Abstract

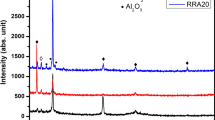

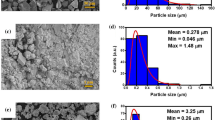

High entropy alloy composites (HEACs) have recently been explored for use in industrial applications. This study investigates the impact of particle size (micro or nano) and content (5 and 10 wt%) of YSZ on the microstructure and tribological properties of AlCoCrFeNi. The samples were prepared using a combination of mechanical alloying and spark plasma sintering. XRD results and Rietveld analysis reveal that HEACs with micro-sized YSZ have a higher BCC/FCC ratio. FESEM and EDS results confirmed the evolution of Al-rich regions in the vicinity of the reinforcements. Especially, in HEA-10NanoYSZ-sample, due to higher interfacial regions, a huge amount of Al-rich phase has been formed which yields the reduction of BCC phase content in this sample. Microhardness and pin-on-disc wear tests show that the samples reinforced with microparticles demonstrate better performance compared to nanocomposite samples. For example, HEA-10MicroYSZ-sample exhibits the highest hardness (5.1 GPa) and the lowest wear characteristics (with a coefficient of friction of 0.8 and a wear rate of 4 × 10−4 mm3/N.m). This can be correlated to the higher hardness and BCC phase content, and grain boundary strengthening in the microcomposites.

Graphical Abstract

Similar content being viewed by others

References

A.O. Mekhrabov, M.V. Akdeniz, Effect of ternary alloying elements addition on atomic ordering characteristics of Fe–Al intermetallics. Acta Mater. 47(7), 2067–2075 (1999)

J.-W. Yeh, S.-K. Chen, S.-J. Lin, J.-Y. Gan, T.-S. Chin, T.-T. Shun, C.-H. Tsau, S.-Y. Chang, Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv. Eng. Mater. 6(5), 299–303 (2004)

Z. Li, K.G. Pradeep, Y. Deng, D. Raabe, C.C. Tasan, Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature 534(7606), 227–230 (2016)

J. Miao, H. Liang, A. Zhang, J. He, J. Meng, Y. Lu, Tribological behavior of an AlCoCrFeNi2.1 eutectic high entropy alloy sliding against different counterfaces. Tribol. Int. 153, 106599 (2021)

Y.A. Alshataif, S. Sivasankaran, F.A. Al-Mufadi, A.S. Alaboodi, H.R. Ammar, Manufacturing methods, microstructural and mechanical properties evolutions of high-entropy alloys: a review. Met. Mater. Int. 26(8), 1099–1133 (2020)

X. Li, Y. Wang, F. Wang, A. Liang, Subsonic-flame-sprayed CoCrFeNi, AlCoCrFeNi and MnCoCrFeNi-based high-entropy alloy coatings and their tribological behaviors. J. Therm. Spray Technol. 32(1), 96–110 (2023)

Y. Wang, R. Wang, J. Lin, L. Wang, Z. Chen, Mechanical and high-temperature wear resistance properties of WC-reinforced AlCoCrFeNiTi0.5 high entropy alloy matrix composite. Ceram. Int. 50(1), 2162–2176 (2024)

K.R. Rao, S.K. Dewangan, A.H. Seikh, S.K. Sinha, B. Ahn, Microstructure and mechanical characteristics of AlCoCrFeNibased ODS high-entropy alloys consolidated by vacuum hot pressing. Met. Mater. Int. 30(3), 726–734 (2024)

Ł Rogal, Z. Szklarz, P. Bobrowski, D. Kalita, G. Garzeł, A. Tarasek, M. Kot, M. Szlezynger, Microstructure and mechanical properties of Al–Co–Cr–Fe–Ni base high entropy alloys obtained using powder metallurgy. Met. Mater. Int. 25(4), 930–945 (2019)

J. Feng, Y. Tang, J. Liu, P. Zhang, C. Liu, L. Wang, Bio-high entropy alloys: progress, challenges, and opportunities. Front. Bioeng. Biotechnol. 10, 977282 (2022)

M.C. Gao, J.-W. Yeh, P.K. Liaw, Y. Zhang (eds), High-Entropy Alloys: Fundamentals and Applications (Springer, Cham, 2016).

P. Zhou, P.K. Wong, P. Niu, M. Chen, C.T. Kwok, Y. Tang, R. Li, S. Wang, H. Pan, Anodized AlCoCrFeNi high-entropy alloy for alkaline water electrolysis with ultra-high performance. Sci. China Mater. 66(3), 1033–1041 (2023)

S.K. Dewangan, A. Mangish, S. Kumar, A. Sharma, B. Ahn, V. Kumar, A review on high-temperature applicability: a milestone for high entropy alloys. Eng. Sci. Technol. Int. J. 35, 101211 (2022)

D.B. Miracle, O.N. Senkov, A critical review of high entropy alloys and related concepts. Acta Mater. 122, 448–511 (2017)

Y.F. Ye, Q. Wang, J. Lu, C.T. Liu, Y. Yang, High-entropy alloy: challenges and prospects. Mater. Today 19(6), 349–362 (2016)

T. Fujieda, H. Shiratori, K. Kuwabara, M. Hirota, T. Kato, K. Yamanaka, Y. Koizumi, A. Chiba, S. Watanabe, CoCrFeNiTi-based high-entropy alloy with superior tensile strength and corrosion resistance achieved by a combination of additive manufacturing using selective electron beam melting and solution treatment. Mater. Lett. 189, 148–151 (2017)

J. Fan, W. Zhang, Atomic scale diffusion study in quaternary and quinary alloys of Co–Cr–Fe–Mn–Ni system. Met. Mater. Int. 30(2), 457–468 (2024)

H. Zheng, R. Chen, G. Qin, X. Li, Y. Su, H. Ding, J. Guo, H. Fu, Microstructure evolution, Cu segregation and tensile properties of CoCrFeNiCu high entropy alloy during directional solidification. J. Mater. Sci. Technol. 38, 19–27 (2020)

H. Yang, J. Li, T. Guo, W.Y. Wang, H. Kou, J. Wang, Fully recrystallized Al0.5CoCrFeNi high-entropy alloy strengthened by nanoscale precipitates. Met. Mater. Int. 25(5), 1145–1150 (2019)

A. Shafiei, Design of eutectic high entropy alloys in Al–Co–Cr–Fe–Ni system. Met. Mater. Int. 27(1), 127–138 (2021)

J.-M. Wu, S.-J. Lin, J.-W. Yeh, S.-K. Chen, Y.-S. Huang, H.-C. Chen, Adhesive wear behavior of AlxCoCrCuFeNi high-entropy alloys as a function of aluminum content. Wear 261(5), 513–519 (2006)

C.T. Wang, Y. He, Z. Guo, X. Huang, Y. Chen, H. Zhang, Y. He, Strain rate effects on the mechanical properties of an AlCoCrFeNi high-entropy alloy. Met. Mater. Int. 27(7), 2310–2318 (2021)

L. Guo, D. Xiao, W. Wu, S. Ni, M. Song, Effect of Fe on microstructure, phase evolution and mechanical properties of (AlCoCrFeNi)100−xFex high entropy alloys processed by spark plasma sintering. Intermetallics 103, 1–11 (2018)

T.-T. Shun, W.-J. Hung, Effects of Cr content on microstructure and mechanical properties of AlCoCrxFeNi high-entropy alloy. Adv. Mater. Sci. Eng. 2018, 5826467 (2018)

Y. Wang, X. Li, A. Liang, Wear behavior and microstructural transformation of single fcc phase AlCoCrFeNi high-entropy alloy at elevated temperatures. Int. J. Mater. Res. 113(8), 730–743 (2022)

A. Faraji, M. Farvizi, T. Ebadzadeh, H.S. Kim, Microstructure, wear performance, and mechanical properties of spark plasma-sintered AlCoCrFeNi high-entropy alloy after heat treatment. Intermetallics 149, 107656 (2022)

S. Praveen, B.S. Murty, R.S. Kottada, Phase evolution and densification behavior of nanocrystalline multicomponent high entropy alloys during spark plasma sintering. JOM 65(12), 1797–1804 (2013)

I. Basu, V. Ocelík, J.T. De Hosson, BCC-FCC interfacial effects on plasticity and strengthening mechanisms in high entropy alloys. Acta Mater. 157, 83–95 (2018)

M. Farvizi, M. Bahamirian, A. Faraji, H.S. Kim, Role of particle size of Al2O3 reinforcement on the wear performance of NiTi-based composites. Met. Mater. Int. 28, 101726 (2023)

R. Zhou, G. Chen, B. Liu, J. Wang, L. Han, Y. Liu, Microstructures and wear behaviour of (FeCoCrNi)1−x(WC)x high entropy alloy composites. Int. J. Refract Metal Hard Mater. 75, 56–62 (2018)

D. Yim, P. Sathiyamoorthi, S.-J. Hong, H.S. Kim, Fabrication and mechanical properties of TiC reinforced CoCrFeMnNi high-entropy alloy composite by water atomization and spark plasma sintering. J. Alloy. Compd. 781, 389–396 (2019)

B. Li, L. Zhang, Y. Xu, Z. Liu, B. Qian, F. Xuan, Selective laser melting of CoCrFeNiMn high entropy alloy powder modified with nano-TiN particles for additive manufacturing and strength enhancement: process, particle behavior and effects. Powder Technol. 360, 509–521 (2020)

L. Zong, L. Xu, C. Luo, Z. Jiao, X. Li, W. Sun, S. Wei, Mechanical properties and strengthening mechanism of the nano-sized m-ZrO2 ceramic particle reinforced NbMoTaW refractory high-entropy alloy. Int. J. Refract Metal Hard Mater. 113, 106201 (2023)

S. Yang, X. Yan, K. Yang, Z. Fu, Effect of the addition of nano-Al2O3 on the microstructure and mechanical properties of twinned Al0.4FeCrCoNi1.2Ti0.3 alloys. Vacuum 131, 69–72 (2016)

B. Gwalani, R.M. Pohan, O.A. Waseem, T. Alam, S.H. Hong, H.J. Ryu, R. Banerjee, Strengthening of Al0.3CoCrFeMnNi-based ODS high entropy alloys with incremental changes in the concentration of Y2O3. Scr. Mater. 162, 477–481 (2019)

M. Farvizi, T. Ebadzadeh, M.R. Vaezi, E.Y. Yoon, Y.J. Kim, H.S. Kim, A. Simchi, Microstructural characterization of HIP consolidated NiTi–nano Al2O3 composites. J. Alloy. Compd. 606, 21–26 (2014)

U. Mücke, Ceramic microstructures. Property control by processing. von W. E. Lee und W. M. Rainforth, 590 Seiten, Zahlreiche Abbildungen, Chapman & Hall, London, Glasgow, Weinheim. New York, Tokio, Melbourne, Madras, 1994, £ 89.00, ISBN 0-412-43140-8. Mater. Corros. 47(6), 346–347 (1996).

M. Woydt, A. Skopp, I. Dörfel, K. Witke, Wear engineering oxides/anti-wear oxides. Wear 218(1), 84–95 (1998)

M. Ghanbariha, M. Farvizi, T. Ebadzadeh, Microstructural development in nanostructured AlCoCrFeNi–ZrO2 high-entropy alloy composite prepared with mechanical alloying and spark plasma sintering methods. Mater. Res. Express 6(12), 1265b5 (2019)

M. Ghanbariha, M. Farvizi, T. Ebadzadeh, A. Alizadeh Samiyan, Effect of ZrO2 particles on the nanomechanical properties and wear behavior of AlCoCrFeNi–ZrO2 high entropy alloy composites. Wear 484, 204032 (2021)

T. Liao, Y.-K. Cao, W.-M. Guo, Q.-H. Fang, J. Li, B. Liu, Microstructure and mechanical property of NbTaTiV refractory high-entropy alloy with different Y2O3 contents. Rare Met. 41(10), 3504–3514 (2022)

A. Sanaty-Zadeh, Comparison between current models for the strength of particulate-reinforced metal matrix nanocomposites with emphasis on consideration of Hall–Petch effect. Mater. Sci. Eng. A 531, 112–118 (2012)

Z. Zhang, Y.H. Xie, X.Y. Huo, S.L.I. Chan, J.M. Liang, Y.F. Luo, D.K.Q. Mu, J. Ju, J. Sun, J. Wang, Microstructure and mechanical properties of ultrafine grained CoCrFeNi and CoCrFeNiAl0.3 high entropy alloys reinforced with Cr2O3/Al2O.3 nanoparticles. Mater. Sci. Eng. A 816, 141313 (2021)

F.S. Kaplan, I.G. Shulik, L.S. Alekseenko, G.P. Orekhova, Properties of slips of zirconia stabilized by oxides of rare earth metals. Refractories 36(3), 82–85 (1995)

O.A. Graeve, Zirconia, in Ceramic and Glass Materials: Structure, Properties and Processing, ed. by J.F. Shackelford, R.H. Doremus (Springer, New York, 2008), pp. 169–197

G.P. Cousland, X.Y. Cui, A.E. Smith, A.P.J. Stampfl, C.M. Stampfl, Mechanical properties of zirconia, doped and undoped yttria-stabilized cubic zirconia from first-principles. J. Phys. Chem. Solids 122, 51–71 (2018)

S.A. Ataie, R. Keshtmand, M.R. Zamani-Meymian, Nano-mechanical properties of Cr-Zr-Nb-N medium entropy alloy films produced by reactive sputtering. Int. J. Refract Metal Hard Mater. 110, 106006 (2023)

S.A. Ataie, M. Soltanieh, R. Naghizadeh, A. Cavaleiro, M. Evaristo, F. Fernandes, F. Ferreira, Effect of substrate bias voltage on structural and tribological properties of W-Ti-C-N thin films produced by combinational HiPIMS and DCMS co-sputtering. Wear 520–521, 204654 (2023)

R. Liu, D.Y. Li, Y.S. Xie, R. Llewellyn, H.M. Hawthorne, Indentation behavior of pseudoelastic TiNi alloy. Scripta Mater. 41(7), 691–696 (1999)

K. Raja, P. Ganeshan, B.K. Singh, R.K. Upadhyay, P. Ramshankar, V. Mohanavel, Effect of mol% of Yttria in Zirconia matrix alongside a comparative study among YSZ, alumina & ZTA ceramics in terms of mechanical and functional properties. Sādhanā 48(2), 72 (2023)

G. Fiquet, C. Narayana, C. Bellin, A. Shukla, I. Estève, A.L. Ruoff, G. Garbarino, M. Mezouar, Structural phase transitions in aluminium above 320GPa. C.R. Geosci. 351(2), 243–252 (2019)

S.A. Makhlouf, E. Ivanov, K. Sumiyama, K. Suzuki, Structural and magnetic properties of nanocrystalline b.c.c. cobalt particles obtained by leaching of mechanically alloyed Co Al. J. Alloys Compd. 189(1), 117–121 (1992)

S. Tailor, M. Singh, A.V. Doub, Synthesis and characterization of yttria-stabilized zirconia (YSZ) nano-clusters for thermal barrier coatings (TBCs) applications. J. Clust. Sci. 27(4), 1097–1107 (2016)

B.P. Dhonge, T. Mathews, S. Rajagopalan, S. Dash, S. Dhara, A.K. Tyagi, Cubic fluorite yttria stabilized zirconia (YSZ) film synthesis by combustion chemical vapour deposition(C-CVD), in Proceedings of the International Conference on Nanoscience, Engineering and Technology (ICONSET 2011), Chennai, 28-30 November 2011 (IEEE, New York, 2011), pp. 65–68

J. Yang, W.N. Martens, R.L. Frost, Transition of chromium oxyhydroxide nanomaterials to chromium oxide: a hot-stage Raman spectroscopic study. J. Raman Spectrosc. 42(5), 1142–1146 (2011)

K. Song, Y. Lee, M.R. Jo, K.M. Nam, Y.-M. Kang, Comprehensive design of carbon-encapsulated Fe3O4 nanocrystals and their lithium storage properties. Nanotechnology 23(50), 505401 (2012)

S. Benafia, D. Retraint, S. Yapi Brou, B. Panicaud, J.L. Grosseau Poussard, Influence of surface mechanical attrition treatment on the oxidation behaviour of 316L stainless steel. Corros. Sci. 136, 188–200 (2018)

C. Laurent, A. Rousset, Metal-oxide ceramic matrix nanocomposites. Key Eng. Mater. 108–110, 405–406 (1995)

M. Bai, L. Yang, J. Li, L. Luo, S. Sun, B. Inkson, Mechanical and tribological properties of Si and W doped diamond like carbon (DLC) under dry reciprocating sliding conditions. Wear 484–485, 204046 (2021)

X. Liu, Y. Wang, L. Qin, Z. Guo, Z. Lu, X. Zhao, H. Dong, Q. Xiao, Friction and wear properties of a novel interface of ordered microporous Ni-based coating combined with MoS2 under complex working conditions. Tribol. Int. 189, 108970 (2023)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

None.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ghanbariha, M., Farvizi, M., Ataie, S.A. et al. Effect of YSZ Particle Size and Content on Microstructure, Mechanical and Tribological Properties of (CoCrFeNiAl)1−x(YSZ)x High Entropy Alloy Composites. Met. Mater. Int. (2024). https://doi.org/10.1007/s12540-024-01656-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12540-024-01656-2