Abstract

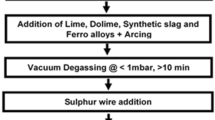

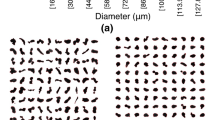

In the long traditional process of steelmaking, excess oxygen is blown into the converter, and alloying elements are used for deoxidation. This inevitably results in excessive deoxidation of products remaining within the steel liquid, affecting the cleanliness of the steel. With the increasing requirements for steel performance, reducing the oxygen content in the steel liquid and ensuring its high cleanliness is necessary. After more than a hundred years of development, the total oxygen content in steel has been reduced from approximately 100 × 10−6 to approximately 10 × 10−6, and it can be controlled below 5 × 10−6 in some steel grades. A relatively stable and mature deoxidation technology has been formed, but further reducing the oxygen content in steel is no longer significant for improving steel quality. Our research team developed a deoxidation technology for bearing steel by optimizing the entire conventional process. The technology combines silicon–manganese predeoxidation, ladle furnace diffusion deoxidation, and vacuum final deoxidation. We successfully conducted industrial experiments and produced interstitial-free steel with natural decarbonization predeoxidation. Non-aluminum deoxidation was found to control the oxygen content in bearing steel to between 4 × 10−6 and 8 × 10−6, altering the type of inclusions, eliminating large particle Ds-type inclusions, improving the flowability of the steel liquid, and deriving a higher fatigue life. The natural decarbonization predeoxidation of interstitial-free steel reduced aluminum consumption and production costs and significantly improved the quality of cast billets.

Similar content being viewed by others

References

R.Y. Yin, Review on the study of metallurgical process engineering, Int. J. Miner. Metall. Mater., 28(2021), No. 8, p. 1253.

Y.J. Wang, H.B. Zuo, and J. Zhao, Recent progress and development of ironmaking in China as of 2019: An overview, Iron-making Steelmaking, 47(2020), No. 6, p. 640.

E. Mousa, Modern blast furnace ironmaking technology: Potentials to meet the demand of high hot metal production and lower energy consumption, Metall. Mater. Eng., 25(2019), No. 2, p. 69.

M. Naito, K. Takeda, and Y. Matsui, Ironmaking technology for the last 100 years: Deployment to advanced technologies from introduction of technological know-how, and evolution to next-generation process, ISIJ Int., 55(2015), No. 1, p. 7.

Z.D. Tang, H.X. Xiao, Y.S. Sun, P. Gao, and Y.H. Zhang, Exploration of hydrogen-based suspension magnetization roasting for refractory iron ore towards a carbon-neutral future: A pilot-scale study, Int. J. Hydrogen Energy, 47(2022), No. 33, p. 15074.

M. Lv, R. Zhu, and L.Z. Yang, High efficiency dephosphorization by mixed injection during steelmaking process, Steel Res. Int., 90(2019), p. 1800454.

C. Liu, L.X. Tang, J.Y. Liu, and Z.H. Tang, A dynamic analytics method based on multistage modeling for a BOF steelmaking process, IEEE Trans. Autom. Sci. Eng., 16(2019), No. 3, p. 1097.

J. Guo, S.S. Cheng, and H.J. Guo, Thermodynamics and industrial trial on increasing the carbon content at the BOF endpoint to produce ultra-low carbon IF steel by BOF–RH–CSP process, High Temp. Mater. Process., 38(2019), No. 2019, p. 822.

S.K. Choudhary and A. Ghosh, Mathematical model for prediction of composition of inclusions formed during solidification of liquid steel, ISIJ Int., 49(2009), No. 12, p. 1819.

P.Y. Dong, S.G. Zheng, and M.Y. Zhu, Numerical study on gas–metal–slag interaction with single-flow postcombustion oxygen lance in the steelmaking process of a top-blown converter, JOM, 74(2022), No. 4, p. 1509.

L. Holappa, Historical overview on the development of converter steelmaking from Bessemer to modern practices and future outlook, Miner. Process. Extr. Metall., 128(2019), No. 1–2, p. 3.

Y.Q. Ji, C.Y. Liu, H.X. Yu, X.X. Deng, F.X. Huang, and X.H. Wang, Oxygen transfer phenomenon between slag and molten steel for production of IF steel, J. Iron Steel Res. Int., 27(2020), No. 4, p. 402.

Z.Y. Deng, M.Y. Zhu, and S.C. Du, Effect of refractory on non-metallic inclusions in Al-killed steel, Metall. Mater. Trans. B, 47(2016), No. 5, p. 3158.

H.B. Yin, H. Shibata, T. Emi, and M. Suzuki, “In-situ” observation of collision, agglomeration and cluster formation of alumina inclusion particles on steel melts, ISIJ Int., 37(1997), No. 10, p. 936.

A. Mehralizadeh, S. Reza Shabanian, and G. Bakeri, Effect of modified surfaces on bubble dynamics and pool boiling heat transfer enhancement: A review, Therm. Sci. Eng. Prog., 15(2020), art. No. 100451.

R.Y. Chen and W.Y.D. Yeun, Review of the high-temperature oxidation of iron and carbon steels in air or oxygen, Oxid. Met., 59(2003), No. 5–6, p. 433.

G.H. Zhang and K.C. Chou, Deoxidation of molten steel by aluminum, J. Iron Steel Res. Int., 22(2015), No. 10, p. 905.

W. Xiao, M. Wang, and Y.P. Bao, The research of low-oxygen control and oxygen behavior during RH process in silicon-deoxidization bearing steel, Metal:, 9(2019), No. 8, art. No. 812.

G.F. Huff, G.R. Bailey, and J.H. Richards, Sampling of liquid steel for dissolved oxygen, JOM, 4(1952), No. 11, p. 1162.

D. Kalisz, P. Migas, M. Karbowniczek, M. Moskal, and A. Hornik, Influence of selected deoxidizers on chemical composition of molten inclusions in liquid steel, J. Mater. Eng. Perform., 29(2020), No. 3, p. 1479.

C.B. Shi, X.C. Chen, H.J. Guo, Z.J. Zhu, and H. Ren, Assessment of oxygen control and its effect on inclusion characteristics during electroslag remelting of die steel, Steel Res. Int., 83(2012), No. 5, p. 472.

E.S. Alley and R.W. Neu, Microstructure-sensitive modeling of rolling contact fatigue, Int. J. Fatigue, 32(2010), No. 5, p. 841.

W. Wang, H.J. Liu, C.C. Zhu, Wei P., and W. Wu, Micromechanical analysis of gear fatigue-ratcheting damage considering the phase state and inclusion, Tribol. Int., 136(2019), p. 182.

Z.M. Ma, S.Z. Dong, H. Zhu, et al., Research on the failure mechanism of the high-speed train bearing steel under static load failure, Eng. Fail. Anal., 137(2022), art. No. 106169.

S.I. Gubenko, Plasticity origin of heterophase inclusions at steel forming, Steel Transi, 50(2020), No. 10, p. 730.

W. Xiao, Y.P. Bao, C. Gu, et al., Ultrahigh cycle fatigue fracture mechanism of high-quality bearing steel obtained through different deoxidation methods, Int. J. Miner. Metall. Mater., 28(2021), No. 5, p. 804.

C. Gu, Z.Y. Lyu, Q. Hu, and Y.P. Bao, Investigation of the structural, electronic and mechanical properties of CaO–SiO2 compound particles in steel based on density functional theory, Int. J. Miner. Metall. Mater., 30(2023), No. 4, p. 744.

L. Wang, B. Song, Z.B. Yang, X.K. Cui, Z. Liu, W.S. Cheng, and J.H. Mao, Effects of Mg and La on the evolution of inclusions and microstructure in Ca–Ti treated steel, Int. J. Miner. Metall Mater., 28(2021), No. 12, p. 1940.

L. Cao, L.G. Zhu, and Z.H. Guo, Research status of inclusions in bearing steel and discussion on non-alloy deoxidation process, J. Iron Steel Res. Int., 30(2023), No. 1, p. 1.

K.W. Lange, Thermodynamic and kinetic aspects of secondary steelmaking processes, Int. Mater. Rev., 33(1988), No. 1, p. 53.

N. Rimbert, L. Claudotte, P. Gardin, and J. Lehmann, Modeling the dynamics of precipitation and agglomeration of oxide inclusions in liquid steel, Ind. Eng. Chem. Res., 53(2014), No. 20, p. 8630.

S.G. Jansto, MicroNiobium alloy approach in medium and high carbon steel bar, plate and sheet products, Metall. Mater. Trans. B, 45(2014), No. 2, p. 438.

N.A. Gokcen and J. Chipman, Silicon-oxygen equilibrium in liquid iron, JOM, 4(1952), No. 2, p. 171.

N.A. Gokcen and J. Chipman, Aluminum–oxygen equilibrium in liquid iron, JOM, 5(1953), No. 2, p. 173.

K. Semura and H. Matsuura, Past development and future prospects of secondary refining technology, Tetsu-to-Hagane, 100(2014), No. 4, p. 456.

K. Nakanishi, J. Szekely, T. Fujii, Y. Mihara, and S. Iwaoka, Stirring and its effect on aluminum deoxidation of steel in the ASEA-SKF furnace: Part I. Plant scale measurements and preliminary analysis, Metall. Trans. B, 6(1975), No. 1, p. 111.

R.V. Väinólä, L.E.K. Holappa, and P.H.J. Karvonen, Modern steelmaking technology for special steels, J. Mater. Process. Technol., 53(1995), No. 1–2, p. 453.

R. Fandrich, H. Lüngen, and C. Wuppermann, Actual review on secondary metallurgy, Rev. Met. Paris, 105(2008), 7–8, p. 364.

L. Holappa, On physic-chemical and technical limits in clean steel production, Steel Res. Int., 81(2010), No. 10, p. 869.

Y. Wang, A. Karasev, J.H. Park, and P.G. Jónsson, Non-metallic inclusions in different ferroalloys and their effect on the steel quality: A review, Metall. Mater. Trans. B, 52(2021), No. 5, p. 2892.

D. Roy, P. Pistorius, and R. Fruehan, Effect of silicon on the desulfurization of Al-killed steels: Part II. Experimental results and plant trials, Metall. Mater. Trans. B, 44(2013), p. 1095.

C.Y. Chen, Z.H. Jiang, Y. Li, et al., State of the art in the control of inclusions in tire cord steels and saw wire steels–A review, Steel Res. Int., 90(2019), No. 8, art. No. 180054.

B. Suler, J. Burja, and J. Medved, Modification of non-metallic inclusions with rare-earth metals in 50CrMoV13-1 steel, Mater. Tehnol., 53(2019), No. 3, p. 441.

J. Le Coze, Purification of iron and steels a continuous effort from 2000 BC to AD 2000, Mater. Trans. JIM, 41(2000), 1, p. 219.

J. Leach, The application of vacuum to steel making, Vacuum, 19(1969), No. 4, p. 155.

A. Tix, Production-scale vacuum steel degassing, JOM, 8(1956), No. 4, p. 420.

V.D. Tutarova, A.N. Shapovalov, and A.N. Kalitaev, Removal of hydrogen in the vacuum treatment of steel, Steel Transl., 47(2017), No. 3, p. 153.

R.F. Bunshah, History and current status of vacuum metallurgy, J. Vac. Sci. Technol. A, 12(1994), No. 4, p. 936.

J.H. Wei, N.W. Yu, Y.Y. Fan, S.L. Yang, J.C. Ma, and D.P. Zhu, Study on flow and mixing characteristics of molten steel in RH and RH-KTB refining processes, J. Shanghai Univ., 6(2002), No. 2, p. 167.

T. Nishioka and K. Emoto, On the ASEA-SKF process, Tetsu-to-Hagane, 60(1974), No. 12, p. 1661.

R.D. Pehlke and T. Fuwa, Control of sulphur in liquid iron and steel, Int. Met. Rev., 30(1985), No. 1, p. 125.

T. Emi, Steelmaking technology for the last 100 years: Toward highly efficient mass production systems for high quality steels, ISIJ Int., 55(2015), No. 1, p. 36.

H.G. Huang, M. Yan, J.N. Sun, and F.S. Du, Heat transfer of calcium cored wires and CFD simulation on flow and mixing efficiency in the argon-stirred ladle, Ironmaking Steelmaking, 45(2018), No. 7, p. 626.

Y. Hu, W.Q. Chen, C.J. Wan, F.J. Wang, and H.B. Han, Effect of deoxidation process on inclusion and fatigue performance of spring steel for automobile suspension, Metall. Mater. Trans. B, 49(2018), No. 2, p. 569.

C. Gu, Y.P. Bao, P. Gan, J.H. Lian, and S. Münstermann, An experimental study on the impact of deoxidation methods on the fatigue properties of bearing steels, Steel Res. Int., 89(2018), p. 1800129.

Z.Y. Deng and M.Y. Zhu, Deoxidation mechanism of Al-killed steel during industrial refining process, ISIJ Int., 54(2014), No. 7, p. 1498.

D.L. You, C. Bernhard, A. Viertauer, and B. Linzer, Simulation of the refining process of ultra-low carbon (ULC) steel, Crystals, 11(2021), No. 8, art. No. 893.

L.D. Way, Cleanness, castability, and surface quality of form-able sheet steels, Mater. Sci. Technol., 17(2001), No. 10, p. 1175.

S.K. Choudhary, S. Chandra, and A. Ghosh, Prediction of deoxidation and inclusion precipitation in semikilled steel, Metall. Mater. Trans. B, 36(2005), No. 1, p. 59.

H. Goto and K.I. Miyazawa, Reoxidation behavior of molten steel in non-killed and Al-killed steels, ISIJ Int., 38(1998), No. 3, p. 256.

H. Ohta and H. Suito, Activities in CaO-MgO-Al2O3 slags and deoxidation equilibria of Al, Mg, and Ca, ISIJ Int., 36(1996), No. 8, p. 983.

T. Furukawa, N. Saito, and K. Nakashima, Evaluation of interfacial energy between molten Fe and Fe–18%Cr–9%Ni alloy and non-metallic inclusion-type oxides, ISIJ Int., 61(2021), No. 9, p. 2381.

Y.Y. Xiao, G.C. Wang, H. Lei, and S. Sridhar, Formation pathways for MgO·Al2O3 inclusions in iron melt, J. Alloys Compd., 813(2020), art. No. 152243.

X.M. Yang, C.B. Shi, M. Zhang, G.M. Chai, and F. Wang, A thermodynamic model of sulfur distribution ratio between CaO–SiO2–MgO–FeO–MnO–Al2O3 slags and molten steel during LF refining process based on the ion and molecule coexistence theory, Metall. Mater. Trans. B, 42(2011), No. 6, p. 1150.

M. Swinnerton, The Influence of Slag Evolution on BOF De-phosphorization [Dissertation], University of Wollongong, New South Wales, 2005, p. 107.

Y.H. Li, Y.P. Bao, M. Wang, R. Wang, and D.C. Tang, Influence of process conditions during Ruhrstahl–Hereaeus refining process and effect of vacuum degassing on carbon removal to ultra-low levels, Ironmaking Steelmaking, 42(2015), No. 5, p. 366.

H.B. Li, P.C. Lu, H. Feng, P.F. Zhang, S.C. Zhang, and Z.H. Jiang, Influence mechanism of crucible materials on cleanliness and inclusion characteristics of high-nitrogen stainless bearing steel during vacuum carbon deoxidation, Metall. Mater. Trans. B, 54(2023), No. 3, p. 1099.

L. Zhu, A. Al-Sakeeri, F. Lenrick, et al., Surface chemistry and diffusion of trace and alloying elements during in vacuum thermal deoxidation of stainless steel, Surf. Interface Anal., 54(2022), No. 2, p. 99.

S. Yuan, U.B. Pal, and K.C. Chou, Modeling and scaleup of galvanic deoxidation of molten metals using solid electrolyte cells, J. Am. Ceram. Soc., 79(1996), No. 3, p. 641.

K.E. Oberg, L.M. Friedman, W.M. Boorstein, and R.A. Rapp, Electrochemical deoxidation of induction-stirred copper melts, Metall. Trans., 4(1973), No. 1, p. 75.

M. Iwase, M. Tanida, A. McLean, and T. Mori, Electronically driven transport of oxygen from liquid iron to CO + CO2 gas mixtures through stabilized zirconia, Metall. Trans. B, 12(1981), No. 3, p. 517.

S. Yuan, U. Pal, and K.C. Chou, Deoxidation of molten metals by short circuiting yttria-stabilized zirconia electrolyte cell, J. Electrochem. Soc., 141(1994), No. 2, p. 467.

L. Kong, T. Ouchi, C.Y. Zheng, and T. Okabe, Electrochemical deoxidation of titanium scrap in MgCl2–HoCl3 system, J. Electrochem. Soc., 166(2019), p. E429.

J.J. Li and Y. Kobayashi, A new design of oxygen sensor for electromotive force measurement and electrochemical deoxidation by using oxygen pump, ISIJ Int., 60(2020), No. 6, p. 1135.

M.A. Makarov, A.A. Aleksandrov, and V.Y. Dashevskii, Deep decarburization of iron-based melts, Russ. Metall. Met., 2007(2007), No. 2, p. 91.

M.N. Dastur and J. Chipman, Equilibrium in the reaction of hydrogen with oxygen in liquid iron, JOM, 1(1949), No. 8, p. 441.

W. Xing, Study on Deoxidation by Hydrogen and Natural Gas in Molten Steel [Dissertation], Wuhan University of Science and Technology, Wuhan, 2009, p. 39.

S.C. Tung and M.L. McMillan, Automotive tribology overview of current advances and challenges for the future, Tribol. Int., 37(2004), No. 7, p. 517.

J.P. Birat, Impact of steelmaking and casting technologies on processing and properties of steel, Ironmaking Steelmaking, 28(2001), No. 2, p. 152.

K. Hashimoto, T. Fujimatsu, N. Tsunekage, K. Hiraoka, K. Kida, and E.C. Santos, Study of rolling contact fatigue of bearing steels in relation to various oxide inclusions, Mater. Des., 32(2011), No. 3, p. 1605.

A. Melander and A. Gustavsson, An FEM study of driving forces of short cracks at inclusions in hard steels, Int. J. Fatigue, 18(1996), No. 6, p. 389.

P.F.F. Walker, Improving the reliability of highly loaded rolling bearings: The effect of upstream processing on inclusions, Mater. Sci. Technol., 30(2014), No. 4, p. 385.

B.H. Yoon, K.H. Heo, J.S. Kim, and H.S. Sohn, Improvement of steel cleanliness by controlling slag composition, Ironmaking Steelmaking, 29(2002), No. 3, p. 214.

Y. Kato, T. Masuda, K. Kawakami, and K. Hashizume, Recent improvements in cleanliness in high carbon chromium bearing steel, ISIJ Int., 36(1996), p. S89.

K. Matsuoka, T. Terabarake and K. Kameyarna, Improvement of quality of steel for bearing at JFE West Japan Works, [in] The 4th International Congress on the Science and Technology of Steelmaking, Gifu, 2008, p. 457.

C.Y. Liu, F.X. Huang, and X.H. Wang, The effect of refining slag and refractory on inclusion transformation in extra low oxygen steels, Metall. Mater. Trans. B, 47(2016), No. 2, p. 999.

K. Sorimachi, S. Yamada, J. Hasunuma, and H. Nomura, Kawasaki Steel’s steelmaking technologies for mass production of high quality slabs, Rev. Met. Paris, 96(1999), No. 4, p. 465.

S. Xu, J.R. Brown, and W.R. Tyson, Influence of residual elements on mechanical properties of two carbon steel grades, Steel Res. Int., 77(2006), No. 11, p. 825.

S.F. Chen, H. Lei, M. Wang, B. Yang, L.J. Dai, and Y. Zhao, Two-way coupling calculation for multiphase flow and decar-burization during RH refining, Vacuum, 167(2019), p. 255.

S. Zhu, Q.Y. Zhao, X.L. Li, Y. Liu, T.C. Li, and T.A. Zhang, Flow and penetration behavior of submerged side-blown gas, Int. J. Miner. Metall. Mater., 30(2023), No. 6, p. 1067.

H. Takechi, Metallurgical aspects on interstitial free sheet steel from industrial viewpoints, ISIJ Int., 34(1994), No. 1, p. 1.

S. Hoile, Processing and properties of mild interstitial free steels, Mater. Sci. Technol., 16(2000), No. 10, p. 1079.

L. Yang and G.G. Cheng, Characteristics of Al2O3, MnS, and TiN inclusions in the remelting process of bearing steel, Int. J. Miner. Metall. Mater., 24(2017), No. 8, p. 869.

Z.L. Wang, Y.P. Bao, C. Gu, W. Xiao, Y. Liu, and Y.S. Huang, Key metallurgical technology for high-quality bearing steel production based on the nonaluminum deoxidation process, Chin. J. Eng., 44(2022), No. 9, p. 1607.

H.P. Sun and K. Mori, Oxidation rate of aluminum in molten iron by CaO–SiO2–Al2O3–FeO-MnO slag, ISIJ Int., 36(1996), p. S34.

H.T. Ling and L.F. Zhang, A mathematical model for prediction of carbon concentration during RH refining process, Metall. Mater. Trans. B, 49(2018), No. 6, p. 2963.

J.L. Guo, L.H. Zhao, Y.P. Bao, S. Gao, and M. Wang, Carbon and oxygen behavior in the RH degasser with carbon powder addition, Int. J. Miner. Metall. Mater., 26(2019), No. 6, p. 681.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 52174297). The authors wish to express their gratitude to the foundation for providing financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Yanping Bao is an editorial board member for this journal and was not involved in the editorial review or the decision to publish this article. The authors have no competing interests to declare that are relevant to the content of this article.

Rights and permissions

About this article

Cite this article

Wang, Z., Bao, Y. Development and prospects of molten steel deoxidation in steelmaking process. Int J Miner Metall Mater 31, 18–32 (2024). https://doi.org/10.1007/s12613-023-2740-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-023-2740-4