Abstract

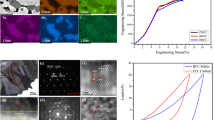

In this study, NbTaTiV refractory high-entropy alloys (RHEAs) reinforced with dispersed oxides were successfully designed and fabricated by mechanical alloying and subsequent spark plasma sintering (SPS). The effects of Y2O3 content on the microstructure and mechanical properties have been systematically studied. The results show that the oxide dispersion strengthening (ODS) RHEAs are mainly composed of body centered cubic (BCC) matrix and multiscale oxides, including submicron Ti-(N, O) particles, nano-sized Y-Ti-O particles and nano-sized Y2O3 particles. The ODS-RHEAs have excellent mechanical properties due to the multiscale oxides. With the content of Y2O3 increasing from 1 wt% to 3 wt% Y2O3, the compressive yield strength of the ODS-RHEAs significantly increases from 1528 to 1866 MPa, while the fracture strain slightly reduces from 22% to 16%. The enhancement of the mechanical property is mainly attributed to the increased amount of multiscale oxide particles and the refined grain structure.

Graphical abstract

摘要

在这项研究中, 通过机械合金化(MA)和随后的放电等离子烧结(SPS)成功设计和制造了弥散氧化物增强的NbTaTiV难熔高熵合金(RHEA)。系统研究了Y2O3含量对合金显微组织和力学性能的影响。结果表明, 氧化物弥散强化 (ODS)RHEAs主要由BCC基体和多尺度氧化物组成, 包括亚微米Ti-(N,O)颗粒、纳米Y-Ti-O颗粒和纳米Y2O3颗粒。由于多尺度氧化物的存在, ODS-RHEAs具有优异的机械性能。随着Y2O3含量从1 wt% Y2O3增加到3 wt% Y2O3, ODS-RHEA的压缩屈服强度从1528 MPa显著提高到1866 MPa, 而断裂应变从22% 略微降低到16%。力学性能的提高主要归因于多尺度氧化物颗粒数量的增加和细化的晶粒结构。

Similar content being viewed by others

References

Chen J, Zhou X, Wang W, Liu B, Lv Y, Yang W, Xu D, Liu Y. A review on fundamentals of high entropy alloys with promising high-temperature properties. J Alloy Compd. 2018;760:15.

Senkov ON, Wilks GB, Miracle DB, Chuang CP, Liaw PK. Refractory high-entropy alloys. Intermetallics. 2010;18(9):1758.

Senkov ON, Wilks GB, Scott JM, Miracle DB. Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys. Intermetallics. 2011;19(5):698.

Xiang L, Guo WM, Liu B, Fu A, Li J, Fang QH, Liu Y. Microstructure and mechanical properties of TaNbVTiAlx refractory high-entropy alloys. Entropy. 2020;22(3):282.

Yao HW, Qiao JW, Gao MC, Hawk JA, Ma SG, Zhou HF, Zhang Y. NbTaV-(Ti, W) refractory high-entropy alloys: experiments and modeling. Mat Sci Eng A. 2016;674:203.

An Z, Mao S, Liu Y, Wang L, Zhou H, Gan B, Zhang Z, Han X. A novel HfNbTaTiV high-entropy alloy of superior mechanical properties designed on the principle of maximum lattice distortion. J Mater Sci Technol. 2021;79:109.

Yao HW, Qiao JW, Hawk JA, Zhou HF, Chen MW, Gao MC. Mechanical properties of refractory high-entropy alloys: experiments and modeling. J Alloy Compd. 2017;696:1139.

Fu A, Guo WM, Liu B, Cao YK, Xu L, Fang QH, Yang H, Liu Y. A particle reinforced NbTaTiV refractory high entropy alloy-based composite with attractive mechanical properties. J Alloy Compd. 2020;815: 152466.

Gwalani B, Pohan RM, Waseem OA, Alam T, Hong SH, Ryu HJ, Banerjee R. Strengthening of Al0.3CoCrFeMnNi-based ODS high entropy alloys with incremental changes in the concentration of Y2O3. Scr Mater. 2019;162:477.

Rao KR, Sinha SK. Effect of sintering temperature on microstructural and mechanical properties of SPS processed CoCrCuFeNi based ODS high entropy alloy. Mater Chem Phys. 2020;256:123709.

Peng S, Lu Z, Yu L. Effects of Y2O3/Ti/Zr addition on microstructure and hardness of ODS-CoCrFeNi HEAs produced by mechanical alloying and spark plasma sintering. J Alloy Compd. 2021;861:157940.

Liu Y, Zhang YA, Wang W, Li DS, Ma YJ. Influence of rare earth Y on microstructure and high temperature oxidation behavior of Ni-Fe-Co-Cu alloy. Chin J Rare Met. 2020;44(1):9.

El-Genk MS, Tournier JM. A review of refractory metal alloys and mechanically alloyed-oxide dispersion strengthened steels for space nuclear power systems. J Nucl Mater. 2005;340(1):93.

Gwalani B, Pohan RM, Lee J, Lee B, Banerjee R, Ryu HJ, Hong SH. High-entropy alloy strengthened by in situ formation of entropy-stabilized nano-dispersoids. Sci Rep-UK. 2018;8:14085.

Prasad H, Singh S, Panigrahi BB. Mechanical activated synthesis of alumina dispersed FeNiCoCrAlMn high entropy alloy. J Alloy Compd. 2017;692:720.

Hadraba H, Chlup Z, Dlouhy A, Dobes F, Roupcova P, Vilemova M, Matejicek J. Oxide dispersion strengthened CoCrFeNiMn high-entropy alloy. Mat Sci Eng A. 2017;689:252.

Gao N, Long Y, Peng H, Zhang W, Peng L. Microstructure and mechanical properties of TiVNbTa refractory high-entropy alloy prepared by powder metallurgy. Chin J Mater Res. 2019;33(8):572.

Liu Q, Wang G, Sui X, Liu Y, Li X, Yang J. Microstructure and mechanical properties of ultra-fine grained MoNbTaTiV refractory high-entropy alloy fabricated by spark plasma sintering. J Mater Sci Technol. 2019;35(11):2600.

Liu Q, Wang G, Sui X, Xu Y, Liu Y, Yang J. Ultra-fine grain TixVNbMoTa refractory high-entropy alloys with superior mechanical properties fabricated by powder metallurgy. J Alloy Compd. 2021;865:158592.

Ressel G, Holec D, Fian A, Mendez-Martin F, Leitner H. Atomistic insights into milling mechanisms in an Fe–Y2O3 model alloy. Appl Phys A. 2014;115:851.

Wu Y, Zhao HZ, Li JK, Zhang YY, Liu T. Effects of Y4Zr3O12 addition on the microstructure and mechanical properties of Fe–15Cr–2W-0.35Ti ODS steels. Mat Sci Eng A. 2021;804:140734.

Guo WM, Liu B, Liu Y, Li T, Fu A, Fang QH, Nie Y. Microstructures and mechanical properties of ductile NbTaTiV refractory high entropy alloy prepared by powder metallurgy. J Alloy Compd. 2019;776:428.

Wang SP, Xu J. (TiZrNbTa)-Mo high-entropy alloys: dependence of microstructure and mechanical properties on Mo concentration and modeling of solid solution strengthening. Intermetallics. 2018;95:59.

Senkov ON, Gild J, Butler TM. Microstructure, mechanical properties and oxidation behavior of NbTaTi and NbTaZr refractory alloys. J Alloy Compd. 2021;862: 158003.

Juan CC, Tsai MH, Tsai CW, Lin CM, Wang WR, Yang CC, Chen SK, Lin SJ, Yeh JW. Enhanced mechanical properties of HfMoTaTiZr and HfMoNbTaTiZr refractory high-entropy alloys. Intermetallics. 2015;62:76.

Liu Y, Zhang Y, Zhang H, Wang N, Chen X, Zhang H, Li Y. Microstructure and mechanical properties of refractory HfMo0.5NbTiV0.5Six high-entropy composites. J Alloy Compd. 2017;694:869.

Yao HW, Qiao JW, Gao MC, Hawk JA, Ma SG, Zhou HF. MoNbTaV medium-entropy alloy. J Mater Sci Technol Entropy. 2016;18(5):189.

Yang L, Ryutan C, Zheng Y, Mohammad HSB, Abdul R, Zhang C, Chen H, Yang ZG. Spalling resistance of thermally grown oxide based on NiCoCrAlY(Ti) with different oxide peg sizes. Rare Met. 2021;40(3):663.

Hu YM, Liu XD, Guo NN, Wang L, Su YQ, Guo JJ. Microstructure and mechanical properties of NbZrTi and NbHfZrTi alloys. Rare Met. 2019;38(9):840.

Cao YK, Zhang WD, Liu B, Liu Y, Du M, Fu A. Phase decomposition behavior and its effects on mechanical properties of TiNbTa0.5ZrAl0.5 refractory high entropy alloy. J Mater Sci Technol. 2021;66:10.

Wen H, Topping TD, Isheim D, Seidman DN, Lavernia EJ. Strengthening mechanisms in a high-strength bulk nanostructured Cu-Zn-Al alloy processed via cryomilling and spark plasma sintering. Acta Mater. 2013;61(8):2769.

Seeger A. On the theory of radiation damage and radiation hardening. Proc 2nd UN Int Conf on Peaceful Uses of Atomic Energy. Geneva; 1958.6.

Alinger MJ, Odette GR, Hoelzer DT. On the role of alloy composition and processing parameters in nanocluster formation and dispersion strengthening in nanostructured ferritic alloys. Acta Mater. 2009;57(2):392.

Wu Y, Liaw PK, Zhang Y. Preparation of Bulk TiZrNbMoV and NbTiAlTaV high-entropy alloys by powder sintering. Metals. 2021;11(11):1748.

Zhang S, Wang Z, Yang HJ, Qiao JW, Wang ZH, Wu YC. Ultra-high strain-rate strengthening in ductile refractory high entropy alloys upon dynamic loading. Intermetallics. 2020;121: 106699.

Guo Y, Li M, Chen C, Li P, Li W, Ji Q, Zhang Y, Chang Y. Oxide dispersion strengthened FeCoNi concentrated solid-solution alloys synthesized by mechanical alloying. Intermetallics. 2020;117: 106674.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (Nos. 51771232 and 52104365).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Liao, T., Cao, YK., Guo, WM. et al. Microstructure and mechanical property of NbTaTiV refractory high-entropy alloy with different Y2O3 contents. Rare Met. 41, 3504–3514 (2022). https://doi.org/10.1007/s12598-022-02038-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-022-02038-6