Abstract

Grafting is one of the best method for the modification of physicochemical properties of the cellulose. The –OH groups present at C2, C3, and C6 atoms of each β-d-glucopyranose units of cellulose chains are the most susceptible active sites for the grafting of many monomer units or polymers for the formation of a variety of cellulose-based graft copolymers with advanced properties and potential applications as compared to the bare cellulose. In this review article, a brief introduction to get an insight into the structural features of cellulose is given. After that, the potential applications and recent advancements of various cellulose graft copolymers made in fields of controlled drug delivery, adsorption of harmful, toxic and non-biodegradable dyes from industrial effluents, sorption of heavy metal ions from aqueous medium, modification of electrolyte, electrodes and separators of the modern age Lithium ion batteries, and fabrication of smart and innovative food packaging materials are reviewed.

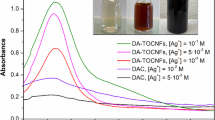

Graphical abstract

[Reprinted with permission from Ref. [18], © 2009 Elsevier Ltd.]

[Reprinted with permission from Ref [34], © The Royal Society of Chemistry 2014]

[Reprinted with permission from Ref [35], ©2014 Elsevier Ltd]

[Reprinted with permission from Ref [55], © 2013 American Chemical Society]

[Reprinted with permission from Ref. [61], © 2016 Elsevier Ltd.]

Similar content being viewed by others

Abbreviations

- AA:

-

Acrylic acid

- AA-g-CLCF:

-

Acrylic acid-g-cellulosic Luffa cylindrical fiber

- AAm:

-

Acrylamide

- AAm-g-HEC:

-

Acrylamide-g-hydroxyethylcellulose

- AASO3H:

-

2-Acrylamido-2-methylpropane sulfonic acid

- AB-93:

-

Acid blue-93

- ABCN:

-

Azobiscyclohexanecarbonitrile

- AN:

-

Acrylonitrile

- ASA:

-

Aminosalicylic acid

- ATPR:

-

Atom transfer radical polymerization

- BC-g-PAA:

-

Bacterial cellulose-g-poly(acrylic acid)

- BEMA:

-

Bisphenol A ethoxylate (15 EO/phenol) dimethacrylate

- BF:

-

Basic fuchsine

- BGE-g-HEC:

-

Butyl glycidyl ether-g-hydroxyethyl cellulose

- BOD:

-

Biological oxygen demand

- BSA:

-

Bovine serum albumin

- CAN:

-

Ceric ammonium nitrate

- CCDA:

-

Cross-linked cellulose dialdehyde

- CD:

-

Cyclodextrin

- Cell-g-PAA-co-AM:

-

Cellulose-g-poly(acrylic acid-co-acrylamide)

- Cell-g-PAm/HBH:

-

Cellulose-g-polyacrylamide/hydroxyapatite biocomposite hydrogel

- CipHCl:

-

Ciprofloxacin hydrochloride

- CMC:

-

Carboxy methyl cellulose

- CMC-g-HPAM:

-

Hydrolyzed polyacrylamide-g-carboxymethyl cellulose

- CMC-g-PAAm:

-

Carboxymethyl cellulose-g-polyacrylamide

- CMC-g-PDMAEMA:

-

Carboxymethyl cellulose-g-poly(dimethylaminoethyl methacrylate)

- CMC-g-PDMAEMA:

-

Carboxymethylcellulose-g-poly(2-(dimethylamino) ethylmethacrylate)

- CMC-g-PHEA:

-

Carboxymethyl cellulose-g-poly(hydroxyethyl acrylate)

- COD:

-

Chemical oxygen demand

- CR:

-

Congo red

- CRP:

-

Controlled radical polymerization

- CV:

-

Crystal violet

- DAA:

-

N,N-Dimethylacetamide

- EC:

-

Ethyl cellulose

- EC–DEC:

-

Ethylene carbonate–diethyl carbonate

- EC-g-PDEAEMA:

-

Ethyl cellulose-g-poly(2-(diethylamino) ethyl methacrylate)

- EC-g-PHEMA-g-PSPMA:

-

Ethylcellulose-g-poly(2-hydroxyethyl methacrylate)-g-poly(spiropyran ether methacrylate)

- EC-g-PPEGMA:

-

Ethyl cellulose-g-poly(poly(ethylene glycol) methyl ether methacrylate)

- ECH:

-

Epichlorohydrin

- EE:

-

Encapsulation efficiency

- GA:

-

Glycidyl acrylate

- GMA:

-

Glycidyl methacrylate

- GMA/DTPA-g-cellulose:

-

Glycidyl methacrylate/diethylenetriamine pentaacetic acid-g-cellulose

- HEC-g-LANM:

-

Hydroxyethylcellulose-g-linoleic acid nano micelles

- HEMA:

-

2-Hydroxy methacrylate

- HPC:

-

Hydroxypropylcellulose

- HPMC-g-PAM:

-

Hydroxypropyl methyl cellulose-g-polyacrylamide

- KET:

-

Ketoprofen

- LCST:

-

Lower critical solution temperature

- LE:

-

Loading efficiency

- MA/Aam-g-LCF:

-

Methyl acrylate/acrylamide-g-Luffa cylindrical fiber

- MB:

-

Methylene blue

- MBA:

-

N,N′-Methylene bisacrylamide

- MCA-E0.7/CMC-g-PDMDAAC:

-

Monochloroacetic acid-modified epichlorohydrin cross-linked carboxymethyl cellulose-g-dimethyl diallyl ammonium chloride

- MC-g-A/GM:

-

Methyl cellulose-g-acrylamide/gelatin microspheres

- MFC:

-

Microfibrillated cellulose

- MG:

-

Malachite green

- MMA:

-

Methyl methacrylate

- MO:

-

Methyl orange

- NaPAA-g-CMC:

-

Poly(acrylic acid sodium)-g-carboxymethyl cellulose

- NFC:

-

Nanofibrillated cellulose

- NFD:

-

Nifedipine

- NMP:

-

Nitroxide-mediated polymerization

- NR:

-

Nile red

- ODDMAC:

-

Octadecyldimethyl (3-trimethoxysilylpropyl) ammonium chloride

- OR-II:

-

Orange red-II

- PAA:

-

Poly(acrylic acid sodium)

- PAM:

-

Polyacrylamide

- PBS:

-

Phosphate buffer solution

- PDEAEMA:

-

Poly(2-(diethylamino) ethyl methacrylate)

- PE:

-

Polyethylene

- PEGMA:

-

Poly(ethylene glycol) methyl ether methacrylate)

- PNIPAAm:

-

Poly(N-isopropylacrylamide)

- PP:

-

Polypropylene

- PSPMA:

-

Poly(spiropyran ether methacrylate)

- PTFE:

-

Poly(tetrafluoroethylene)

- PVC:

-

Polyvinyl chloride

- PVDF-HPF:

-

Poly(vinylidene fluoride-co-hexafluoropropylene)

- RAFT:

-

Reversible addition fragmentation chain transfer

- RB-2:

-

Reactive blue-2

- RIF:

-

Rifampicin

- ROP:

-

Ring-opening polymerization

- SET-LRP:

-

Single-electron transfer living radical polymerization

- SPMA:

-

Spiropyran ether methacrylate

- THA:

-

Theophylline

- THF:

-

Tetrahydrofuran

References

Anwar Z, Gulfraz M, Irshad M (2014) Agro-industrial lignocellulosic biomass a key to unlock the future bio-energy: a brief review. J Radiat Res Appl Sci 7:163–173. doi:10.1016/j.jrras.2014.02.003

Bali G, Meng X, Deneff JI, Sun Q, Ragauskas AJ (2015) The effect of alkaline pretreatment methods on cellulose structure and accessibility. Chemsuschem 8:275–279. doi:10.1002/cssc.201402752

Habibi Y, Lucia LA, Rojas OJ (2010) Cellulose nanocrystals: chemistry, self-assembly, and applications. Chem Rev 110:3479–3500. doi:10.1021/cr900339w

Koh J (2011) Dyeing of cellulosic fibres. In: Clark M (ed) Handbook of Textile and industrial dyeing. Woodhead Publishing Limited, Sawston, pp 129–146

Oehme DP, Downton MT, Doblin MS, Wagner J, Gidley MJ, Bacic A (2015) Unique aspects of the structure and dynamics of elementary iβ cellulose microfibrils revealed by computational simulations. Plant Physiol 168:3–17. doi:10.1104/pp.114.254664

Hansson S, Trouillet V, Tischer T, Goldmann AS, Carlmark A, Barner-Kowollik C, Malmström E (2013) Grafting efficiency of synthetic polymers onto biomaterials: a comparative study of grafting- from versus grafting- to. Biomacromolecules 14:64–74. doi:10.1021/bm3013132

Carlmark A (2013) Tailoring cellulose surfaces by controlled polymerization methods. Macromol Chem Phys 214:1539–1544. doi:10.1002/macp.201300272

Roy D, Semsarilar M, Guthrie JT, Perrier S (2009) Cellulose modification by polymer grafting: a review. Chem Soc Rev 38:2046–2064. doi:10.1039/b808639g

Bertoldo M, Zampano G, La Terra F, Villari V, Castelvetro V (2011) Amphiphilic amylose-g-poly(meth)acrylate copolymers through “click” onto grafting method. Biomacromolecules 12:388–398. doi:10.1021/bm101143q

Kang H, Liu R, Huang Y (2015) Graft modification of cellulose: methods, properties and applications. Polymer (United Kingdom) 70:A1–A16. doi:10.1016/j.polymer.2015.05.041

Deng J, Wang L, Liu L, Yang W (2009) Developments and new applications of UV-induced surface graft polymerizations. Prog Polym Sci 34:156–193. doi:10.1016/j.progpolymsci.2008.06.002

Bhattacharya A, Misra BN (2004) Grafting: a versatile means to modify polymers: techniques, factors and applications. Prog Polym Sci 29:767–814. doi:10.1016/j.progpolymsci.2004.05.002

Uhrich KE, Cannizzaro SM, Langer RS, Shakesheff KM (1999) Polymeric systems for controlled drug release. Chem Rev 99:3181–3198. doi:10.1021/cr940351u

Fomina N, Sankaranarayanan J, Almutairi A (2012) Photochemical mechanisms of light-triggered release from nanocarriers. Adv Drug Deliv Rev 64:1005–1020. doi:10.1016/j.addr.2012.02.006

Wang D, Tan J, Kang H, Ma L, Jin X, Liu R, Huang Y (2011) Synthesis, self-assembly and drug release behaviors of pH-responsive copolymers ethyl cellulose-graft-PDEAEMA through ATRP. Carbohydr Polym 84:195–202. doi:10.1016/j.carbpol.2010.11.023

Mohd Amin MCI, Ahmad N, Halib N, Ahmad I (2012) Synthesis and characterization of thermo- and pH-responsive bacterial cellulose/acrylic acid hydrogels for drug delivery. Carbohydr Polym 88:465–473. doi:10.1016/j.carbpol.2011.12.022

Tan J, Li Y, Liu R, Kang H, Wang D, Ma L, Liu W, Wu M, Huang Y (2010) Micellization and sustained drug release behavior of EC-g-PPEGMA amphiphilic copolymers. Carbohydr Polym 81:213–218. doi:10.1016/j.carbpol.2010.02.017

Chang C, Duan B, Cai J, Zhang L (2010) Superabsorbent hydrogels based on cellulose for smart swelling and controllable delivery. Eur Polym J 46:92–100. doi:10.1016/j.eurpolymj.2009.04.033

Kajjari PB, Manjeshwar LS, Aminabhavi TM (2011) Semi-interpenetrating polymer network hydrogel blend microspheres of gelatin and hydroxyethyl cellulose for controlled release of theophylline. Ind Eng Chem Res 50:7833–7840. doi:10.1021/ie200516k

Babu VR, Kanth VR, Mukund JM, Aminabhavi TM (2010) Novel methyl cellulose-grafted-acrylamide/gelatin microspheres for controlled release of nifedipine. J Appl Polym Sci 115:3542–3549. doi:10.1002/app.30480

Al-Kahtani AA, Sherigara BS (2014) Controlled release of diclofenac sodium through acrylamide grafted hydroxyethyl cellulose and sodium alginate. Carbohydr Polym 104:151–157. doi:10.1016/j.carbpol.2014.01.018

Wang B, Chen K, Yang R, Yang F, Liu J (2014) Stimulus-responsive polymeric micelles for the light-triggered release of drugs. Carbohydr Polym 103:510–519. doi:10.1016/j.carbpol.2013.12.062

Moghaddam PN, Avval ME, Fareghi AR (2014) Modification of cellulose by graft polymerization for use in drug delivery systems. Colloid Polym Sci 292:77–84

Salama A, El-Sakhawy M, Kamel S (2016) polymer. Int J Biol Macromol 93:1647–1652. doi:10.1016/j.ijbiomac.2016.04.029

Yang Y, Guo Y, Sun R, Wang X (2016) Self-assembly and β-carotene loading capacity of hydroxyethyl cellulose-graft-linoleic acid nanomicelles. Carbohydr Polym 145:56–63

Das R, Pal S (2013) Hydroxypropyl methyl cellulose grafted with polyacrylamide: application in controlled release of 5-amino salicylic acid. Colloids Surf B Biointerfaces 110:236–241. doi:10.1016/j.colsurfb.2013.04.033

Singh DJ, Jain RR, Soni PS, Abdul S, Darshana H, Gaikwad RV, Menon MD (2015) Preparation and evaluation of surface modified lactose particles for improved performance of fluticasone propionate dry powder inhaler. J Aerosol Med Pulm Drug Deliv 28:254–267. doi:10.1089/jamp.2014.1146

Muñoz-García RO, Hernández ME, Ortiz GG, Fernández VV, Arellano MR, Sánchez-Díaz JC (2015) A novel polyacrylamide-based hydrogel crosslinked with cellulose acetate and prepared by precipitation polymerization. Quim Nova 38:1031–1036

Young PM, Wood O, Ooi J, Traini D (2011) The influence of drug loading on formulation structure and aerosol performance in carrier based dry powder inhalers. Int J Pharm 416:129–135. doi:10.1016/j.ijpharm.2011.06.020

Hu J, Li HY, Williams GR, Yang HH, Tao L, Zhu LM (2016) Electrospun poly(N-isopropylacrylamide)/ethyl cellulose nanofibers as thermoresponsive drug delivery systems. J Pharm Sci 105:1104–1112. doi:10.1016/S0022-3549(15)00191-4

Lin X, Tang D, Cui W, Cheng Y (2012) Controllable drug release of electrospun thermoresponsive poly(N-isopropylacrylamide)/poly(2-acrylamido-2-methylpropanesulfonic acid) nanofibers. J Biomed Mater Res Part A 100A:1839–1845. doi:10.1002/jbm.a.34142

Jabbour L, Gerbaldi C, Chaussy D, Zeno E, Bodoardo S, Beneventi D (2010) Microfibrillated cellulose–graphite nanocomposites for highly flexible paper-like Li-ion battery electrodes. J Mater Chem 20:7344. doi:10.1039/c0jm01219j

Jabbour L, Bongiovanni R, Chaussy D, Gerbaldi C, Beneventi D (2013) Cellulose-based Li-ion batteries: a review. Cellulose 20:1523–1545. doi:10.1007/s10570-013-9973-8

Chiappone A, Nair J, Gerbaldi C, Zeno E, Bongiovanni R (2014) Flexible and high performing polymer electrolytes obtained by UV-induced polymer–cellulose grafting. RSC Adv 4:40873–40881. doi:10.1039/C4RA07299E

Chiappone A, Nair JR, Gerbaldi C, Zeno E, Bongiovanni R (2014) Cellulose/acrylate membranes for flexible lithium batteries electrolytes: balancing improved interfacial integrity and ionic conductivity. Eur Polym J 57:22–29. doi:10.1016/j.eurpolymj.2014.05.004

Chelmecki M, Meyer WH, Wegner G (2007) Effect of crosslinking on polymer electrolytes based on cellulose. J Appl Polym Sci 105:25–29

Paracha RN, Ray S, Easteal AJ (2012) Grafting of LiAMPS on ethyl cellulose: a route to the fabrication of superior quality polyelectrolyte gels for rechargeable lithium ion batteries. J Mater Sci 47:3698–3705

Mazouzi D, Karkar Z, Hernandez CR, Manero PJ, Guyomard D, Roué L, Lestriez B (2015) Critical roles of binders and formulation at multiscales of silicon-based composite electrodes. J Power Sources 280:533–549. doi:10.1016/j.jpowsour.2015.01.140

Koo B, Kim H, Cho Y, Lee KT, Choi NS, Cho J (2012) A highly cross-linked polymeric binder for high-performance silicon negative electrodes in lithium ion batteries. Angew Chemie Int Ed 51:8762–8767. doi:10.1002/anie.201201568

Ryou MH, Kim J, Lee I, Kim S, Jeong YK, Hong S, Ryu JH, Kim TS, Park JK, Lee H, Choi JW (2013) Mussel-inspired adhesive binders for high-performance silicon nanoparticle anodes in lithium-ion batteries. Adv Mater 25:1571–1576. doi:10.1002/adma.201203981

Wei L, Chen C, Hou Z, Wei H (2016) Poly(acrylic acid sodium) grafted carboxymethyl cellulose as a high performance polymer binder for silicon anode in lithium ion batteries. Sci Rep 6:19583. doi:10.1038/srep19583

Arora P, Zhang Z (2004) Battery separators. Chem Rev 104:4419–4462. doi:10.1021/cr020738u

Zhang SS (2007) A review on the separators of liquid electrolyte Li-ion batteries. J Power Sources 164:351–364. doi:10.1016/j.jpowsour.2006.10.065

Kim M, Han GY, Yoon KJ, Park JH (2010) Preparation of a trilayer separator and its application to lithium-ion batteries. J Power Sources 195:8302–8305. doi:10.1016/j.jpowsour.2010.07.016

Choi J-A, Kim SH, Kim D-W (2010) Enhancement of thermal stability and cycling performance in lithium-ion cells through the use of ceramic-coated separators. J Power Sources 195:6192–6196. doi:10.1016/j.jpowsour.2009.11.020

Zaccaria M, Gualandi C, Fabiani D, Focarete ML, Croce F (2012) Effect of oxide nanoparticles on thermal and mechanical properties of electrospun separators for lithium-ion batteries. J Nanomater. doi:10.1155/2012/216012

Hsu C-H, Chien L-H, Kuo P-L (2016) High thermal and electrochemical stability of a SiO2 nanoparticle hybird-polyether cross-linked membrane for safety reinforced lithium-ion batteries. RSC Adv 6:18089–18095. doi:10.1039/C5RA26694G

Choudhury S, Mangal R, Agrawal A, Archer LA (2015) A highly reversible room-temperature lithium metal battery based on crosslinked hairy nanoparticles. Nat Commun 6:10101. doi:10.1038/ncomms10101

Jeong HS, Lee SY (2011) Closely packed SiO2 nanoparticles/poly(vinylidene fluoride-hexafluoropropylene) layers-coated polyethylene separators for lithium-ion batteries. J Power Sources 196:6716–6722. doi:10.1016/j.jpowsour.2010.11.037

Zhang J, Liu Z, Kong Q, Zhang C, Pang S, Yue L, Wang X, Yao J, Cui G (2013) Renewable and superior thermal-resistant cellulose-based composite nonwoven as lithium-ion battery separator. ACS Appl Mater Interfaces 5:128–134. doi:10.1021/am302290n

Xu Q, Kong Q, Liu Z, Wang X, Liu R, Zhang J, Yue L, Duan Y, Cui G (2014) Cellulose/polysulfonamide composite membrane as a high performance lithium-ion battery separator. ACS Sustain Chem Eng 2:194–199. doi:10.1021/sc400370h

Zahrim AY, Tizaoui C, Hilal N (2011) Coagulation with polymers for nanofiltration pre-treatment of highly concentrated dyes: a review. Desalination 266:1–16. doi:10.1016/j.desal.2010.08.012

Wojnárovits L, Földváry CM, Takács E (2010) Radiation-induced grafting of cellulose for adsorption of hazardous water pollutants: a review. Radiat Phys Chem 79:848–862. doi:10.1016/j.radphyschem.2010.02.006

Kumar R, Kumar G, Umar A (2014) Zinc oxide nanomaterials for photocatalytic degradation of methyl orange: a review. Nanosci Nanotechnol Lett 6:631–650. doi:10.1166/nnl.2014.1879

Roy A, Adhikari B, Majumder SB (2013) Equilibrium, kinetic, and thermodynamic studies of azo dye adsorption from aqueous solution by chemically modified lignocellulosic jute fiber. Ind Eng Chem Res 52:6502–6512

Lee KE, Teng TT, Morad N, Poh BT, Mahalingam M (2011) Flocculation activity of novel ferric chloride-polyacrylamide (FeCl3-PAM) hybrid polymer. Desalination 266:108–113. doi:10.1016/j.desal.2010.08.009

Batmaz R, Mohammed N, Zaman M, Minhas G, Berry RM, Tam KC (2014) Cellulose nanocrystals as promising adsorbents for the removal of cationic dyes. Cellulose 21:1655–1665

Cai T, Yang Z, Li H, Yang H, Li A, Cheng R (2013) Effect of hydrolysis degree of hydrolyzed polyacrylamide grafted carboxymethyl cellulose on dye removal efficiency. Cellulose 20:2605–2614

Gupta VK, Agarwal S, Singh P, Pathania D (2013) Acrylic acid grafted cellulosic Luffa cylindrical fiber for the removal of dye and metal ions. Carbohydr Polym 98:1214–1221. doi:10.1016/j.carbpol.2013.07.019

Gupta VK, Pathania D, Agarwal S, Sharma S (2014) Amputation of congo red dye from waste water using microwave induced grafted Luffa cylindrical cellulosic fiber. Carbohydr Polym 111:556–566. doi:10.1016/j.carbpol.2014.04.032

Kumari S, Mankotia D, Chauhan GS (2016) Crosslinked cellulose dialdehyde for Congo red removal from its aqueous solutions. J Environ Chem Eng 4:1126–1136. doi:10.1016/j.jece.2016.01.008

Liu L, Gao ZY, Su XP, Chen X, Jiang L, Yao JM (2015) Adsorption removal of dyes from single and binary solutions using a cellulose-based bioadsorbent. ACS Sustain Chem Eng 3:432–442

Mahdavinia GR, Bazmizeynabad F (2014) Synthesis of anti-salt hydroxypropyl methylcellulose-polyacrylamide/laponite RD nanocomposite hydrogel and its application to remove cationic dye. Polym Plast Technol Eng 53:411–422

Oladipo AA, Gazi M, Saber-Samandari S (2014) Adsorption of anthraquinone dye onto eco-friendly semi-IPN biocomposite hydrogel: equilibrium isotherms, kinetic studies and optimization. J Taiwan Inst Chem Eng 45:653–664. doi:10.1016/j.jtice.2013.07.013

Salama A, Shukry N, El-Sakhawy M (2015) Carboxymethyl cellulose-g-poly(2-(dimethylamino) ethyl methacrylate) hydrogel as adsorbent for dye removal. Int J Biol Macromol 73:72–75. doi:10.1016/j.ijbiomac.2014.11.002

Tian Y, Ju B, Zhang S, Hou L (2016) Thermoresponsive cellulose ether and its flocculation behavior for organic dye removal. Carbohydr Polym 136:1209–1217. doi:10.1016/j.carbpol.2015.10.031

Lin Q, Gao M, Chang J, Ma H (2016) Adsorption properties of crosslinking carboxymethyl cellulose grafting dimethyldiallylammonium chloride for cationic and anionic dyes. Carbohydr Polym 151:283–294

Zhou Y, Zhang M, Hu X, Wang X, Niu J, Ma T (2013) Adsorption of cationic dyes on a cellulose-based multicarboxyl adsorbent. J Chem Eng Data 58:413–421

Mahmoodi NM, Hayati B, Arami M (2012) Kinetic, equilibrium and thermodynamic studies of ternary system dye removal using a biopolymer. Ind Crops Prod 35:295–301. doi:10.1016/j.indcrop.2011.07.015

Zhou Y, Zhang M, Wang X, Huang Q, Min Y, Ma T, Niu J (2014) Removal of crystal violet by a novel cellulose-based adsorbent: comparison with native cellulose. Ind Eng Chem Res 53:5498–5506. doi:10.1021/ie404135y

Ozacar M, Sengil IA (2005) Adsorption of metal complex dyes from aqueous solutions by pine sawdust. Bioresour Technol 96:791–795. doi:10.1016/j.biortech.2004.07.011

Nandi BK, Goswami A, Das AK, Mondal B, Purkait MK (2008) Kinetic and equilibrium studies on the adsorption of crystal violet dye using kaolin as an adsorbent. Sep Sci Technol 43:1382–1403

Nordberg G, Fowler B, Nordberg M, Friberg L (2007) Handbook on the toxicology of metals. Academic, San Diego. doi:10.1017/CBO9781107415324.004

O’Connell DW, Birkinshaw C, O’Dwyer TF (2008) Heavy metal adsorbents prepared from the modification of cellulose: a review. Bioresour Technol 99:6709–6724. doi:10.1016/j.biortech.2008.01.036

Mudhoo A, Garg VK, Wang S (2012) Removal of heavy metals by biosorption. Environ Chem Lett 10:109–117. doi:10.1007/s10311-011-0342-2

Hokkanen S, Bhatnagar A, Sillanpää M (2016) A review on modification methods to cellulose-based adsorbents to improve adsorption capacity. Water Res 91:156–173. doi:10.1016/j.watres.2016.01.008

Yousif AM, Labib SA (2016) Fabrication of new cellulose-based sorbents for fast and efficient removal of hazardous Al(III) ions from their aqueous solutions. J Dispers Sci Technol 37:565–574

Abdel-Halim ES (2012) Preparation and characterization of poly(acrylic acid)-hydroxyethyl cellulose graft copolymer. Carbohydr Polym 90:930–936. doi:10.1016/j.carbpol.2012.06.022

Wichaita W, Samart C, Yoosuk B, Kongparakul S (2015) Cellulose graft poly(acrylic acid) and polyacrylamide: grafting efficiency and heavy metal adsorption performance. Macromol Symp 354:84–90

Rahman ML, Sarkar SM, Yusoff MM, Abdullah MH (2016) Efficient removal of transition metal ions using poly(amidoxime) ligand from polymer grafted kenaf cellulose. RSC Adv 6:745–757

Anirudhan TS, Nima J, Divya PL (2015) Adsorption and separation behavior of uranium(VI) by 4-vinylpyridine-grafted-vinyltriethoxysilane-cellulose ion imprinted polymer. J Environ Chem Eng 3:1267–1276. doi:10.1016/j.jece.2014.10.006

Zhu L, Zhang L, Tang Y, Ma D, Yang J (2015) Synthesis of kaolin/sodium alginate-grafted poly(acrylic acid-co-2-acrylamido-2-methyl-1-propane sulfonic acid) hydrogel composite and its sorption of lead, cadmium, and zinc ions. J Elastomers Plast 47:488–501

Singha AS, Guleria A (2015) Synthesis and applications of functional polymers from natural okra fibers for removal of Cu(II) Ions from aqueous solution. J Nat Fibers 12:587–603. doi:10.1080/15440478.2014.984049

Abdel-Halim ES, Al-Deyab SS (2012) Chemically modified cellulosic adsorbent for divalent cations removal from aqueous solutions. Carbohydr Polym 87:1863–1868. doi:10.1016/j.carbpol.2011.10.028

Tian Y, Wu M, Liu R, Wang D, Lin X, Liu W, Ma L, Li Y, Huang Y (2011) Modified native cellulose fibers—a novel efficient adsorbent for both fluoride and arsenic. J Hazard Mater 185:93–100. doi:10.1016/j.jhazmat.2010.09.001

Marsh K, Bugusu B (2007) Food packaging? Roles, materials, and environmental issues. J Food Sci 72:R39–R55. doi:10.1111/j.1750-3841.2007.00301.x

Cha DS, Chinnan MS (2004) Biopolymer-based antimicrobial packaging: a review. Crit Rev Food Sci Nutr 44:223–237. doi:10.1080/10408690490464276

Zhang D, Xiao H (2013) Dual-functional beeswaxes on enhancing antimicrobial activity and water vapor barrier property of paper. ACS Appl Mater Interfaces 5:3464–3468. doi:10.1021/am400585m

Qian L, Guan Y, He B, Xiao H (2008) Modified guanidine polymers: synthesis and antimicrobial mechanism revealed by AFM. Polymer (Guildf) 49:2471–2475. doi:10.1016/j.polymer.2008.03.042

Andresen M, Stenius P (2007) Water in oil emulsions stabilized by hydrophobized microfibrillated cellulose. J Dispers Sci Technol 28:837–844. doi:10.1080/01932690701341827

Missoum K, Sadocco P, Causio J, Belgacem MN, Bras J (2014) Antibacterial activity and biodegradability assessment of chemically grafted nanofibrillated cellulose. Mater Sci Eng C Mater Biol Appl 45:477–483. doi:10.1016/j.msec.2014.09.037

Fernandes SCM, Sadocco P, Alonso-Varona A, Palomares T, Eceiza A, Silvestre AJD, Mondragon I, Freire CSR (2013) Bioinspired antimicrobial and biocompatible bacterial cellulose membranes obtained by surface functionalization with aminoalkyl groups. ACS Appl Mater Interfaces 5:3290–3297. doi:10.1021/am400338n

Missoum K, Bras J, Belgacem MN (2012) Organization of aliphatic chains grafted on nanofibrillated cellulose and influence on final properties. Cellulose 19:1957–1973. doi:10.1007/s10570-012-9780-7

Wilson AE, Bergaentzlé M, Bindler F, Marchioni E, Lintz A, Ennahar S (2013) In vitro efficacies of various isothiocyanates from cruciferous vegetables as antimicrobial agents against foodborne pathogens and spoilage bacteria. Food Control 30:318–324. doi:10.1016/j.foodcont.2012.07.031

Saini S, Belgacem MN, Missoum K, Bras J (2015) Natural active molecule chemical grafting on the surface of microfibrillated cellulose for fabrication of contact active antimicrobial surfaces. Ind Crops Prod 78:82–90. doi:10.1016/j.indcrop.2015.10.022

Tankhiwale R, Bajpai SK (2009) Graft copolymerization onto cellulose-based filter paper and its further development as silver nanoparticles loaded antibacterial food-packaging material. Colloids Surf B Biointerfaces 69:164–168. doi:10.1016/j.colsurfb.2008.11.004

Vuoti S, Laatikainen E, Heikkinen H, Johansson LS, Saharinen E, Retulainen E (2013) Chemical modification of cellulosic fibers for better convertibility in packaging applications. Carbohydr Polym 96:549–559. doi:10.1016/j.carbpol.2012.07.053

Wu Y, Luo X, Li W, Song R, Li J, Li Y, Li B, Liu S (2016) Green and biodegradable composite films with novel antimicrobial performance based on cellulose. Food Chem 197:250–256. doi:10.1016/j.foodchem.2015.10.127

Elegir G, Kindl A, Sadocco P, Orlandi M (2008) Development of antimicrobial cellulose packaging through laccase-mediated grafting of phenolic compounds. Enzyme Microb Technol 43:84–92. doi:10.1016/j.enzmictec.2007.10.003

Lee SY, Lee SJ, Choi DS, Hur SJ (2015) Current topics in active and intelligent food packaging for preservation of fresh foods. J Sci Food Agric 95:2799–2810. doi:10.1002/jsfa.7218

Dong C, Ye Y, Qian L, Zhao G, He B, Xiao H (2014) Antibacterial modification of cellulose fibers by grafting β-cyclodextrin and inclusion with ciprofloxacin. Cellulose 21:1921–1932. doi:10.1007/s10570-014-0249-8

Lavoine N, Givord C, Tabary N, Desloges I, Martel B, Bras J (2014) Elaboration of a new antibacterial bio-nano-material for food-packaging by synergistic action of cyclodextrin and microfibrillated cellulose. Innov Food Sci Emerg Technol 26:330–340. doi:10.1016/j.ifset.2014.06.006

Barbiroli A, Bonomi F, Capretti G, Iametti S, Manzoni M, Piergiovanni L, Rollini M (2012) Antimicrobial activity of lysozyme and lactoferrin incorporated in cellulose-based food packaging. Food Control 26:387–392. doi:10.1016/j.foodcont.2012.01.046

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Kumar, R., Sharma, R.K. & Singh, A.P. Grafted cellulose: a bio-based polymer for durable applications. Polym. Bull. 75, 2213–2242 (2018). https://doi.org/10.1007/s00289-017-2136-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-017-2136-6