Abstract

The Ukraine conflict has put critical pressure on gas supplies and increased the price of fertilisers. As a consequence, biogas has gained remarkable attention as a local source of both gas for energy and biofertiliser for agriculture. Moreover, climate change-related damage incentivises all sectors to decarbonise and integrate sustainable practices. For instance, anaerobic digestion allows decarbonisation and optimal waste management. Incorporating a biogas system in each country would limit global warming to 2 °C. If suitable policies mechanisms are implemented, the biogas industry could reduce global greenhouse gas emissions by 3.29–4.36 gigatonnes carbon dioxide equivalent, which represent about 10–13% of global emissions. Here, we review the role of the biogas sector in capturing methane and mitigating carbon emissions associated with biogas outputs. Since biogas impurities can cause severe practical difficulties in biogas storing and gas grid delivering systems, we present upgrading technologies that remove or consume the carbon dioxide in raw biogas, to achieve a minimum of 95% methane content. We discuss the role of hydrogen-assisted biological biogas upgrading in carbon sequestration by converting carbon dioxide to biomethane via utilising hydrogen generated primarily through other renewable energy sources such as water electrolysis and photovoltaic solar facilities or wind turbines. This conceptual shift of 'power to gas' allows storing and utilising the excess of energy generated in grids. By converting carbon dioxide produced during anaerobic digestion into additional biomethane, biogas has the potential to meet 53% of the demand for fossil natural gas. We also evaluate the role of digestate from biogas systems in producing biochar, which can be used directly as a biofertiliser or indirectly as a biomethanation enhancement, upgrading, and cleaning material.

Similar content being viewed by others

Introduction

The 2022 Ukraine conflict has put pressure on gas supplies, highlighting the need for more local energy resources. Renewable green energy transitions are necessary to mitigate global climate change and reduce carbon emissions worldwide (Levenda et al. 2021; Chen et al. 2022a). Bioenergy generation via anaerobic digestion of biomass in conjunction with carbon capture and storage or utilisation is one of the most frequently discussed negative emissions tools in recent years (Al-Wahaibi et al. 2020). Collecting all available wastes and anaerobically digesting them for biogas generation can reduce greenhouse gases emissions by 3.29 to 4.36 billion tonnes of carbon dioxide equivalent, which corresponds to 10–13% of the global greenhouse gas emissions from renewable bioenergy production, crop burning, evaded emissions management, landfill gas, deforestation, and fertiliser production emissions. Globally, the potential for energy generation from currently available and recovered feedstocks ranges between 10,100 and 14,000 terra watt-hours. That energy could account for approximately 6–9% of primary energy consumed or approximately 23–32% of coal consumed globally. Anaerobic digestate as a soil biofertiliser has the potential to replace 5–7% of chemical fertiliser and fertilise over 80 million hectares of land (Jain et al. 2019; IEA 2018a).

Carbon dioxide sequestered or removed from raw biogas would reduce carbon dioxide emissions from anaerobic digestion systems, contribute to greenhouse gas mitigation, and have a more beneficial environmental effect. Thus, purification or upgrading of biogas is critical to removing carbon dioxide, increasing biogas electricity transmission efficiency, achieving optimal standardisation for direct integration into natural gas grids, and facilitating biogas transportation and storage, thereby optimising the function of renewable biogas as a fossil fuel substitute (Khan et al. 2021). In this regard, biological upgrading of biogas has been recognised as a simple and sustainable method for increasing the methane content of generated biogas while also stabilising wastes (Treu et al. 2018). The biological biogas upgrading technology is a hydrogen-assisted process that aims to sequester carbon dioxide by converting carbon dioxide to biomethane using hydrogen generated primarily from affordable renewable energy sources such as water electrolysis, photovoltaic solar facilities, or wind turbines, thereby forming a new energy shifting technology called power to gas shift (Fu et al. 2021; Zhu et al. 2020a; Zabranska and Pokorna 2018).

In this review, we proposed that hydrogen transportation costs can be avoided if the applied hydrogen is derived from surplus hydrogen produced by water hydrolysis or wind or solar energy close to the biogas plant, which would provide sustainable, environmentally friendly, and cost-effective tools for upgrading biogas and sequestering carbon dioxide. Additionally, the digestates produced by the biogas system are massive, typically exceeding the required land area, and are stored in open tanks for an extended period, emitting greenhouse gases and polluting the environment. As a result, anaerobic digestion can be used in conjunction with biochar to establish circular multiple benefit concepts.

Therefore, several benefits can be obtained from biogas upgrading via biohydrogen injection and digestate-converted biochar recycling as shown in Fig. 1: (1) capturing and utilising upgraded biomethane ensures greenhouse gases zero-emission, thereby mitigating climate changes and global warming; (2), pyrolysis of digestate to biochar may ensure carbon sequestration, and hence, carbon zero-emission to the environment can be verified; (3), recycling biochar within the anaerobic reactor can improve biomethane upgrading by boosting biomethane, enhancing microbial growth, and absorbing undesirable products (hydrogen sulphide and ammonia); (4), biochar produced from digestate can be easily stored and transported to the land for soil amendment purposes or making biochar-based fertiliser, along with other carbon sink applications; and (5) besides achieving the concept of “net-carbon zero emissions”, economic and sustainable outcomes can be accomplished.

System connecting anaerobic digestion, biochar, and dihydrogen to achieve carbon sequestration and climate change mitigation tool. Surplus hydrogen derived from water hydrolysis, wind, or solar electricity energy can be introduced into the anaerobic digestion system as a hydrogen-assisted biological biogas upgrading mean that can convert the carbon dioxide into biomethane to achieve new energy shifting technology called power to gas shift, offering sustainable, environmental, and cost-effective tool to upgrade the biogas and sequester the carbon dioxide. In addition, the utilisation of digestate from the biogas system for biochar production would act as a long-term carbon sink that would be a useful tool for carbon sequestration and can be recycled inside the biogas system as a biomethanation enhancement and biogas impurities purification material, achieving circular approach

Biogas yield worldwide

Climate change directly impacts people's health, livelihoods, and well-being (Manning and Clayton 2018; AghaKouchak et al. 2020). In 2018, the world experienced over 300 climate-related natural disasters, affecting over 68 million people, resulting in approximately 131.7 billion dollars in economic losses, of which floods, storms, droughts, and wildfires accounted for 93%. The economic losses caused by wildfires in 2018 are nearly identical to the cumulative losses caused by wildfires over the last decade. Additionally, water, food, health, infrastructure, human habitat, and ecosystem are identified as the most vulnerable sectors to the climate crisis (Fawzy et al. 2020). As a result, climate change mitigation is critical to avoiding the worst of these consequences.

Greenhouse gas emissions, particularly carbon dioxide, are the primary cause of global climate change (Ritchie and Roser 2020). Global carbon dioxide emissions from fossil fuels were approximately 6 billion tonnes in 1950 and had exponentially increased to 34.81 billion tonnes in 2020 (Ritchie and Roser 2020), accounting for approximately 89% of the global carbon dioxide emission (Rogelj et al. 2018). As a result of global warming, 195 countries committed to the Paris Agreement in 2016 as a plan for global warming countermeasures. The agreement aims to keep the global temperature increase this century below 2℃ and to pursue efforts to limit global temperature to 1.5℃ by 2050. This would be accomplished by developing technologies with net-zero carbon emissions and reducing global greenhouse gas emissions (Osman et al. 2021a).

Renewable energy is the fastest-growing sector globally, with a projected 30% share of electricity in 2023, up from about 25% in 2018 (IEA 2018b). Additionally, by 2040, renewable energy is expected to account for two-thirds of global capacity for electricity production (IEA 2018b). By 2050, bioenergy sources such as biogas, biomethane, liquid biofuels, and solid biomass will account for 25% of the total primary energy supply (IRENA 2021). The share of bioenergy is equivalent to 460 megatonnes of oil in 2016 and is estimated to increase by 16.5% by 2023 (Xue et al. 2020); in addition, bioenergy share is estimated to be around three-quarters of renewable energy worldwide, of which biomass represents more than the half (Xue et al. 2020).

Biomass has the potential to significantly increase energy supply in several countries with high energy demands, such as China and India (IRENA 2019). However, the utilisation rate for bioenergy production is different. For instance, from 1.4 gigatonnes of generated crop residues, about 900 million tonnes are annually utilised in China, as well as around 44% of the 2.05 gigatonnes of livestock and poultry manure are utilised (Xue et al. 2020). In comparison, Europe consumes approximately 1.2 gigatonnes of manure per year from a total of 1.35 gigatonnes generated (Scarlat et al. 2018a). Theoretically, in China, around 74 billion cubic metres of upgraded biogas (biomethane) can be produced from the 1.4 gigatonnes of wastes annually; however, the actual biogas produced in China is around 15.8 billion cubic metres in 2015 (Xue et al. 2020).

In comparison, European Union produced about 16.08 billion cubic metres of biogas from manure only (Scarlat et al. 2018b), which is greater than the entire yield of China despite China's higher quantity of manure produced (Xue et al. 2020). The differences in waste utilisation between Europe and China are attributed to the robustness of biomass storage and transportation systems (Xue et al. 2020); besides, the bioenergy consumption rates in the European Union are much higher than that in China (Wang et al. 2016). This difference indicates that most energy has not been utilised with contemporary biogas biotechnologies; however, China could potentially become a global leader in bioenergy consumption by implementing carbon sequestration and decarbonisation policies. As a result, standardisation of storage and transportation systems is critical to ensuring an adequate supply of biogas systems, as is optimising the use and development of biogas sectors.

Globally, there are 132,000 small to large scale biodigesters and around 50 million operating micro-scaled biodigesters that are primarily used for heating or cooking (Jain et al. 2019). The International Renewable Energy Agency’s data demonstrate that the worldwide electricity produced from biogas was 46,243 gigawatt-hours in 2010 and nearly doubled to 91,819 gigawatt-hours in 2019 (IRENA 2019). This demonstrates a phenomenal growth trend in biogas production via anaerobic digestion. The anaerobic digestion system has the potential to generate 10,100–14,000 tera watt-hours of energy, which is equivalent to 6–9% of global primary energy consumption or approximately 32% of global coal consumption if the majority of wastes are utilised (IEA 2018a). Despite the growth in biogas production, approximately 407 tera watt-hours of biogas were produced globally in 2018, representing a small fraction of the biomethane energy potential estimated by the International Energy Agency, of which Europe, China, the United States of America, and the rest of the world produced, respectively, 209, 84, 42, and 47 tera watt-hours (WBA 2021).

Europe is the world leader in biogas generation and utilisation, with 17,783 plants producing approximately 30 billion cubic metres per year (more than half of the world's total) and 63,504 gigawatt-hours biogas-derived electricity in 2018 (Lai et al. 2021). Around 74% of biogas generated in Europe comes from anaerobic digestion of agricultural residues, manure, and energy crops; 17% comes from landfills; and 9% comes from wastewater treatment plant sludge (Scarlat et al. 2018b). In 2015, European biogas was primarily used to generate 61 tera watt-hours of electricity and 127 terajoules of heat (50% biogas consumption). Additionally, Europe is the world's largest producer of biomethane used as a transportation fuel, with 697 biomethane filling stations supplying 0.16 billion cubic metres of biomethane to vehicles in 2015 as a transportation biofuel (Scarlat et al. 2018b).

On a regional scale, Germany, China, and the United States are the largest biogas-producing countries, with 328 picojoules, 272 picojoules and 156 picojoules, respectively (Lu and Gao 2021). Overall, Germany leads Europe's biogas sector with 10,971 large-scale plants, followed by 1665 biogas plants in Italy, 742 in France, 632 and 613 plants in Switzerland, and the United Kingdom, respectively (EBA 2019). Additionally, 110,448 biogas operations in China, of which 6972 large-scaled (2015), 2200 anaerobic biodigesters with 977 megawatts installed capacity in the United States, 180 digesters in Canada with 196 megawatts installed capacity, and 300 megawatts installed biogas capacity in India (Jain et al. 2019). The details of biogas plants and their production are listed in Table 1.

Biomethane conversion from biogas is a developed technology that aims to use biomethane as a vehicle fuel or to inject biomethane into regional gas grids. Alternatively, capturing biomethane and carbon dioxide during the establishment of biogas plants serves as a carbon sequestration tool. Certain plants begin to utilise the carbon dioxide captured in greenhouses, food processing plants, and beverage co-facilities. Of the 700 biogas upgrading plants worldwide, 570 are in Europe, with 203 in Germany, 96 in the United Kingdom, 69 in Sweden, 53 in the Netherlands, and 47 in France. Outside of Europe, there are approximately 50 upgrading plants in the United States, 25 in China, and 20 in Canada, as well as a few in Japan, India, Brazil, and South Korea (Jain et al. 2019; Bioenergy 2020).

According to the International Energy Agency Bioenergy Task 37-member countries, the biomethane markets in some countries like Germany, Sweden and the United Kingdom have extended, and the generated biomethane is used mainly for electricity and heat production, along with fuel for the vehicle. Countries have various financial support systems, such as tax exemptions, feed-in tariffs, and investment grants. A linear correlation between the way biogas is utilised and the financial support system is obvious in the Task 37-member countries. In countries such as Germany, the United Kingdom, and Austria, the feed-in tariffs support for electricity generation has resulted in the use of almost all biogas in electricity generation, while the tax exemption system in Sweden encourages biomethane utilisation as a vehicle fuel. Other countries have developed financial support mechanisms for gas injection into their gas grids (Bioenergy 2022).

Energy transition and greenhouse gas mitigation potential from the anaerobic digestion process in wastewater treatment plants are critical. Global wastewater production is estimated to be 309.52 gigatonnes per year. Currently, the energy-consuming in the conventional activated sludge process is about 0.26–0.68 kilowatt-hour (kW-h)/cubic metre of the wastewater treatment process, with an average of 0.47 kW-h/cubic metre (Zhang and Ma 2020). If 40% of inflowing waste sludge’s chemical oxygen demand is converted into methane via anaerobic digestion with a recoverable energy rate of 13.91 kilojoules (kJ)/g methane chemical oxygen demand, the recoverable energy unit via anaerobic digestion of waste sludge could be estimated as 500 g/cubic metre × 0.40 × 13.91 kJ/g = 2782 kilojoules/cubic metre. At an electricity conversion efficiency of 35%, total electrical energy of about 973.7 kilojoules/cubic metre (i.e. 0.27 kW-h/cubic metre) would be ultimately produced via anaerobic digestion of waste sludge meanwhile 1808.3 kJ/cubic metre would be harvested as heat from methane combustion. As discussed above, about 0.27 kW-h/cubic metre of electrical energy could be recovered through anaerobic digestion of waste sludge, indicating that the energy recovered in a current wastewater treatment plant could offset about 50–60% of total input energy (electricity only) consumption (Zhang and Ma 2020).

On the other hand, Pabi et al. (2013) reported that the wastewater treatment plants typically consumed about 4% of total electricity demand in the United States, accounting for more than 30% of total wastewater treatment costs. Nevertheless, the energy content of 13 MJ/kg chemical oxygen demand in wastewater sewage sludge (Gandiglio et al. 2017) is 3–5 times that of the total energy required for wastewater treatment. Consequently, effective utilisation of anaerobic digestion’s biogas in wastewater treatment plants would facilitate a hypothesis transfer in wastewater treatment plants from an energy-intensive industry to an energy-positive or energy-neutral industry, thereby enhancing the economic development for the water treatment process.

Germany

In Germany, the overall renewable energy share would be increased to about 40–45%, 55–60%, and 80% by 2025 2035, and 2050, respectively. The biogas plants in Germany mainly treat wastewater treatment plants (1271), biowaste (292), agriculture (8400), biomethane (232), and landfill (280). The 10,551 biogas plants in Germany are generating 33,600 and 20,500 GW-h/year) of electricity and heat, respectively. Based on the legalisation of using cultivated biomass for energy targets, the total calculated biogas potential for energy supply fluctuates between 155 and 265 TW-h/year. About 30% of the estimated potential is presently used for biogas production in Germany. In 2020, most biogas generated in Germany was applied for electricity (62.7%) and heat production (35.6%), though biomethane utilisation as an automobile fuel improved from 389 to 884 GW-h/year in 2019 and 2020, respectively. The number of filling stations delivering biomethane has risen from 100 in 2018 to approximately 550 stations in 202 (Bioenergy 2022).

The United Kingdom

The number of biogas plants in the United Kingdom is 170, 127, 342, and 46 for wastewater treatment plants, biowaste, agriculture, and industrial wastes, respectively. 120 biogas plants from the 685 anaerobic digestion plants in the United Kingdom inject their biomethane into gas grids (Bioenergy 2022). The overall biogas plants rapidly increased from 200 in 2010 to 650 in 2017, followed by very slow progress in the last years. There are 558 anaerobic digestion plants in the United Kingdom that generate electricity, 120 biogas plants for biomethane, and 7 plants only producing heat in 2020, in addition to 10 vehicle filling stations delivering biomethane (share of 67%) with compressed natural gas blended from the gas grid. The United Kingdom government implemented a 2050 net-zero carbon strategy by 2033–2037 (Bioenergy 2022). This challenging task to meet the United Kingdom’s carbon net-zero target pushed the government and stakeholders toward decarbonising heat by applying anaerobic digestion-based biogas plants, ensuring carbon saving over natural gas.

The United Kingdom launched several initiative policies to address the decarbonisation of heat targets, such as the Sustainable Farming Incentive, Green Gas Support Scheme, and the Slurry Investment Scheme to further develop the biogas area (Bioenergy 2022). For instance, the green gas support scheme encourages injecting biomethane from anaerobic digestion into the gas grids. This support policy aimed to provide 2.8 TW-h of renewable heat/year by 2030. The green gas support scheme provides a 5.51 £/kW-h for the first 60 GW-h and 3.53 £/kW-h for the next 40 GW-h, then 1.56 £/kW-h for the rest of the biomethane production as a fixed tariff rate for biomethane uses for 15 years to increase the investment targets to this project. The new Green Gas Levy will provide £150 million per year to the anaerobic digestion industry, which would support 45 new biomethane plants (Bioenergy 2022).

In conclusion, the long-term carbon net-zero recognises anaerobic digestion-based biogas plants as a useful organic waste treatment alternative for the renewable production of heat fuel or electricity, and biogas’ role in facilitating the decarbonisation of the gas grid is promising. In addition, the effluent nutrient-rich digestate has been recognised as a potential strategy to reduce greenhouse gas emissions (Bioenergy 2022). The biogas production in the United Kingdom is listed in Table 1.

France

The French Environment and Energy Management Agency aims to generate 70 terra watt-hours biogas annually by 2035. The vision is to establish 400 biogas plants every year. The generated energy from biogas plants represents 47% converted into electricity, 43% into heat and about 10% into biomethane. In 2017, 44 out of 47 upgrading plants injected biomethane into grids, generating 406 GW-h. In 2050, the vision is to produce 100 terra watt-hours/year (Bioenergy 2019).

Sweden

The Swedish climate and energy goals drive expanded renewable energy use, particularly in the transportation sector. The local 2020 renewable energy targets were achieved, with 50% overall energy utilisation and 10% transport goals. The Swedish Gas Association established a “Green gas 2050” vision that includes targets of 50 terra watt-hours renewable gas production by 2050, contributing to fossil-free land transportation, climate-neutral industry, fossil-free electricity and heat generation, and cleaner shipping (Bioenergy 2022).

The biogas plants in Sweden mainly treat wastewater treatment plants (134), biowaste (36), agriculture (54), industrial (7), and landfills (51). The 282 biogas plants in Sweden generate an overall 2.16 terra watt-hours of biogas in 2020. The generated biogas originated mostly from various co-digestion residues and bio-waste (52%), and sewage sludge (33%). Recently, 68 biomethane upgrading plants generating more than 1.3 TW-h biomethane per year, in addition to two biomethane liquefaction plants producing 78 gigawatt-hours/year, were installed (Bioenergy 2022).

Swedish biogas uses in transportation have increased promptly; however, biogas utilisation for heating has declined. Whereby 65% of the generated biogas was upgraded and used primarily as fuel for transportation due to a satisfactory financial support system. Biomethane use as vehicle gas steadily increased until 2014 and nearly stabilised at about 1500 gigawatt-hours. Biomethane utilisation accounted for over 95% of automobile gas usage in 2019–2020. Accordingly, the number of gas filling stations has risen from below 20 in 2000 to around 200 filling stations in 2021, along with 60 private stations. During the same period, gas-dependent vehicles have increased from only a few hundred to about 53,982 in 2019, from which 2618 buses (representing 15% of all overall buses) and 1034 trucks, while the remaining number was for passenger and light cars (Bioenergy 2022).

Brazil

In Brazil, the biogas sector has increased in the last few years, with a total of 638 biogas plants in 2020 producing about 1.8 billion normal cubic metres/year (11.7 TW-h/year). The agricultural biogas plants were dominant (79%), yet almost of the biogas produced (73%) originated from sanitary landfills and wastewater treatment plants. The potential biogas generation from biomass has likely to be 82.58 billion normal cubic metres/year; hence 2% of the biogas potential is currently utilised (Bioenergy 2022). Most gas generated is used for electricity production (73%), while 8% for heat generation in 2020. The biomethane produced from the 8 biogas upgrading plants is utilised as a vehicle fuel and produces electricity. Brazil dedicated greenhouse gas emissions reduction by up to 43% by 2030, so biogas plants will contribute to meeting the carbon emissions reduction (Bioenergy 2022).

Denmark

Denmark's vision is to establish free fossil fuels dependency concept by 2050. Biogas production will assist in converting the fossil-dependent transport sector into a green-dependent (Bioenergy 2019). Biogas production has received considerable attention in the last few years as a significant and economical tool for mitigating climatic change and sequestering carbon dioxide emissions from the agricultural, transport, and energy sectors. Hence, the 172 biogas plants operating in Denmark in 2018 produced 3.7 TW-h energy. Almost of plants are agricultural (85%), either centralised biogas plants in farm clusters or on single farms. In 2018, 34 upgrading biogas plants were established to upgrade 54% of the generated biogas in Denmark. Besides, 29, 18.61, and 17% of the biogas produced were used for heat, biomethane, and power generation, respectively. The number of biomethane filling stations was 18 in 2018. Biomethane is anticipated to share by 30% in 2023 and 100% by 2035 as green utilised gas. Biomethane production would contribute to achieving the national climate vision and meeting the Paris Agreement commitment, as well as biomethane may be stored in present gas networks, offsetting other wind and green solar energies at no extra cost. The compressed upgraded biomethane utilisation for city trucks and busses is also growing to avoid pollution and to meet economic incentives compared with imported diesel (Bioenergy 2019).

Republic of Korea

In Korea, 119 biogas plants are operating to produce 2815 GW-h per year of biogas. Biogas contributes from 31.8% (landfill), 22.4% (sewage sludge), and 45.5% (bio-waste). The most important feedstock of biogas comprises food waste, food waste leachate, and other co-substrates. About 1112 GW-h (39.5%) of the biogas generated is utilised for electricity production, and 667 GW-h (23.7%) is used for heat production. Around 4.2% of the generated biogas is utilised for biomethane, while compressed gas supplies 39,081 buses as a fuel, with 201 gas filling stations reached, of which 6 biomethane filling stations supplying 0.2% of the total number of buses (Bioenergy 2019).

United States

Nearby over 2200 digesters produce biogas all over the United States, including 250 on-farm digesters, 1269 digesters treated water resources, 66 food treated digesters, and 652 landfill gas facilities. The potential biogas industry growth in the United States is huge, with possible 14,958 more sites ready for expansion nowadays, involving 8574 dairy, swine, and poultry and 3878 water treatment amenities, in addition to 2036 food scrap industries. The new biogas systems would generate 103 trillion kilowatt-hours of electricity/year and decrease the emissions, equal to the removal of 117 million customer vehicles from the street (ABC 2022).

According to the Environmental Protection Agency, manure-based anaerobic digestion systems increased from 169 in 2010 to 317 in 2021. The biogas plants include 112 cornered lagoons, 99 plug flow, 91 complete mix digesters, and 15 others. In 2021, the manure-based anaerobic digesters generated 1.59 million megawatt-hours of energy compared to 594.8 million kilowatt-hours equivalent in 2010 (EPA 2021). In addition, AgSTAR's Market Opportunities for Biogas Recovery Systems at United States Livestock Facilities stated that dairy and swine operations could produce 15.84 million megawatt-hours of electricity per year, corresponding to over 2009 megawatts of electrical grid capacity or around 5.4 million British thermal units of displaced fossil fuel use. The AgSTAR also estimated that the methane generation potential of swine and dairy farms is sufficient to heat more than 2.7 million homes or produce over 8 billion pounds of compressed natural gas annually (equal to 1.3 billion gallons of diesel), adequate to fuel approximately 150,000 trucks (EPA 2021).

Summary

Renewable energy share is nearly 19% of the worldwide energy mix, with an estimated increase of 50% by 2050. Bioenergy is shared by up to 10% of the worldwide primary energy supply with an expected increase to 60% owing to the potential impact of biogas production to diminish the fossil fuel uses and reduce greenhouse gas emissions by achieving carbon net-zero emissions. Europe is leading in biomethane production, so following Europe in creating sufficient biogas technologies to effectively utilise bioenergy is preferable. With increasing feedstock utilisation, the anaerobic digestion can produce over 14,000 terra watt-hours of energy, equivalent to 32% of the world’s coal consumption by 2050. Increased use of bioenergy alongside other renewable sources will shift the world from coal-dependent to green energy-dependent. To achieve those goals, the government or decision-makers should encourage the biogas system establishment by launching several biogas support initiatives and other forms of tax exemption policies.

Role of biogas systems in climatic change mitigation

Role of biogas plants in greenhouse gases reduction

Anaerobic digestion of biomass is one of several waste-to-energy transmission technologies that can generate clean bioenergy in the form of biogas. This process can produce bioenergy from a variety of organic wastes, including agricultural residues, livestock manure, food waste, wastewater sludge, and macroalgae (Farghali et al. 2019; Yuhendra et al. 2021; Muhammad Nasir et al. 2012). Biogas is one of the most sustainable energy sources available for reducing reliance on and consumption of fossil fuels, reducing carbon emissions, alleviating the current fossil fuel crisis, avoiding deforestation, reducing harmful wastes, and enhancing soil fertility. Additionally, as previously discussed, biogas's diverse end-use capabilities and high utilisation efficiency are advantageous.

Carbon capturing and storage technologies can actively revert greenhouse gas emissions by locking the carbon contained in bio-carbon dioxide away from the atmosphere. Anaerobic digestion plants have the potential to become a carbon hub, concentrating atmospheric carbon within a digester and preparing carbon for permanent storage within materials or underground. The global industry would generate over 12,500 terra watt-hours of biogas at full capacity, equivalent to 1560 million tonnes of carbon dioxide (WBA 2021). Incorporating anaerobic digestion technologies into establishing a global green economy achieves both decarbonisation of waste management and defossilisation of fossil fuels, the matter that meets nine of the seventeen Sustainable Development Goals (SDGs) by 2030 (WBA 2021).

Collecting all available wastes and anaerobically digesting them for biogas production is expected to reduce greenhouse gas emissions by 3.29–4.36 billion tonnes of carbon dioxide equivalent, or 10–13% of global greenhouse gas emissions from renewable bioenergy production, crop burning, evaded emissions management, landfill gas, deforestation, and fertiliser production emissions, as seen in Table 2.

Biomass can be converted to a variety of renewable energy sources, including electricity, biogas, and liquid biofuels, thereby promoting environmental protection, public health, and sustainability (Osman et al. 2021b). For instance, the biogas produced by a single household-based biogas reactor can replace nearly 1.5 tonnes of straw and firewood combined each year. This could reduce two tonnes of carbon dioxide emissions per year (Xue et al. 2020). Additionally, capturing carbon from various biomass through anaerobic digestion has the potential to reduce 3–4 gigatonnes of carbon dioxide, or more than 10% of global greenhouse gas emissions (Jain et al. 2019). Compressed biogas reduced greenhouse gas emissions by 93–131% to fossil diesel (van den Oever et al. 2021).

The reduction in methane emissions from a biogas system (anaerobic lagoon) was estimated compared to a manure storage tank or pond on a 500-cow dairy farm in California. The baseline manure management process emits 82.6 tonnes of methane per year, which is equivalent to 2064 tonnes of carbon dioxide equivalent per year; however, biogas capturing reduces methane emissions by 179.4 tonnes per year (equivalent to 4485 tonnes of carbon dioxide equivalent per year). Additionally, utilising biogas for electricity generation could reduce 828 tonnes of carbon dioxide equivalent per year from conventional power generation sources, as fewer fossil fuels are combusted by electric power plants (EBA 2018).

In 2020, the United States 317 manure-based anaerobic digesters reduced greenhouse gas emissions by 5.29 million metric tonnes of carbon dioxide equivalent (MMTCO2eq), resulting from 4.44 MMTCO2eq direct methane reductions + 0.83 MMTCO2eq emissions avoided. At the same time, an increased reduction from direct (5.07) and indirect emissions (0.88) of 5.95 MMTCO2eq was achieved from livestock farms-based anaerobic digesters in 2021. Besides, between 2000 and 2020, livestock manure-based digesters established in the United States have reduced direct and indirect emissions by 48.3 MMTCO2eq (EPA 2021). As a result, biogas generated through anaerobic digestion significantly impacts energy resources and carbon emissions to the environment.

Olesen et al. (2021) analysed and quantified the potential of the biogas system to abate greenhouse gas emissions. The authors selected five biogas production models with varying bioresources compositions to illustrate how Danish biogas technology is best applied. Additionally, they used various digestion "retention" times ranging from 45 to 90 days and assumed that the biogas was generated by centralised large biogas systems that converted biogas to biomethane with the same value as natural gas. The authors assumed that 50% of digested effluent is stored in solid-covered tanks for a period of 20 days prior to being transported to farms. The greenhouse gas and environmental effects were calculated using the greenhouse gas warming potentials of nitrous oxide and methane, which are 298 and 25 carbon dioxide equivalents, respectively.

Table 3 illustrates the greenhouse gas emissions associated with various assumed scenarios. The greenhouse gas emissions calculated include biogas energy production that offsets fossil fuel-based carbon dioxide emissions; 1% methane escape from biogas upgrading; methane emitted during biomass storage; and nitrous oxide emitted during storage, nitrate leaching ammonia volatilisation, and field application. Their findings showed a total greenhouse gas reduction of 65–106 kg of carbon dioxide equivalent per tonne of biomass at 45 days retention time in the modelled biogas systems. The major greenhouse gas offset was achieved by utilising biogas via a natural gas grid that replaces fossil fuel and methane-producing from conventional storage of wet biomasses.

In the United Kingdom, 67% rated greenhouse gas emissions as fairly important to extremely important when making decisions about their livestock, crops, and land in 2021. 56% of them have a strategy to mitigate their farm's greenhouse gas emissions. The most frequently cited actions for reducing greenhouse gas emissions on farms were waste recycling (83%), energy efficiency improvement (79%), and increased accuracy or efficiency in nitrogen fertiliser application (62%) (DEFRA 2021).

Role of biomethane as fuel in greenhouse gas reduction

Climate change can lead to massive irreversible and negative impacts on humanity and ecosystems, combined with immense socioeconomic consequences. Therefore, reducing anthropogenic greenhouse gas emissions resulting from the extraction and combustion of fossil fuels is critical (Gaulin and Le Billon 2020) to keep global warming lower than 1.5 °C, as indicated in the Paris Agreement. Transportation of people and goods consumes enormous amounts of energy and is classified as an air polluter and a greenhouse gas emitter (Tian et al. 2018). Transportation accounts for 29% of global carbon dioxide emissions, the majority of which result from fossil-fuel combustion (EPA 2019).

Calculations of greenhouse gas emissions from the transportation of gas can be classified as tank-to-wheel, well-to-tank, the cascade steps required to generate fuel from primary source to delivery and vehicle refuelling, or well-to-wheel, which encompasses the entire fuel production life cycle from a primary source to end-use, as shown in Fig. 2. We can quantify the climate impacts of biogas systems at various stages of their life cycle by implementing the well-to-wheel concept. For instance, by using animal manure as a feedstock for the biogas system, avoiding the climate effects associated with traditional manure management is possible, in which methane is produced and emitted in an uncontrolled manner as a result of manure open storage. Alternatively, feeding manure into a biogas system that captures the methane produced and the carbon dioxide produced by the engine's methane combustion produces less greenhouse gas (Ammenberg et al. 2021). Thus, proper handling and treatment of manure, combined with proper fertilisation practices for the digestate, can result in a carbon–neutral lifecycle approach from a climate standpoint (Börjesson and Iverfeldt 2016).

Well-to-wheel concept. The greenhouse gas emissions calculations from the transportation sector of the gas sector can classify into tank-to-wheel, well-to-tank (the cascade steps to generate fuel from the primary source to fuel delivery and vehicle refuelling), well-to-wheel, which involve the whole fuel production life cycle to the end-user. Utilising biomethane for transportation can significantly reduce the consumption of fossil fuels, thereby lowering greenhouse gas emissions. Currently, engines in trucks and buses are adapted to utilise methane in order to meet environmental and climate goals

In general, biomethane produced from wastes performs better in terms of climate and environmental performance than biomethane produced from energy crops, owing to the larger environmental problem associated with wastes. Typically, digestate benefits are not considered in life cycle assessments of biogas potentials that use biomethane for transportation, despite the significant indirect definite climate impacts associated with digestate produced by biogas sectors. Wherever digestates are applied to soils, they can be used in place of inorganic fertilisers (McCabe et al. 2020) that require vast quantities of natural gas.

Natural gas emits fewer greenhouse gases than diesel (Börjesson and Iverfeldt 2016; Speirs et al. 2020). However, this reduction is limited by methane leakage, the lower efficiency of gas engines compared to diesel engines, and the fact that natural gas is a fossil fuel. Additionally, the production of liquified natural gas resulted in greenhouse gas emissions (Stettler et al. 2019; Cooper et al. 2019). Technically, fossil-derived natural gas can simply be replaced with biomethane derived from renewable sources, either liquefied or compressed. The utilisation of biomethane in the transportation sector has several advantages: (1) biomethane is derived from organic biomass that has nearly identical properties to natural gas (Speirs et al. 2018); (2) biomethane from biogas plants can be produced and used locally, thereby avoiding the difficulties associated with natural gas importation, particularly in Europe (Eurostat 2022; Kampman et al. 2017); and (3) utilising biomethane in transportation systems would be a cost-effective way to reduce carbon emissions and combat climate change. Currently, the use of biomethane in vehicles is extremely limited, with Sweden leading the way in Europe.

The environmental merits of using biomethane as a vehicle fuel can be summarised as follow:

Prussi et al. (2020) found that biomethane derived from manure, whether liquefied or compressed, had the lowest well-to-wheel greenhouse gas emissions of 250 energy carriers for road transport studied, with renewable biomethane offering a net emission of − 239.3 g carbon dioxide equivalent/megajoule fuel when the manure managed in a closed storage system. Similarly, Pääkkönen et al. (2019) concluded that by 2030, biomethane fuel shifting could support 50% of Finland's heavy-duty transportation sector. Additionally, the authors estimated a biomethane production cost of 81–190 €/MW-h, which is comparable to diesel's consumer price of 152 €/MW-h. If all biomethane is used in heavy-duty transport, carbon dioxide emissions are reduced by 50%, reducing environmental impact and mitigating global warming (Lyng and Brekke 2019). Biomethane produced from manure has the potential to reduce greenhouse gas emissions by 1.0–2.6 kilogrammes carbon dioxide equivalent, resulting in a net negative emission across the well-to-wheel cycle of − 2.2 to − 0.6 kg carbon dioxide equivalent/km bus transportation. Additionally, replacing mineral fertilisers with biomethane derived from food waste would result in negative emissions of − 0.90 (Lyng and Brekke 2019).

The most frequently used feedstock for biomethane production is livestock manure, which accounts for 43% of the European transport sector (Baldino et al. 2018; Hijazi et al. 2016). Renewable biomethane use in road transports has the potential to reduce the greenhouse gas emissions by − 264 g carbon dioxide equivalent/megajoule (− 9.45 kg carbon dioxide equivalent/cubic metre) from the anaerobic digestion of livestock manure compared to emissions of 26, 68.6, 46.9, and 72 g carbon dioxide equivalent/megajoule from renewable solar power-to-gas (electrolysis and methanation) in 2030–2050, EU-28 Power production, grid average in 2030–2050, and Fossil fuel-derived fossil gas, respectively (Baldino et al. 2018). The lower rate of biomethane use in transportation compared to electricity and heat is due to the financial incentives associated with low carbon production approaches (Baldino et al. 2018). Ammenberg et al. (2021) and Long and Murphy (2019) reported that the utilisation of biomethane from grass silage and slurry met sustainability criteria for heat and transportation, emitting 27 and 22.95 g of carbon dioxide equivalent/megajoule biomethane, respectively, compared to 80- and 94-g carbon dioxide equivalent/megajoule for the fossil fuel comparator, implying a 66–76% reduction in emissions.

Cenex (2019) evaluated the performance of 20 biomethane-fueled gas vehicles in the United Kingdom. The findings indicated an 80% significant reduction in greenhouse gas emissions compared to diesel across all vehicle types; specifically, using fossil-derived natural gas would result in emissions savings of 13% to a 4% increase compared to diesel. If the trial vehicles travelled more than 2.2 million kilometres, they would save over 1400 tonnes of carbon dioxide equivalent from well-to-wheel. This is equivalent to the carbon dioxide emitted by 3150 trees over their lifetime, occupying an area roughly the size of 18 football pitches Ammenberg et al. (2021) concluded that using renewable biomethane as a vehicle fuel reduced the greenhouse gas by 80–90% according to different calculations compared to gasoline- and diesel-fueled vehicles, whereas fossil natural gas could reduce greenhouse gas emissions by 10–15% when compared to gasoline.

Atkins et al. (2021) demonstrated that using biomethane as a vehicle fuel could be a quick way to decarbonise heavy-duty trucks. Where a lifecycle assessment indicated that liquefied biomethane could reduce greenhouse gas emissions by 75% compared to a diesel standard, battery-electric and fossil natural gas could reduce greenhouse gas emissions by 49 and 8%, respectively. Due to the substitution of fossil fuels and avoided methane emissions, upcycling biomethane from sewer systems and waste grass anaerobic digestion resulted in net negative carbon dioxide equivalent emissions of 246%.

However, technical and energy barriers exist, such as the need to increase gas grid pressure to 240 bar for gas vehicle fueling, as well as the inefficiency of regional delivery, distribution, and charging processes for electric vehicles. Piechota and Igliński (2021) reported that compressed natural gas/biomethane is subject to more restrictions than liquefied petroleum gas. Where approximately 200 bar pressure is required to compress the volatile gas into costly tanks; in addition, biomethane fueled vehicles can travel approximately 400 kms on a single tank. The authors proposed liquefied biomethane as an optimised solution not only for the aforementioned technical barriers but also as a green energy generation, waste disposal, and negative carbon emissions technology with a 75–200% reduction in carbon emissions compared to diesel.

Numerous authors emphasised the environmental benefits of liquified biomethane over diesel in heavy-duty trucks (Shanmugam et al. 2018; Hagos and Ahlgren 2018; Gustafsson et al. 2021). Gustafsson et al. (2021) found a positive correlation between climate change mitigation and the proportion of biomethane in compressed natural gas versus fossil-derived natural gas or fossil diesel. In this context, a 50% biomethane content in compressed natural gas would reduce the climate change impact of vehicles by 35 and 45%, respectively, compared to fossil compressed natural gas and fossil diesel. A 100% biomethane share would mitigate climate change by over 65 and 75%, respectively, compared to fossil compressed natural gas and fossil diesel. If the anaerobic digestate is included, the climate change impact is reduced by 45–60% at a 50% biomethane content in compressed natural gas and by 95% at a 100% biomethane content (Gustafsson et al. 2021). Compared well-to-wheel scenarios to assess the environmental impacts of liquefied biomethane and liquefied natural gas over their respective life cycles. The authors concluded that liquefied natural gas could contribute 10% more to climate change than diesel. However, liquefied biomethane can significantly reduce environmental impact by 45–70% and 50–75%, respectively, compared to a diesel with manure-derived liquefied biomethane and food waste-derived liquefied biomethane. Additionally, when biogas digestate is used in place of chemical fertiliser, the climate benefits of using liquefied biomethane as a diesel substitute are greater. Where liquefied biomethane derived from manure has the potential to reduce climate change by 100–125%, compared to 80–105% for liquefied biomethane derived from food waste (Gustafsson and Svensson 2021).

Role of biogas plants in emissions savings by displacing synthetic fertiliser with digestate

Fertilisers are primarily used on crops in order to meet global food demand. Intensive use of inorganic fertilisers has resulted in risks to human health and the environment, including a high carbon footprint, a high cost, nitrate leaching pollution, eutrophication risk in water bodies, decreased soil microbial activity, and soil organic carbon loss where inorganic fertilisers do not deliver the organic matter to the soil. From a soil health perspective, the application of inorganic fertilisers may reduce soil productivity, water retention capacity, salinity, alter soil minerals, and expose crops to various infections (Rahman and Zhang 2018).

The manufactured nitrogen cycle is unsustainable, with 30–40% of applied nitrogen being used by crops and thus entering the food chain, while the remainder is frequently lost to waterways or the atmosphere. Additionally, approximately 12.5% of the food chain's nitrogen is excreted by humans and returned to the atmosphere via aeration. This cycle typically consumes two litres of fossil fuel to generate one kilogramme of nitrogen, which is unsustainable (WBA 2021).

Mineral fertilisers are produced artificially by converting chemicals into usable forms. The Haber Bosch process is by far the most common, as the Haber Bosch process combines nitrogen gas from the atmosphere with hydrogen from fossil natural gas (methane) to form liquid ammonium. This process consumes a large amount of natural gas and energy. According to multiple studies, nitrogen fixation consumes approximately 3–5% of global natural gas generation and accounts for 1–2% of the global annual energy supply to produce approximately 450 million tonnes of nitrogen fertiliser (WBA 2021; Akbar et al. 2021).

Fertiliser consumption varies significantly across the globe. Brazil consumes approximately 186 kilogrammes per hectare of arable land, 503 kilogrammes per hectare for China, 165 kilogrammes per hectare for India, 231 kilogrammes per hectare of arable land for Indonesia, more than 1240 kilogrammes per hectare of arable land for Ireland, 71 kilogrammes per hectare of arable land for Morocco, 59 kilogrammes per hectare of arable land for South Africa, 138 kilogrammes per hectare of arable land for the United States, and 253 kilogrammes per hectare of arable land for the United Kingdom (WBA 2021).

Apart from the environmental and soil concerns raised by the use of fossil fuels to synthesise chemical fertilisers, the concern about the depletion of chemical fertilisers' global natural resources has increased; for example, phosphorus is expected to be depleted within 50 to 100 years, posing a threat to crop development and food security (Akbar et al. 2021). Within 30 to 40 years, the existing phosphorus supplies possibly would be insufficient to meet global agricultural demand (WBA 2021). Thus, sustainable and novel alternatives to the traditional use of chemical fertilisers are required.

To avoid the limitations mentioned above, the digestate output of anaerobic digestion can be used as a bio-fertiliser in place of inorganic fertilisers. Anaerobic digestate contains abundant nutrients, has excellent fertiliser potential, and has a significant global capacity (Kumar et al. 2020a).

Digestate is the term used to describe anaerobic digestion feedstock that has been degassed. Typically, scientists combine the suffix 'ate' to denote the result of an action; thus, the effluent of anaerobic digestion is digest–ate, the result of digestion. For every tonne of feedstock degassed in a digester, approximately 50–85% by weight of the feedstock is recovered as digestate. Anaerobic digestion treats nutrients that would have been disposed of in water bodies or landfills without anaerobic digestion. Digestate contains all of the nutrients contained in organic wastes. As such, digestate is known by various other names throughout the world, including biofertiliser and organic/natural fertiliser (WBA 2021). In general, digestate takes on various forms: With less than 5% total solids, the first form is comparable to livestock slurry. This material is extracted directly from the digester and may then be separated into two parts: A liquid biofertiliser in which the majority of the total solids have been separated and a solid biofertiliser in which the remaining dry matter has been retained.

Following solid–liquid segregation, the liquid fraction contains a higher nitrogen content (70–80% of total ammonium nitrogen) and a lower phosphorus content (35–45%), whereas the solid fraction contains a higher phosphorus content (55–65% of total phosphorus) and a residual of total ammonium nitrogen (20–30%) (Logan and Visvanathan 2019). Thus, the solid digestate fraction has a greater potential for soil improvement, whereas the fluid digestate fraction has a higher fertiliser potency.

Digestate has the potential to significantly reduce the demand for mineral fertilisers by recovering nutrients from organic wastes. As a result, digestate reduces our reliance on fossil natural gas, the need for the global transportation of these fertilisers, and all associated emissions. When one tonne of mineral fertiliser is replaced with a tonne of organic fertiliser, one tonne of oil, 108 tonnes of water, and 5–9 tonnes of carbon dioxide equivalent emissions are saved (WBA 2021). Likewise, Akbar et al. (2021) reported that digestate biofertilisers could substitute synthetic fertilisers in a natural, cost-effective, degradable, and environment-friendly way; additionally, they promote mineral recirculation and increase global food safety potential by increasing crop productivity and soil fertility in a shorter period of time. Along these, anaerobic digestates provide several benefits, including a low carbon footprint, the ability to manufacture locally with relatively low manufacturing costs, and the ability to reduce greenhouse gas emissions. The United Kingdom frequently spends more than £250 million per year on synthetic fertilisers. The authors also noted that substituting digestate for one tonne of synthetic fertiliser saves nearly 108 tonnes of water and 4 tonnes of carbon dioxide equivalent.

Timonen et al. (2019) stated that considering the climate potential and credits of the anaerobic digestate is extremely important, the matter which is allocated mainly for energy production and use. The authors reported that the storage, transportation, and use of digestate biofertiliser on-farm produced more greenhouse gases than mineral fertiliser used on-farm. Nonetheless, total anaerobic digestion cycle emissions up to digestate utilisation were significantly reduced compared to mineral fertiliser generation and field application. By substituting digestate for inorganic fertiliser, the agroecosystem shifted from 2.7 tonnes of carbon dioxide equivalent/square metric hectare/year to 8.8 tonnes of carbon dioxide equivalent/square metric hectare/year carbon sink (Liu et al. 2015).

Challenges facing biogas systems

Numerous countries recognise the critical role of biogas system expansion due to the sustainability transition, energy demand, and climate change mitigation. Nonetheless, global biogas production is still relatively low, with only 5% of generated biogas being used to generate biomethane, whereas complete utilisation of organic wastes for biomethane generation could meet 20% of global gas demand (Golmakani et al. 2022; IEA 2020). Indeed, this sector faces several major obstacles limiting the biogas sector's ability to achieve the objectives mentioned above. The following are the major barriers to the widespread use of biogas globally: technical considerations, economic constraints, market opportunity, institutional constraints, and sociocultural considerations (Nevzorova and Kutcherov 2019). This section focuses on the technical barrier facing the widespread adoption of biogas plants.

Impurities in biogas are a significant issue, affecting both uptake and utilisation, as well as the performance of biogas equipment. Carbon monoxide, water vapour, hydrogen sulphide, nitrogen gas, oxygen, ammonia, and siloxanes, in particular, may present difficulties, including toxicity, corrosion, and a decrease in the heating value of biogas (Khan et al. 2021; Bragança et al. 2020).Hydrogen sulphide is frequently the cause of the corrosion, and hydrogen sulphide presence in biogas at concentrations greater than 800 mg/l can result in unconsciousness, respiratory palsy, or even death. The siloxanes are converted to silica during biogas ignition, which initiates abrasion of the vehicle's spark plugs, cylinder heads, and valve heads. Water vapour in biogas causes severe corrosion when water reacts with hydrogen sulphide, ammonia, and carbon dioxide, resulting in the formation of acid (Golmakani et al. 2022; Muñoz et al. 2015). Besides, the presence of carbon dioxide in the biogas produced is another major challenge. Huang et al. (2016) reported that injecting raw biogas containing impurities into the gas pipe system decreased biogas heating value due to the presence of the carbon dioxide, could block the pipes network due to the existence of dust, and might damage and clog equipment and pipe systems due to the presence of liquid water, which may freeze at low temperatures. The presence of solid sol could block the compressors, valves, and other facilities. The hazards of impurities to biogas facilities summarise in Table 4.

Carbon dioxide is more abundant in biogas than any other impurity. The heating value of raw biogas is approximately 5000 kcal/normal cubic metre, with a methane content of 60% (volume/volume). After carbon dioxide and other impurities such as water and hydrogen sulphide are removed, the residual gas is identified as biomethane, which has properties similar to purified natural gas. As a result, this value would be increased to levels comparable to natural gas (8000 kcal/normal cubic metre) when biogas is upgraded to biomethane with a concentration greater than 96% (Tabatabaei et al. 2020). Hence, the calorific value and valorising degree of biogas are mainly dependent on the methane content; hence, removing carbon dioxide considerably improves the calorific value of biogas.

Among several technical difficulties, infrastructural difficulties are a frequent critical barrier. The limited transportation infrastructure for gas-fuelled vehicles, in particular, makes the transportation sector more difficult to reach a fossil-free vehicle station, restricting biogas expansion (Nevzorova and Kutcherov 2019). Additionally, the shortages of pipelines connected to the grid systems, as well as challenges such as suitable waste collection, waste segregation, and storage, impede the utilisation and distribution of biogas (Chien Bong et al. 2017; Mittal et al. 2018).

In Latin America, household biodigesters are completely reliant on locally generated organic waste. Nonetheless, feedstock collection, construction resources, and digestate flow are not always feasible in remote and rural areas due to difficult or lengthy transportation routes (Einarsson and Persson 2017; Garfí et al. 2016). Thus, establishing suitable land for installing biogas equipment alongside an adequate number of livestock to supply feedstock in rural and developing countries is critical. Other obstacles, such as a lack of available local biogas facilities, could increase imported equipment's investment and maintenance costs (Kamp and Forn 2016; Hoo et al. 2018). Additionally, a lack of knowledge about the proper use and fertilisation of digestate hinders the successful use of biofertiliser and biogas; thus, farmers should be trained and educated on the proper use of feedstock for biofertiliser production (Uddin et al. 2016). Continuous training in the operation and maintenance of digesters is critical to ensuring an efficient supply of energy to households, as is knowledge of the safety and limitations of biogas plants (Garfí et al. 2016). The detailed challenges associated with digestate utilisation are discussed in Sect. 2.

Summary

Carbon capture and storage technologies can actively revert greenhouse gas emissions by locking the carbon contained in bio-carbon dioxide away from the atmosphere. Anaerobic digestion plants have the potential to become a carbon hub, concentrating atmospheric carbon within a digester and preparing carbon for permanent storage within materials or underground. At full capacity, the global industry would generate over 12,500 terra watt-hours of biogas, equivalent to 1560 million tonnes of carbon dioxide. Additionally, by collecting all available wastes and digesting them anaerobically for biogas generation, greenhouse gas emissions can be reduced by 3.29 to 4.36 billion tonnes of carbon dioxide equivalent, or 10–13% of global greenhouse gas emissions. Due to the potential role of anaerobic digestion technologies in establishing a global green economy, both waste management decarbonisation and fossil fuel defossilisation would be achieved by 2030, enabling the implementation of nine of the seventeen Sustainable Development Goals (SDGs).

Transportation accounts for 29% of global carbon dioxide emissions, the vast majority of which result from fossil fuel combustion. Transportation powered by biomethane has the potential to significantly reduce fossil fuel consumption and greenhouse gas emissions. Technically, fossil-fuelled natural gas could simply be substituted with biomass-derived biomethane, either liquefied or compressed.

The utilisation of biomethane in the transportation sector has several advantages: (1) biomethane is produced from organic biomass, which has nearly identical properties to natural gas; (2) biomethane produced by biogas plants can be produced and used locally, thereby avoiding the difficulties associated with natural gas importation, particularly in Europe (Eurostat 2022); and (3) employing biomethane in transportation systems would provide a carbon-saving option and effectively reduce climate change by 50–246% to gasoline- and diesel-fueled vehicles, depending on the calculations and well-to-wheel life cycles used, whereas fossil natural gas would reduce greenhouse gas emissions by 10–15% when compared to gasoline. Renewable liquefied biomethane is expected to significantly positively affect the climate. However, cost-effective small-scale liquified biomethane schemes require further development.

The extensive use of inorganic fertilisers has resulted in risks to human health and the environment, such as a high carbon footprint. Digestate can assist in reducing the demand for mineral fertilisers by recovering nutrients from organic waste. As a result, digestate reduces our reliance on fossil natural gas, the need to transport these fertilisers globally, and all associated emissions. When one tonne of mineral fertiliser is replaced by one tonne of natural fertiliser, natural fertiliser could save one tonne of oil, 108 tonnes of water, and 5–9 tonnes of carbon dioxide equivalent emissions.

Some recommendations and prospects are obtained

-

Biogas should not be measured solely in terms of the cost of a kilowatt-hour or megajoule of heat but rather in terms of the overall beneficial outcomes for environmental services and wider human benefits.

-

Carbon is the most effective way to quantify all anaerobic digestion's environmental benefits. Carbon trading schemes, carbon taxes, or emissions limits, all increase the carbon gain value. As a result, any policy aimed at decarbonisation will positively contribute to the development of anaerobic digestion, and anaerobic digestion will positively contribute to decarbonisation.

-

Incentives should be used to encourage sustainable agriculture, particularly in terms of carbon emissions reduction.

-

Large-scale liquefied biomethane production should be subsidised to offset fossil fuel consumption and meet environmental standards.

Biogas upgrading

Biogas has the potential to be classified as a carbon sink renewable energy source because biogas derives the carbon from organic sources (livestock manure, sludge, food wastes, household organic waste, and agricultural residues), thereby lowering atmospheric carbon dioxide levels (Esposito et al. 2019). The biogas produced by organic biomass digestion was primarily composed of methane (40–75%) and carbon dioxide (15–60%), with a small amount of trace gases such as hydrogen sulphide (0.005–2%), nitrogen (0–2%), water vapour (5–10%), and other traces (Kapoor et al. 2019; Mahmudul et al. 2021).

Methane is the bioenergy-rich element in biogas, whereas other undesirable components reduce the sophisticated biogas utilisation as follows: (1) The presence of biogas contaminants, particularly the carbon dioxide, reduces the calorific value of biogas (around 20–25 MJ/cubic metre compared to 30–35 MJ/cubic metre of the natural gas), and substantially reduces the gas cylinder’s volumetric capacity, thereby allowing the generated biogas to be used for low energy utilisation applications, e.g. cooking (Golmakani et al. 2022; Muñoz et al. 2015; Angelidaki et al. 2019). (2) Due to the limited infrastructure within biogas facilities, biogas is typically stored for a short period of time (a few hours), and as a result, biogas is typically stored under high pressure, a condition that results in the transformation of carbon dioxide, if present, obstructing biogas transportation (Kapoor et al. 2019; Angelidaki et al. 2018). (3) The presence of destructive hydrogen sulphide in raw biogas may cause significant damage to gas engines through sulphur dioxide emissions following ignition (Angelidaki et al. 2018). Thus, sequestering or removing carbon dioxide from raw biogas would reduce carbon dioxide emissions from anaerobic digestion systems, contribute to greenhouse gas mitigation, and have a greater positive environmental impact.

In many countries, households use raw biogas for heating and cooking without or with little monitoring of impurity effects. However, a more beneficial application of biogas is in the generation of electricity, transportation biofuel, natural gas substitute, and substrate for the chemical industry (Khan et al. 2021; Nguyen et al. 2021), and solid oxide fuel cells (SOFCs) or micro turbines applications (Saadabadi et al. 2019), which achieved via upgrading of biogas to biomethane. Due to the technical and environmental risks associated with impurities, several countries have proposed regulations governing biogas injection into natural gas grids, with a minimum methane content of more than 95% in many cases (Angelidaki et al. 2019). The European biomethane standards for transportation fuel and grid injection require hydrogen sulphide concentrations to be less than 1 part per million and siloxanes concentrations to be less than 0.5 mg/normal cubic metre for grid injection and transportation fuel (Nguyen et al. 2021).

Numerous concise definitions exist for the biogas purification process: (1) biogas cleaning refers to the removal of other undesirable impurities (hydrogen sulphide, siloxanes, and ammonia, among others) that are harmful to gas grids or end-appliances; hydrogen sulphide cleaning is sometimes referred to as biogas desulphurisation; and (2) biogas upgrading refers to the removal of carbon dioxide from raw biogas in order to maximise the biomethane value of the final yield gas or the conversion of carbon (Angelidaki et al. 2019). After biogas upgrading, the final product is referred to as biomethane, which contains 95–99% methane. Germany and Sweden have the world's largest markets for biomethane. Other countries, particularly the United Kingdom, Switzerland, and France, are paying increasing attention (Nguyen et al. 2021).

The global market for biomethane was valued at $0.62 billion in 2017, and with a 26% annual growth rate, the market is expected to reach $4.96 billion by 2026. Numerous countries have established targets for replacing natural gas with biomethane in residential applications (Hoo et al. 2020). For instance, France intends to support 8 TW-h of biomethane production by 2023 (Herbes et al. 2018). The United Kingdom aims to use biomethane as the primary source of green gas in the future. On the other hand, the obtained biomethane can be compressed or liquefied to make biomethane more efficient in storage and transportation fuel. Liquefied biomethane is suitable for use in large vehicles, has a higher energy content, and has a long transport range. Recently, awareness of the benefits of liquified biomethane as a transportation fuel has grown. Sweden, for example, has set a target of using % biomethane-based transportation fuel by 2030.

Additionally, according to the European biomethane map, the total number of biomethane plants in Europe has doubled from 483 in 2018 to 729 in 2020. At the moment, 18 European countries produce biomethane. Germany has the most biomethane plants with 232, followed by France with 131 and the United Kingdom with 80 (EBA 2020). Around 47% of active biomethane plants in Europe are connected to the network grid, while 20% are connected to the transport grid. 10% of European biomethane plants are not connected to the grid, and information on the remaining 23% of plants is unavailable (EBA 2020). Figure 3 summarises the number of biomethane plants. In addition to the biogas purifications to meet the end-uses requirements, the removal and utilisation or storage of carbon dioxide can potentially decarbonise biogas or make biogas a carbon-negative energy resource.

Biogas upgrading plants and commercially available technologies (Bioenergy 2020). According to the European biomethane map in 2020, there are about 677 biomethane plants. Germany is the leading country with 203 biomethane plants, followed by the United Kingdom (96) and Sweden (69), as shown in a. Around 29% of the biomethane plants currently rely on water scrapping, 26% on membrane separation, and 16% on chemical scrubbing (b). Almost, biomethanation plants are present in Europe

Biogas upgrading technologies

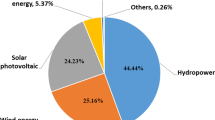

Nowadays, several upgrading technologies aim to remove unwanted carbon dioxide from biogas to broaden the application range of biogas. These physical/chemical technologies, including water, organic, and chemical scrubbing, membrane separation, pressure swing adsorption, cryogenic separation, and biological-based methods, are widely used commercially. Scrubbers for water/chemicals, membrane separation, and pressure swing are well-established and widely used, accounting for more than 74% of the total market (Fig. 3), while in recent years, the biological biogas upgrading method has been proposed (Fu et al. 2021). The optimal approach for upgrading raw biogas depends entirely on the biogas end-use, the efficiency of the upgrade, and the economics involved.

Different microbial pathways exist for biogas upgrading via hydrogen injection. Hydrogen injection into the anaerobic digestion bioreactor facilitated the hydrogenotrophic methanogens' utilisation of carbon dioxide to produce biomethane. Additionally, the Homoacetogens can convert carbon dioxide to acetate, which is primarily consumed by acetoclastic methanogens in methane production. Syntrophic relationships between bacteria and archaea are critical for system stability

Scrubbing technologies

Water scrubbing has traditionally been based on the differences in the solubility of carbon dioxide and methane gas in the washing solution. Water (water scrubbing) or an organic solvent such as polyethylene glycol dimethyl ether (organic scrubbing) may be used as the washing solution. Carbon dioxide is 26 times more soluble in water than methane at 25 °C. Scrubbing methods frequently lack chemical reactions (physical process). Since gas solubility increases as pressure increases, pretreated biogas can be pressurised and introduced into the scrubbing column (Nguyen et al. 2021).

Hydrogen sulphide is first removed from raw biogas using a scrubber in the water scrubber method. The desulphurised biogas is then compressed to approximately 4–6.5 bar and delivered from the bottom side of the washing column to meet the injected water from the top. Carbon dioxide is absorbed by water, while biomethane diffuses from the top of the washing column. After drying the biomethane, biomethane is purified using an activated carbon filter to remove volatile organic carbon and then compressed into the gas grid (Ardolino et al. 2021). The carbon dioxide-rich water wash is injected into a stripping column, which uses atmospheric pressure air to remove carbon dioxide from the water (i.e. water reusable) (Nguyen et al. 2021). Water scrubbing technology is more than 98% effective at removing carbon dioxide (Angelidaki et al. 2018).

Organic scrubbing is similar to water scrubbing, but organic scrubbing purifies raw biogas using organic solvents such as propanol and polyethylene glycol. This is a more efficient process than water scrubbing because carbon dioxide dissolves more readily in an organic solvent than in water. This process yields 93–98% biomethane (Nguyen et al. 2021; Mulu et al. 2021; Singhal et al. 2017).

Chemical scrubbing is typically carried out with solvents derived from common organic amines such as methyldiethanolamine, diethanolamine, monoethanolamine, and diglycolamine (Nguyen et al. 2021). In principle, the operation is similar to that of water scrubbing; however, amine solvents have a higher absorption efficiency for carbon dioxide than water per unit volume, making them more effective at removing larger amounts of carbon dioxide and thus requiring smaller upgrading units (Ardolino et al. 2021). Due to the fact that the chemical adsorbent method is only reactive with carbon dioxide, methane leakage is minimal (0.1–0.2%) (Sun et al. 2015). As a result, post-combustion of the lean gas is unnecessary. Additionally, chemical scrubbing can produce methane with a purity of 99%. However, hydrogen sulphide must be removed upstream to avoid a degradative and corrosive reaction with the amine solution (Nguyen et al. 2021).

Pressure swing adsorption

This method utilises a porous medium to adsorb the target molecule from an injected gas; the adsorbed molecule is then released using a high-pressure value (Ntiamoah et al. 2016). By considering the various molecular dimensions of methane (0.38 nm) and carbon dioxide (0.34 nm), pressure swing adsorption units can be used to upgrade biogas (Ardolino et al. 2021). Consequently, filling an adsorbent substrate, such as activated carbons and zeolites with pore sizes of 0.37 nm in a column can retain carbon dioxide within the pores, while methane flows freely without being retained (Nguyen et al. 2021; Ardolino et al. 2021). Hydrogen sulphide removal from the upstream biogas is required in this method, as hydrogen sulphide is permanently removed by the adsorption material and has toxic effects.

The pressure swing method is accomplished by compressing the pretreated raw biogas to 4–8 bar and then injecting biogas into the sorption column via a bottom inlet. Thus, the smaller carbon dioxide molecules accumulate on the adsorption surfaces or are retained in the pores, whereas the larger methane molecules remain primarily in the gas phase and exit the column top as a biomethane-rich byproduct gas. Once the methane is released, the column pressure decreases to atmospheric pressure, releasing adsorbed carbon dioxide from the material surfaces and converting carbon dioxide to gas. The carbon dioxide-rich exhaust gas is vented through a valve located at the column's base. The column is then injected with biogas to initiate a new cycle of upgrading (Nguyen et al. 2021).

Membrane separation technology

The membrane separation technique is based on the theory that biogas permeates through a different membrane pores selectivity, where the membrane is highly permeable (20 times more permeable) to a small molecule (carbon dioxide) and impermeable to a large molecule (methane) (Nguyen et al. 2021). The permeated carbon dioxide is extremely pure (99.9%, particularly at − 30 °C for separation of oxygen, nitrogen, and residual methane) and can be used in the beverage and food industries (Esposito et al. 2019), or carbon dioxide can be liquefied or compressed for use in other ways (Nguyen et al. 2021).

Membrane permeation occurs in various designs, with operating pressures ranging from 7 to 36 bars (Kapoor et al. 2019; Peppers et al. 2019). The membrane can be designed in two-stage cascades to achieve high methane purity. Where the gas can be returned from the first membrane to the inlet via a circulation loop, while the methane-enriched gas flows into the second membrane (Nguyen et al. 2021).

Cryogenic treatment

The principle of cryogenic technology stems from the fact that gases condense differently at high pressure or low temperature. Carbon dioxide can solidify at − 78.5 °C and 1 bar, whereas methane remains gaseous. As a result, gaseous methane can be easily separated from solidified carbon dioxide. Cryogenic treatment can achieve up to 99.9% methane or carbon dioxide purity with less than 1% methane loss.

However, the increased energy demand for refrigeration and compression of the gas is the primary constraint to this technology, as the required energy consumption accounts for 10% of the generated methane. Additionally, preventing frozen carbon dioxide from clogging the equipment and removing biogas impurities are critical issues (Nguyen et al. 2021); thus, this technology is not yet been fully established (Nguyen et al. 2021). Utilising biomethane as a liquefied biomethane (− 125 °C and 15 bar), and selling frozen carbon dioxide as dry ice, can help this technology consume less energy and overcome some of the biomethane limitations (Esposito et al. 2019), thereby increasing biomethane commercial viability.

Overall, the operational requirements of different biogas upgrading methods are listed in Table 5.

Drawbacks of traditional biogas upgrading methods

Traditional biogas upgrading technologies are widely used and account for approximately 99% of all biogas upgrading plants (Khan et al. 2021). Nonetheless, these technologies have a number of limitations that may result in an increase in the cost of upgrading raw biogas. For instance, a water scrubber, which is frequently used in 41% of biogas upgrading plants, consumes enormous amounts of water (each 1000 normal cubic metre/hour gas flow consumes 200 cubic metres/hour of water); thus, regenerating water significantly increases the cost of water treatment (Sun et al. 2015; Hoyer et al. 2016). Additionally, the water scrubbing technique can result in up to 3% or more methane loss, and exhaust gas combustion is required for emission regulation (Ardolino et al. 2021). Water scrubbing may be economically viable when applied at wastewater treatment plants where effluents from the secondary and tertiary treatment stages are used as non-regenerating water resources (Angelidaki et al. 2018).