Abstract

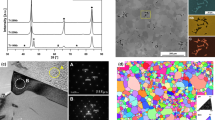

The objective of the present work is to study the mechanical and tribological properties of SiC-hBN such as hardness, density, fracture toughness, friction and wear behavior with and without additives. Therefore, SiC-hBN composite with different composition of hBN (0, 5, 10, and 35 vol. %) and 2 vol.% sintering additive Y2O3 was fabricated by spark plasma sintering at 1800 °C with 55 MPa load for 5 min. under argon atmosphere. SEM–EDS and XRD were used for the microstructural evaluation and characterization of the composite. The hardness of the composite shows a decreasing trend from 19.20 MPa to 16.73 MPa while fracture toughness increases from 2.33 MPa-m1/2 to 3.93 MPa-m1/2, when the hBN volume fraction increases from 5 to 35 vol. % in the composite. The wear and friction behaviour of composites were studied through ball-on-disc wear test rig without lubrication. The wear volume, wear track width, as well as coefficient of friction, decreased by increasing the h-BN volume fraction. The size and shape of debris particles decreased uniformly as the hBN content increases, whereas non-uniformly wear debris was observed in the additive-free composite. The composites with additives showed excellent mechanical and tribological performance as compared to additive-free composites.

Similar content being viewed by others

Data Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Low IM Advances in Ceramic Matrix Composites: Second Edition, 2018 Elsevier Woodhead Publishing, 2018

Manoj Kumar BV, Kim YW, Lim DS, Seo WS (2011) Influence of small amount of sintering additives on unlubricated sliding wear properties of SiC ceramics. Ceram Int 37:3599–3608. https://doi.org/10.1016/j.ceramint.2011.06.018

Roewer G, Herzog U, Trommer K et al (2007) Silicon Carbide — A Survey of Synthetic Approaches, Properties and Applications. High Perform Non-Oxide Ceram I 101:59–135. https://doi.org/10.1007/3-540-45613-9_2

Sharma SK, Kumar BVM, Kim YW (2016) Tribological behavior of silicon carbide ceramics - A review. J Korean Ceram Soc 53:581–596. https://doi.org/10.4191/kcers.2016.53.6.581

Lafon-Placette S, Delbé K, Denape J, Ferrato M (2015) Tribological characterization of silicon carbide and carbon materials. J Eur Ceram Soc 35:1147–1159. https://doi.org/10.1016/j.jeurceramsoc.2014.10.038

Sharma SK, Kumar BVM, Zugelj BB et al (2017) Room and high temperature reciprocated sliding wear behavior of SiC-WC composites. Ceram Int 43:16827–16834. https://doi.org/10.1016/j.ceramint.2017.09.080

Micele L, Palombarini G, Guicciardi S, Silvestroni L (2010) Tribological behaviour and wear resistance of a SiC-MoSi2 composite dry sliding against Al2O3. Wear 269:368–375. https://doi.org/10.1016/j.wear.2010.04.021

Ajayi OO, Erdemir A, Lee RH, Nichols FA (1993) Sliding Wear of Silicon Carbide—Titanium Boride Ceramic-Matrix Composite. J Am Ceram Soc 76:511–517. https://doi.org/10.1111/j.1151-2916.1993.tb03815.x

Xue JX, Liu JX, Xie BH, Zhang GJ (2011) Pressure-induced preferential grain growth, texture development and anisotropic properties of hot pressed hexagonal boron nitride ceramics. Scr Mater 65:966–969. https://doi.org/10.1016/j.scriptamat.2011.08.025

Zhai F, Li S, Sun J, Yi Z (2017) Microstructure, mechanical properties and thermal shock behavior of h-BN-SiC ceramic composites prepared by spark plasma sintering. Ceram Int 43:2413–2417. https://doi.org/10.1016/j.ceramint.2016.11.030

Niu L, Hojamberdiev M, Xu Y, Wu H (2010) Microstructure and mechanical properties of Hadfield steel matrix composite reinforced with oriented high-chromium cast iron bars. J Mater Sci 45:4532–4538. https://doi.org/10.1007/s10853-010-4549-6

Li X, Gao Y, Pan W et al (2015) Fabrication and characterization of B4C-based ceramic composites with different mass fractions of hexagonal boron nitride. Ceram Int 41:27–36. https://doi.org/10.1016/j.ceramint.2014.07.042

Chkhartishvili L, Tabatadze G, Nackebia D, Bzhalava T, Kalandadze I (2016) Hexagonal Boron nitride as a solid lubricant additive (An overview). Nano Stud 51:91–98

Da Costa Gonçalves P, Furlan KP, Hammes G, et al (2014) Self-lubricating sintered composites with hexagonal boron nitride and graphite mixtures as solid lubricants. Adv Powder Metall Part Mater - 2014, Proc 2014 World Congr Powder Metall Part Mater PM 2014 910–917

Li X, Gao Y, Yang Q et al (2015) Evaluation of tribological behavior of B4C-hBN ceramic composites under water-lubricated condition. Ceram Int 41:7387–7393. https://doi.org/10.1016/j.ceramint.2015.02.050

Kovalčíková A, Balko J, Balázsi C et al (2014) Influence of hBN content on mechanical and tribological properties of Si3N4/BN ceramic composites. J Eur Ceram Soc 34:3319–3328. https://doi.org/10.1016/j.jeurceramsoc.2014.02.021

Chen W, Gao Y, Chen C, Xing J (2010) Tribological characteristics of Si3N4-hBN ceramic materials sliding against stainless steel without lubrication. Wear 269:241–248. https://doi.org/10.1016/j.wear.2010.04.003

Woydt M, Skopp A, Wäsche R (1992) Ceramic-ceramic composite materials with improved friction and wear properties. In: 4th international symposium on ceramic materials and components for engines. Springer, Dordrecht, pp 1219–1239

Cho KS, Kim YW, Choi HJ, Lee JG (1996) SiC-TiC and SiC-TiB2 composites densified by liquid-phase sintering. J Mater Sci 31:6223–6228. https://doi.org/10.1007/BF00354442

Gasch MJ, Ellerby DT, Johnson SM (2006) Ultra High Temperature Ceramic Composites. Handb Ceram Compos 197–224. https://doi.org/10.1007/0-387-23986-3_9

Monteverde F, Bellosi A (2003) Oxidation of ZrB[sub 2]-Based Ceramics in Dry Air. J Electrochem Soc 150:B552. https://doi.org/10.1149/1.1618226

Pastor H (1977) Metallic Borides: Preparation of Solid Bodies — Sintering Methods and Properties of Solid Bodies. Boron Refract Borides 457–493. https://doi.org/10.1007/978-3-642-66620-9_25

Malik R, Kim YW, Kim KJ, Manoj Kumar BV (2020) Tuning the electrical, thermal, and mechanical properties of SiC-BN composites using sintering additives. J Asian Ceram Soc 8:353–364. https://doi.org/10.1080/21870764.2020.1743412

Ghasali E, Baghchesaraee K, Orooji Y (2020) Study of the potential effect of spark plasma sintering on the preparation of complex FGM/laminated WC-based cermet. Int J Refract Met Hard Mater 92:105328. https://doi.org/10.1016/j.ijrmhm.2020.105328

Ghasali E, Ghahremani D, Orooji Y, Faeghi-nia A, Kazem-zadeh AE (2022) Microstructure and phase formation of mullite-Pr6O11 composite prepared by spark plasma sintering. J Rare Earths. https://doi.org/10.1016/j.jre.2022.03.018

Gupta Y, Venkateswaran T, Kumar BVM (2020) Influence of angle of incidence, temperature and SiC content on erosive wear behavior of ZrB2-SiC composites. Int J Appl Ceram Technol 17:459–467. https://doi.org/10.1111/ijac.13392

Ghasali E, Alizadeh M, Pakseresht AH, Ebadzadeh T (2017) Preparation of silicon carbide/carbon fiber composites through high-temperature spark plasma sintering. J Asian Ceram Soc 5:472–478. https://doi.org/10.1016/j.jascer.2017.10.004

Orooji Y, Derakhshandeh MR, Ghasali E et al (2019) Effects of ZrB2 reinforcement on microstructure and mechanical properties of a spark plasma sintered mullite-CNT composite. Ceram Int 45:16015–16021. https://doi.org/10.1016/j.ceramint.2019.05.113

Seo YK, Kim YW, Kim KJ, Seo WS (2016) Electrically conductive SiC-BN composites. J Eur Ceram Soc 36:3879–3887. https://doi.org/10.1016/j.jeurceramsoc.2016.06.040

Dorkar NV, Kim YW, Kumar BVM (2020) Influence of temperature, impact angle and h-BN content on the erosive wear behavior of hot-pressed SiC-BN composites. Wear 458–459:203447. https://doi.org/10.1016/j.wear.2020.203447

Kim Y (2012) Influence of Y2O3 Addition on Electrical Properties of β -SiC Ceramics Sintered in Nitrogen Atmosphere. https://doi.org/10.1016/j.jeurceramsoc.2012.07.001

Agarwal BD, Broutman LJ, Agarwal BD, Broutman LJ (1990) Analysis and performance of fiber composites Second edition. John Wiley & Sons 1990. Leave Form.Pdf

Quinn GD (2008) Fracture Toughness of Ceramics by the Vickers Indentation Crack Length Method: A Critical Review. 45–62. https://doi.org/10.1002/9780470291313.

Li Y, Wu H, Yin J et al (2013) High electrical resistivity of pressureless sintered in situ SiC-BN composites. Scr Mater 69:740–743. https://doi.org/10.1016/j.scriptamat.2013.08.016

Kim KJ, Lim KY, Kim YW, Kim HC (2013) Temperature dependence of electrical resistivity (4–300 K) in aluminum- and boron-doped SiC ceramics. J Am Ceram Soc 96:2525–2530. https://doi.org/10.1111/jace.12351

Zhou Y, Tanaka H, Otani S, Bando Y (1999) Low-Temperature Pressureless Sintering of α-SiC with. Ind Res 64:1959–1964

Kim YW, Mitomo M (1999) Fine-grained silicon carbide ceramics with oxynitride glass. J Am Ceram Soc 82:2731–2736. https://doi.org/10.1111/j.1151-2916.1999.tb02149

Kim KJ, Lim KY, Kim YW (2012) Influence of Y 2O 3 addition on electrical properties of β-SiC ceramics sintered in nitrogen atmosphere. J Eur Ceram Soc 32:4401–4406. https://doi.org/10.1016/j.jeurceramsoc.2012.07.001

Malik R, Kim HM, Kim YW, Kim KJ (2018) Grain-growth-induced high electrical conductivity in SiC–BN composites. Ceram Int 44:16394–16399. https://doi.org/10.1016/j.ceramint.2018.06.049

Kim KJ, Cho TY, Kim YW et al (2015) Electrical and thermal properties of silicon carbide-boron nitride composites prepared without sintering additives. J Eur Ceram Soc 35:4423–4429. https://doi.org/10.1016/j.jeurceramsoc.2015.08.011

Bate P (2001) The effect of deformation on grain growth in Zener pinned systems. Acta Mater 49:1453–1461. https://doi.org/10.1016/S1359-6454(01)00033-7

Jang SH, Kim YW, Kim KJ (2017) Electrical and thermal properties of SiC-Zr2CN composites sintered with Y2O3-Sc2O3 additives. J Eur Ceram Soc 37:477–484. https://doi.org/10.1016/j.jeurceramsoc.2016.09.001

Kim KJ, Kim KM, Kim YW (2014) Highly conductive SiC ceramics containing Ti2CN. J Eur Ceram Soc 34:1149–1154. https://doi.org/10.1016/j.jeurceramsoc.2013.11.001

Chen J, Chen J, Wang S et al (2020) Tribological properties of h-BN matrix solid-lubricating composites under elevated temperatures. Tribol Int 148:106333. https://doi.org/10.1016/j.triboint.2020.106333

Murthy VSR, Kobayashi H, Tsurekawa S et al (2004) Influence of humidity and doping elements on the friction and wear of SiC in unlubricated sliding. Tribol Int 37:353–364. https://doi.org/10.1016/j.triboint.2003.11.002

Evans AG, Marshall DB (1981) Wear mechanisms in ceramics. In: Rigney DA (ed) Friction and wear of materials. ASM, Metals Park, Ohio, pp 439–452

Zhao X, Liu J, Zhu B et al (1997) Tribological characteristics of Si3N4 ceramic sliding on stainless steel. Wear 206:76–82. https://doi.org/10.1016/S0043-1648(96)07372-3

Murthy VSR, Kobayashi H, Tamari N et al (2004) Effect of doping elements on the friction and wear properties of SiC in unlubricated sliding condition. Wear 257:89–96. https://doi.org/10.1016/j.wear.2003.10.016

Acknowledgements

Deepak Kumar thanks the IIT Roorkee for its support to carry out this research work.

Funding

The author declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study’s conception and fabricate the new materials. The experimental work performed and analyzed by Deepak Kumar. The first draft of the manuscript was written by Deepak Kumar and Santosh Kumar Rajak and the final version is reviewed by Dr. R. Seetharam and Dr. Harpreet Singh. All authors read carefully and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics Approval

Not Applicable.

Consent to Participate

Not Applicable.

Consent for Publication

Yes.

Competing Interest

The authors have no relevant financial or non-financial interests to disclose.

Conflict of Interest

Authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, D., Rajak, S.K., Seetharam, R. et al. Effects of hBN and Y2O3 Addition on Mechanical and Tribological Behavior of SiC Ceramic Matrix Composites Prepared by Spark Plasma Sintering. Silicon 15, 2297–2311 (2023). https://doi.org/10.1007/s12633-022-02184-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-022-02184-7