Abstract

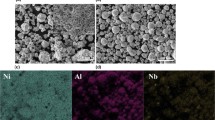

This work proposes to characterize the composites manufactured of SiC, WC, and Co [x SiC–(1-x) WC–10 wt.% Co], with x = 0, 0.25, 0.50, 0.75 and 1. These composites were prepared by high-energy milling (HEM) and consolidated by spark plasma sintering (SPS). The results showed that HEM promoted a decrease in particle size, dispersion, and homogenization of the constituent phases, improving the densification and mechanical properties of the composites. The WC-Co showed high relative density (96.37%) and microhardness (9.4 GPa) values. The tribological behavior of the composites was evaluated by a pin-on-disk tribometer, applied against 1020 steel discs with a 5-N load in non-lubricated conditions. There was a significant effect from the variations in the contents of SiC and WC in the wear volumes (3.13 × 10−2–49.0 × 10−2 mm3) and wear rates (0.63 × 10−5–9.83 × 10−5 mm3/N m) of the composites. Tribological tests showed that the composites sintered by SPS proved to be a promising material with good tribological performance and attractive for components/devices subjected to wear.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of a continuing study.

References

H. Abderrazak, and E.S.B. Hadj Hmi, in Prop (Appl, Silicon Carbide (InTech), 2011).

B. Ghosh, and S.K. Pradhan, J. Alloys Compd. 486, 480 (2009).

G. Roewer, U. Herzog, K. Trommer, E. Müller, and S. Frühauf, in High Perform. Non-Oxide Ceram. I (Springer Berlin Heidelberg, Berlin, Heidelberg, 2002), pp. 59–135.

V. Raman, O.P. Bahl, and U. Dhawan, J. Mater. Sci. 30, 2686 (1995).

S.K. Sharma, B. Venkata Manoj Kumar, and Y.W. Kim, Int. J. Refract. Met. Hard Mater. 68, 166 (2017).

S.K. Sharma, B.V.M. Kumar, K.-Y. Lim, Y.-W. Kim, and S.K. Nath, Ceram. Int. 40, 6829 (2014).

S. Gupta, S.K. Sharma, B.V.M. Kumar, and Y.W. Kim, Ceram. Int. 41, 14780 (2015).

S.K. Sharma, B.V.M. Kumar, and Y.-W. Kim, J. Korean Ceram. Soc. 53, 581 (2016).

H. Liu, M.E. Fine, and H.S. Cheng, J. Am. Ceram. Soc. 74, 2224 (1991).

C. Zishan, L. Hejun, F. Qiangang, C. Yanhui, W. Shaolong, and H. Zibo, Ceram. Int. 39, 1765 (2013).

B. Guimarães, C.M. Fernandes, D. Figueiredo, M.F. Cerqueira, O. Carvalho, F.S. Silva, and G. Miranda, Ceram. Int. 46, 3002 (2020).

A. Fazili, M.R. Derakhshandeh, S. Nejadshamsi, L. Nikzad, M. Razavi, and E. Ghasali, J. Alloys Compd. 823, 153857 (2020).

H.V.S.B. Azevêdo, R.A. Raimundo, D.D.S. Silva, L.M.F. Morais, F.A. Costa, D.A. Macedo, D.G.L. Cavalcante, and U.U. Gomes, J. Mater. Eng. Perform. 30, 1504 (2021).

X. Li, Y. Liu, W. Wei, M. Du, K. Li, J. Zhou, and K. Fu, Mater. Des. 90, 562 (2016).

L. An, J. Han, and J. Chen, J. Univ. Sci. Technol. Beijing. Miner. Metall. Mater. 13, 174 (2006).

Z. Wang, Y. Liu, K. Liu, and B. Wang, Ceram. Int. 45, 23658 (2019).

P. Siwak, and D. Garbiec, Trans. Nonferrous Met. Soc. China 26, 2641 (2016).

P.A. Olubambi, K.K. Alaneme, and A. Andrews, Int. J. Refract. Met. Hard Mater. 50, 163 (2014).

R.M. Genga, G. Akdogan, J.E. Westraadt, and L.A. Cornish, Int. J. Refract. Met. Hard Mater. 49, 240 (2015).

K.H. Lee, S.I. Cha, B.K. Kim, and S.H. Hong, Int. J. Refract. Met. Hard Mater. 24, 109 (2006).

H.V.S.B. Azevêdo, R.A. Raimundo, D.D.S. Silva, L.M.F. Morais, D.A. Macedo, D.G.L. Cavalcante, and U.U. Gomes, Int. J. Refract. Met. Hard Mater. 94, 105408 (2021).

D.M. Hulbert, A. Anders, J. Andersson, E.J. Lavernia, and A.K. Mukherjee, Scr. Mater. 60, 835 (2009).

D. Hitchcock, R. Livingston, and D. Liebenberg, J. Appl. Phys 17(17), 174505 (2015).

S. Hocquet, V. Dupont, F. Cambier, F. Ludewig, and N. Vandewalle, J. Eur. Ceram. Soc. 40, 2586 (2020).

E. Ghasali, R. Yazdani-rad, K. Asadian, and T. Ebadzadeh, J. Alloys Compd. 690, 512 (2017).

E. Ghasali, H. Nouranian, A. Rahbari, H. Majidian, M. Alizadeh, and T. Ebadzadeh, Mater. Res. 19, 1189 (2016).

Z.A. Munir, U. Anselmi-Tamburini, and M. Ohyanagi, J. Mater. Sci. 41, 763 (2006).

C. Suryanarayana, Prog. Mater. Sci. 46, 1 (2001).

C. Suryanarayana, and N. Al-Aqeeli, Prog. Mater. Sci. 58, 383 (2013).

N.T. Câmara, R.A. Raimundo, C.S. Lourenço, L.M.F. Morais, D.D.S. Silva, R.M. Gomes, M.A. Morales, D.A. Macedo, U.U. Gomes, and F.A. Costa, Adv. Powder Technol. 32, 2950 (2021).

M.C.L. Silva, M.M.B. Leite, R.A. Raimundo, G.F. Henriques, S.M. Valcacer, M. Mashhadikarimi, M.A. Morales, and U.U. Gomes, Ceram. Int. 48, 19026 (2022).

M. Shirani, M. Rahimipour, M. Zakeri, S. Safi, and T. Ebadzadeh, Ceram. Int. 43, 14517 (2017).

J.F. Guria, A. Bansal, V. Kumar, and B.V. Manoj Kumar, Ceram. Int. 48, 12675 (2022).

E. Ghasali, T. Ebadzadeh, M. Alizadeh, and M. Razavi, J. Alloys Compd. 786, 938 (2019).

S. Liu, D.Q. Yi, Y.X. Li, and D. Zou, Acta Metall. Sin. 15, 448 (2002).

R.A. Raimundo, K.V.A. Santos, C.S. Lourenço, F.A. Costa, M.A. Morales, D.A. Macedo, A.G.P. Silva, and U.U. Gomes, Ceram. Int. 47, 677 (2021).

C.A. Schneider, W.S. Rasband, and K.W. Eliceiri, Nat. Methods 9, 671 (2012).

ASTM B962-13: Standard Test Methods for Density of Compacted or Sintered Powder Metallurgy (PM) Products Using Archimedes’ Principle. ASTM International (2013).

K. Ponhan, K. Tassenberg, D. Weston, K.G.M. Nicholls, and R. Thornton, Ceram. Int. 46, 26956 (2020).

M.A. Taha, and M.F. Zawrah, Ceram. Int. 46, 19519 (2020).

ASTM E384-99: Standard Test Method for Microindentation Hardness of Materials. ASTM International (1999).

J.F. Archard, J. Appl. Phys. 24, 981 (1953).

W. Pitschke, H. Hermann, and N. Mattern, Powder Diffr. 8, 74 (1993).

P. Krishna, and A.R. Verma, Acta Crystallogr. 15, 383 (1962).

E. A. Owen and D. M. Jones, IOPScience 456 (1954)

J. García, V. Collado Ciprés, A. Blomqvist, and B. Kaplan, Int. J. Refract. Met. Hard Mater. 80, 40 (2019).

A. Nino, Y. Nakaibayashi, S. Sugiyama, and H. Taimatsu, Mater. Trans. 52, 1641 (2011).

R.W. Rice, C.C. Wu, and F. Boichelt, J. Am. Ceram. Soc. 77, 2539 (1994).

E.A.D. Leal, U.U. Gomes, S.M. Alves, and F.A. Costa, Int. J. Refract. Met. Hard Mater. 92, 105275 (2020).

W. Zhang, S. Yamashita, and H. Kita, Mater. Des. 190, 108528 (2020).

W. Zhang, S. Yamashita, and H. Kita, J. Mater. Res. Technol. 9, 12880 (2020).

W. Zhang, Curr. Opin. Solid State Mater. Sci. 26, 101000 (2022).

A. Öztürk, K.V. Ezirmik, K. Kazmanlı, M. Ürgen, O.L. Eryılmaz, and A. Erdemir, Tribol. Int. 41, 49 (2008).

M. Sarkar, and N. Mandal, Mater. Today Proc. 66, 3762 (2022).

M. Godet, Wear 136, 29 (1990).

K.H. Zum Gahr, R. Blattner, D.H. Hwang, and K. Pöhlmann, Wear 250(1–12), 299–310 (2001).

S.K. Sharma, B.V.M. Kumar, and Y.W. Kim, Ceram. Int. 41, 3427 (2015).

D.C. Cranmer, J. Mater. Sci. 20, 2029 (1985).

V.S.R. Murthy, H. Kobayashi, S. Tsurekawa, N. Tamari, T. Watanabe, and K. Kato, Tribol. Int. 37, 353 (2004).

S.K. Sharma, B.V. Manoj Kumar, and Y.W. Kim, Friction. 7, 129–142 (2019).

P. Andersson, and A. Blomberg, Wear 174, 1 (1994).

B.M. Kumar, Y.W. Kim, D.S. Lim, and W.S. Seo, Ceram. Int. 37(8), 3599–3608 (2011).

S.K. Sharma, B.V. Kumar, K.Y. Lim, Y.W. Kim, and S.K. Nath, Ceram. Int. 40(5), 6829–6839 (2014).

S.K. Sharma, B.V.M. Kumar, B.B. Zugelj, M. Kalin, and Y.W. Kim, Ceram. Int. 43, 16827 (2017).

I. Gotman, E.Y. Gutmanas, and G. Hunter, Compr. Biomater. II 1, 165 (2017).

W. Fu, Q.Y. Chen, C. Yang, D.L. Yi, H.L. Yao, H.T. Wang, G.C. Ji, and F. Wang, Ceram. Int. 46, 14940 (2020).

ISO 4287–02: Geometrical Product Specifications (GPS) –Surface Texture: Profile Method–Terms, Definitions and Surface Texture Parameters (2002).

ISO 25178–2: Geometrical Product Specifications (GPS)-Surface Texture: Areal--Part 2: Terms, Definitions and Surface Texture Parameters (2012).

Acknowledgements

The authors would like to acknowledge the support from the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior–Brazil (CAPES) –Finance Code 001. The LAINEZ is acknowledged for supplying the tungsten carbide powder.

Funding

General financial support received from CAPES/Brazil. No interference with study design and data analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Azevêdo, H.V.S.B., Raimundo, R.A., Morais, L.M.F. et al. Microstructure, Mechanical and Tribological Properties of the x SiC—(1-x) WC—10 wt.% Co Composites Prepared by High-Energy Milling and Spark Plasma Sintering. JOM 75, 1660–1671 (2023). https://doi.org/10.1007/s11837-023-05754-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-05754-1