Abstract

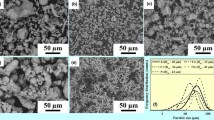

The study investigates that a high-entropy alloy based on AlCoCrFeNi is mechanically alloyed (MA) for 40 h with 1 wt% Y2O3 dispersed and then consolidated through vacuum hot pressing (VHP). In VHP, three temperatures are used for consolidation: 800 °C, 900 °C, and 1000 °C. Microanalysis of the powder aggregate formed by MA revealed the presence of mostly face-centered cubic (FCC) and body-centered cubic (BCC) phases, along with a metastable AlFe4O12Y3 garnet phase. The enthalpy of mixing Y and Al induced the development of the garnet phase. In addition, after the consolidation of the powder sample at different temperatures, microstructural investigations indicated that the FCC and BCC phases generated during MA were stable owing to sluggish diffusion. By contrast, the garnet phase generated during the MA dissociated into an intermetallic phase based on Yttrium. The slower heating rates associated with VHP (in comparison to the rapid heating rates associated with spark plasma sintering) may be responsible for the dissociation of the garnet phase. The sample sintered at 1000 °C exhibited a bimodal grain distribution, with grain sizes ranging from 100 to 800 nm, as determined by transmission electron microscopy. In addition, this sample had the highest measured hardness of 1353 ± 20 Hv.

Graphical Abstract

Similar content being viewed by others

References

B.S. Murty, J.W. Yeh, S. Ranganathan, in High Entropy Alloys (Butterworth-Heinemann, Oxford, 2014), pp. 13–35, https://doi.org/10.1016/B978-0-12-800251-3.00002-X

C. Nagarjuna, S.K. Dewangan, A. Sharma, K. Lee, S.J. Hong, B. Ahn, Met. Mater. Int. 29, 1968 (2023). https://doi.org/10.1007/S12540-022-01355-W

A. Sharma, H. Lee, B. Ahn, Met. Mater. Int. 28, 2216 (2022). https://doi.org/10.1007/S12540-021-01125-0

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, S.Y. Chang, Adv. Eng. Mater. 6, 299 (2004). https://doi.org/10.1002/ADEM.200300567

M.H. Tsai, J.W. Yeh, Mater. Res. Lett. 2, 107 (2014). https://doi.org/10.1080/21663831.2014.912690

K.R. Rao, S.K. Sinha, Vacuum 184, 109802 (2021). https://doi.org/10.1016/j.vacuum.2020.109802

K.R. Rao, S.K. Sinha, Mater. Sci. Eng. B 281, 115720 (2022). https://doi.org/10.1016/j.mseb.2022.115720

K.R. Rao, S.K. Sinha, Manuf. Lett. 20, 5 (2019). https://doi.org/10.1016/j.mfglet.2019.02.004

S.K. Dewangan, D. Kumar, S. Samal, V. Kumar, J. Mater. Eng. Perform 30, 4421 (2021). https://doi.org/10.1007/s11665-021-05552-3

S. K. Dewangan, Studies on Microstructure, Mechanical and High-Temperature Oxidation Behaviour of Tungsten Containing High Entropy Alloys, (Indian Institute of Technology Indore, 2021), http://dspace.iiti.ac.in:8080/jspui/handle/123456789/307. Accessed 1 Sep 2021

Z. Liang, Y. Zhang, Y. Liu, Z. Zhu, H. Zhang, Mater. Lett. 317, 132092 (2022). https://doi.org/10.1016/j.matlet.2022.132092

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, Z.P. Lu, Prog. Mater. Sci. 61, 1 (2014). https://doi.org/10.1016/j.pmatsci.2013.10.001

O.N. Senkov, G.B. Wilks, J.M. Scott, D.B. Miracle, Intermetallics 19, 698 (2011). https://doi.org/10.1016/j.intermet.2011.01.004

B. Raj, U.K. Mudali, Proc. Indian Natl. Sci. Acad. 81, 801 (2015). https://doi.org/10.16943/ptinsa/2015/v81i4/48298

S.S. Kumar, S. ES, S.B. Chandrasekhar, S.K. Karak, Mater. Res. 19, 175 (2016). https://doi.org/10.1590/1980-5373-MR-2015-0593

J.M. Byun, C.W. Park, Y.D. Kim, Met. Mater. Int. 24, 1309 (2018). https://doi.org/10.1007/S12540-018-0136-1

C. Suryanarayana, A.A. Al-Joubori, Z. Wang, Met. Mater. Int. 28, 41 (2022). https://doi.org/10.1007/S12540-021-00998-5

S. Ohtsuka, S. Ukai, M. Fujiwara, T. Kaito, T. Narita, Mater. Trans. 46, 3 (2005). https://doi.org/10.2320/matertrans.46.487

B. Gwalani, R.M. Pohan, O. Ahmed, T. Alam, S. Hyung, H. Jin, R. Banerjee, Scr. Mater. 162, 477 (2019). https://doi.org/10.1016/j.scriptamat.2018.12.021

C.L. Chen, Intermetallics 113, 106570 (2019). https://doi.org/10.1016/j.intermet.2019.106570

H. Hadraba, Z. Chlup, A. Dlouhy, F. Dobes, P. Roupcova, M. Vilemova, J. Matejicek, Mater. Sci. Eng. A 689, 252 (2017). https://doi.org/10.1016/j.msea.2017.02.068

S. Varalakshmi, M. Kamaraj, B.S. Murty, J. Alloys Compd. 460, 253 (2008). https://doi.org/10.1016/j.jallcom.2007.05.104

A. Dwivedi, C.C. Koch, K.V. Rajulapati, Mater. Lett. 183, 44 (2016). https://doi.org/10.1016/j.matlet.2016.07.083

A. Takeuchi, A. Inoue, Mater. Trans. 46, 2817 (2005). https://doi.org/10.2320/matertrans.46.2817

B. Gwalani, R.M. Pohan, J. Lee, B. Lee, R. Banerjee, H.J. Ryu, S.H. Hong, Sci. Rep. 8, 14085 (2018). https://doi.org/10.1038/s41598-018-32552-6

M. Murali, S.P.K. Babu, B.J. Krishna, A. Vallimanalan, Prog. Nat. Sci.: Mater. Int. 26, 380 (2016). https://doi.org/10.1016/j.pnsc.2016.06.008

K.R. Rao, S.K. Sinha, Mater. Sci. Forum 978, 145 (2020). https://doi.org/10.4028/www.scientific.net/MSF.978.145

A. Patra, R. Saxena, S.K. Karak, T. Laha, S.K. Sahoo, J. Alloys Compd. 707, 245 (2017). https://doi.org/10.1016/j.jallcom.2016.11.424

S.K. Karak, T. Chudoba, Z. Witczak, W. Lojkowski, I. Manna, Mater. Sci. Eng. A 528, 7475 (2011). https://doi.org/10.1016/j.msea.2011.06.039

A. Zeybek, S. Pirfo Barroso, K.B. Chong, L. Edwards, M.E. Fitzpatrick, J. Mater. Eng. Perform. 23, 2120–2130 (2014). https://doi.org/10.1007/s11665-014-0988-6.

H. Cheng, W. Chen, X. Liu, Q. Tang, Y. Xie, P. Dai, Mater. Sci. Eng. A 719, 192 (2018). https://doi.org/10.1016/j.msea.2018.02.040

S. Mohanty, T.N. Maity, S. Mukhopadhyay, S. Sarkar, N.P. Gurao, S. Bhowmick, K. Biswas, Mater. Sci. Eng. A 679, 299 (2017). https://doi.org/10.1016/j.msea.2016.09.062

Acknowledgements

The authors would like to acknowledge the Researchers Supporting Project number (RSP2023R373), King Saud University, Riyadh, Saudi Arabia.

Funding

This research was funded by the Researchers Supporting Project number RSP2023R373.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The author declares no competing financial interests. One of the coauthors, Byungmin Ahn, is a current editor of the Metals and Materials International journal.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rao, K.R., Dewangan, S.K., Seikh, A.H. et al. Microstructure and Mechanical Characteristics of AlCoCrFeNi-Based ODS High-Entropy Alloys Consolidated by Vacuum Hot Pressing. Met. Mater. Int. 30, 726–734 (2024). https://doi.org/10.1007/s12540-023-01530-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01530-7