Abstract

This review summarizes the use of cellulose and polylactide for medical applications with particular emphasis on modern dressings. Although classic cotton and viscose dressings are still available and popular, the usefulness of new forms of cellulose (Cel) and its derivatives opens new wound treatment options. Therefore, trends in functionalizing traditional cellulose dressings, including products made of bacterial cellulose, and dressings from cellulose derivatives, are discussed. Polylactide (PLA), in turn, is a biodegradable and biocompatible polyester that fulfills plenty of tasks in many medical fields, from surgery to modern diagnostic methods. However, polylactide dressings can still be advantageous to the market. Thus, the next part of the article contains a recent update of available knowledge about PLA and its applications in regenerative medicine and drug-delivery systems. The last part is devoted to the possibilities of combining both materials in dressings and related problems and benefits. Methods for compatibilization with the surface of both polymers and new techniques for producing Cel/PLA composite materials are also described.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

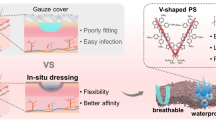

Cellulose dressings as a form of wound treatment are present in medical practice since antiquity. Ancient literature presents dressings as one of the stages of wound care (Nicoli Aldini et al. 2008). Textiles made of natural vegetable fibers, such as linen bandages, often soaked with therapeutic and antibacterial substances, were already used in ancient Egypt (Sipos et al. 2004; Thomas and Uzun 2019; Wilkins 1964). In the twentieth century, the development of plastics industry resulted in the introduction of synthetic fibers, in parallel with an increase of the wound-treating materials available, from classic woven, knitted and nonwoven dressings up to modern foams (Fogh and Nielsen 2015; Salisbury et al. 2022), hydrogels (Francesko et al. 2018; Shu et al. 2021; Wu et al. 2023; Zhang et al. 2019), hydrocolloids (Stoica et al. 2020b; Thomas 2008) and thin membranes (Graça et al. 2021). Composite dressings combine multiple functions in one product and their form varies depending on the raw materials used and the expected functionality (Gupta and Edwards 2019).

This work focuses on analyzing materials for modern products supporting regenerative medicine composed of cellulose and polylactide. It contains present-day state of knowledge about these two polymers and their combination for medical applications, however, with strong emphasis on wound dressings. It may also help with establishing whether polylactide/cellulose (PLA/Cel) systems have some unique advantages over these polymers acting alone. To understand their mutual interactions, many points are discussed, including structural, functional, and engineering issues. One of the biggest problems related to combining PLA and cellulose is their different affinity to water. Polylactide is hydrophobic and cellulose is hydrophilic, so the goal is to modify them in such way that will enhance interphase PLA/Cel interactions and improve mechanical properties of their composites.

Cellulose is the most classic and well-known natural polymer. From the earliest beginnings of wound healing, it has been present as a part of medical equipment and until this day it has not lost its great significance in the scientific world. As one can see, the versatility of cellulose applications has strongly increased with the material and chemical engineering development, although classical cotton fabrics are not forgotten in medicine and hospital environment (Graça et al. 2021). The aim of developing new solutions leads from the activation of medical products, which were previously passive like cotton gauzes and bandages (Graça et al. 2021; Lumbreras-Aguayo et al. 2019b), constructing cotton-reinforced modern forms of dressings (Lumbreras-Aguayo et al. 2019b), to pure nanoscale cellulose and its derivatives as healing materials (Alavi and Nokhodchi 2020; Cidreira et al. 2021; Liu et al. 2020). In addition, bacterial cellulose has also been considered as a smart material with some advantages over plant-based cellulose (Portela et al. 2019; Rathinamoorthy 2022).

In the face of a long history of cellulosic dressings, polylactide occurs as a quite new product, however, it has been known for years. Polylactide (PLA) is a biodegradable and biocompatible polymer (Basu et al. 2016; Gupta and Kumar 2007; Michalski et al. 2019) and is recognized as safe by the U.S. Food and Drug Administration. Therefore, PLA has attracted considerable attention as a candidate capable of replacing petroleum-based polymers due to its good processing and mechanical properties (Raquez et al. 2013). PLA is proposed for various applications in industrial, pharmaceutical, and environmental fields. Among these multiple fields of PLA utilization, biomedical usage is one of the most frequently proposed for PLA-based materials (Sinha Ray 2012).

It seems that both cellulose and polylactide as materials for medical applications can now have similar functionalities. However, traditional cellulose dressings still have a strong market position, also for economic reasons. Enriching them with a polylactide in active form, for example as a medium for drugs, could be a relatively cheap and effective way to modernize them and at the same time to meet the specific needs of patients. This can be the simplest way to launch PLA on the market, as the use of dressings in everyday life does not require medical consultation but they need to be affordable and easy to apply. The combination of both polymers in one material (for example via grafting or polymerization) may provide a possibility for new modifications, considering their different physical and chemical properties, the capability to perform different chemical reactions with other compounds, as well as the ability to degrade with all the consequences. Finally, it is worth examining whether the characteristics of the PLA/Cel systems are a simple sum of the features of their components or, on the contrary, the ingredients complement each other, presenting an improved quality, not available when they perform separately.

The structure and properties of cellulose

The main building block of a cotton fiber is cellulose, whose quality and structure determine its most important properties. Cotton has the highest content of cellulose from all-natural sources, reaching up to 96% dry matter (Segal and Wakelyn 1985), followed by sisal and pineapple leaf fibers (Gassan et al. 2001). Cellulose, a polysaccharide with a summary formula (C6H10O5)n, is a large molecular structure polymer resulting from a natural polycondensation. The cellulose macromolecule chain is made of β-d-glucopyranosyl units connected with 1,4-β-glycosidic bonds. The repeated unit is the glucose residue (French 2017).The non-reducing end of a cellulose chain is composed of a hydroxyl group, whereas the reducing end is a hemiacetal. The presence of hydroxyl groups in the molecule determines the reactivity of cellulose, although these groups, due to the location in the spatial structure, are not just as reactive. The most reactive group is the one located at C2, then with C6 carbon. Hydroxyl groups, as they are characterized by polarity, form hydrogen bonds between macromolecules, which in turn causes stiffening of the chain and the formation of strongly ordered spatial structures—the so-called crystalline phase in fiber.

To describe the properties of the cellulose polymer, specify such features as:

-

average polymerization degree;

-

average degree of crystallinity;

-

construction of the elementary cell in the crystalline phase.

High dispersity of molar mass is a typical feature of cellulose isolated from natural sources. Native cellulose consists of macromolecules with different polymerization degrees, while the average polymerization degree is different for cellulose materials of different origins (e.g., for cotton cellulose and cellulose from wood). Similar diversity can be observed in the degree of crystallinity. Various sources give the following value: according to Urbańczyk (1985), the degree of crystallinity in cellulose derived from plant fibers reaches 60–80%; according to "Handbook of Polymers", it is 75% for cotton (which is the cleanest source of cellulose I), while according to "Comprehensive Cellulose Chemistry" it is about 60%, with this applying to cotton fibers undergoing initial physicochemical treatment (Klemm et al. 1998). However, as in the case of all cellulosic materials, crystallinity values have considerable dependence on the exact methods, even just considering X-ray diffraction (French 2020).

A crystal’s unit cell is the smallest unit of the crystal that can be used figuratively to construct the structure of the crystal by simple repetition of the unit cell along the X, Y, and Z axes of the crystal. The six basic parameters are in the XYZ axis system of the lattice, (a, b, c)—the distances at which the cell elements are repeated, and the angles between the axles (α, β, γ). However, the Miller indicators (h, k, l) define crystallographic planes that result in the various peaks of photon intensity on a diffraction pattern. These characteristics are different for every polymorph (French 2014). Chemical and physicochemical treatment has a significant impact on the form of an elementary cell, a crystallographic variety, as well as the content of crystalline material in fiber. An example would be the mercerization process, where under specific conditions native cellulose I is converted to cellulose II, whose parameters of the structure of the elementary cell of crystalline differ from the output material (Takahashi and Takenaka 1987). A different shape of the elementary cell carries, therefore, a change in physical and chemical parameters, such as changing the density of the material, differences in mechanical properties, as well as the ability to bind dyes. Other polymorphic forms of cellulose are cellulose III, which can be obtained as a result of ammonia swelling cellulose I or II, and cellulose IV, an effect of force and heat to other cellulose varieties (Klemm et al. 1998). The degree of cellulose crystallinity changes with the origin of the material and the processing it was subjected to, moreover, the properties of converted polymorphs depend on their parental structures (Wada et al. 2004). A different question is whether these conversions are reversible. Hindi (2016) lists seven interconvertible polymorphs of cellulose, namely, Iα, Iβ II, IIII, IIIII, IVI, and IVII and states that celluloses IIII and IIIII revert to their previous forms in a high temperature and humid environment. The reversion is possible also in the case of cellulose IV.

Bacterial cellulose

Although cellulose II is typically the result of mercerization with NaOH or dissolution and regeneration as in the viscose or NMMO processes for making rayon or lyocell, its natural sources are known. This material occurs in the sea algae from Halicystis species, under certain rare conditions. Mutant bacteria have also produced cellulose II. The bacterial cellulose in the form of cellulose II is most often produced by the strain of Gluconacetobacter xylinus (Dufresne 2017). However, the typical bacterial and algal cellulose is cellulose I, and more precisely Iα (Picheth et al. 2017; Rusdi et al. 2022; Wada et al. 2001), whereas, as the research on Acetobacter xylinum ATCC23769 indicated, the crystallographic structure of cellulose (I or II) can be modified the culture conditions (Hirai et al. 1997). Other bacteria strains used for cellulose production are Agrobacterium, and Sarcina. The quality of bacterial cellulose can be diversified by controlling nutrient sources (meaning carbon sources) and culture conditions of bacteria strains (Abeer et al. 2014; Gullo et al. 2017). The influence of pH, temperature, and access to UV light was studied by Lazarini et al. (2018) on the Gluconacetobacter hansenii. The G. hansenii variants grown under different pH and UV conditions showed lower capacity to BC production when compared to original G. hansenii ATCC 23769 (Lazarini et al. 2018). In the review of bacterial cellulose for wound healing applications (Ahmed et al. 2020), BC in general is characterized by greater purity, the ability to absorb water, and porosity (Table 1). The authors discuss also mechanical properties of BC, and its Young’s modulus and tensile strength which are comparable to aramid fibers, and indicate it as a reinforcement in composites. Moreover, BC is a promising medical material that does not require initial, time-consuming and expensive purification. Naomi et al. (2020) describes bacterial and plant cellulose in detail. According to that work, the main BC differences compared to vegetable cellulose are:

-

1.

Purity of the material (without the presence of hemicellulose, lignin, waxes, and other impurities).

-

2.

Mechanical properties (Young’s modulus, tensile strength) beneficial for tissue scaffolding structure, e.g. bone tissue (Torgbo and Sukyai 2018)

-

3.

The higher degree of crystallinity (over 80%) (Revin et al. 2021).

-

4.

High water absorption, but relatively low Water Vapor Transmission Rate.

-

5.

No immune response, no inflammatory reaction after contact with live tissue.

-

6.

Ease of shaping due to the high flexibility module.

-

7.

Much higher porosity, as well as a larger size of pores.

-

8.

Higher hydrophilicity.

However, these differences, especially mechanical properties and water absorption, depend on production medium composition, for example the concentration of sugar. As reported, BC from sago liquid waste showed a tensile strength of 44.2–87.3 MPa, Young’s Modulus of 0.86–1.64 GPa and water holding capacity of 85.9–98.6 g g−1. It could also be observed that the increased mechanical strength is linked to lower water holding capacity (Yanti et al. 2021). It is also worth mentioning that mechanical modifications influence BC properties as well as cultivation methods (Betlej et al. 2021). As one can see, many factors affecting the final form of BC determine its versatility for various applications. Usefulness for therapeutic purposes and biocompatibility with human tissues, however, seems to be at a similar level as plant cellulose—the effectiveness of improving processes of regeneration, cell adhesion and hemostatic effects depend mainly on the modifications and the presence of additional medicinal compounds. Some authors, nevertheless, emphasize that its natural structure also closely mimics many biological tissue properties (e.g. collagen fibers of bone and skin tissue), it has an ability to regulate cell adhesion, and its antigen immobilization capability for biosensor applications (Abazari et al. 2021).

Currently, bacterial cellulose is used in various aspects of regenerative medicine, from wound treatment, through the use of drug delivery systems, to tissue reconstruction (Table 2). BC occurs in various forms, both on a micro and nanoscale—as membranes, fibers (and materials made of them, usually nonwoven), hydrogels and composites. A commercial example is Dermafill® (previously known as Biofill®) membrane dressing that acts as a temporary skin substitute (Castro et al. 1988), but there are more products on the market and even more solutions under research, proving usefulness of this material (Zhong 2020).

Natural cellulose materials and traditional dressings

Fibrous dressings, regardless of the type of fibers found in them (both natural and artificial/synthetic) are manufactured in the woven and non-woven form. Structures such as cotton wool were made use of relatively late (compared to the world history of wound dressings)—around 200 years ago. Cotton wool consisted of washed, loose and combed cotton fibers. Therefore, it was supposed to replace the traditional linen ripped strips or unraveled threads made of old clothing (Elliott 1957).

Although the last few dozen years have allowed for the development of advanced technologies of dressings supporting wound treatment, still the most typical and widely available cellulose dressing is gauze, bleached fabric, loosely woven with canvas weave. Initially, it was produced only from natural cotton fibers, but currently on the market there are also gauzes made of artificial cellulose fibers or cotton/viscose mix. Gauze dressings only fulfill basic tasks, like protecting the wound against the external environment and absorbing exudate. Their properties are determined by the number of warp threads- the greater the number, the more the dressing absorbs. A sufficiently strong twist of yarn and other parameters of spinning are also important to prevent the dressing from being undesirably distributed when removing it from the wound. Gauze as a compress absorbs blood and bodily fluids. While in the form of a bandage, it is also used as a secondary dressing, holding and covering the primary (or, in other words, active) dressing, which has therapeutic properties and needs to be secured from moving and/or from external environment. An example of primary dressing that is combined with topical cover is non-adherent HELIX3-CM® Collagen Matrix, suitable for burns, sores, blisters, ulcers, and wounds. Simplicity and the relatively low cost of the production of the standard gauze, as well as the ease of adapting to the patient's specific needs, mean that its high popularity will probably last long.

An interesting attempt to enrich the functionality of gauze to a wide extent was presented by Said (2021). The designed gauze was first pre-modified by chitosan cationization or anionic carboxymethylation. Then, by successively applying hydroxyapatite, silver nanoparticles and ginger oil, it gained anti-inflammatory, antimicrobial and anti-UV properties. Another strategy was to modify the surface of the gauze by grafting the poly(Methacrylic Acid) (PMAA), which was followed by testing the implementation of ZnO nanoparticles to obtain the antibacterial and antimicrobial functions and by investigation of the drug releasing profile after loading it with nalidixic acid. Compared to an unmodified gauze, the antibacterial effect was the result of PMAA grafting itself. The results were due to bactericidal properties of acrylic acid polymers. The explanation is that acidic environment disturbs cytoplasmic homeostasis pH, while acid groups reduce bacterial adhesion. However, 100% inhibition effect for S. epidermidis bacteria was achieved only by adding ZnO (Lumbreras-Aguayo et al. 2019a). The process of hemostasis is to be supported by gauze with grafted carboxymethyl chitosan and covered with gelatin and alginate using the Layer-By-Layer method, a technique of fabrication of thin films made by depositing respectively oppositely-charged materials (Zheng et al. 2021). A relatively simple way to improve functionality is to use cotton gauze, present on the market (classic and covered with anti-adhesive wax) to apply 2-deoxy-D-ribose (2dDR) which would support angiogenesis (Andleeb et al. 2020). In the case of a hydrophobic wax dressing, it was necessary to construct a carrier using paraffin, ethanol, and poly(ethylene glycol) (PEG) in various configurations or implement 2dDR in a partly diluted wax cover. Another way of modifying conventional cotton fabric was grafting L-cysteine (Cys) on the surface and then implementing copper nanoparticles in the presence of citric acid. Such material exhibited satisfactory activity against bacteria S. aureus and E. coli and excellent washing fastness (Qingbo Xu et al. 2018a, b).

In recent years, the greige cotton, which is unbleached cotton as a dressing material conducive to hemostatic processes in open wounds, has become the object of wider interest. In the work of Edwards et al. (2022), it occurred that highly cleaned and sterile unbleached cotton, due to its constituents, may produce hydrogen peroxide at a certain level. Moreover, it can be modulated with ascorbic acid by impregnation with classical pad-dry method, resulting in antimicrobial properties. It is beneficial from the ecological and economic point of view to omit the cotton bleaching stage and avoid the use of chemicals necessary for this process (such as wetting agents, and whitening agents based on hydrogen peroxide or chlorine compounds). It is worth emphasizing that naturally occurring substances remain on the fibers—pectins, proteins, waxes, hemicellulose, fats, as well as vestigial amounts of inorganic compounds called ash. Leaving them on the fiber affects the hydrophobicity and polarity of the surface and creates an environment conducive to blood clotting. On the other hand, dressings consisting only of greige cotton may not absorb exudate sufficiently for exactly the same reasons (Vincent Edwards et al. 2020).

Apart from cotton, attempts are made to adapt other natural cellulose fibers to the needs of wound treatment. As in the case of greige cotton, cellulose material with a natural addition of specific substances supporting treatment is linen (Linum L.). Recent research shows that linen dressings have healing effects on wounds not only because of cellulose material and polymers naturally occurring with it (hemicellulose, lignin, pectin), but also because of the presence of potentially bioactive substances, such as vanillin, 4-hydroxybenzoic acid, ferulic acid, coumaric acid, syringaldehyde, olyhydroxybutyrate/hydroxybutyrate, and polyamines. By examination on cellular line of mouse BALB/3T3 fibroblasts and normal human dermal fibroblast (NHDF), and normal human epidermal keratinocytes (NHEK) line, human dermal microvascular endothelial (HMVEC) cell line, epidermal carcinoma cancer A431, and monocyte THP-1 cell line, it has been shown that genetically modified linen fibers, differing from unmodified fibers with increased content of the above-mentioned compounds, accelerated the proliferative activity of damaged tissues (Gębarowski et al. 2020).

Cellulose derivatives for dressings

The presence of hydroxyl groups in cellulose macromolecules results in high reactivity of the polymer and great possibilities for modification for medical purposes. Typical reactions with OH groups are etherification, esterification, acetalization, and oxidation. Some of the obtained derivatives (especially esters and ethers) are well known and have been produced commercially for a long time (Klemm et al. 1999).

In an overview of cellulose and its derivatives for wound healing, Tudoroiu mentions: cellulose esters, cellulose acetate (CA), cellulose acetate butyrate (CAB), cellulose acetate phthalate (CAP), cellulose acetate trimelitate (CAT), hydroxypropylmethylcellulose phthalate (HPMCP), and hydroxypropyl methylcellulose acetate succinate (HPMCAS). Among ethers, there are sodium carboxymethylcellulose (NaCMC), hydroxypropylmethylcellulose (HPMC), methylcellulose (MC), hydroxyethylcellulose (HEC), ethylcellulose (EC), hydroxypropylcellulose (HPC), hydroxyethylmethylcellulose (HEMC), and benzylcellulose. They appear also in combinations of two or more and usually contain active pharmaceutical ingredients (Tudoroiu et al. 2021). Usually, most reports also mention bacterial cellulose, although its production is significantly different.

Cellulose derivatives due to their specific properties influencing the easy forming of various forms of dressing and healing process (alone or with other components) are versatile and flexible materials. The main advantage over pure cellulose is improved solubility in water with some exception of, for example, ethylcellulose or cellulose acetate. Moreover, the properties of cellulose-based nanoparticles can prolong circulation of drug carriers in organism by increasing drug solubility and stability and thus enhance their bioavailability, or perform as biosensors and as a tool of targeted therapy thanks to easy customization for specific tasks (Hosny et al. 2022). Biosensors based on oxidized or carboxylated cellulose nanomaterials promote amide linkage between amide groups of proteins and nucleic acids, and carboxyl groups grafted onto cellulose molecules which increases their resistance to external environment (Teodoro et al. 2021). As biosensors, they might be useful for detection of such bio-molecules as urea, lactate, glucose, genes, amino acids, cholesterol, and proteins (Kamel and Khattab 2020). Cellulose derivatives, in particular carboxymethyl cellulose (CMC), cellulose acetate and bacterial cellulose were also discussed from a clinical point of view. Some advantages are as follows:

-

1.

cellulose acetate—excellent scaffolding biomaterial for implementation of drugs and other compounds with anti-microbial, antioxidant, anti-inflammatory, and antiviral activity

-

2.

carboxymethyl cellulose—the ability to construct hydrogels in the presence of metallic ions,

-

3.

bacterial cellulose – highly effective surface area, and a hydrophilic nature that gives it a high liquid loading capacity, ability to drug carrying, good mechanical properties and breathability (Abazari et al. 2021)

In recent years, (CMC)-based wound dressing materials have been strongly discussed due to their biocompatibility, biodegradability, low cost, and other properties such as tissue resembling and non-toxicity (Kanikireddy et al. 2020). Various forms and practical use of dressings are possible (Fig. 1).

CMC-based dressings. Reprinted from (Kanikireddy et al. 2020) with permission from Elsevier

Some CMC dressings are already present on the market, such as Aquacel®, which was proven to encapsulate potentially pathogenic bacteria in its gel structure when it covers the wound (Walker et al. 2003). The basic Aquacel® is composed only of sodium carboxymethylcellulose spun into fibers and then shaped into dressing form. Put into the wound, it absorbs exudation inside of the fibers, keeping it away from the tissue. At the same time, it changes the structure to the gel and maintains the moist wound environment for optimal healing (Williams 1999). Attempts were made to use cotton cellulose from waste remaining after production processes to produce CMC and create hydrogel wound dressing. Recovered cotton fibers were cut and pretreated with 20% sodium hydroxide solution to remove impurities, and then bleached in 6% solution of sodium hypochlorite. In the next step, CMC was synthesized by the etherification with various amounts of sodium monochloroacetate (SMCA). Hydrogel was obtained through the cross-linking reaction in the presence of epichlorohydrin (ECH). Different combinations of cellulose and CMC were used to achieve desired results- suitable exudate absorption, wound dehydration, and tissue regeneration environment (Jirawitchalert et al. 2022).

Hydroxypropyl cellulose (HPC) was a matrix for nanocomposite films enriched with graphene oxide (GO) grafted silver-coated zinc oxide nanoparticles (Ag/ZnO) (Fig. 2). These so-called AGO nanofillers positively influenced mechanical strength, UV resistance, and antibacterial performance (Wang et al. 2019a, b). Another solution for antibacterial properties was Polyhexamethylene guanidine hydrochloride (PHMG) grafted to cellulose diacetate (CDA) wound dressing surface through an amide reaction. The dressing had a nanofibrous structure made by electrospinning, which additionally enhanced hydrophilicity. Such prepared materials were tested for water absorption, and absorbing capacity (or, in different words, water holding capacity). In the first case, the weight of samples soaked with saline solution for 10 s was compared to the weight of lyophilized ones. Secondly, the weight of samples previously immersed in saline overnight was measured to determine water retention over a certain period of time. Results showed that increasing amount of PHMG has significantly influenced all those parameters (Xiao et al. 2022). Cellulose diacetate wound dressing also supports hemostasis and counteracts excessive blood loss (Liang et al. 2021).

Hydroxypropyl methylcellulose (HPMC) combined with collagen enriched with povidone-iodine and formed into scaffolds effectively facilitated the proliferation of fibroblast cells with no toxic effects (Kesavan et al. 2022). A combination of ethylcellulose/hydroxypropyl methylcellulose nanofibers was loaded with aloe vera extract and formed into a wound healing dressing mat, which exhibited enhanced cell proliferation, adhesion, and antibacterial activity (Mohebian et al. 2022).

Polylactide

In this part of the review, the focus will be on the application of PLA-based materials for regenerative medicine and drug delivery systems. Since there are numerous reviews about PLA-based materials in drug delivery, describing PLA safety (Pawar et al. 2014; Ramot et al. 2016) and biomedical applications of its copolymers (Bawa and Oh 2017; Jain et al. 2016; Oh 2011), stereocomplexes (Bertin 2012; Brzeziński and Biela 2015; Tsuji 2016), hydrogels (Basu et al. 2016), and nanoparticles (NPs) (Casalini et al. 2019; Kumari et al. 2010; Tyler et al. 2016). Moreover, the clinical applications of PLA were also summarized (DeStefano et al. 2020). There are also some examples of PLA-based NPs under clinical trials (Niza et al. 2021; Prabhu et al. 2015), for instance, Genexol-PM or BIND-014®. Therefore, this part presents only recent achievements in this field which were published last or this year. However, there is also intention to outline wider use of polylactide in form of fibers, its modifications and perspectives.

Polylactide (PLA) is a biocompatible polyester that can be obtained by polycondensation of lactic acid or the ring-opening polymerization (ROP) of lactide. (Slomkowski et al. 2014). The building block of PLA can be composed both from optically active l- and d-enantiomers. Therefore, pure poly-l-lactic acid (PLLA) or poly-d-lactic acid (PDLA) can be produced from l-lactic and d-lactic acid, respectively (Zibiao Li et al. 2016). Moreover, the polymerization of a racemic mixture of both enantiomers leads to the preparation of poly-d,l-lactic acid (PDLLA). The structure of the PLA chain determines the properties of the resulting macromolecule and, as consequence, PLLA/PDLA are semi-crystalline polymers whereas the PDLLA is an amorphous polymer. In addition, the equimolar mixture of PLLA and PDLA forms a supramolecular complex which is called stereocomplex (Tsuji 2005). The formation of this complex improves the mechanical and thermal resistance for degradation of PLA-based materials (Zibiao Li et al. 2016).

The PLAs are typically obtained via polycondensation or polymerization (Slomkowski et al. 2014). The first method uses the reaction between hydroxyl and carboxyl groups of lactic acid to form ester bonds and obtain the desired polymer (Cheng et al. 2009). The ring-opening polymerization (ROP) of lactide (cyclic dimer of lactic acid) is the most popular method for PLA synthesis because it allows for the preparation of high molecular weight polymers with the absence of the side products typically observed during polycondesation. Moreover, the stannous octoate (Sn(Oct)2) as catalyst and alcohol as initiator are used for the PLA synthesis (Kowalski et al. 2000). However, various new catalysts both for coordination, cationic, and organocatalyzed polymerization were recently proposed (Kamber et al. 2007; Mezzasalma et al. 2017; Sebai et al. 2018). In addition, the star-shaped, hyper-branched, and dendritic PLAs can be prepared from the appropriate initiators of LA polymerization (Bednarek 2016; Michalski et al. 2019).

Polylactide in regenerative medicine

Research on the use of polylactide in medicine, including regenerative medicine, has been conducted with high intensity for several decades (Li et al. 2020). At the end of the twentieth century, Bendix (1998) presented an application for PLA and its copolymers (such as glycolide, trimethylene carbonate, and caprolactone) mainly in the form of screws, pins (which means surgical accessories intended for bone fixation), plates in surgery and orthopedics (homopolymers, PDLLA, L- and d,l-lactide copolymers), chopped drug release systems, surgical thread components and other medical textile materials (PLA and its copolymers with glycolide and TMC). Currently, the scope of polylactide applications has expanded significantly. As reported in 2016, Tyler (2016) mentions such fields of medicine as:

-

Orthopedics (bone regeneration, resorbable screws),

-

Neurology (peripheral nerves, spinal cord),

-

Cardiology (stents),

-

Dentistry (tissue regeneration, fillers),

-

General and plastic surgery (hernial nets, surgical threads, lifting threads, fillers),

-

Gynecology (stabilizing nets),

-

Radiology (theranostic imaging),

-

Oncology (drug delivery systems, vaccines).

Until recently, polyesters (both aromatic and aliphatic) were not the main component of broadly understood dressings but were used as a strengthening add-on. An example is the Silflex® dressing made of a polyester mesh, whose functionality is based on the outer, coating silicone layer. There are already dressings on the market with polylactide. Suprathel® is a flexible and permeable to gases and liquid membrane, with such components as polylactide, trimethylene carbonate, and ε-caprolactone. Suprathel® is intended for treating burns, and thanks to the ability to biodegradate, it avoids painful changes of the dressing because it degrades directly in the wound. The conducted research among patients suffering from chronic wounds associated with diabetes (for example diabetic foot) also indicated its effectiveness in reducing the size of treated chronic wounds, at the same level as in the case of non-diabetic wounds (Nischwitz et al. 2021). The positive effect of polylactide on wounds is also confirmed by other studies in which nanofibrous polylactide nonwovens were subjected to tests on the porcine model (Menclová et al. 2021a, b). It has also been shown in vivo that PLA product strengthened the proliferative phase in the treatment of wounds compared to chitosan fabrics of similar structure (Menclová et al. 2021a, b). This shows that in the case of dressing materials, polylactide is still a relatively new material and the possibilities of the use of polylactide dressing materials are still to be learned and require further research.

Attempts are being made to modify its properties without the participation of additional substances, for example by plasma. In the 2015 examination, two types of non-woven fabrics, spun-bonded and needle-punched, both made of D-lactide, were put under the low-temperature plasma. The action of plasma was tested in two variants, in the presence of atmospheric air and C6F14 (perfluorohexane). The operation of the plasma from the air has increased the sorption properties of polylactide fibers, which according to the authors of the study predestines the received material for the category of superabsorbents. In turn, as a result of plasma treatment, perfluorohexane increased its hydrophobicity. The disadvantage of modification may be its impermanence, because the changes in the surface activity of the fibers disappeared after a few months (Urbaniak-Domagala et al. 2016).

The subject of interest is polylactide and its copolymers, most often in the form of nanofibers produced by the electrospinning method (Kanmaz et al. 2018). Nanofibers, due to the specific dimensions and significant advantage of the surface above the volume, are materials with increased surface activity affecting interactions in the treated area and can imitate the properties of external cell matrix (Extracellular Matrix, ECM), in particular, peptide and hyaluronic acid nanofibers (Mohiti-Asli and Loboa 2016).

Polylactide nonwovens can be modified for special applications already at the production stage, through production parameters, or by changing the parameters of the spinning solution, including the addition of active substances and drugs. Several factors influence the final form and functionality (Sharifi et al. 2020; Antoniya Toncheva et al. 2014). Production parameters determine the physical, thermal, and mechanical properties of fibers, while the additives primarily give medicinal, antiseptic, and antibacterial properties, although above a certain concentration production also requires adaptation of spinning conditions due to the impact on the properties of a spinning solution (by changing viscosity, the presence of dispersion agents). The form of fibers, porosity, and transverse dimensions are also affected by the presence of copolymers. It is also known that copolymers affect the effectiveness of dressings. It has been shown in in vitro and in vivo research that the membrane from the polylactide/poly(vinyl alcohol)/sodium alginate (PLA/PVA/SA) mix improves fibroblast proliferation and reduces the inflammatory response at an early stage of healing compared to membranes of pure PLA, while the effect of collagen deposition is clearer in the case of the latter (Bi et al. 2020). However, the effectiveness of releasing drugs is influenced by the crystallinity of the polymer due to the difficult access of water molecules to the crystalline phase. The use of nanofibers with active medical compounds for the treatment of wounds is already the subject of several studies (Ambekar and Kandasubramanian 2019; Arida et al. 2021; Liu et al. 2017). Typical active additives for the spinning solution used in various combinations are natural extracts, metal nanoparticles, peptides, antibiotics, growth factors, both in molecular form and encapsulated, or mixture of copolymers and it is summarized in Table 3.

Surface modification of PLA fibers

The polylactide products, such as nanofibers, foams, and films, regardless of whether they have been enriched in the production process, undergo further modifications. In tissue engineering, the change in surface properties is often aimed at increasing an affinity to the human tissues. Cells' adhesion is influenced by the polymer surface wettability, free surface energy, surface charge (an electric charge present on the surface of the material), as well as the chemical structure of the outer layer and its morphology. Generally, highly adhesive tissue material is hydrophilic with a surface charge with the opposite charge to the surface of the cells. Specific needs determine the values of the above parameters (Wang et al. 2005). However, it is worth mentioning that some results show that the cells are able to adhere and proliferate either on hydrophilic and hydrophobic surfaces, although the number of cells on hydrophobic surface initially decreases to finally increase after time (Ishizaki et al. 2010). Another research on superhydrophobic materials and their interactions with proteins and cells highlights the importance of surface topology in protein and cell adhesion (Lourenço et al. 2012). In this study, protein adsorption was higher on smooth surfaces than textured. The relationship between cell adhesion and surface roughness was also relevant, as cell adhesion and proliferation were inhibited on rough surfaces; however, cells remained viable and active. This means that good tissue affinity is a complex phenomenon and cannot be easily determined (Ferrari et al. 2019). Increasing the hydrophilicity of polylactide products is the subject of great interest. It is usually achieved with physical and chemical methods, through γ-ray irradiation (Qi et al. 2019), surface hydrolysis (Lee and Yeo 2016; Liu et al. 2019; Tham et al. 2014), plasma or laser treatment (Kudryavtseva et al. 2017; Mohsenimehr et al. 2020; Rytlewski et al. 2012; Stoleru et al. 2016; Wan et al. 2004), and the choice of the method also affects other surface properties such as roughness (surface morphology) or cell affinity. Plasma is the most versatile method and its impact causes various interactions with the material: cleaning, etching, activation by creating functional groups, grafting, and polymerization (Cools et al. 2014). At the stage of spinning the fibers, admixtures of hydrophilic copolymers, including poly(ethylene glycol), are used in the spinning solution (Hendrick and Frey 2014; Suzuki et al. 2018). In the wetting tests (by contact angle measurement), it has been shown that the value of the wetting angle decreases proportionally as the PEG percentage in the mixture increases (Athanasoulia et al. 2019; Athanasoulia and Tarantili 2017). Another solution is to impregnate polylactide material with poly(ethylene glycol) copolymers. PDLLA membranes saturated with an amphiphilic monomethoxyl poly(ethylene glycol)-b-poly(d,l-lactide) (PEG-PDLLA) showed changes in the wetting angle from 74.5° to 50°, depending on the solution concentration (Yang et al. 2018). The PEG connection method to PLA (mixing or grafting to the surface) is important from the point of view of the mechanical properties and parameters of the spinning solution, because the PEG add-on causes a reduction of the strength of the mixture and increases the viscosity of the spinning solution (Kruse et al. 2018; Toncheva et al. 2016). Zhu modified films from high molecular weight poly-l-lactide by immersing them with poly-d-lactide with low molecular weight and poly (d-lactic acid-co-glucose) copolymer (PDLAG) dissolved in chloroform (Zhu et al. 2021). The submersion in a solution for more than 3 min resulted in swelling of the foil, and in a further step its destabilization. As a result, stereocomplexed crystals are formed on the surface of the foil, and homogeneous crystals inside the foil, and hydrophilicity improved because of the presence of glucose. The next method of connecting the PEG hydrophilic groups is to create a three-element structure (scaffolding), in which the PLA-b-PEG block copolymer is a kind of "glue" bonding with a hydrophobic PLA and hydrophilic PEG. The dissolved mixture was slowly poured into the powdered NaCl which then, after the polymer's solving and thermal recrystallization, was washed out and thus obtained a porous scaffolding structure (Zhu et al. 2015).

PLA as matrix for drug delivery systems, a recent update

PLA-based NPs with anticancer properties

The PLA-based NPs are widely used as a carrier of anti-cancer drugs to enhance their stability and efficiency. The recent trends are focused on the design of the stimuli-responsive polymers that can recognize the difference between the tumor and healthy tissues since there is a distinct difference between pH around the tumor site. Moreover, the co-delivery of two or more active agents is proposed to enhance the effectiveness of nanotherapies. Therefore, this section is describing recent strategies of improvement in the delivery of chemotherapeutics by PLA-based nanosystems. It is divided by the applied drug or their combination, however with one exception for photodynamic therapy since it was excluded from this classification and described separately.

Doxorubicin

Doxorubicin (DOX) is a drug from a group of anthracycline antibiotics and its mode of action is related to the blocking of the topoisomerase II. Since PLA does not possess any functionalities in the backbone that allows for its sensitivity to the external stimuli, therefore one possible strategy could be its copolymerization with appropriate monomers. For instance, the stimuli-responsive PLA copolymers with allyl-glycidyl ether (AGE) (Kost et al. 2021), l-proline derivative (Brzeziński et al. 2021) were proposed for the preparation of PLA-based NPs loaded with DOX. Both nanoformulations exhibit pH-depended DOX release, however the cross-linking by supramolecular interactions between enantiomeric PLA chains decrease the release from obtained NPs. Their efficiency has been proven in vitro against AGS (human gastric adenocarcinoma) and HeLa (human epithelioid cervix carcinoma) cell lines. In addition, the copolymers of poly(2-hydroxyethylmethacrylate)-g-poly(lactide)-b-poly(ethyleneglycol)-b-poly(2-hydroxyethylmethacrylate)-g-poly(lactide) (PHEMA-g-PLA)-b-PEG-b-(PHEMA-g-PLA) were obtained via combination of reversible addition fragmentation chain (RAFT) and ring-opening polymerization (ROP) methods (Ghamkhari et al. 2021). Subsequently, these copolymers were used for the covering of graphene oxide surface and, as a result, the DOX-loaded nanocomposites were obtained. The pH-triggered drug release from nanocomposites was shown and their efficiency has been proved against mouse breast cancer (4T1) cell line.

Docetaxel

Docetaxel (DTX) is classified as a plant alkaloid and it could bind to the Bcl-2 protein that is responsible for the stopping of apoptosis in cancer cells or inhibit the microtubular depolymerization. To efficiently encapsulate DTX, two different macromolecules were utilized for the preparation of nanoparticles: disulfide-crosslinked star-PLGA nanoparticles (HA-sPLGA XNPs) and hyaluronic acid combined with PDLLA (Wang et al. 2021). For this purpose, the nanoprecipitation was used to prepare DTX-loaded NPs that were cross-linked and compared with those un-crosslinked ones. Moreover, the release of DTX could be accelerated by the addition of glutathione. The NPs can be also effectively uptaken by the human lung carcinoma (A459) cells. However, the in vivo tests against A549 tumor-bearing mice models revealed prolonged half-life elimination of cross-linked NPs and indicated that the decrease of tumor growth can be achieved after their administration.

Paclitaxel and cis-platin

Paclitaxel (PTX) origins from the Pacific yew tree and its mode of action is related to inhibition of spindle bodies formation during mitosis. The microfluidic technique was employed for the preparation of NPs composed of PLLA macromolecules (Zhang et al. 2021a, b). This method relies on the mixing of NPs solutions in a solvent with non-solvent in the microfluidic channels that leads to the nanoprecipitation of the polymeric matrix (Brzeziński et al. 2019). The PTX-loaded particles were prepared by applying a commercially available microfluidic chips and dichloromethane was used as solvent of PLLA dissolution. However, SDS was added to the formulation to stabilize the obtained NPs. The benefits of microfluidic preparation of nanocarriers could be mainly related to their sustained drug release characteristic in comparison to those prepared by traditional nanoprecipitation. It was also shown that the slower release can be achieved by embedding the PTX-loaded NPs in microparticles. Moreover, magneto-sensitive PLA-based NPs were prepared by film rehydration and further modified with maghemite to introduce sensitivity to a magnetic field (Pigareva et al. 2021). The obtained particles were stable in different pH values; however NPs can be slowly decomposed by enzymatic hydrolysis after 7 days due to the stabilization effect of PEG-corona. Finally, the efficiency of NPs was proved against human breast adenocarcinoma cells (MCF7).

Curcumin

Curcumin (Cur) is a hydrophobic natural compound that has been investigated for cancer treatment since it inhibits cancer growth by downregulating cyclin B1 or activating the caspase-9/3 cascade. For its encapsulation, the copolymers composed of galactosamine-modified poly(ethylene glycol)-poly(lactide) (Gal-PEG-PLA) and D-α-tocopherol poly(ethylene glycol) 1000 succinate (TPGS) and micelles were synthesized by thin-film dispersion method (Sun et al. 2021a, b, c). The size of micelles was ranging from 80 to 120 nm, and their biocompatibility was proven by MMT assay in Caco-2 (human colon adenocarcinoma) cells. Most importantly, the micelles were distributed mainly in the jejunum and ileum and the maximum concentration in plasma (Cmax) was enhanced by encapsulation of Cur in nanocarriers. Moreover, due to the presence of galactosamine moiety, the micelles possess the liver-targeting ability.

Camptothecin

Camptothecin (CPT) is a well-known topoisomerase inhibitor used for cancer treatment with CPT-loaded NPs. In this regard, poly(lactic acid)-hyperbranched polyglycerol (PLA-HPG) was prepared and used as a matrix for CPT encapsulation (Hu et al. 2021). The main aim was to prolong intratumoral drug retention and enhance nonsurgical treatment of skin cancer. Moreover, two types of NPs were prepared since PLA-HPG NPs were also treated with sodium periodate and non-adhesive NPs were transformed into bioadhesive particles due to the formation of aldehydes in the polymeric backbone. The NPs release their payloads within 100 h, however the bioadhesive NPs can efficiently enter the interior of the cell by clathrin-mediated endocytosis. The intradermal transplantation of mice carcinoma squamous cells (PDVC57 SCC) into syngeneic C57BL/6 strain of laboratory mice allows to show the enhanced biodistribution of bioadhesive NPs within the tumor parenchyma by confocal microscopy. In addition, co-delivery of bioadhesive NPs with immunostimulating CpG oligodeoxynucleotides induce the reduction of tumor growth.

Poly(lactic acid)-block-poly(ethylene glycol) (PLA-b-PEG) NPs were produced by flash nanoprecipitation hand-made confined impinging jet mixer (Wilson et al. 2021). To enhance the properties of CPT, it was conjugated with an acid derivative of α-tocopherol (vitamin E), yielding the novel prodrug molecule. The NPs with the size around 100 nm were further encapsulated in PEG microgel microparticles to achieve the prolonged release of the prodrug.

Imiquimod (R837)

Imiquimod (R837) is a compound responsible for the activation of immune system response against cancer. This molecule was grafted on the mPEG-b-PLA backbone by an acid-sensitive bond (Li et al. 2021a, b, c). This approach allows for the release of R837 in the acidic environment of the tumor. The in vitro activation of macrophages by P-R837 was tested in human umbilical vein endothelial cells (HUVECs) and the results clearly showed their pH-triggered activation.

Ursolic acid

Ursolic acid (UA) is a naturally derivate triterpene that could inhibit cancer proliferation. This compound was encapsulated in the interior of the PLA-based NPs covered by chitosan with a size between 300 and 350 nm (Antonio et al. 2021). The release of UA occurs in a sustainable way for 144 h. Moreover, due to the presence of chitosan on the surface of NPs, the mucoadhesive properties of the carriers were improved. The obtained NPs exhibit good hemocompatibility, low cytotoxicity, and bioavailability after oral delivery to model rats.

Mithramycin

Mithramycin (MTM) is another example of an antibiotic natural product used against testicular cancer, glioblastoma, or Ewing sarcoma. It is proposed that MTM could bind to GC-rich sequences in DNA which results in the disfunction of transcription factors. To enhance its stability, MTM was encapsulated in the hydrogel, PLA, and liposomal NPs and tested against sarcomas (Estupiñán et al. 2021). These three materials release MTM with different velocities, nonetheless the most sustained release was observed from liposomes. The myxoid liposarcoma models MSC-5 H-FC and T-5 H-FC#1 were utilized and similar effect was observed for all proposed formulations of the drug. In addition, all prepared drug-delivery systems were able to reduce the growth of CSC-enriched 3D clonal sphere cultures (tumorspheres) of T-5 H-FC#1 cells. Finally, their high efficiency has been also proven (liposomal nanocarriers) by the in vivo assay mice carrying T-5 H-FC#1 cells without the presence of side effects.

Co-delivery of two anticancer drugs

The co-delivery of two different active compounds in one nanocarrier is done to increase their therapeutic effect. It was implemented to modulate different signaling pathways, reduce the dose of anticancer drugs, and overcome intrinsic drug resistance of cancer. However, to fully utilize this potential, those drugs should be encapsulated in the polymeric nanocarriers, since this approach enhances their bioavailability and stability. Moreover, the embedding in the polymeric matrix allows for control over the drug release kinetics. In this section, the different strategies of the co-delivery are briefly summarized:

-

(a)

A combination of sorafenib (inhibitor of multikinase) and paclitaxel was encapsulated in the poly(lactide) and hyaluronic acid co-modified half-generation of PAMAM G4.5 dendrimers (sPA) matrix (Ma et al. 2021). The pH-dependent release of the drug and enhanced efficiency in killing of human hepatocyte carcinoma (HepG2) cells by the co-delivery of two different drugs (in vitro) was observed.

-

(b)

Sophisticated copolymers composed of lactide and modified lactides were used for conjugation of sulfobetaine, paclitaxel, and gemcitabine (inhibition of DNA synthesis) (Sun et al. 2021a, b, c). These copolymers self-assemble in water to form the desired NPs. The cytotoxicity assay at Paca-2 (human pancreatic ductal adenocarcinoma) cells in vitro and in vivo on mouse model revealed their superior properties in comparison to a combination of pure drugs.

-

(c)

PLGA matrix was used for the delivery of gemcitabine and erlotinib (epidermal growth factor receptor (EGFR) inhibitor) due to its positive effect during clinical trials (Cai et al. 2021a, b). Their ability to decrease the cancer cells viability was proven against human pancreatic cancer (PANC-1) cells line. Most importantly, the tumor growth can be efficiently inhibited, as well as, the percent of mice survival significantly increased after treatment of drug combination delivered by NPs, as shown in Fig. 3. The authors concluded that this was a proof-of-concept for the potential clinical applications of their drug delivery system.

-

(d)

Commercially available PLA–PEG functionalized with biotin (targeting moiety) was used for the preparation of micelles co-loaded with epothilone B (apoptosis inducer, cytotoxic for cells overexpressing P-glycoprotein) and rapamycin (mTOR inhibitor) (Zajdel et al. 2021). Their co-encapsulation in polymeric matrix decreases the survival of human breast cancer (MCF-7 and MDA-MB-231) cells exposed to the NPs with both drugs in their interior in comparison to single-loaded NPs.

-

(e)

Star-shaped PLAs with cholic acid core were mixed with E-tocopheryl poly(ethylene glycol) succinate (TPGS) and curcumin (Cur), yielding the polymeric micelles (Guan et al. 2021). The combined effect was related to downregulating P-gp expression of tumor cells due to the presence of TPGS moiety, with the simultaneous effect of Cur as an anticancer drug. Their efficiency was tested against MCF-7/ADR (breast cancer) cells and it was concluded that the utilization of obtained nanocarriers allows for reversal of tumor immunosuppression mediated by CD47 and PD-L1.

-

(f)

Poly(ethylene glycol)–polylactide (PEG–PLA) copolymers were used for the delivery of tumor-associated antigen vaccine (antigen agent) with chemotherapeutic DBPR114 (quinazoline-based, multi-kinase inhibitor for the treatment of myeloid leukemia) (Huang et al. 2021a, b, c). The experiments on the tumor-bearing mouse demonstrated the synergistic effect of co-delivery of antitumor drug/antigen agents slowing down the tumor growth.

-

(g)

The copolymer with pendant functions such as polylactide-poly(ethylene) glycol-2-(3-((S)-5-amino-1-carboxypentyl)-ureido) pentanedioate/triphenylphosphonium (PLA-PEG-ACUPA/TPP) can be used for encapsulation of ingenol-3-angelate and DOX (Wang et al. 2022). The dual-drug-loaded particles were obtained via nanoprecipitation to induce effective immunogenic cell death (ICD). As expected, the tumor growth was suppressed most efficiently by the administration of NPs loaded with the mixture of both active compounds. Interestingly, due to the treatment by NPs, the increase of CD8+ T cells and CD4+ T cells indicates the inhibition of the immune response of cancer.

-

(h)

Ag-TiO2/poly(lactic acid) nanohybrid was prepared by loading of norfloxacin (NOR) and tenoxicam (TENO) on the surface of Ag-TiO2 which was finally covered by PLA layer by solution casting (Salahuddin et al. 2021). Such approach allows for the preparation of nanocarriers effective against different bacteria strains (Ag) and simultaneously against cancer cells (the co-delivery of the drugs). Interestingly, the release of both drugs was faster at the physiological conditions than in the acidic medium typically observed near tumors. This was explained by the more effective shedding effect of PLA and the difference in the ionic interactions in these two distinct pH environments, nevertheless, this feature may limit their applications. Subsequently, their antimicrobial activity was tested against several bacteria strains and it was proved their efficiency against gram-positive and gram-negative bacteria. However, the nanohybrids were able to decrease the viability of different cancer cells, their cytotoxicity was lower in comparison to DOX.

In vivo antitumor effect of MPGNPs combined with erlotinib. A The PANC-1 pancreatic cancer tumor model was established. Drugs were intravenously injected every 3 days, and the tumor was collected after 3 weeks. B Representative photographs of mice w with the tumor circled in each group. C Tumor growth curve of the differentially treated mice. D Survival curves of the mice in the different groups calculated by the Kaplan − Meier estimate for 50 days. E Image and F weight of the tumor. G Representative images of H&E-stained liver, heart, lung, spleen, and kidney. Scale bar = 50 μm. Data are shown as the mean ± SD. *P < 0.05; **P < 0.01; NS, no significance (n = 5 for each group). Reprinted with permission from (Cai et al. 2021a, b).

Photodynamic and photothermal therapy

Photodynamic (PDT) and photothermal (PTT) therapies are based on the utilization of molecules that can be activated by light to annihilate the cancer cells. The advantage of this type of therapy is its low invasiveness and selectivity against cancer cells. To address this challenge, indocyanine green (ICG) loaded PLA-based NPs were prepared via nanoprecipitation (Güney Akkurt and Gülsoy 2022). NPs with a size of 300 nm embedded approximately 8.3 μM of ICG per 1 mg of nanocarriers and 70% of the drug was released after 96 h. The cell viability of PC-3 (human prostatic adenocarcinoma) cells was assessed in the dark and after light irradiation to show the light-triggered action of ICG, the results clearly indicated that a high decrease in the cell viability can be only achieved upon laser light irradiation. A similar approach was proposed by Santos-Oliveira et al. however the combination of two active substances (dacarbazine and zinc phthalocyanine) encapsulated in the PLA and poly(vinyl alcohol) matrix (do Reis et al. 2021). The NPs were prepared by emulsion-based method and their morphology was shown by atomic force microscopy (AFM), interestingly their adhesion properties increase significantly after drug encapsulation. The MTT assay performed on human amelanotic melanoma (MV3) cells line indicated that the combination of chemotherapeutic drug dacarbazine with photosensitive zinc phthalocyanine gives the best results and inhibits the cancer cells recovery. Jin and Lo et al. followed the approach of a combination of a drug and photoactive compounds in one nanocarrier (Guo et al. 2021a, b, c). However, the main difference was that they conjugate both DOX and zinc phthalocyanine to one macromolecule. Subsequently, the NPs were fabricated by nanoprecipitation, however the addition of PEG5000-PDLLA5000 was necessary for the stability of the obtained ZnPc–Dox@micelles. As expected, the ZnPc–Dox@micelles more efficiently kill cancer cells in comparison to DOX-loaded NPs after laser irradiation. Most importantly, the obtained nanocarriers were localized at the tumor site in the mice model and were able to decrease the tumor growth after light irradiation.

In addition, the micelles composed of the chitosan-g-polylactide loaded with photoporphyrin IX were also proposed for photodynamic therapy (Sibarani et al. 2021). However, apart from their size, morphology, and cytotoxicity, there was no example of the light-triggered enhancement of their efficiency. It might be assumed that this will be shown in the follow-up work.

Antimicrobial nanomaterials

Polylactide NPs loaded with 1,2-benzisothiazolin-3-one (BIT) were covered with chitosan to induce their antimicrobial activity and enhance the activity of the drug (Yao et al. 2021). The particles were fabricated by oil/water (o/w) solvent evaporation, dried, re-suspended in the acetic acid aqueous solution of chitosan to prepare the desired nanospheres. The release kinetics revealed that the coating by chitosan decreased the drug release from nanospheres, in addition, the chitosan-modified nanospheres were the most effective against E. coli and S. aureus. Their improved efficiency was correlated with their efficient cellular uptake and disruption of a cellular structure due to membrane damage. Moreover, micelles obtained by self-assembly of PLA-b-PEG copolymers were used to cover a coverslip glass surface (Caruso et al. 2021). To introduce the antimicrobial properties, the photosensitizer (PS) was encapsulated in the interior of the micelles which was able to generate reactive oxygen species (ROS). The release of PS strongly depends on the degree of branching of block copolymers and the most stable micelles that can release PS in 48 h were subsequently utilized for the coating of the surface. As expected, the micelles were inactive in the dark, however the dose-depended killing of S. aureus after the irradiation was observed. Similarly, the strategy of using PLA- or PLGA-based copolymers was proposed for the treatment of biofilm-relevant infections associated with acidity (Guo et al. 2021a, b, c). To prepare pH-sensitive micelles poly(β-amino ester) block was introduced to the copolymer backbone, as shown in Fig. 4. Finally, triclosan (TCS) was loaded and their antimicrobial properties were tested. Due to the pH-sensitivity of obtained micelles, their interactions with the negatively charged component of bacteria can be greatly enhanced. This feature affects the TCS release from the micelles and the enhanced release was observed in the acidic pH. Moreover, the micelles showed superior killing efficiency against bacteria in comparison to free TCS. This was explained by their good penetration and accumulation in bacteria biofilm due to the charge switch at pH 5. This was also proven by the in vivo test on the subcutaneously implanted catheters covered with E. coli biofilms.

A different approach was proposed by Kammann et. al (2021) since both microparticles (MPs) and NPs loaded with cholesterol (Chol) were tested against S. pneumoniae induced lung damage. Three different formulations of MPs and NPs were prepared from PLGA, E100–PLGA blends (methacrylic acid copolymer (Eudragit 100) and poly(d,l-lactide-co-glycolide), 40:60 w/w), and PLA–Chol, however, they also varied after encapsulation of cholesterol. Among all tested cholesterol carriers, the NPs composed of cationic Eudragit and PLGA exhibited the most efficient uptake by cells with results in the high intracellular level of cholesterol. This allows for the cellular defense action which results in neutralizing the pneumolysin (PLY) level to protect the cells from damage caused by toxins. It was concluded that polymeric cholesterol carriers can be used as a supply to enhance the cell defense mechanism against bacterial infections.

NPs for brain treatment

An interesting approach was proposed by Higazy et al. (2021), in which polylactide-co-caprolactone-based nanoparticles were loaded with lamotrigine (LTG), which is used for the treatment of epilepsy. The prepared formulation was stabilized by the addition of different amounts of PVA to the aqueous phase. After centrifugation and drying, the size and stability of re-dispersed NPs were tested. It was shown that the size decreased with the increasing amount of PVA. In addition, the presence of PVA on the NPs surface also decreased their zeta potential. The release of LTG varied between different formulations, nonetheless in all cases the burst release was observed, after which the sustained release of the drug occurred. Most importantly, the comparison of the effectiveness of LTG-loaded NPs with Lamictal® (lamotrigine, an anti-epileptic medication) tablets indicated that NPs more efficiently target the brain, and as result the drug targeting efficiency or direct transport percentage values were significantly higher for NPs.

NPs for DNA and RNA delivery

PLA-based NPs can be used as vehicles for the delivery of DNA, RNA, and genes (Mendes et al. 2022). Since these materials can be very easily degraded in the human body or cannot cross the cell membrane, therefore the encapsulation of genetic materials in NPs is a perfect solution. To understand the interactions between PLA and DNA, Maiti et.al performed multiple experiments of their binding interactions, as well as, the DNA release from the nanocarriers (Senapati et al. 2021). The addition of DNA to PLA increases the size of obtained NPs. Moreover, it also alters the surface charge of NPs due to the presence of free phosphate groups. For instance, UV–vis analysis revealed a blue shift of DNA after the formation of the complex with PLA which indicates their strong dipolar interactions. The release of DNA from NPs followed the Korsmeyer − Peppas model and the non-Fickian diffusion mechanism. The MTT assay showed good biocompatibility of such carriers. Finally, the simulation of their interactions indicated that PLA can more effectively interact with the AT-rich region of DNA in comparison to the GC-rich region.

Moreover, the PLGA NPs were used as carriers of interfering RNAs (siRNAs) or short hairpin RNAs (shRNAs) for the treatment of inflammatory bowel disease (IBD) (Bao et al. 2021). The NPs were prepared by the emulsion-based method and their size ranged from 265 to 285 nm. The NPs prepared by this method exhibit high load of SNX10-shRNA plasmids (SRP). To assess their efficiency in vivo, the chronic IBD mice were treated with SRP-loaded NPs and a control. The IL-1β, TNF-α, and IL-23 levels were decreased, therefore, it prevents reduction in the mice body weight. The authors proposed that the anti-inflammatory effect of NPs induced by signaling pathways in epithelial cells.

NPs for peptide delivery

Peptides are an important class of bioactive compounds that required encapsulation for the preservation of their biological activity. For this purpose, core–shell NPs composed of poly(ethylene oxide)-poly(lactide) were used for encapsulation of glutamyl-cysteinyl-glycine (GSH), and their properties were compared with particles made from cholesterol and sorbitan monostearate (Span 60) (Ghorbanizamani et al. 2021). The particles were prepared by dispersion of copolymers or lipid with surfactant dissolved in the proper solvent, in phosphate-buffered saline (PBS). The size of GSH-loaded particles was 148 and 90 nm for copolymeric and cholesterol/Span 60, respectively. The high encapsulation efficiency was achieved, however the release of GSH was relatively low, both in the physiological and acidic conditions. As a result of NPs action in HeLa (cervical cancer) and U87 (human glioblastoma astrocytoma) cells, a significant decrease of glycation end products and beta-sheet formation was observed, nevertheless more efficient were those built from cholesterol/Span 60.

In addition, the copolymers of zwitterionic poly(d-glucose carbonate) and semicrystalline polylactide were used for encapsulation of insulin and insulin glargine (Elsabahy et al. 2021). The authors proposed an interesting approach in which the control over the morphology of nanoassemblies was achieved by varying the block length in copolymers. As a result, three distinct morphologies could be obtained: spherical, cylindrical, and platelet-like. The binding of insulin to the nanoparticles was confirmed by gel retardation assays and the highest value was obtained for platelet-like NPs. The obtained NPs were biocompatible, and their uptake depended on their size and shape, notwithstanding the cell type also should be considered. The in vivo test in diabetic rats indicated that insulin-loaded NPs exhibit better hypoglycemic activity than free insulin. However, the cylindrical NPs were the most effective ones. Therefore, the control over the morphology of NPs could be a good tool for the improvement of the pharmacological availability of insulin.

PLA for bone regeneration

PLA is often chosen as a matrix for bone repair purposes (Naseem et al. 2021). In this regard, β-tricalcium phosphate/poly(l-lactic acid) (TCP/PLLA) scaffolds with incorporated zinc ions were proposed for bone healing (Huang et al. 2021a, b, c). The in vitro and in vivo assays confirmed that the presence of Zn2+ from the scaffolds was able to promote differentiation of periosteum-derived progenitor cells (PDPCs) and transition from M1 to M2 macrophages. As a result, the implanted scaffolds (5% Zn group) participate in bone regeneration in vivo. Moreover, the scaffolds were biocompatible and no side effects in organs were observed. In addition, the PLA composite fracture fixator with the addition of vancomycin cationic liposome was tested for its ability to suppress the bacterial growth and for reduction of antibiotics toxicity (Cai et al. 2021a, b). The in vitro drug release test showed sustained vancomycin release that could decrease the damage to fibroblasts. The inhibition zone of composite against E. coli and S. aureus showed their beneficial antimicrobial properties. The cell adhesion studies on MC3T3-E1 (mouse bone) cells revealed superior properties of the composite in comparison to pure PLA, and as a result, increased proliferation was observed. Additionally, the composite exhibits a better osteogenic effect due to lowering of the inflammatory effect after implantation of the scaffold. The multi-component composite system consisting of chitosan (CS)-coated polytrimethylene carbonate (PTMC)/polylactic acid (PLLA)/oleic acid-modified hydroxyapatite (OA-HA)/vancomycin hydrochloride (VH) was proposed by Zhang et al. (He et al. 2021). In this contribution, the VH-loaded microspheres were prepared by emulsion technique, and their properties were compared with PTMC/PLLA, PTMC/OA-HA composite microspheres. The sustained release of the drug was obtained and almost all of the drug was released from the interior of the microspheres after 30 days. The incubation of microspheres with osteoblast cells indicated their favorable biocompatibility. The alkaline phosphatase (ALP) activity of MC3T3-E1 preosteoblast cells cultured on the obtained scaffolds showed the increased activity. Therefore, it could be postulated that the proposed microspheres can promote bone regeneration. Although, the in vivo tests were not performed.

The copolymers of PLA with ε-caprolactone (Radwan et al. 2021) with poly(ethylene glycol) (Tang et al. 2021) were also used as materials for enhancing bone regeneration. In the first contribution, drug-loaded poly (L-lactide-co-ε-caprolactone)/calcium phosphate (CaP) composite was prepared via in situ formation of composites powder, in addition, the composite without polymer and blank composite powder was also prepared. As a drug, the antibiotic moxifloxacin hydrochloride (MOX) was added as it is used for the treatment of chronic osteomyelitis (OM). The obtained material exhibits suitable porosity and sustained release of the drug. The prepared scaffolds exhibited all typically required properties for the materials for bone regeneration, such as improved proliferation and differentiation of osteoblast cells, antimicrobial effect, and induction of new bone-cell formation. Therefore, the authors recommended their clinical experiments on humans (Radwan et al. 2021). A different approach was proposed by Zhu et al (2021) in which platelet lysate (PL) used for cartilage tissue engineering was embedded in PDLLA-PEG-PDLLA hydrogel. To enhance its delivery, PL was encapsulated in NPs composed of heparin (Hep) and ε-poly-l-lysine (PLL) and added to the hydrogel. This allows for the release of drug-loaded NPs, followed by the PL diffusion from the hydrogel matrix. The test against IL-1β induced human chondrocytes showed that the obtained biomaterials exhibit anti-inflammatory properties. Finally, ACLT-Induced osteoarthritic rats were treated with PL-loaded hydrogel and it was shown that the presence of the hydrogel allows repairing of the cartilage defect in rats since it was filled with soft and friable tissue (Tang et al. 2021).

Micro-sized systems

Microparticles of PLLA were prepared by the emulsion-based method for diabetes treatment in animals, such as equids, dogs, cats, and rabbits (Bouriche et al. 2021). Metformin hydrochloride was chosen as an active ingredient for diabetes treatment. Due to the fact that microparticles were prepared by emulsification, the obtained particles exhibit a high dispersity index, and their size was ranging from 1 to 55 μm. The size distribution can highly influence the drug release, thus an alternative methods of particles preparation should be considered in the future. Finally, the concentration of the drug in plasma after single-dose administration in rabbits was determined after intravenous, oral, and oral microparticles solution administration. The results indicated that PLA microparticles showed optimal, sustained release of the drug and its increased half-life.

Moreover, the microrods of poly(lactide-co-glycolide) copolymers were used as DOX carriers (Xu et al. 2021). To obtain such morphology of PLGA particles, the one-step electrospray method was used. In addition, the DOX-loaded microspheres were also prepared to compare the effect on particles morphology. Nevertheless, the alteration in processing parameters allows for the preparation of different particles with varying lengths and diameters; DOX was only added to microrods with 16 μm in length and 1 μm in diameter and microspheres with a diameter of 2.95 μm. The cell viability examination indicated the superior efficiency of microrods against microparticles, yet the free drug exhibit higher killing ability than microcarriers. The difference in efficiency between two distinct particles morphology was explained by the faster drug release and larger specific surface area of microrods.

Micro-film

Poly(l-lactide)-co-poly(ε-caprolactone) copolymers were used for the preparation of the micro-film that is flexible enough to fit the sclera (Wu et al. 2021). Those films were loaded with triamcinolone acetonide (TA) which is used for adjunctive intraocular or peri-ocular steroid for the treatment of posteriod globe trauma. The blank and drug-loaded films were made by spraying on the polyfluortetraethylene (PTFE) plate and the obtained materials were dried before peeling off the template. The encapsulation of the drug in the film allows for its sustained release over 200 days. Histology images revealed that there was no inflammatory cell infiltration around the film. Subsequently, the in vivo tests indicated that TA-loaded film can be implanted during the first phase of globe trauma repair and induce the healing of the eye with simultaneous degradation of the polymeric matrix.

Hydrogels as a drug and DNA/RNA depots

Hydrogels are soft materials that due to their porous structure can preserve a large portion of water or aqueous solution (Li et al. 2021a, b, c). Among all studied hydrogels, those composed of polyesters are widely used since the ester bond can be hydrolyzed in an aqueous solution. Typically, the amphiphilic block copolymers of hydrophobic lactide or glycolic acid with hydrophilic ethylene glycol are proposed for their preparation (Basu et al. 2016). In this regard, such hydrogels were recently proposed for photodynamic nitric oxide (NO) (Sun et al. 2021a, b, c) or gene carriers (Kim et al. 2021) for cancer therapy and colitis treatment (Guo et al. 2021a, b, c). In the first contribution, the poly(lactic-glycolic acid) (PLGA) NPs loaded with NO donor l-arginine (l-Arg) photosensitizer indocyanine green (ICG) were added to the poly(ε-caprolactone)-poly(ethylene glycol)-poly(ε-caprolactone) (PCL–PEG–PCL) hydrogel to obtain thermosensitive hydrogels (Sun et al. 2021a, b, c). The rheological test showed that hydrogels possess shear-thinning properties that allow for their facile injection with syringe. Moreover, encapsulation of NPs in the hydrogel matrix could prolong the ICG release which results in increased drug retention in vivo. Most importantly, after NIR irradiation the formation of reactive oxygen species (ROS) is induced which subsequently lets to oxidization of the l-Arg to produce NO gas. Nevertheless, the hydrogels exhibit low cytotoxicity against 4T1 cells; it was dramatically changed after NIR irradiation, cell apoptosis and necrosis were observed. These superior properties were further confirmed by in vivo antitumor study which showcased the inhibition of tumor growth. Likewise, due to the formation of ONNO− at the tumor site, the degradation of collagen was observed which is responsible for tumor progression. In the second contribution, the sophisticated spermine-grafted copolymer was synthesized (MPEG-b-[polycaprolactone-ran-poly(spermine-l-lactide)]) to prepare hydrogels as gene depots (Kim et al. 2021). This pendant cationic group can form a complex with tat3-small hairpin RNA (St3-shRNA) which may induce the downregulation of the signal transducer and activator of transcription 3. This complex was further used for the in situ forming hydrogel gene depot since the obtain copolymers exhibit sol–gel transition at 37 °C. Due to the macromolecules amphiphilic structure, the formed complex was stable even after incubation with serum, DNase or heparin for a long time. Moreover, the cytotoxicity of the obtained copolymer with St3-shRNA was significantly lower in comparison with St3-shRNA/polyethylene amine (PEI) which is typically used to form a complex with RNA or DNA. The antitumor activity was tested after intratumoral injection into mice and the volume of the tumor rapidly decreased, especially after multiple injections at 3, 6, 9, 12, and 15 days.