre-treatment before the seeds coating with agrochemicals. The aim of this study was to decrease the dustiness of coated seeds using plasma pre-treatment. The optimization process of plasma treatment parameters for individual seed species consisted of choosing a suitable exposure time (20 s, 60 s) and airflow (10 L/min, 15 L/min). The plasma made the seeds' surface more hydrophilic; therefore, better agrochemicals adhesion was achieved on the seeds' surface. Wettability improvement was demonstrated via water uptake of seeds and apparent contact angle change. Ambient air plasma at a 15 L/min flow rate was measured using optical emission spectroscopy, and the values of vibrational (3000 K) and rotational (347 K) temperatures were obtained from spectra simulation. The surface temperature of the MSDBD ceramics plate was measured with a thermal camera for different gas flow rates and constant input power of 30 W because the temperature is crucial parameter for seed treatment. The surface morphology was not affected due to plasma treatment, even for a longer exposure time. A significant decrease in dustiness measured according to the Heubach method was achieved for pea (57.1%) and parsley (41.4%) seeds. A lower decrease in dustiness was registered in the case of wheat (14.6%) and maize (17%) seeds. The results showed that MSDBD plasma generated in the air at optimized conditions is able to decrease the coated seed dustiness regardless of seed type and size, while seeds germination and surface coverage percentage remained unchanged.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

One of the most important areas of plasma technology is the use of non-thermal plasma in low-temperature applications. Due to the non-equilibrium state of plasma, where the electron energies are much larger than the energy of other particles, plasma treatment at a relatively low temperature of the working gas is possible. It is essential in several applications in biology, agriculture, the food industry, and medicine, where high temperatures may have undesirable and damaging effects on plasma-treated materials. Plasma applications for biology-related areas have a long history, such as sterilization, promoting cell attachment and proliferation on biomaterial surfaces, and modifying biomaterial surface wettability.

In the last decades, research on applying low-temperature plasmas in the agriculture and food industry gained a significant impulse. The effects of non-thermal or cold plasma are currently under extensive investigation in agricultural science as an alternative to traditional seed treatment technologies. The traditional chemical methods were usually uneconomic because large amounts of chemicals were needed, and some residual chemicals on the seed coat would bring soil pollution; therefore, more concern has been given to the physical methods for enhancing seed vigour. Numerous studies provide evidence that plasma seed treatment improved the agricultural performance of crops. Seed exposure to plasma can lead to stimulation of germination and seedling development. The improvement of germination and reduction of diseases as well as changing their water absorption properties, are crucial parameters for the growth process of agricultural seeds. Plasma treatment of seeds for various types of crops represents a promising technology for agriculture and food production. The effect of low-temperature plasmas on seeds has been tested at low and atmospheric pressure for different discharge configurations and various seeds.

A detailed review focusing on the use of non-thermal plasma treatment of agricultural seeds to stimulate germination and remove surface contamination [1,2,3,4,5], as well as a review describing the role of plasma technology in the food industry [6,7,8,9,10] were published. Low-pressure discharges are widely used for decontamination and germination improvement of agricultural seeds. The effect of the radio frequency plasma source on different plant species was studied in several works [11, 12].

Radio-frequency (RF) plasma stimulation of germination and inactivation of pathogenic microorganisms on grain crops, legumes and aster were investigated by Filatova et al. [13]. The interaction of cold radiofrequency plasma with the seeds of beans (Phaseolus vulgaris) focused on water absorption was studied by Bormashenko et al. [14]. It was observed that plasma treatment promotes hydrophilization and markedly accelerates water absorption. The effect of the RF discharge operating in helium on the germination rate of well-watered oilseeds and oilseeds under drought stress was examined. The apparent contact angle was reduced, and the germination rate significantly improved after the plasma treatment. Cold plasma treatment improved oilseed rape drought tolerance and was able to protect oilseed rape seedlings against damage caused by drought stress [15].

Low-temperature atmospheric pressure plasma (APP) has emerged as a powerful technology to improve the properties of seeds [16]. APP plasma sources have benefits such as the ability to be large-scaling, low costs, no needed expensive vacuum systems and high processing speed.

Various types of plasma sources were used, for example, plasma jets [17, 18] or dielectric barrier discharges [19,20,21,22]. The so-called Diffuse Coplanar Surface Barrier Discharge (DCSBD) generating a cold plasma in ambient air with high power volume density was used to treat seeds, too [23,24,25]. The plasma treatment of seeds with DCSBD brought promising results. Structural damage on the surface was observed via scanning electron microscopy (SEM) for pea seeds after long-time plasma treatment (120 s, 600 s). It was shown that a higher and more intensive water uptake positively correlates with the increasing exposure time of cold plasma [26]. Growth, anatomy, and enzyme activity changes in maize roots induced by the treatment of seeds with DCSBD were evaluated by Henselová et al. [27].

Many authors studied plasma-activated water [28,29,30] for improved seed properties. Positive effects of cold plasma treatment on seed germination and seedling growth were observed for many types of seed, for example, maize [31, 32] pea [24, 33] and wheat [34,35,36].

In this study, we focus on the cold atmospheric pressure plasma (CAPP) treatment of different vegetable seeds to increase the wettability and adhesion of agrochemicals to the seeds' surface. Adhesion improvement of agrochemicals leads to the decrease of coated seeds' dustiness. Fine particles of agrochemicals released from coated seeds during the handling of seeds are inhaled by workers, which negatively affects their health. Besides this, it has a negative effect on the environment due to air, water, and soil pollution [37]. Therefore, reducing the amount of released particles from coated seeds is desirable. A novel plasma system called Multi-hollow Surface Dielectric Barrier Discharge (MSDBD) was used for seed treatment in ambient air with exposure times in the range of 10–120 s. Dried seeds of maize, pea, wheat and parsley differing in size and surface type were examined. Improvement of wettability was monitored by water uptake measurement and contact angle analysis. The surface morphology was evaluated using scanning electron microscopy to check the possible changes on the surface. Seeds germination and planting of seedlings in the field were controlled by appropriate methods standardly used in agriculture. The plasma treatment of seeds was used as a pre-treatment before seed dressing with agrochemicals. Therefore, the surface coverage of seeds with agrochemicals with and without plasma pre-treatment was evaluated. The effect of plasma treatment on the dustiness of coated seeds was monitored by the standardized Heubach method, and the aim was to decrease the dustiness. Besides these analytical methods, part of the article is devoted to plasma diagnostics and electrical characteristics of MSDBD. Optical emission spectroscopy (OES) and thermal imaging camera were applied for plasma temperature monitoring and evaluation because the temperature is a crucial parameter for thermal-sensitive samples. Simulation of OES spectra was used for the estimation of rotational and vibrational temperatures.

Materials and Methods

Plant Material

Dried seeds of maize (Zea mays L.), pea (Pisum sativum L.), wheat (Triticum aestivum L.) and parsley (Petroselinum crispum) used in the experiments were obtained from the SEMO, a.s. company located in Smržice, Czech Republic. The seeds were stored at room temperature in closed bags in the dark.

Plasma Source and Treatment of Seeds

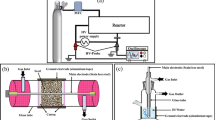

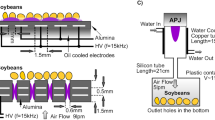

The multi-hollow surface dielectric barrier discharge (MSDBD) operating at atmospheric pressure in ambient air was used to modify the seed's surface properties. MSDBD ceramics purchased from Kyocera consists of 105 holes with a diameter of 0.6 mm each, spaced at 1.8 mm horizontally and 2.1 mm vertically. The plasma unit is made of metallic parallel electrodes, with an inter-electrode distance of 0.5 mm, embedded in an alumina (Al2O3) ceramics plate. The dimensions of the entire ceramics plate are 30 × 30 × 1.5 mm, and the total active area of produced plasma corresponds to 18 × 18.9 mm. The 3D model and profile view of the MSDBD ceramics plate is presented elsewhere [38]. The plasma was generated by a sinusoidal alternate-current (AC), high-voltage (HV) power source with an external signal of frequency ≈ 18 kHz. The operation of MSDBD plasma is possible at different flow rates from 0 to 50 L per minute (L/min) in ambient air or various gases such as nitrogen, oxygen, argon, and pure water vapour [38,39,40,41,42]. The flowing gas serves not only to blow the plasma out of the holes but also to cool the ceramic plate. Therefore, the gas flow affects the resulting ceramic surface temperature along with the input power value. Possible input power is in the 2–30 W range and is monitored with a wattmeter. Produced plasma fills all the holes in the MSDBD ceramics at specific input power differing in used gas and also covers the surface of ceramics with increasing the input power. This type of plasma discharge is used for the treatment of polycarbonate surfaces [38] or ozone generation [41].

Plasma treatment was done on apparatus consisting of 4 MSDBD plasma units (see Fig. 1) at an input power of 30 W for each unit and a flow rate of 15 L/min for each plasma unit. Only in the case of parsley seeds, due to their small size and weight, we used a flow rate of 10 L/min. A higher flow rate than usual was chosen due to the lower temperature of the ceramics plate, which was measured using a thermal camera. Examined exposure times were in the range of 10–120 s. Samples were in direct contact with the ceramics plate surface, and the movement was carried out by mechanical movement. Seeds were rotated many times during the plasma exposure.

Plasma Diagnostics

Electrical Characterization

The V-A characteristics of the MSDBD plasma unit were captured using two passive high voltage (HV) probes P6015A (Tektronix UK Ltd.) and current probe M4100 (Pearson Electronics), connected to the channels of oscilloscope 6100A WaveRunner, 4‐Channel, 1 GHz (Teledyne LeCroy Corporation). The peak‐to‐peak values of voltage were measured by a passive HV probe connected to the HV electrode and a second passive HV probe connected to the grounded electrode. The current probe recorded the discharge current on the cable to the grounded electrode, and the scheme is presented elsewhere [43]. The resulting total voltage was calculated as the difference between the voltage measured on the HV electrode and the voltage acquired on the grounded electrode. The total input power of HV power source was monitored by a wattmeter OM402PWR (Orbit Merret) with an accuracy of 0.3%.

Temperature Monitoring

Since the MSDBD ceramic is heated during the plasma generation, we measured its temperature depending on the plasma treatment parameters. The thermal camera TiS10 (Fluke Europe B.V) with an IR resolution of 80 × 60 px was used for monitoring the MSDBD ceramic temperature, and the emissivity was set to 0.95. The temperature was monitored at the input power of 30 W for different flow rates (5–20 L/min) until the value stabilized (up to 3 min).

Optical Emission Spectroscopy

The vibrational and rotational temperatures in plasma were calculated from optical emission spectra obtained via optical fibre connected to a Shamrock 750 spectrograph (Andor Technology), at a grid of 600 gr/mm, with a Newton CCD detector (Andor Technology) cooled by a Peltier cooler set to − 60 °C. The measured data were processed with massiveOES software [44,45,46] using a spectra simulation.

Analytical Methods

Water Uptake

Dry seeds of maize and pea (40 seeds for each species) were weighed on the analytical balance RADWAG AS 310.R2 (RADWAG Váhy s.r.o.) plasma treated (60–120 s) and weighted after the treatment to monitor the possible weight loss during the plasma treatment. The defined number of seeds was submerged in its entire volume in a Petri dish with distilled water for 5 min at a room temperature of 24 °C. Imbibed seeds were dried using filtration paper, weighed, and put again in a new distilled water with the same volume for different times (0.5 h, 1 h, 1.5 h, 2 h, 2.5 h, 5 h) up to 20 h in total [24]. The procedure of drying and weighing seeds was repeated after each time interval. The increase in seeds' weight during the imbibition was compared with a reference value of untreated seeds that were also imbibed, and the tests were carried out in 9 repetitions. Water uptake (WU) can be expressed by the following equation [47],

where FW – is the fresh weight of samples stored in distilled water, DW – is the weight of dry samples.

Wettability Change Evaluation

Wettability change after the plasma treatment was demonstrated using a drop (1 µl) of methylene blue solution p.a. (supplied by PENTA s.r.o.) placed on the surface of wheat seed. Photographs were captured with See System software (Advex Instruments, s.r.o.); however, the water-based solution contact angle cannot be measured due to the highly curved seed surface. This test was used only as a qualitative analysis showing the wettability change observable by the naked eye.

Germination

The germination of individual seed species was determined according to the International Seed Testing Association (ISTA) methodology [48], which sets the conditions for carrying out the tests, such as the type of substrate (filtration paper), temperature regime (constant 20 °C for pea and wheat seeds or temperature changing in a regime of 20/30 °C for maize and parsley seeds), light regime (artificial light source alternating light and darkness) and special pre-treatment of seeds (pre-cooling in case of wheat for dormancy breaking). The ISTA methodology specifies for each type of seed the number of days after which germination should be calculated. For maize, it is after seven days, for peas after eight days, for parsley after 28 days and for wheat after eight days. Tests were carried out in the germination chamber and were done in four repetitions for each species. An amount of 50 seeds was used for one test, and the standard error was determined from test repetitions. Germination testing was done by manually counting the seedlings, whereas reference samples without plasma treatment were evaluated too. Germination value was calculated as a ratio of germinated seeds (capable of growth) after a certain number of days after sowing, divided by the total number of planted seeds × 100.

Morphological Changes of Seed Surface

Imaging of surface morphology was done on Scanning Electron Microscope Mira3 (Tescan). The detector of secondary electrons and accelerating voltage of 5–15 kV was used. Seeds were covered with 20 nm of Au/Pd layer by sputter coater Quorum Q150R-ES (Quorum Technologies) to prevent sample charging. The surface morphology analysis was carried out with a magnification of up to 10 000.

Seed Dressing

A few seed species differing in size, from a few mm to 1 cm, and surface type, from smooth to irregular, are examined in this study. Therefore, these seed species vary in sensitivity to abrasion and absorption capacity. These factors and seeds' properties affect the seed coating process with agrochemicals (fungicides), which should protect the seed from pathogens and diseases. There are many ways to dress the seed surface with agrochemicals, from wet to dry or combined methods. In our case, we used incrustation technology in which a mixture of polymer, additive and dye is applied to the seeds' surface. The incrustation technology is characterized by high coverage. The liquid mordant is injected onto the seed surface when seeds are placed in a closed drum rotating at a certain velocity. A thin film of mordant is formed on the surface of the seed, and the coated seeds are dried immediately after. The dose of mordant per 1 kg of seeds corresponds to 6 ml for pea, maize, and wheat seeds. A higher amount of 56 ml is used for parsley seeds due to their smaller size and, therefore, a higher amount of seeds in 1 kg. Surface coverage tests were done externally (Agritec s.r.o.) when plasma-treated seeds were coated with mordant using incrustation technology, dried and sent for analysis.

Dustiness of Coated Seeds

To determine the dustiness of the coated seeds, we used a device for measuring dustiness according to the standardized Heubach method called "Assessment of free-floating dust and abrasion particles of treated seeds as a parameter of the quality of treated seeds" [49]. The measurement takes place by filling a defined amount of coated seeds (100 g) into the metal drum, inserting filter paper made of glass microfibers Whatman GF 92 with a diameter of 47 mm (HELAGO-CZ, s.r.o.) into the filter unit and folding it together. We connect other device components and start the measurement cycle on the control unit. During the experiment, the drum with the seeds rotates at a defined speed for 2 min, and due to the rubbing of the seeds against each other, dust particles are released, which are carried away by the air stream and subsequently captured on the filter paper. Analytical balances with high accuracy (0.1 mg) are needed to evaluate dustiness. We weighed the filtration unit with the filter paper before and after the experiment with adhered dust particles. We obtain the value of dustiness P in grams per 100 kg of seeds by a subsequent calculation according to formula 1.2 [37]. The dustiness was evaluated for each seed species in three repetitions, and the value given represents the average of these measurements:

W1 – the weight of the filtration unit with filter after dust measurement; W0 – the weight of the filtration unit with the filter before dust measurement; Ws – the seed batch weight.

Results and Discussion

Plasma Diagnostics

Electrical Characterization

Typical voltage and discharge current waveforms of the MSDBD plasma are shown in Fig. 2 for an input power of 30 W and 15 L/min flow rate. The plasma unit was powered by a sinusoidal signal with an amplitude of approximately 15 kV (peak-to-peak) and 18 kHz frequency. It is obvious that a typical phase shift between the current and voltage corresponds to π/2 rad value. Curves C2 and C3 show the voltage curves measured through two high-voltage probes. We get the resulting total voltage by subtracting them. On the maxima of the current sinusoidal waveform are visible typical sharp peaks representing the filamentary component of the MSDBD plasma. Besides sharp peaks near the current maxima, we also observe recurring peaks caused by the type of generator used. However, it does not affect the measurement result because its value cancels itself out under the curve.

Surface Temperature Monitoring

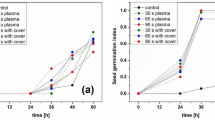

The temperature of the MSDBD ceramic plate was monitored in time in dependence on a flow rate of compressed ambient air at the constant input power of 30 W (Fig. 3a). The initial temperature of the ceramic plate before each plasma ignition corresponded to 20 °C. The measurement started at a flow rate of 5 L/min when the temperature reached the value of 87 °C after 3 min. The value decreased to 68 °C at a flow rate of 10 L/min, to 59 °C at a flow rate of 15 L/min, and to 53 °C at a flow rate of 20 L/min. The cooling of the ceramic plate is more intensive with increasing flow rate; therefore, the temperature decreases with increasing gas flow. We used the flow rate of 15 L/min for experiments with seeds when the maximal temperature in the centre of the ceramic plate was 59.5 °C (Fig. 3b).

Optical Emission Spectroscopy

Optical emission spectra of MSDBD plasma were captured in different gases (air, nitrogen), and the nitrogen vibrational bands are shown in Fig. 4. The rotational and vibrational temperatures were calculated from the nitrogen vibrational bands of the second positive system (SPS) of Δυ = − 2 (transition C3Πu → B3Πg) in the range of 366–382 nm. The distributions of the calculated rotational (Trot) and vibrational (Tvib) temperatures in dependence on the gas flow rate (5–50 L/min) are presented in Fig. 5. The vibrational and rotational temperatures were determined from simulated spectra [44]. It was observed that the Trot value is decreasing with an increasing flow rate independent of used gas (air, nitrogen). MSDBD rotational temperatures for airflow rates of 5 L/min and lower were calculated by Homola et al. [38], and the value of 360 K for a 5 L/min flow rate is in accordance with our results. We used higher gas flow rates resulting in more intensive cooling of the ceramic plate to achieve lower surface temperatures for seeds treatment as thermal-sensitive samples. Trot for 15 L/min flow rate, which was used in experiments, corresponds to the value of 347 K for air and 331 K for nitrogen. The maximal examined flow rate was 50 L/min resulting in a decrease of Trot to 328 K in air and 319 K in the nitrogen atmosphere. The vibrational temperature is independent of the gas flow rate (air, nitrogen) and reaches around 3000 K in air and 2000 K in nitrogen. The standard error of rotational and vibrational temperatures was estimated to be 10%.

Seed Treatment

Wettability Change Evaluation

It is generally known that plasma treatment changes the surface wettability of materials, which also applies to seeds. Chemical changes on the seeds' surface induced by plasma treatment are often responsible for the wettability change due to upper surface functionalization via reactive particles generated directly in the discharge and plasma afterglow (plasma-chemical reaction with the composition of treated surface; formation of functional groups with different, e.g. polar character) as it is described elsewhere [23,24,25,26,27, 31]. In addition, wettability improvement is often related to better adhesion. For this reason, we tried to evaluate the change in seed wettability after plasma treatment. The standard method of measuring the contact angle could not be used here due to the curved and irregular surface of the seeds. However, it served us for qualitative analysis only when we could distinguish with the naked eye the difference in the contact angle size of the methylene blue drop applied on the untreated surface and the plasma-treated surface of the seed. Wettability change after plasma treatment was demonstrated on the surface of wheat seeds (Fig. 6) and maize seeds (Fig. 7) for different exposure times.

Water Uptake

The principle of this method is that the seed volume increases during the imbibition process due to the water soaking into the intercellular spaces inside the seed. Water uptake was tested on pea and maize seeds due to bigger seed sizes for easier handling. Initially, it was checked that the plasma treatment caused seed weight losses of less than 1% due to the heating. The average weight of the dry seed batch corresponded to 3.2 g for pea seeds and 6.1 g for maize seeds. These weighted seeds were imbibed for 5 min—afterwards, the increase in water uptake after plasma treatment is already noticeable for maize seeds (Fig. 8). Water uptake after 5 min imbibition was 2% higher compared to the control sample; however, the effect of plasma exposure time was not evident yet. The steepest increase in water absorption was observed during the first 2.5 h. After 2.5 h, the water uptake value differed by 3% for 60 s treated and 4.6% for 120 s treated maize seeds compared to the control sample. The influence of plasma treatment duration on the amount of absorbed water is pronounced in time. After 5 h of imbibition, the difference in water uptake between untreated and plasma-treated maize seeds was similar to after 2.5 h. It seems that water uptake in time slows down after 5 h. Finally, water uptake was evaluated after 20 h of imbibition in total, and the difference between untreated and plasma-treated maize seeds was more significant than for shorter imbibition times. The amount of absorbed water was 5.1% higher for 60 s PT maize seeds and even 6.7% higher after 120 s plasma exposure. Overall, the control sample of maize was able to soak water in an amount corresponding to about 75.6% of its original weight. After MSDBD plasma treatment, this amount increased to 80.6% (60 s PT) and 82.2% (120 s PT), respectively.

A similar situation occurred for imbibed pea seeds (Fig. 9), with the difference that after 5 min of imbibition, the increase in water uptake of plasma-treated seeds was low (0.5–0.8%). After 2.5 h, the water uptake value differed by 4% for 60 s treated and almost 6.4% for 120 s treated pea seeds compared to the control sample. The increase in water uptake is higher than for maize seeds after the same imbibition time. After 5 h of imbibition, the water uptake increases after plasma treatment were comparable for pea and maize seeds. In total, the control sample of pea seeds was able to soak water in an amount corresponding to about 139.5% of its original weight. After MSDBD plasma treatment, this amount increased to 142.5% (60 s PT) and 140.7% (120 s PT), respectively. After 20 h, we observed comparable results for pea seeds within the margin of error. Standard deviations (SD) shown in the graphs (Figs. 8, 9) were calculated from 9 repetitions (n = 9).

Effect on Germination

Germination tests were carried out for the exposure times of 20 s and 60 s for wheat, pea and maize seeds, while the parsley seeds were treated only for 10 s and 20 s due to smaller seeds size (Fig. 10). Reference sample of untreated seeds was tested as well for all species. This study aimed not to improve germination; however, to ensure that germination is not significantly decreased after plasma exposure. Wheat seeds germination (97%) was stable regardless of the plasma treatment duration. The germination of parsley is also relatively high (93%), and due to the plasma treatment, it has only slightly decreased to 92% and 91%, respectively. However, within the margin of error, it is comparable to the germination of the untreated sample. Germination of maize started at 83%, slightly increased after 20 s plasma treatment, and this trend continued with a longer exposure time of 60 s when germination reached 88%. It follows the results in the study of maize seeds treated with DCSBD for 60 s [47]. A different trend was observed for pea seeds when germination decreased from 88 to 84% after 20 s plasma exposure and reached its original value of 88% after 60 s treatment. In comparison, Švubová et al. observed the same value of germination after 60 s DCSBD treatment of pea seeds as for reference value [24]. We can conclude that the germination stayed stable regardless of MSDBD plasma treatment time up to 60 s and did not decrease significantly for all seed species, while in some cases, it even slightly increased.

In addition, the germination of plasma-treated seed was also tested under real field conditions. The growth rate and plant size of plasma-treated seeds cultivated in the field were comparable with untreated samples.

Surface Morphology

We did not observe any changes in the seed surface morphology using scanning electron microscopy after MSDBD plasma treatment. Considering that the seed surface is irregular and differs in various parts of the seed, it is not easy to compare individual seeds of one species with each other. However, we did not register any ruptures or damage on the seed surface after plasma treatment compared to the untreated control sample. SEM images of pea, maize, wheat and parsley surfaces are presented in Fig. 11 with a 5000 × magnification for MSDBD plasma treated and untreated seeds. The exposure time of 60 s was applied on pea and maize seeds (Fig. 11a–d), whereas wheat and parsley seeds (Fig. 11e–h) were treated for 20 s. Surface analysis of pea and maize seeds plasma treated for a longer time (120 s) was carried out as well. However, no changes on the seed surface were noticed neither in this case.

Surface Coverage Tests

Surface coverage tests evaluate how much of the seed surface area is covered with a mordant; the value is expressed in percentage. High values of surface coverage (%) were obtained already for untreated seeds (96–99%) of pea, maize, parsley and wheat (Table 1). Surface coverage of 20 s plasma-treated seeds was similar or even slightly higher (97–99%). We can conclude that the surface coverage percentage was stable regardless of the plasma treatment.

Dustiness of Coated Seeds

As shown in previous chapters, the wettability and water absorption improved after the MSDBD plasma treatment. The main goal of this study was to evaluate the effect of plasma treatment on the dustiness of coated seeds. The dustiness was measured according to the standardized Heubach method when the free-floating particles released from the coated seeds during the rubbing process were captured on specialized filters (Fig. 12). It was observed that the plasma treatment significantly decreased the Heubach dust value of free-floating dust and abrasion particles of coated seeds already after 20 s exposure in plasma (Table 2). The decrease is calculated as the difference between the dustiness of coated untreated seeds and coated plasma-treated seeds. We measured the most significant decrease in dustiness for pea (57.1%) and parsley (41.4%) seeds. The dustiness of wheat and maize seeds decreased after the plasma treatment lower, whereas the decrease was equal to 14.6% and 17%, respectively. The positive influence of MSDBD plasma treatment on the decrease of dustiness is evident from the results regardless of seed type and size.

Conclusions

The aim of this study was to evaluate the effect of MSDBD plasma treatment on the dustiness of coated seeds of pea, maize, wheat, and parsley. The optimization process of plasma treatment parameters for individual seed species consisted of choosing a suitable exposure time (20 s, 60 s) and gas flow (15 L/min), which is used for cooling the plasma source. The electrical and temperature characteristics of MSDBD plasma were investigated before seed treatment. Typical voltage and current waveforms for used plasma treatment parameters are presented here, where on the maxima of the current sinusoidal waveform are visible typical sharp peaks representing the filamentary component of the MSDBD plasma. The surface temperature of the ceramics plate monitored with a thermal camera reached the value of 59 °C at a flow rate of 15 L/min and 30 W input power. Rotational and vibrational temperatures were simulated from optical emission spectra for gas flow rates in the 5–50 L/min range. The rotational temperature for the 15 L/min flow rate corresponds to the value of 347 K for air and 331 K for nitrogen. It was found that rotational temperature decreases with the increasing gas flow rate. The vibrational temperature is independent of the gas flow rate (air, nitrogen) and reaches the value of around 3000 K in air and 2000 K in nitrogen.

It is generally known that plasma treatment changes the surface wettability of materials, which also applies to seeds. Chemical changes on the seeds' surface induced by plasma treatment are often responsible for the wettability change due to the increase of oxygen containing functional groups with polar character. The standard method of measuring the contact angle of the drop could not be used here due to the curved and irregular surface of the seeds. However, it served us for qualitative analysis only when we could distinguish with the naked eye the difference in the contact angle size of the methylene blue drop applied on the untreated surface and the plasma-treated surface of the seed. Wettability change after plasma treatment was demonstrated on the surface of wheat seeds and maize seeds. Besides this, water uptake of maize and pea seeds was tested using an imbibition process when water was soaked into the intercellular spaces inside the seed in time. After 20 h of imbibition, the amount of absorbed water was 5.1% higher for 60 s plasma-treated maize seeds and even 6.7% higher after 120 s plasma exposure. Overall, the control sample of maize was able to soak water in an amount corresponding to about 75.6% of its original weight. After MSDBD plasma treatment, this amount increased to 80.6% (60 s plasma treatment) and 82.2% (120 s plasma treatment), respectively. After 20 h, we observed comparable results also for pea seeds within the margin of error.

The way how to verify the seed viability after plasma treatment is to test its germination. We can generally state that seed germination values after plasma treatment with MSDBD discharge were similar to those without plasma treatment. We can conclude that the germination stayed stable regardless of MSDBD plasma treatment time up to 60 s and did not decrease significantly for all seed species, while in some cases, it even slightly increased. No morphological changes were observed on the surface of the seeds after 60 s treatment of pea and maize and 20 s treatment of wheat and parsley seeds. Surface analysis of pea and maize seeds plasma treated for a longer time (120 s) was carried out as well. However, no changes on the seed surface were noticed neither in this case.

It was confirmed that the surface coverage percentage of the seed surface by the mordant was stable regardless of the plasma treatment. Plasma treatment led to a significant reduction in the dustiness of the investigated types of coated seeds. The most significant decrease was observed in the case of pea (57.1%) and parsley (41.4%) seeds. A lower decrease in dustiness was registered in the case of wheat (14.6%) and maize (17%) seeds. The results showed that MSDBD plasma generated in the air at optimized parameters is able to decrease the coated seed dustiness regardless of seed type and size, whereas germination and surface coverage percentage were unchanged. Thanks to the reduction of dustiness due to plasma treatment, it would hypothetically be possible to reduce the dose of the active substance in the mordant or the amount of mordant used.

Data Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Rifna EJ, Ratish Ramanan K, Mahendran R (2019) Emerging technology applications for improving seed germination. Trends Food Sci Technol 86:95–108. https://doi.org/10.1016/j.tifs.2019.02.029

Randeniya LK, de Groot GJJB (2015) Non-thermal plasma treatment of agricultural seeds for stimulation of germination, removal of surface contamination and other benefits: a review. Plasma Process Polym 12:608–623. https://doi.org/10.1002/ppap.201500042

Ranieri P, Sponsel N, Kizer J et al (2021) Plasma agriculture: review from the perspective of the plant and its ecosystem. Plasma Process Polym 18:1–24. https://doi.org/10.1002/ppap.202000162

Sasi S, Prasad K, Weerasinghe J et al (2023) Plasma for aquaponics. Trends Biotechnol 41:46–62. https://doi.org/10.1016/j.tibtech.2022.08.001

Šerá B, Šerý M (2018) Non-thermal plasma treatment as a new biotechnology in relation to seeds, dry fruits, and grains. Plasma Sci Technol 20:1–8. https://doi.org/10.1088/2058-6272/aaacc6

Dharini M, Jaspin S, Mahendran R (2023) Cold plasma reactive species: generation, properties, and interaction with food biomolecules. Food Chem 405:1–15. https://doi.org/10.1016/j.foodchem.2022.134746

Shanker MA, Khanashyam AC, Pandiselvam R et al (2023) Implications of cold plasma and plasma activated water on food texture- a review. Food Control 151:1–10. https://doi.org/10.1016/j.foodcont.2023.109793

Pipliya S, Kumar S, Babar N, Srivastav PP (2023) Recent trends in non-thermal plasma and plasma activated water: effect on quality attributes, mechanism of interaction and potential application in food & agriculture. Food Chem Adv 2:1–23. https://doi.org/10.1016/j.focha.2023.100249

Ucar Y, Ceylan Z, Durmus M et al (2021) Application of cold plasma technology in the food industry and its combination with other emerging technologies. Trends Food Sci Technol 114:355–371. https://doi.org/10.1016/j.tifs.2021.06.004

Mir SA, Shah MA, Mir MM (2016) Understanding the role of plasma technology in food industry. Food Bioproc Tech 9:734–750. https://doi.org/10.1007/s11947-016-1699-9

Sohan MSR, Hasan M, Hossain MF, Sajib SA, Miah MM, Iqbal MA, Reza MA (2021) Improvement of seed germination rate, agronomic traits, enzymatic activity and nutritional composition of bread wheat (triticum aestivum) using low-frequency glow discharge plasma. Plasma Chem Plasma Process 41:923–944. https://doi.org/10.1007/s11090-021-10158-7

Billah M, Karmakar S, Mina FB et al (2021) Investigation of mechanisms involved in seed germination enhancement, enzymatic activity and seedling growth of rice (Oryza Sativa L.) using LPDBD (Ar+Air) plasma. Arch Biochem Biophys. https://doi.org/10.1016/j.abb.2020.108726

Filatova II, Azharonok VV, Goncharik SV et al (2014) Effect of rf plasma treatment on the germination and phytosanitary state of seeds. J Appl Spectrosc 81:250–256. https://doi.org/10.1007/s10812-014-9918-5

Bormashenko E, Shapira Y, Grynyov R et al (2015) Interaction of cold radiofrequency plasma with seeds of beans (Phaseolus vulgaris). J Exp Bot 66:4013–4021. https://doi.org/10.1093/jxb/erv206

Ling L, Jiangang L, Minchong S et al (2015) Cold plasma treatment enhances oilseed rape seed germination under drought stress. Sci Rep 5:1–10. https://doi.org/10.1038/srep13033

Rongsangchaicharean T, Srisonphan S, Onwimol D (2022) Responses of rice seed quality to large-scale atmospheric nonthermal plasmas. Plasma Chem Plasma Process 42:1127–1141. https://doi.org/10.1007/s11090-022-10261-3

Hendeniya N, Sandanuwan T, Attygalle D et al (2022) Non-thermal atmospheric pressure plasma: an alternative method to enhance the seed quality in long bean-KPN (Vigna unguiculate L.) seeds. Mater Today Proc 56:1691–1695. https://doi.org/10.1016/j.matpr.2021.10.329

Sarapirom S, Yu LD (2021) Low-pressure and atmospheric plasma treatments of sunflower seeds. Surf Coat Technol. https://doi.org/10.1016/j.surfcoat.2020.126638

Ito M, Oh J-S, Ohta T et al (2018) Current status and future prospects of agricultural applications using atmospheric-pressure plasma technologies. Plasma Process Polym 15:1–15. https://doi.org/10.1002/ppap.201700073

Koga K, Thapanut S, Amano T et al (2016) Simple method of improving harvest by nonthermal air plasma irradiation of seeds of Arabidopsis thaliana (L.). Appl Phys Expr 9:1–3. https://doi.org/10.7567/APEX.9.016201

Park Y, Oh KS, Oh J et al (2018) The biological effects of surface dielectric barrier discharge on seed germination and plant growth with barley. Plasma Process Polym 15:1–8. https://doi.org/10.1002/ppap.201600056

Smet C, Baka M, Dickenson A et al (2018) Antimicrobial efficacy of cold atmospheric plasma for different intrinsic and extrinsic parameters. Plasma Process Polym 15:1–8. https://doi.org/10.1002/ppap.201700048

Zahoranová A, Henselová M, Hudecová D et al (2016) Effect of cold atmospheric pressure plasma on the wheat seedlings vigor and on the inactivation of microorganisms on the seeds surface. Plasma Chem Plasma Process 36:397–414. https://doi.org/10.1007/s11090-015-9684-z

Švubová R, Kyzek S, Medvecká V et al (2020) Novel insight at the effect of cold atmospheric pressure plasma on the activity of enzymes essential for the germination of pea (Pisum sativum L. cv. Prophet) seeds. Plasma Chem Plasma Process 40:1221–1240. https://doi.org/10.1007/s11090-020-10089-9

Štěpánová V, Slavíček P, Kelar J et al (2018) Atmospheric pressure plasma treatment of agricultural seeds of cucumber (Cucumis sativus L.) and pepper (Capsicum annuum L.) with effect on reduction of diseases and germination improvement. Plasma Processes Polym 15:1–9. https://doi.org/10.1002/ppap.201700076

Stolárik T, Henselová M, Martinka M et al (2015) Effect of low-temperature plasma on the structure of seeds, growth and metabolism of endogenous phytohormones in pea (Pisum sativum L.). Plasma Chem Plasma Process 35:659–676. https://doi.org/10.1007/s11090-015-9627-8

Henselová M, Slováková Ľ, Martinka M, Zahoranová A (2012) Growth, anatomy and enzyme activity changes in maize roots induced by treatment of seeds with low-temperature plasma. Biologia (Bratisl) 67:490–497. https://doi.org/10.2478/s11756-012-0046-5

Rashid M, Rashid MM, Reza MA, Talukder MR (2021) Combined effects of air plasma seed treatment and foliar application of plasma activated water on enhanced paddy plant growth and yield. Plasma Chem Plasma Process 41:1081–1099. https://doi.org/10.1007/s11090-021-10179-2

Darmanin M, Kozak D, de Oliveira MJ et al (2020) Generation of plasma functionalized water: antimicrobial assessment and impact on seed germination. Food Control 113:1–8. https://doi.org/10.1016/j.foodcont.2020.107168

Sajib SA, Billah M, Mahmud S et al (2020) Plasma activated water: the next generation eco-friendly stimulant for enhancing plant seed germination, vigor and increased enzyme activity, a study on black gram (Vigna mungo L.). Plasma Chem Plasma Process 40:119–143. https://doi.org/10.1007/s11090-019-10028-3

Szőke C, Nagy Z, Gierczik K et al (2018) Effect of the afterglows of low pressure Ar/N2-O2 surface-wave microwave discharges on barley and maize seeds. Plasma Processes Polym 15:1–12. https://doi.org/10.1002/ppap.201700138

Karmakar S, Billah M, Hasan M et al (2021) Impact of LFGD (Ar+O2) plasma on seed surface, germination, plant growth, productivity and nutritional composition of maize (Zea mays L.). Heliyon 7:1–12. https://doi.org/10.1016/j.heliyon.2021.e06458

Bu F, Feyzi S, Nayak G et al (2023) Investigation of novel cold atmospheric plasma sources and their impact on the structural and functional characteristics of pea protein. Innov Food Sci Emerg Technol 83:1–12. https://doi.org/10.1016/j.ifset.2022.103248

Meng Y, Qu G, Wang T et al (2017) Enhancement of germination and seedling growth of wheat seed using dielectric barrier discharge plasma with various gas sources. Plasma Chem Plasma Process 37:1105–1119. https://doi.org/10.1007/s11090-017-9799-5

Lotfy K, Al-Harbi NA, Abd El-Raheem H (2019) Cold atmospheric pressure nitrogen plasma jet for enhancement germination of wheat seeds. Plasma Chem Plasma Process 39:897–912. https://doi.org/10.1007/s11090-019-09969-6

Velichko I, Gordeev I, Shelemin A et al (2019) Plasma jet and dielectric barrier discharge treatment of wheat seeds. Plasma Chem Plasma Process 39:913–928. https://doi.org/10.1007/s11090-019-09991-8

Zwertvaegher IKA, Foqué D, Devarrewaere W et al (2016) Assessment of the abrasion potential of pesticide-treated seeds using the Heubach test. Int J Pest Manag 62:348–359. https://doi.org/10.1080/09670874.2016.1206993

Homola T, Krumpolec R, Zemánek M et al (2017) An array of micro-hollow surface dielectric barrier discharges for large-area atmospheric-pressure surface treatments. Plasma Chem Plasma Process 37:1149–1163. https://doi.org/10.1007/s11090-017-9792-z

Voráč J, Britun N, Nikiforov A et al (2019) Photofragmentation laser-induced fluorescence of ozone: an in situ tool for precise mapping of ozone concentration in non-thermal plasmas. Appl Phys Expr 12:1–5. https://doi.org/10.7567/1882-0786/ab3d15

Dvořák P, Procházka V, Krumpolec R, Zemánek M (2020) Solution to the perturbation of LIF measurements via photodissociation, OH measurement in atmospheric-pressure multihollow DBD. Plasma Processes Polym 17:1–7. https://doi.org/10.1002/ppap.202000020

Homola T, Prukner V, Hoffer P, Šimek M (2020) Multi-hollow surface dielectric barrier discharge: an ozone generator with flexible performance and supreme efficiency. Plasma Sources Sci Technol 29:1–15. https://doi.org/10.1088/1361-6595/aba987

Kelar Tučeková Z, Vacek L, Krumpolec R et al (2021) Multi-hollow surface dielectric barrier discharge for bacterial biofilm decontamination. Molecules 26:1–13. https://doi.org/10.3390/MOLECULES26040910

Štěpánová V, Šrámková P, Sihelník S et al (2023) Adhesion improvement on the inner side of LLDPE/PA tubular film exposed to DCSBD roll-to-roll plasma system from the outer side of the film. Plasma Process Polym 20:1–13. https://doi.org/10.1002/ppap.202200226

Voráč J, Kusýn L, Synek P (2019) Deducing rotational quantum-state distributions from overlapping molecular spectra. Rev Sci Instrum 90:1–10. https://doi.org/10.1063/1.5128455

Voráč J, Synek P, Procházka V, Hoder T (2017) State-by-state emission spectra fitting for non-equilibrium plasmas: OH spectra of surface barrier discharge at argon/water interface. J Phys D Appl Phys 50:1–14. https://doi.org/10.1088/1361-6463/aa7570

Voráč J, Synek P, Potočňáková L et al (2017) Batch processing of overlapping molecular spectra as a tool for spatio-temporal diagnostics of power modulated microwave plasma jet. Plasma Sources Sci Technol 26:1–12. https://doi.org/10.1088/1361-6595/aa51f0

Zahoranová A, Hoppanová L, Šimončicová J et al (2018) Effect of cold atmospheric pressure plasma on maize seeds: enhancement of seedlings growth and surface microorganisms inactivation. Plasma Chem Plasma Process 38:969–988. https://doi.org/10.1007/s11090-018-9913-3

International Rules for Seed Testing (2023) https://www.seedtest.org/en/useful-links-footer/ista-rules/international-rules-seed-testing.html. Accessed 24 May 2023

Euroseeds STAT Dust Working Group (2011) Physical method Assessment of free-floating dust and abrasion particles of treated seeds as a parameter of the quality of treated seeds HEUBACH TEST. https://euroseeds.eu/app/uploads/2020/02/ESA_11.0387.1.pdf. Accessed 31 May 2023

Acknowledgements

This research has been supported by the project LM2018097 funded by the Ministry of Education, Youth and Sports of the Czech Republic. We want to thank our excellent colleague Dr. Miroslav Zemánek, who passed away in November 2021, for his help.

Funding

Open access publishing supported by the National Technical Library in Prague. This work was supported by the project LM2018097 funded by the Ministry of Education, Youth and Sports of the Czech Republic.

Author information

Authors and Affiliations

Contributions

PS: Conceptualization; investigation; writing—original draft; funding acquisition; writing—review and editing. VŠ: Investigation; funding acquisition; writing—original draft; writing—review and editing. MF: Investigation; writing—review and editing. JK: Investigation. ZKT: Investigation; writing—review and editing. JJ: Investigation; writing—review and editing. MP: Investigation. VP: Investigation. JP: Conceptualisation; funding acquisition; investigation. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article. Neither of them is a Editor or Editorial Board member of any journal. PS, VŠ, MF, JK, ZKT, JJ, MP are employees of the Masaryk University; VP and JP are employees of SEMO a.s.

Ethical Approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Slavíček, P., Štěpánová, V., Fleischer, M. et al. The Multi-Hollow Surface Dielectric Barrier Discharge Usage for the Seeds' Treatment Aimed to the Dustiness Decrease of Free-Floating Particles from Agrochemicals. Plasma Chem Plasma Process 43, 1887–1906 (2023). https://doi.org/10.1007/s11090-023-10396-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-023-10396-x