Abstract

Pretreatment is the key step to overcome the recalcitrance of lignocellulosic biomass making sugars available for subsequent enzymatic hydrolysis and microbial fermentation. During the process of pretreatment and enzymatic hydrolysis as well as fermentation, various toxic compounds may be generated with strong inhibition on cell growth and the metabolic capacity of fermenting strains. Zymomonas mobilis is a natural ethanologenic bacterium with many desirable industrial characteristics, but it can also be severely affected by lignocellulosic hydrolysate inhibitors. In this review, analytical methods to identify and quantify potential inhibitory compounds generated during lignocellulose pretreatment and enzymatic hydrolysis were discussed. The effect of hydrolysate inhibitors on Z. mobilis was also summarized as well as corresponding approaches especially the high-throughput ones for the evaluation. Then the strategies to enhance inhibitor tolerance of Z. mobilis were presented, which include both forward and reverse genetics approaches such as classical and novel mutagenesis approaches, adaptive laboratory evolution, as well as genetic and metabolic engineering. Moreover, this review provided perspectives and guidelines for future developments of robust strains for efficient bioethanol or biochemical production from lignocellulosic materials.

Similar content being viewed by others

Background

Due to the exhaustibility of fossil fuels and its indiscriminate use, there is an urgent need for the development of sustainable and affordable alternatives. Lignocellulosic materials such as agriculture wastes, forestry residues, and energy plants are considered as an abundant and renewable feedstock for bioenergy production through biochemical conversion. However, these biomass resources are naturally recalcitrant that carbohydrates of cellulose and hemicellulose are closely associated with lignin in the plant cell wall. Pretreatment is required to breakdown the rigid cell wall structure and to make polysaccharides available for subsequent enzymatic hydrolysis and fermentation. During the deconstruction processes, various inhibitory compounds with strong inhibition on cell growth and metabolic capacity of fermenting strains are generated due to the partial over-degradation of lignocellulose. The toxic nature of the lignocellulosic hydrolysate severely impedes its efficient substrate utilization and bioethanol fermentation. Although methods to remove inhibitors physically, chemically, or biologically may help moderate the problem of toxic compounds in lignocellulosic hydrolysates, it is not economically feasible to remove inhibitors from hydrolysate prior to fermentation due to the cost associated with additional processing steps and the potential loss of fermentable sugars (Jönsson et al. 2013; Parawira and Tekere 2011). Therefore, it is a key barrier to develop and employ robust inhibitor-tolerant microorganisms for economic lignocellulosic biofuel production.

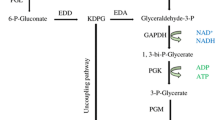

Several microorganisms have been applied for ethanol production from lignocellulose, including both bacteria and yeasts (Olsson and Hahn-Hägerdal 1996). As a model bioethanol producer, Zymomonas mobilis has attracted considerable attention over the past decades due to its excellent industrial characteristics, such as the unique Entner–Doudoroff (ED) pathway under anaerobic conditions resulting in low cell mass formation, high specific rate of sugar uptake, high ethanol yield, notable ethanol tolerance, and the generally regarded as safe (GRAS) status (Panesar et al. 2006; Rogers et al. 2007). Furthermore, the availability of multiple genome sequences for 12 Zymomonas strains with small genome size around 2 Mb (Seo et al. 2005; Yang et al. 2009a; Zhao et al. 2012), multiple genome-scale metabolic models (Kalnenieks et al. 2014; Pentjuss et al. 2013; Widiastuti et al. 2011), and versatile genetic engineering strategies (Jia et al. 2013; Shui et al. 2015; Tan et al. 2016) also accelerates the research progress in Z. mobilis. Z. mobilis has also been engineered for the production of sorbitol, gluconic acid, levan, 2,3-butanediol, isobutanol, and other biochemicals, which is proposed as an ideal microbial chassis for future synthetic biology and biorefinery (He et al. 2014; Yang et al. 2016).

Although Z. mobilis demonstrates advantages in ethanol fermentation, the inhibitors derived from biomass deconstruction and hydrolysis still have detrimental effects on Z. mobilis, especially when high biomass solid loading is used during pretreatment and enzymatic hydrolysis steps to generate high concentration of sugars besides the potential additive or synergistic inhibitions of various inhibitors in the hydrolysate (Franden et al. 2013). In this review, we reviewed the progress of strain improvement in Z. mobilis to enhance its lignocellulosic hydrolysate inhibitor tolerance capability for economic lignocellulosic biochemical production. Specifically, strategies to identify and quantify potential inhibitory compounds generated during lignocellulose pretreatment and enzymatic hydrolysis were discussed. Different approaches especially the high-throughput ones to evaluate the inhibitory compounds on Z. mobilis were examined. Moreover, strategies of both forward and reverse genetics for inhibitor tolerance improvement in Z. mobilis were summarized. These strategies include classical and novel mutagenesis approaches, adaptive laboratory evolution (ALE), as well as genetic and metabolic engineering. We further proposed potential research directions to construct robust strains for bioethanol or biochemical production from lignocellulose feedstock in the synthetic biology era (Fig. 1).

Overview of the progress on lignocellulosic hydrolysate inhibitor tolerance improvement in Zymomonas mobilis. ILs ionic liquids, STEX steaming or steam explosion, AFEX ammonia fiber explosion, LHW liquid hot water, HPLC/GC high-performance liquid chromatography or gas chromatography, GC/LC–MS gas chromatography or liquid chromatography–mass spectrometer, NMR nuclear magnetic resonance, ICP-MS inductively coupled plasma mass spectrometer, ICP-OES inductively coupled plasma optical emission spectrometry, NTG N-methyl-N′-nitro-N-nitrosoguanidine, ALE adaptive laboratory evolution, ED pathway Entner–Doudoroff pathway

Identification and quantification of inhibitors in lignocellulosic hydrolysate

Lignocellulose consists of three major polymerized components of cellulose, hemicellulose, and lignin, which are joined together with complex covalent bond, and difficult for microbial digestion (Sun and Cheng 2002). Owing to the recalcitrant structural characteristics of plant cell wall, pretreatment and enzymatic hydrolysis are the crucial steps to release mono-sugars from biomass for fermentation. The purpose of the pretreatment is to break down the lignin structure, disrupt the crystalline of cellulose, and increase the porosity of lignocellulose for enhancing enzymes accessibility to the cellulose during hydrolysis process. Various pretreatment approaches have been developed and examined. Generally, they can classified into four categories: physical methods including mechanical comminution, extrusion, and irradiation; chemical methods including acid pretreatment (dilute acid or concentrated acid), alkaline pretreatment, oxidation, organosolv, and ionic liquids (ILs) pretreatment; physico-chemical methods including steaming or steam explosion (STEX), ammonia fiber explosion (AFEX), liquid hot water (LHW), and CO2 explosion; and biological methods, which use microorganisms or enzymes to degrade lignocellulosic materials. Different pretreatment methods with regard to their features, advantages, and disadvantages as well as their impact on lignocellulosic materials have been discussed in detail in other reviews (Baral et al. 2014; Capolupo and Faraco 2016; Silveira et al. 2015; Sun et al. 2016). During the pretreatment process, a number of degradation products of lignin and sugar are generated, which could have detrimental effects on subsequent enzymatic hydrolysis and microbial cell fermentation (Jönsson et al. 2013).

Different biomass feedstock and pretreatment methods generate hydrolysates with distinctive toxic compounds, but three major groups of toxic compounds are usually classified in general. These are furan aldehydes, 2-furylaldehyde (furfural), and 5-hydroxymethyl-2-furaldehyde (HMF) produced by the dehydration of pentose and hexose sugars, respectively; weak organic acids, especially acetic acid produced by the deacetylation of hemicellulose and lignin, formic acid produced by the degradation of furans, and levulinic acid produced by the degradation of HMF; as well as phenolic compounds formed by the breakdown of lignin components (Almeida et al. 2007; Klinke et al. 2004). In addition to these three major components, a range of inorganic salts including alkali salts and heavy metal salts are present in lignocellulosic hydrolysates in varying degrees. Inorganic salts are different from all above three categories, since they are not generated from the over-degradation of lignocellulosic biomass, but from chemicals added during pretreatment process or the corrosion of the walls of the pretreatment equipment (Klinke et al. 2004).

Many different kinds of analytical methods have been employed to identify and quantify compounds in the lignocellulosic hydrolysates. The major components of glucose, xylose, arabinose, acetic acid, and furans, as well as a wide variety of aliphatic acid compounds can be detected directly from hydrolysate samples by high-performance liquid chromatography (HPLC) or gas chromatography (GC) using different columns and detectors (Franden et al. 2013; Gu et al. 2014). Minor components, especially for phenolic compounds, have been extracted from hydrolysate using organic solvents, concentrated by evaporation, and analyzed by gas chromatography–mass spectrometer (GC–MS), liquid chromatography–mass spectrometer (LC–MS), and/or inductively coupled plasma mass spectrometer (ICP-MS) (Gu et al. 2014; Wang et al. 2014). Inductively coupled plasma optical emission spectrometry (ICP-OES) has also been used for inorganic ion analysis and many different mineral elements such as magnesium, potassium, manganese, iron, copper, and calcium have been identified in lignocellulosic hydrolysates (Jin et al. 2013; Le et al. 2014). In addition, nuclear magnetic resonance (NMR) has been used recently as a nondestructive method for the structural investigation of lignocellulosic biomass at a molecular level during the deconstruction process which can contribute to the identification of new inhibitor compounds (Shi et al. 2011).

Evaluation of the effect of hydrolysate inhibitors on Z. mobilis

Fermentation performances of different microorganisms in lignocellulosic hydrolysates are distinctive, which are related to inhibitory compounds generated from diversified feedstock and pretreatment strategies. It is thus critical to examine the toxic effect of hydrolysate compounds on cell growth and fermentation performance to help elucidate inhibitor tolerance mechanisms and to allow the development of robust industrial strains for economic biochemical production. Since cell growth is closely associated with ethanol production for many microorganisms including Z. mobilis (Delgenes et al. 1996; Zaldivar et al. 1999), it can provide relatively reliable estimates of the inhibitory effect of toxic compounds on microbial cells by measuring cell viability and growth with sensitive assays.

Traditional shake flask culture techniques for individual growth-associated assays are routinely used, but it is time-consuming, laborious, and inefficient. To solve the disadvantages of this classical method, various high-throughput evaluation techniques have been developed recently such as Biolog’s Penotype Microarrays, Bioscreen C, and BioLector. Phenotype Microarray system has been used to profile nearly 2000 Z. mobilis cellular phenotypes and provided an overview of Z. mobilis physiology (Bochner et al. 2010). In addition, a quantitative high-throughput biological growth assay based on turbidometric measurements using the Bioscreen C system was also established. This approach is capable of monitoring two 100-well plates at a 0.4-mL scale simultaneously, and has been widely used for cellular growth measurement in the presence of inhibitors and hydrolysate (Franden et al. 2009, 2013). It can provide detailed inhibitory kinetic data for individual inhibitory compounds in terms of continuing cellular growth and final cell mass.

Using conventional and high-throughput growth assays, effects of inhibitory hydrolysate compounds on Z. mobilis growth and fermentation have been investigated (Dong et al. 2013; Franden et al. 2009, 2013; Gu et al. 2015; Yi et al. 2015). The results demonstrated that acetate, furfural, and phenolic aldehydes are three major inhibitors in the dilute acid-pretreated corn stover hydrolysate for Z. mobilis, and the inhibitory activity was strongly correlated to the hydrophobicity of these compounds. Furthermore, combinations of HMF, furfural, and acetate resulted in additive rather than synergistic inhibition to Z. mobilis cell growth (Franden et al. 2013). It was also observed that Z. mobilis is capable of converting aldehydes of furfural, HMF, vanillin, 4-hydroxybenzaldehyde, and syringaldehyde to their corresponding alcohol forms of furfuryl, 5-hydroxymethylfurfural, vanillyl, 4-hydroxybenzyl, and syringyl alcohol, respectively (Franden et al. 2013; Yi et al. 2015). These studies suggested that the enhanced conversion of toxic aldehydes into the relatively benign alcohol forms with engineered strains could reduce process cost by improving ethanol yields and/or by reducing fermentation time.

Other than the inhibitory effects directly on cell growth, here, we also summarized the ethanol fermentation performances by Z. mobilis within lignocellulosic hydrolysates (Table 1). Compared with the results with pure sugars, ethanol productions in hydrolysates were impeded significantly (Bothast et al. 1999; Feng et al. 2012; Jennings and Schell 2011; Jeon et al. 2010; Joachimsthal et al. 1999; Krishnan et al. 2000; Mohagheghi et al. 2002, 2004; Schell et al. 2016; Serate et al. 2015; Teixeira et al. 2000; Yanase et al. 2012; Zhao et al. 2014). For example, the ethanol yield was much lower in the hydrolysate (15 g/L) than in pure glucose fermentation (44.9 g/L) (Dong et al. 2013; Zhao et al. 2014). These results showed that more efforts are needed to improve the inhibitor tolerance of Z. mobilis, especially in the hydrolysates where different inhibitors co-exist and with potential additive or synergistic effects.

Strategies to enhance inhibitor tolerance of Z. mobilis

To minimize the toxic effect of lignocellulosic hydrolysates on microbial fermentation and biofuel production, many efforts have been taken to screen and/or develop robust strains with improved tolerance toward these inhibitors. Recent studies showed that Z. mobilis biofilm cells exhibited a higher survival rate and metabolic activity than planktonic or free cells, which can also be developed and applied for the production of valuable bioproducts from toxic lignocellulosic hydrolysates (Li et al. 2006; Todhanakasem et al. 2014, 2015, 2018).

Many genetic approaches including forward and reverse genetics were applied to improve the innate inhibitor tolerance capability of Z. mobilis strains, and will be discussed below in detail (Table 2). Forward genetics approaches use ALE or mutagenesis approaches to generate and select mutants with desired phenotypes. Reverse genetics is an omics-guided systems metabolic engineering method to associate genetic candidates with desired phenotypes and then to transfer the genetic candidates into the host strains for robustness improvement.

Robustness improvement by forward genetics approaches

ALE is a powerful method to improve industrial features of microbial biocatalysts without a priori knowledge of any underlying genetic mechanisms (Portnoy et al. 2011), as long as the desired trait can be coupled with growth or other easily detectable phenotypes (Dragosits and Mattanovich 2013). ALE is still valuable for robustness improvement in Z. mobilis. Z. mobilis strains with increased tolerance toward furfural and acetic acid have been obtained by sequential transfers of cell cultures to synthetic media containing increasing concentrations of inhibitors (Shui et al. 2015). After three rounds of ALE, two selected mutants of ZMF3-3 and ZMA7-2 demonstrated higher growth capacity and faster glucose utilization than wild-type ZM4 under 3 g/L furfural or 7 g/L acetic acid stress conditions. A mutant strain #7 derived from Z. mobilis 8b was generated through adaptation with 5 g/L acetate, which had improved sugar utilization in the presence of inhibitory compounds of acetate and furfural in the pretreated corn stover hydrolysates (Mohagheghi et al. 2014). Similarly, an adapted strain SS3 was selected after 70 days of continuous culturing using a turbidostatic with a gradually increasing concentration of the corn stover hydrolysate liquor, which had higher sugar utilization rate and ethanol productivity than that of parent strain Z. mobilis 8b in the corn stover hydrolysate (Mohagheghi et al. 2015).

To resolve the limitation of low spontaneous mutation rate using ALE natural selection (Lee et al. 2012), various mutagenesis approaches using chemical, physical, or molecular methods have been developed and employed for microbial strain improvement such as chemical mutagenesis, transposon mutagenesis, genome shuffling, or error-prone PCR. Z. mobilis is relatively resistant to mutagenesis, but N-methyl-N′-nitro-N-nitrosoguanidine (NTG) is an effective mutagen (Buchholz and Eveleigh 1990; Typas and Galani 1992). Through mutagenesis with NTG, a salt-tolerant strain ZM482 was isolated, which can tolerate high concentrations of K+, Mg2+, and Cl− ions (Rogers et al. 1984). Similarly, an acetate-tolerant strain of AcR was also obtained by screening the mutants in the presence of sodium acetate. AcR was capable of efficient ethanol production in the presence of 20 g/L sodium acetate, while the parent strain ZM4 was inhibited completely under the same condition (Joachimsthal et al. 1998). Strain ZM401 is a flocculating mutant of ZM4 generated by NTG mutagenesis as well (Lee et al. 1982). Recent study showed that ZM401 had improved tolerance to inhibitory compounds in the hydrolysate, particularly acetic acid and vanillin, than wild-type strain ZM4, and could be a suitable host for bioethanol production (Zhao et al. 2014). The molecular transposon mutagenesis approach was also applied in Z. mobilis (Pappas et al. 1997). A recombinant strain ZMT2 with improved salt tolerance was achieved via the EZ-Tn5-based transposon insertion mutagenesis, which had higher sugar conversion rate to ethanol under up to 2% NaCl stress than that of wild-type strain ZM4 (Wang et al. 2016).

Forward genetics approaches can also be combined to acquire desired phenotypes effectively. For example, a procedure combining both NTG mutagenesis and ALE approaches was applied to generate and select acetate-tolerant Z. mobilis strains, and a desired mutant strain ZMNTG6014 was obtained (Wang 2008). Similar strategy was used to obtain two acetate-tolerant mutants of ZMA-142 and ZMA-167, which exhibited favorable ethanol production under high acetate concentration of 244 mM, while the parental strain ZM481 was completely inhibited by sodium acetate at the concentration above 195 mM (Liu et al. 2017).

Transposon mutagenesis and ALE approaches were also combined to develop robust strains. A transposon-based knockout mutant library of Z. mobilis 8b was constructed, and furfural-tolerant mutants were achieved after adaptation using different concentrations of furfural (Yang et al. 2014b). Another “Super Pgap” mutant library was further constructed where the strong native promoter Pgap of Z. mobilis was randomly integrated throughout the genome of Z. mobilis 33C via an in vitro transposon mutagenesis system. The mutant library included both insertion knockout mutants and mutants with downstream genes overexpressed if inserted into and replacing original promoters. After continual adaption with 40% corn stover hydrolysate, five furfural-tolerant mutants (OEL19, OEL22, OEL23, OEL26, and OEL31) were identified with improved furfural- and ethanol-tolerance capability (Yang et al. 2014b).

Robustness improvement by reverse genetics approaches

With the rapid progress to read genetic information by technologies such as next-generation sequencing (NGS) and mass spectrometry, systems biology approaches such as comparative genomics, transcriptomics, proteomics, and metabolomics have been widely applied to understand the underlying molecular stress response mechanisms and to associate genetic elements with improved robustness phenotypes. For example, transcriptomic profiles of Z. mobilis wild-type strain ZM4 or its xylose-utilizing derivative 8b in response to furfural, acetate, or phenolic aldehyde inhibitors (4-hydroxybenzaldehyde, syringaldehyde, and vanillin) have been investigated (He et al. 2012; Yang et al. 2014a; Yi et al. 2015). In addition, integrated proteomic and transcriptomic approaches were used to understand the molecular mechanism of an acetate-tolerant strain (Yang et al. 2014c). All these studies demonstrated that multiple-gene regulation is responsive for the inhibitor tolerance in Z. mobilis involving in carbohydrate metabolism, DNA replication, recombination and repair, transcriptional regulation, and universal stress responses.

Based on these studies, many candidate genes responsible for the inhibitor tolerance in Z. mobilis have been identified, and recombinant strains with enhanced tolerance to lignocellulosic hydrolysates have been constructed by engineering these candidate genes into parental strains. For example, everal reductase-encoding genes (ZMO1116, ZMO1696, and ZMO1885) were identified to play key roles in response to phenolic aldehydes through transcriptomics study (Yi et al. 2015). Overexpression of these genes increased the tolerance of Z. mobilis ZM4 against hydrolysate inhibitors, especially 4-hydroxybenzaldehyde and vanillin. Transcriptomic studies also led to the identification of a transcriptional regulator hfq (ZMO0347), which was differentially regulated in response to various lignocellulosic hydrolysate inhibitors in Z. mobilis, and its knockout mutant reduced resistance to acetate, vanillin, furfural, and HMF (Yang et al. 2009b, 2010b).

In addition, genome-resequencing analysis was also applied to identify the underlying genetic changes responsible for the altered phenotypes in mutants generated through forward genetics approaches as discussed above (Liu et al. 2017; Mohagheghi et al. 2015; Yang et al. 2010a, 2014b). For example, a 1.5-kb deletion in acetate-tolerant strain AcR was identified through comparative genome sequencing, which likely truncated the majority of gene ZMO0117 and partial of the promoter of the nhaA gene (ZMO0119) encoding a sodium proton antiporter. Further transcriptomics and genetic studies indicated that the acetate tolerance of AcR was attributed to the overexpression of nhaA resulted from the co-transcription of nhaA from ZMO0117 (Yang et al. 2010a). Interestingly, a similar result was achieved in another acetate-tolerant mutant ZMA-167 generated through the combination of NTG mutagenesis and ALE (Liu et al. 2017). These two results indicated that overexpression of nhaA gene conferred sodium acetate tolerance in Z. mobilis.

Another genome-resequencing results of furfural-tolerant mutants confirmed that the improved furfural tolerance of Z. mobilis mutants could be due to the overexpression of a histidine kinase encoding gene ZMO1162, the disruption of a Sigma-54 modulation protein encoding gene ZMO0038, and the disruption of 1-deoxy-D-xylulose-5-phosphate synthase encoding genes of ZMO1598 and/or ZMO1234. In addition, the furfural resistance of Z. mobilis was also increased in knockout mutants of an efflux pump-encoding operon containing genes of ZMO0282, ZMO0283, and ZMO0285 or in a mutant with the repressor gene ZMO0281 of this efflux pump operon overexpressed (Yang et al. 2014b).

Other inhibitor responsive genes include the alpha subunit of the integration host factor (IHF) encoding gene himA (ZMO1122) (Viitanen et al. 2009, 2012; Wang et al. 2016), alcohol dehydrogenase gene ZMO1771 (Wang et al. 2017), TonB-dependent receptor gene ZMO0128 (Yang et al. 2014a), and ZMO1875 with unknown function (Skerker et al. 2013) from Z. mobilis ZM4; a functional type II NADH dehydrogenase gene ndh (ZZ6_0213) and a terminal cytochrome bd-type ubiquinol oxidase gene cydAB (ZZ6_1531 and ZZ6_1532) from Z. mobilis ZM6 (Hayashi et al. 2015); as well as a regulatory protein encoding gene irrE from Escherichia coli (Zhang et al. 2010) and a formate dehydrogenase encoding gene fdh from Saccharomyces cerevisiae (Dong et al. 2013).

The strategy of global transcription machinery engineering (gTME) has also been applied in Z. mobilis to improve inhibitor tolerance (Alper and Stephanopoulos 2007; Tan et al. 2015). For example, the global transcription factor RpoD protein, the main sigma factor σ70 in Z. mobilis, was subjected to random mutagenesis through error-prone PCR with three mutants (ZM4-MF1, ZM4-MF2, and ZM4-MF3) exhibiting enhanced furfural tolerance selected (Tan et al. 2015). This approach provides an alternative route for identifying transcription factor mutants with improved tolerance against various stresses, and will be an effective strategy for improving other similar complex phenotypes involved in multiple genes in the future.

Conclusions and perspectives

Zymomonas mobilis has being developed as an effective model for biofuel and biochemical production from lignocellulosic materials. However, microbial fermentation is still commonly affected by the presence of toxic inhibitors in the hydrolysate, which severely impeded its industrial application (Franden et al. 2013; Yi et al. 2015). Besides the lack of complete information on inhibitory compounds in the hydrolysates due to the detection limitation of current techniques, little is known on potential additional/synergetic effects of these inhibitory compounds on cellular metabolism. In addition, although recombinant strains capable of co-fermentation of pentose and hexose sugars have been achieved (Deanda et al. 1996; Dunn and Rao 2014; Yanase et al. 2012; Zhang and Eddy 1995), all these strains were sensitive to inhibitor stress, especially for the xylose utilization (Kim et al. 2000; Yang et al. 2014a). Pentose sugar xylose actually affects cellular metabolism more significantly than hydrolysate inhibitors for Z. mobilis, and the co-fermentation of xylose and glucose in the presence of inhibitor remains the key barrier for economic lignocellulosic biofuel production.

Numerous approaches have been developed to circumvent or alleviate the hydrolysate toxicity on microbial biocatalysts. One strategy is to improve pretreatment and hydrolysis processes using less severe conditions to increase sugar contents while reducing the inhibitor concentrations. Recently, a highly efficient deacetylation and mechanical refining (DMR) process has been developed resulting in low toxicity and high concentration of mixed sugars that are superior for ethanol production by Z. mobilis (Chen et al. 2012, 2016). Another strategy is to develop robust Z. mobilis strains with enhanced ethanol productivity in the presence of hydrolysate inhibitors.

As discussed above, different forward genetics strategies such as classical ALE, chemical, and transposon mutagenesis have been applied so far in Z. mobilis for inhibitor tolerance improvement. More recently, a novel mutagenesis approach, the atmosphere and room temperature plasma (ARTP) mutation, developed by Tsinghua University, is becoming increasingly popular owing to its rapid mutation, highly diverse mutants, as well as simple and safe operation (Zhang et al. 2014, 2015). ARTP has been demonstrated as a powerful tool for phenotype improvement in many different strains (Cao et al. 2017b; Chen 2016; Jiang et al. 2014). We have applied this method in Z. mobilis to improve its tolerance against low pH and high glucose concentration with positive preliminary results.

Moreover, systems biology approaches, as the reverse genetics strategies, should be continuously carried out and cross-compared to provide a complete understanding of the inhibitor tolerance mechanism of Z. mobilis, and more biological parts related to inhibitor tolerance should be continuously identified and characterized for robust strain development. For example, small RNAs (sRNAs) and 5′UTR in Z. mobilis have been studied recently by transcriptomics and bioinformatics approaches, and the result suggested that sRNAs potentially can be developed as novel biological parts to improve the tolerance against various inhibitors in Z. mobilis (Cho et al. 2014, 2017).

Considering that even simple modification in genome may switch cellular metabolism or redox balance and thereby decrease the overall yield of the system, sophisticated computational models should be developed to guide future genetic or metabolic engineering efforts in Z. mobilis (Kalnenieks et al. 2014; Widiastuti et al. 2011; Yadav et al. 2012). In addition, with the rapid development of synthetic biology tools and strategies especially the recent breakthrough on yeast genome synthesis (Wu et al. 2017; Xie et al. 2017; Zhang et al. 2017), it is advantageous and practical to develop ZM4 as a chassis microorganism through both genome minimization and genome synthesis approaches considering its excellent industrial features, small genome size of 2.06 Mb, and fascinating unique physiology. The synthetic minimal Z. mobilis chassis can facilitate the understanding of functional and regulatory biological parts and their potential synergetic effects as well as the underlying mechanisms against inhibitor tolerance for the development of robust industrial chassis platforms for economic bioproducts. Finally, sophisticated and efficient tools for genome editing need to be developed instantaneously. For example, although CRISPR/Cas system has been investigated in Z. mobilis recently (Cao et al. 2017a; Dong et al. 2016), more efficient strategies are needed for efficient recreation of SNPs for genetics studies to identify the association of SNPs with improved phenotypes in tolerant mutants.

Another major bottleneck impeding strain-engineering efforts are the lack of high-throughput screening and characterization methods to correlate genetic change(s) acquired through forward and reverse genetics approaches with microbial physiology and bioproduction parameters of titer, rate, and productivity. Although high-throughput approaches such as Bioscreen C have been applied in Z. mobilis, cutting-edge versatile high-throughput methods should be continuously developed and employed to accelerate the strain characterization such as microfluidics and microfluidics-based advanced microscopy techniques (Gan et al. 2011; Madren et al. 2012).

In summary, the application of various advanced technological approaches will be further implemented with a promising future in developing more robust Z. mobilis strains for efficient biofuels and biochemicals production from lignocellulosic biomass.

Abbreviations

- ED pathway:

-

Entner–Doudoroff pathway

- GRAS:

-

generally regarded as safe

- ALE:

-

adaptive laboratory evolution

- ILs:

-

ionic liquids

- STEX:

-

steaming or steam explosion

- AFEX:

-

ammonia fiber explosion

- LHW:

-

liquid hot water

- HMF:

-

5-hydroxymethyl-2-furaldehyde

- HPLC:

-

high-performance liquid chromatography

- GC:

-

gas chromatography

- GC–MS:

-

gas chromatography–mass spectrometer

- LC–MS:

-

liquid chromatography–mass spectrometer

- ICP-MS:

-

inductively coupled plasma mass spectrometer

- ICP-OES:

-

inductively coupled plasma optical emission spectrometry

- NMR:

-

nuclear magnetic resonance

- PCR:

-

polymerase chain reaction

- NTG:

-

N-methyl-N′-nitro-N-nitrosoguanidine

- NGS:

-

next-generation sequencing

- sRNAs:

-

small RNAs

- DMR:

-

deacetylation and mechanical refining

References

Almeida JRM, Modig T, Petersson A, Hahn-Hagerdal B, Liden G, Gorwa-Grauslund MF (2007) Increased tolerance and conversion of inhibitors in lignocellulosic hydrolysates by Saccharomyces cerevisiae. J Chem Technol Biotechnol 82:340–349

Alper H, Stephanopoulos G (2007) Global transcription machinery engineering: a new approach for improving cellular phenotype. Metab Eng 9:258–267

Baral NR, Li JZ, Jha AK (2014) Perspective and prospective of pretreatment of corn straw for butanol production. Appl Biochem Biotechnol 172:840–853

Bochner B, Gomez V, Ziman M, Yang S, Brown SD (2010) Phenotype microarray profiling of Zymomonas mobilis ZM4. Appl Biochem Biotechnol 161:116–123

Bothast RJ, Nichols NN, Dien BS (1999) Fermentations with new recombinant organisms. Biotechnol Prog 15:867–875

Buchholz S, Eveleigh D (1990) Genetic modification of Zymomonas mobilis. Biotechnol Adv 8:547–581

Cao QH, Shao HH, Qiu H, Li T, Zhang YZ, Tan XM (2017a) Using the CRISPR/Cas9 system to eliminate native plasmids of Zymomonas mobilis ZM4. Biosci Biotechnol Biochem 81:453–459

Cao S, Zhou X, Jin W, Wang F, Tu R, Han S, Chen H, Chen C, Xie GJ, Ma F (2017b) Improving of lipid productivity of the oleaginous microalgae Chlorella pyrenoidosa via atmospheric and room temperature plasma (ARTP). Bioresour Technol 244:1400–1406

Capolupo L, Faraco V (2016) Green methods of lignocellulose pretreatment for biorefinery development. Appl Microbiol Biotechnol 100:9451–9467

Chen XG (2016) Economic potential of biomass supply from crop residues in China. Appl Energy 166:141–149

Chen X, Tao L, Joseph S, Ali M, Steve D, Wang W, Holly S, Sunkyu P, Himmel ME, Melvin T (2012) Improved ethanol yield and reduced Minimum Ethanol Selling Price (MESP) by modifying low severity dilute acid pretreatment with deacetylation and mechanical refining: 1) Experimental. Biotechnol Biofuels 5:69

Chen X, Kuhn E, Jennings E, Nelson R, Zhang M, Ciesielski PN, Tao L, Tucker MP (2016) DMR (deacetylation and mechanical refining) processing of corn stover achieves high monomeric sugar concentrations (230 g/L) during enzymatic hydrolysis and high ethanol concentration (> 10% v/v) during fermentation without hydrolyzate purification or conce. Energ Environ Sci 9:1237–1245

Cho SH, Lei R, Henninger TD, Contreras LM (2014) Discovery of ethanol-responsive small RNAs in Zymomonas mobilis. Appl Environ Microbiol 80:4189–4198

Cho SH, Haning K, Shen W, Blome C, Yang S, Contreras L (2017) Identification and characterization of 5′untranslated regions (5′UTRs) in Zymomonas mobilis as regulatory biological parts. Front Microbiol 8:2432

Deanda K, Zhang M, Eddy C, Picataggio S (1996) Development of an arabinose-fermenting Zymomonas mobilis strain by metabolic pathway engineering. Appl Environ Microbiol 62:4465–4470

Delgenes JP, Moletta R, Navarro JM (1996) Effects of lignocellulose degradation products on ethanol fermentations of glucose and xylose by Saccharomyces cerevisiae, Zymomonas mobilis, Pichia stipitis, and Candida shehatae. Enzyme Microb Technol 19:220–225

Dong HW, Fan LQ, Luo Z, Zhong JJ, Ryu DD, Bao J (2013) Improvement of ethanol productivity and energy efficiency by degradation of inhibitors using recombinant Zymomonas mobilis (pHW20a-fdh). Biotechnol Bioeng 110:2395–2404

Dong G, He M, Feng H (2016) Functional characterization of CRISPR-Cas system in the ethanologenic bacterium Zymomonas mobilis ZM4. Adv Microbiol 06:178–189

Dragosits M, Mattanovich D (2013) Adaptive laboratory evolution—principles and applications for biotechnology. Microbl Cell Fact 12:64

Dunn KL, Rao CV (2014) Expression of a xylose-specific transporter improves ethanol production by metabolically engineered Zymomonas mobilis. Appl Microbiol Biotechnol 98:6897–6905

Feng Q, Li S, Wang L, Li T (2012) Evaluation on glucose–xylose co-fermentation by a recombinant Zymomonas mobilis strain. Sheng Wu Gong Cheng Xue Bao 28:37–47

Franden MA, Pienkos PT, Zhang M (2009) Development of a high-throughput method to evaluate the impact of inhibitory compounds from lignocellulosic hydrolysates on the growth of Zymomonas mobilis. J Biotechnol 144:259–267

Franden MA, Pilath HM, Mohagheghi A, Pienkos PT, Zhang M (2013) Inhibition of growth of Zymomonas mobilis by model compounds found in lignocellulosic hydrolysates. Biotechnol Biofuels 6:99

Gan M, Su J, Wang J, Wu H, Chen L (2011) A scalable microfluidic chip for bacterial suspension culture. Lab Chip 11:4087–4092

Gu H, Zhang J, Bao J (2014) Inhibitor analysis and adaptive evolution of Saccharomyces cerevisiae for simultaneous saccharification and ethanol fermentation from industrial waste corncob residues. Bioresour Technol 157:6–13

Gu H, Zhang J, Bao J (2015) High tolerance and physiological mechanism of Zymomonas mobilis to phenolic inhibitors in ethanol fermentation of corncob residue. Biotechnol Bioeng 112:1770–1782

Hayashi T, Kato T, Watakabe S, Song W, Aikawa S, Furukawa K (2015) The respiratory chain provides salt stress tolerance by maintaining a low NADH/NAD+ ratio in Zymomonas mobilis. Microbiology 161:2384–2394

He MX, Wu B, Shui ZX, Hu QC, Wang WG, Tan FR, Tang XY, Zhu QL, Pan K, Li Q, Su XH (2012) Transcriptome profiling of Zymomonas mobilis under furfural stress. Appl Microbiol Biotechnol 95:189–199

He MX, Wu B, Qin H, Ruan ZY, Tan FR, Wang JL, Shui ZX, Dai LC, Zhu QL, Pan K, Tang XY, Wang WG, Hu QC (2014) Zymomonas mobilis: a novel platform for future biorefineries. Biotechnol Biofuels 7:101

Jennings EW, Schell DJ (2011) Conditioning of dilute-acid pretreated corn stover hydrolysate liquors by treatment with lime or ammonium hydroxide to improve conversion of sugars to ethanol. Bioresour Technol 102:1240–1245

Jeon YJ, Xun Z, Rogers PL (2010) Comparative evaluations of cellulosic raw materials for second generation bioethanol production. Lett Appl Microbiol 51:518–524

Jia X, Wei N, Wang T, Wang H (2013) Use of an EZ-Tn5-based random mutagenesis system to create a Zymomonas mobilis with significant tolerance to heat stress and malnutrition. J Ind Microbiol Biotechnol 40:811–822

Jiang M, Wan Q, Liu R, Liang L, Chen X, Wu M, Zhang H, Chen K, Ma J, Wei P, Ouyang P (2014) Succinic acid production from corn stalk hydrolysate in an E. coli mutant generated by atmospheric and room-temperature plasmas and metabolic evolution strategies. J Ind Microbiol Biotechnol 41:115–123

Jin M, Bothfeld W, Austin S, Sato TK, La Reau A, Li H, Foston M, Gunawan C, LeDuc RD, Quensen JF, McGee M, Uppugundla N, Higbee A, Ranatunga R, Donald CW, Bone G, Ragauskas AJ, Tiedje JM, Noguera DR, Dale BE, Zhang Y, Balan V (2013) Effect of storage conditions on the stability and fermentability of enzymatic lignocellulosic hydrolysate. Bioresour Technol 147:212–220

Joachimsthal E, Haggett KD, Jang JH, Rogers PL (1998) A mutant of Zymomonas mobilis ZM4 capable of ethanol production from glucose in the presence of high acetate concentrations. Biotechnol Lett 20:137–142

Joachimsthal E, Haggett KD, Rogers PL (1999) Evaluation of recombinant strains of Zymomonas mobilis for ethanol production from glucose/xylose media. Appl Biochem Biotechnol 99:77–79

Jönsson LJ, Alriksson B, Nilvebrant NO (2013) Bioconversion of lignocellulose: inhibitors and detoxification. Biotechnol Biofuels 6:16

Kalnenieks U, Pentjuss A, Rutkis R, Stalidzans E, Fell DA (2014) Modeling of Zymomonas mobilis central metabolism for novel metabolic engineering strategies. Front Microbiol 5:42

Kim IS, Barrow KD, Rogers PL (2000) Nuclear magnetic resonance studies of acetic acid inhibition of rec Zymomonas mobilis ZM4(pZB5). Appl Biochem Biotechnol 84–86:357–370

Klinke HB, Thomsen AB, Ahring BK (2004) Inhibition of ethanol-producing yeast and bacteria by degradation products produced during pre-treatment of biomass. Appl Microbiol Biotechnol 66:10–26

Krishnan MS, Blanco M, Shattuck CK, Nghiem NP, Davison BH (2000) Ethanol production from glucose and xylose by immobilized Zymomonas mobilis CP4 (pZB5). Appl Biochem Biotechnol 84-86(1-9):525–541

Le DM, Sorensen HR, Knudsen NO, Schjoerring JK, Meyer AS (2014) Biorefining of wheat straw: accounting for the distribution of mineral elements in pretreated biomass by an extended pretreatment-severity equation. Biotechnol Biofuels 7:141

Lee JH, Skotnicki ML, Rogers PL (1982) Kinetic studies on a flocculent strain of Zymomonas mobilis. Biotechnol Lett 4:615–620

Lee H, Popodi E, Tang H, Foster PL (2012) Rate and molecular spectrum of spontaneous mutations in the bacterium Escherichia coli as determined by whole-genome sequencing. Proc Natl Acad Sci USA 109:E2774–E2783

Li XZ, Webb JS, Kjelleberg S, Rosche B (2006) Enhanced benzaldehyde tolerance in Zymomonas mobilis biofilms and the potential of biofilm applications in fine-chemical production. Appl Environ Microbiol 72:1639–1644

Liu YF, Hsieh CW, Chang YS, Wung BS (2017) Effect of acetic acid on ethanol production by Zymomonas mobilis mutant strains through continuous adaptation. BMC Biotechnol 17:63

Madren SM, Hoffman MD, Brown PJ, Kysela DT, Brun YV, Jacobson SC (2012) Microfluidic device for automated synchronization of bacterial cells. Anal Chem 84:8571–8578

Mohagheghi A, Evans K, Chou YC, Zhang M (2002) Cofermentation of glucose, xylose, and arabinose by genomic DNA-integrated xylose/arabinose fermenting strain of Zymomonas mobilis AX101. Appl Biochem Biotechnol 98–100:885–898

Mohagheghi A, Dowe N, Schell D, Chou YC, Eddy C, Zhang M (2004) Performance of a newly developed integrant of Zymomonas mobilis for ethanol production on corn stover hydrolysate. Biotechnol Lett 26:321–325

Mohagheghi A, Linger J, Smith H, Yang S, Dowe N, Pienkos PT (2014) Improving xylose utilization by recombinant Zymomonas mobilis strain 8b through adaptation using 2-deoxyglucose. Biotechnol Biofuels 7:19

Mohagheghi A, Linger JG, Yang SH, Smith H, Dowe N, Zhang M, Pienkos PT (2015) Improving a recombinant Zymomonas mobilis strain 8b through continuous adaptation on dilute acid pretreated corn stover hydrolysate. Biotechnol Biofuels 8:55

Olsson L, Hahn-Hägerdal B (1996) Fermentation of lignocellulosic hydrolysates for ethanol production. Enzyme Microb Technol 18:312–331

Panesar PS, Marwaha SS, Kennedy JF (2006) Zymomonas mobilis: an alternative ethanol producer. J Chem Technol Biotechnol 81:623–635

Pappas K, Galani I, Typas M (1997) Transposon mutagenesis and strain construction in Zymomonas mobilis. J Appl Microbiol 82:379–388

Parawira W, Tekere M (2011) Biotechnological strategies to overcome inhibitors in lignocellulose hydrolysates for ethanol production: review. Crit Rev Biotechnol 31:20–31

Pentjuss A, Odzina I, Kostromins A, Fell DA, Stalidzans E, Kalnenieks U (2013) Biotechnological potential of respiring Zymomonas mobilis: a stoichiometric analysis of its central metabolism. J Biotechnol 165:1–10

Portnoy VA, Bezdan D, Zengler K (2011) Adaptive laboratory evolution-harnessing the power of biology for metabolic engineering. Curr Opin Biotechnol 22:590–594

Rogers PL, Skotnicki ML, Lee KJ, Lee JH (1984) Recent developments in the Zymomonas process for ethanol production. Crit Rev Biotechnol 1:273–288

Rogers PL, Jeon YJ, Lee KJ, Lawford HG (2007) Zymomonas mobilis for fuel ethanol and higher value products. Adv Biochem Eng Biotechnol 108:263–288

Schell DJ, Dowe N, Chapeaux A, Nelson RS, Jennings EW (2016) Accounting for all sugars produced during integrated production of ethanol from lignocellulosic biomass. Bioresour Technol 205:153–158

Seo JS, Chong H, Park HS, Yoon KO, Jung C, Kim JJ, Hong JH, Kim H, Kim JH, Kil JI, Park CJ, Oh HM, Lee JS, Jin SJ, Um HW, Lee HJ, Oh SJ, Kim JY, Kang HL, Lee SY, Lee KJ, Kang HS (2005) The genome sequence of the ethanologenic bacterium Zymomonas mobilis ZM4. Nat Biotechnol 23:63–68

Serate J, Xie D, Pohlmann E, Donald C Jr, Shabani M, Hinchman L, Higbee A, McGee M, La Reau A, Klinger GE, Li S, Myers CL, Boone C, Bates DM, Cavalier D, Eilert D, Oates LG, Sanford G, Sato TK, Dale B, Landick R, Piotrowski J, Ong RG, Zhang Y (2015) Controlling microbial contamination during hydrolysis of AFEX-pretreated corn stover and switchgrass: effects on hydrolysate composition, microbial response and fermentation. Biotechnol Biofuels 8:180

Shi J, Pu Y, Yang B, Ragauskas A, Wyman CE (2011) Comparison of microwaves to fluidized sand baths for heating tubular reactors for hydrothermal and dilute acid batch pretreatment of corn stover. Bioresour Technol 102:5952–5961

Shui ZX, Qin H, Wu B, Ruan ZY, Wang LS, Tan FR, Wang JL, Tang XY, Dai LC, Hu GQ, He MX (2015) Adaptive laboratory evolution of ethanologenic Zymomonas mobilis strain tolerant to furfural and acetic acid inhibitors. Appl Microbiol Biotechnol 99:5739–5748

Silveira MHL, Morais ARC, Lopes AMD, Olekszyszen DN, Bogel-Lukasik R, Andreaus J, Ramos LP (2015) Current pretreatment technologies for the development of cellulosic ethanol and biorefineries. Chemsuschem 8:3366–3390

Skerker JM, Leon D, Price MN, Mar JS, Tarjan DR, Wetmore KM, Deutschbauer AM, Baumohl JK, Bauer S, Ibanez AB, Mitchell VD, Wu CH, Hu P, Hazen T, Arkin AP (2013) Dissecting a complex chemical stress: chemogenomic profiling of plant hydrolysates. Mol Syst Biol 9:674

Sun Y, Cheng J (2002) Hydrolysis of lignocellulosic materials for ethanol production: a review. Bioresour Technol 83:1–11

Sun S, Cao X, Sun R (2016) The role of pretreatment in improving the enzymatic hydrolysis of lignocellulosic materials. Bioresour Technol 199:49–58

Tan FR, Dai LC, Wu B, Qin H, Shui ZX, Wang JL, Zhu QL, Hu QC, Ruan ZY, He MX (2015) Improving furfural tolerance of Zymomonas mobilis by rewiring a sigma factor RpoD protein. Appl Microbiol Biotechnol 99:5363–5371

Tan F, Wu B, Dai L, Qin H, Shui Z, Wang J, Zhu Q, Hu G, He M (2016) Using global transcription machinery engineering (gTME) to improve ethanol tolerance of Zymomonas mobilis. Microb Cell Fact 15:4

Teixeira LC, Linden JC, Schroeder HA (2000) Simultaneous saccharification and cofermentation of peracetic acid-pretreated biomass. Appl Biochem Biotechnol 84–86:111–127

Todhanakasem T, Sangsutthiseree A, Areerat K, Young GM, Thanonkeo P (2014) Biofilm production by Zymomonas mobilis enhances ethanol production and tolerance to toxic inhibitors from rice bran hydrolysate. New Biotechnol 31:451–459

Todhanakasem T, Narkmit T, Areerat K, Thanonkeo P (2015) Fermentation of rice bran hydrolysate to ethanol using Zymomonas mobilis biofilm immobilization on DEAE-cellulose. Electron J Biotechnol 18:196–201

Todhanakasem T, Yodsanga S, Sowatad A, Kanokratana P, Thanonkeo P, Champreda V (2018) Inhibition analysis of inhibitors derived from lignocellulose pretreatment on the metabolic activity of Zymomonas mobilis biofilm and planktonic cells and the proteomic responses. Biotechnol Bioeng 115:70–81

Typas MA, Galani I (1992) Chemical and UV mutagenesis in Zymomonas mobilis. Genetica 87:37–45

Viitanen PV, Tao L, Knoke K, Zhang Y, Caimi PG, Zhang M, Chou YC, Franden MA (2009) Process for the production of ethanol from a medium comprising xylose, employing a recombinant Zymomonas strain having a reduced himA expression. WO Patent 2009058938 A2 2009

Viitanen PV, Tao L, Knoke K, Zhang Y, Caimi PG, Zhang M, Chou YC, Franden MA (2012) Zymomonas with improved ethanol production in medium containing concentrated sugars and acetate. EP Patent 2209899 B1 2012

Wang Y (2008) Development of acetic-acid tolerant Zymomonas mobilis strains through adaptation. Georgia Institute of Technology, Atlanta

Wang W, Yang S, Hunsinger GB, Pienkos PT, Johnson DK (2014) Connecting lignin-degradation pathway with pre-treatment inhibitor sensitivity of Cupriavidus necator. Front Microbiol 5:247

Wang JL, Wu B, Qin H, You Y, Liu S, Shui ZX, Tan FR, Wang YW, Zhu QL, Li YB, Ruan ZY, Ma KD, Dai LC, Hu GQ, He MX (2016) Engineered Zymomonas mobilis for salt tolerance using EZ-Tn5-based transposon insertion mutagenesis system. Microbl Cell Fact 15:101

Wang X, Gao Q, Bao J (2017) Enhancement of furan aldehydes conversion in Zymomonas mobilis by elevating dehydrogenase activity and cofactor regeneration. Biotechnol Biofuels 10:24

Widiastuti H, Kim JY, Selvarasu S, Karimi IA, Kim H, Seo JS, Lee DY (2011) Genome-scale modeling and in silico analysis of ethanologenic bacteria Zymomonas mobilis. Biotechnol Bioeng 108:655–665

Wu Y, Li BZ, Zhao M, Mitchell LA, Xie ZX, Lin QH, Wang X, Xiao WH, Wang Y, Zhou X, Liu H, Li X, Ding MZ, Liu D, Zhang L, Liu BL, Wu XL, Li FF, Dong XT, Jia B, Zhang WZ, Jiang GZ, Liu Y, Bai X, Song TQ, Chen Y, Zhou SJ, Zhu RY, Gao F, Kuang Z, Wang X, Shen M, Yang K, Stracquadanio G, Richardson SM, Lin Y, Wang L, Walker R, Luo Y, Ma PS, Yang H, Cai Y, Dai J, Bader JS, Boeke JD, Yuan YJ (2017) Bug mapping and fitness testing of chemically synthesized chromosome X. Science 355:eaaf4706

Xie ZX, Li BZ, Mitchell LA, Wu Y, Qi X, Jin Z, Jia B, Wang X, Zeng BX, Liu HM, Wu XL, Feng Q, Zhang WZ, Liu W, Ding MZ, Li X, Zhao GR, Qiao JJ, Cheng JS, Zhao M, Kuang Z, Martin JA, Stracquadanio G, Yang K, Bai X, Zhao J, Hu ML, Lin QH, Zhang WQ, Shen MH, Chen S, Su W, Wang EX, Guo R, Zhai F, Guo XJ, Du HX, Zhu JQ, Song TQ, Dai JJ, Li FF, Jiang GZ, Han SL, Liu SY, Yu ZC, Yang XN, Chen K, Hu C, Li DS, Jia N, Liu Y, Wang LT, Wang S, Wei XT, Fu MQ, Qu LM, Xin SY, Liu T, Tian KR, Li XN, Zhang JH, Song LX, Liu JG, Lv JF, Xu H, Tao R, Wang Y, Zhang TT, Deng YX, Wang YR, Li T, Ye GX, Xu XR, Xia ZB, Zhang W, Yang SL, Liu YL, Ding WQ, Liu ZN, Liu NZ, Walker R, Luo Y, Shen Y, Yang H, Cai Y, Ma PS, Zhang CT, Bader JS, Boeke JD, Yuan YJ (2017) “Perfect” designer chromosome V and behavior of a ring derivative. Science. 355:eaaf4704

Yadav VG, De Mey M, Lim CG, Ajikumar PK, Stephanopoulos G (2012) The future of metabolic engineering and synthetic biology: towards a systematic practice. Metab Eng 14:233–241

Yanase H, Miyawaki H, Sakurai M, Kawakami A, Matsumoto M, Haga K, Kojima M, Okamoto K (2012) Ethanol production from wood hydrolysate using genetically engineered Zymomonas mobilis. Appl Microbiol Biotechnol 94:1667–1678

Yang S, Pappas KM, Hauser LJ, Land ML, Chen GL, Hurst GB, Pan C, Kouvelis VN, Typas MA, Pelletier DA, Klingeman DM, Chang YJ, Samatova NF, Brown SD (2009a) Improved genome annotation for Zymomonas mobilis. Nat Biotechnol 27:893–894

Yang S, Tschaplinski TJ, Engle NL, Carroll SL, Martin SL, Davison BH, Palumbo AV, Rodriguez M Jr, Brown SD (2009b) Transcriptomic and metabolomic profiling of Zymomonas mobilis during aerobic and anaerobic fermentations. BMC Genom 10:34

Yang S, Land ML, Klingeman DM, Pelletier DA, Lu TY, Martin SL, Guo HB, Smith JC, Brown SD (2010a) Paradigm for industrial strain improvement identifies sodium acetate tolerance loci in Zymomonas mobilis and Saccharomyces cerevisiae. Proc Natl Acad Sci USA 107:10395–10400

Yang S, Pelletier DA, Lu T-YS, Brown SD (2010b) The Zymomonas mobilis regulator hfq contributes to tolerance against multiple lignocellulosic pretreatment inhibitors. BMC Microbiol 10:135

Yang S, Franden MA, Brown SD, Chou YC, Pienkos PT, Zhang M (2014a) Insights into acetate toxicity in Zymomonas mobilis 8b using different substrates. Biotechnol Biofuels 7:140

Yang S, Linger J, Franden MA, Pienkos PT, Zhang M (2014b) Biocatalysts with enhanced inhibitor tolerance, vol US9206445

Yang S, Pan C, Hurst GB, Dice L, Davison BH, Brown SD (2014c) Elucidation of Zymomonas mobilis physiology and stress responses by quantitative proteomics and transcriptomics. Front Microbiol 5:246

Yang S, Fei Q, Zhang Y, Contreras LM, Utturkar SM, Brown SD, Himmel ME, Zhang M (2016) Zymomonas mobilis as a model system for production of biofuels and biochemicals. Microb Biotechnol 9:699–717

Yi X, Gu H, Gao Q, Liu ZL, Bao J (2015) Transcriptome analysis of Zymomonas mobilis ZM4 reveals mechanisms of tolerance and detoxification of phenolic aldehyde inhibitors from lignocellulose pretreatment. Biotechnol Biofuels 8:153

Zaldivar J, Martinez A, Ingram LO (1999) Effect of selected aldehydes on the growth and fermentation of ethanologenic Escherichia coli. Biotechnol Bioeng 65:24–33

Zhang M, Eddy C (1995) Metabolic engineering of a pentose metabolism pathway in ethanologenic Zymomonas mobilis. Science 267:240–243

Zhang Y, Ma RQ, Zhao ZL, Zhou ZF, Lu W, Zhang W, Chen M (2010) irrE, an exogenous gene from Deinococcus radiodurans, improves the growth of and ethanol production by a Zymomonas mobilis strain under ethanol and acid stresses. J Microbiol Biotechnol 20:1156–1162

Zhang X, Zhang X-F, Li HP, Wang LY, Zhang C, Xing XH, Bao CY (2014) Atmospheric and room temperature plasma (ARTP) as a new powerful mutagenesis tool. Appl Microbiol Biotechnol 98:5387–5396

Zhang X, Zhang C, Zhou QQ, Zhang XF, Wang LY, Chang HB, Li HP, Oda Y, Xing XH (2015) Quantitative evaluation of DNA damage and mutation rate by atmospheric and room-temperature plasma (ARTP) and conventional mutagenesis. Appl Microbiol Biotechnol 99:5639–5646

Zhang WM, Zhao GH, Luo ZQ, Lin YC, Wang LH, Guo YK, Wang A, Jiang SY, Jiang QW, Gong JH, Wang Y, Hou S, Huang J, Li TY, Qin YR, Dong JK, Qin Q, Zhang JY, Zou XZ, He X, Zhao L, Xiao YB, Xu M, Cheng EC, Huang N, Zhou T, Shen Y, Walker R, Luo YS, Kuang Z, Mitchell LA, Yang K, Richardson SM, Wu Y, Li BZ, Yuan YJ, Yang HM, Lin JW, Chen GQ, Wu QY, Bader JS, Cai YZ, Boeke JD, Dai JB (2017) Engineering the ribosomal DNA in a megabase synthetic chromosome. Science 355:eaaf3981

Zhao N, Bai Y, Zhao XQ, Yang ZY, Bai FW (2012) Draft genome sequence of the flocculating Zymomonas mobilis strain ZM401 (ATCC 31822). J Bacteriol 194:7008–7009

Zhao N, Bai Y, Liu CG, Zhao XQ, Xu JF, Bai FW (2014) Flocculating Zymomonas mobilis is a promising host to be engineered for fuel ethanol production from lignocellulosic biomass. Biotechnol J 9:362–371

Authors’ contributions

SY conceived the concept with inputs from XW and YY. YY, HM, TY, BG, and MQ prepared and wrote the manuscript. SY revised the manuscript with inputs from QH, SC, and XW. All authors read and approved the final manuscript.

Acknowledgements

We appreciate the valuable discussion and inspiration with Prof. Qiang Fei at Xi’an Jiaotong University for the preparation of this manuscript.

Competing interests

The authors declare that they have no competing interests.

Availability of data and materials

The datasets supporting the conclusions of this article are included in the manuscript file.

Consent for publication

All authors approved the consent for publishing the manuscript.

Ethics approval and consent to participate

Not applicable.

Funding

Funding information is not applicable.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Yang, Y., Hu, M., Tang, Y. et al. Progress and perspective on lignocellulosic hydrolysate inhibitor tolerance improvement in Zymomonas mobilis. Bioresour. Bioprocess. 5, 6 (2018). https://doi.org/10.1186/s40643-018-0193-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40643-018-0193-9