Highlights

-

A comprehensive discussion of monitoring the structure evolutions of catalysts during ORR via multiple in-situ techniques to identify the active sites is presented.

-

The extensive applications of in-situ techniques in elucidating the oxygen reduction reaction (ORR) mechanisms/pathways are reviewed.

-

The challenges and recommendations of current in-situ techniques for monitoring the various dynamic evolutions in ORR are pointed out.

Abstract

Electrocatalytic oxygen reduction reaction (ORR) is one of the most important reactions in electrochemical energy technologies such as fuel cells and metal–O2/air batteries, etc. However, the essential catalysts to overcome its slow reaction kinetic always undergo a complex dynamic evolution in the actual catalytic process, and the concomitant intermediates and catalytic products also occur continuous conversion and reconstruction. This makes them difficult to be accurately captured, making the identification of ORR active sites and the elucidation of ORR mechanisms difficult. Thus, it is necessary to use extensive in-situ characterization techniques to proceed the real-time monitoring of the catalyst structure and the evolution state of intermediates and products during ORR. This work reviews the major advances in the use of various in-situ techniques to characterize the catalytic processes of various catalysts. Specifically, the catalyst structure evolutions revealed directly by in-situ techniques are systematically summarized, such as phase, valence, electronic transfer, coordination, and spin states varies. In-situ revelation of intermediate adsorption/desorption behavior, and the real-time monitoring of the product nucleation, growth, and reconstruction evolution are equally emphasized in the discussion. Other interference factors, as well as in-situ signal assignment with the aid of theoretical calculations, are also covered. Finally, some major challenges and prospects of in-situ techniques for future catalysts research in the ORR process are proposed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Exploration of clean and sustainable energy sources, such as wind, solar, and hydroelectric power and the development of their associated electricity energy storage and conversion technologies are inevitable to undertake a secure and sustainable prospect [1]. For electricity storage and conversion technologies, electrochemical energy technologies including water electrolysis to produce hydrogen, fuel cells to convert hydrogen to electricity, metal–O2/air batteries to store/convert energy, etc., have been awaked as reliable, safe, efficient, environmental, and sustainable selections [2,3,4]. For fuel cells, such as proton exchange membrane fuel cells (PEMFCs), direct borohydride fuel cells (DBFCs), and metal–O2/air batteries such as lithium–O2/air (Li–O2/Air) battery, sodium–O2/air (Na–O2/Air) battery, as well as zinc–O2/air (Zn–O2/Air) battery, the oxygen reduction reaction (ORR) of their cathodes has been distinguished as the reaction dominating the performance of these devices owing to its slow reaction kinetics [5,6,7]. Therefore, some active and stable electrocatalysts coated on the cathodes are necessary to catalyze the ORR to a practical rate.

Currently, the most practical ORR electrocatalysts are platinum (Pt)-based catalysts [8, 9], and their multiple designs for superior ORR activity have been reported extensively. In detail, Pt nano-catalysts with multi-dimensional morphologies [10,11,12], such as nanocages (NC) [13], nano-frames [14], nanosheets [15], nanowires (NW) [16], nanotubes (NT) [17], and nano-dendrites (ND) [18], have been developed. Each catalyst either possesses open, hollow, porous nanostructures, or high-energy surfaces, which can either contribute to increase the exposure density of Pt active sites, facilitate electron transport/mass exchange, or help to enhance Pt atom utilization, eliminate Pt dissolution and aggregation, thereby improving the ORR activity and stability [19,20,21]. Also, a great deal of research has focused on the introduction of economic transition metals (M = Fe, Co, Ni, Cu, etc.) into Pt to form Pt-based alloys (Pt–M) catalysts with high ORR performance. As identified [22, 23], the synergistic effect of geometry, ligands, and optimized electronic structure in the Pt-M catalyst can reduce Pt consumption, enhance Pt intrinsic activity, and reduce other side reactions, thereby strengthening its ORR activity and durability. Furthermore, owing to resource shortage and the high price of Pt-based materials, many low-cost non-platinum catalysts have been explored [24,25,26], containing heme centered mimetic macromolecules (e.g., metal-phthalocyanines or -porphyrins) [27,28,29], metal oxides [30,31,32,33], and transition metals based catalysts [34, 35] etc. Subsequently, nitrogen-functionalized graphene catalysts are widely proven to be metal-free catalysts with high ORR performance [36,37,38]. Thereafter, the field of metal-free catalysts has undergone rapid development and miscellaneous carbon-based catalysts with heteroatom doping have been reported [39]. Expressly, transition metal (i.e., M = Fe, Co, Ni, Cu, and Mn, etc.) and nitrogen dual doped carbon catalysts (i.e., M–N–Cs, containing relevant single-atom catalysts (SACs)) [40,41,42] have stood out among these candidates, owing to their beginning-of-life ORR activities approaching those of Pt-based catalysts in both acidic and alkaline electrolyte liquors [43, 44].

Considering that the superior performance is markedly dependent on the active site of the catalyst [45, 46], it is imperative to clarify the active ingredient and monitor the correlative evolution. Over the past decades, various usual ex-situ characterization techniques are applied to describe the phase, valence, electron transfer, coordination, and spin state of the catalyst before and after the electrocatalytic reaction to identify the active site and infer its variations. However, since the catalyst is prone to irreversible changes when exposed to air during transfer in ex-situ tests, the conclusions drawn may not match the reality and may cause misinterpretation [47]. More importantly, the catalyst always undergoes some dynamic structural evolution under practical conditions, leading to the evolution of active site, also increasing the difficulty of identification. Thus, the development of in-situ characterization techniques to monitor the catalyst structure evolution in real time is essential to determine the active sites, which can also reveal the rationality of the catalyst structure design and guide the synthesis of the highly active catalyst. In addition, despite a rational design of the catalyst with the highly active sites being crucial for efficient ORR, the reactions that occur during synthesis are not known, leading to a complex synthesis process, and exacerbating costs [48, 49]. Thus, the visual monitoring of the structural morphological changes, including nucleation, growth, reconstruction, Ostwald ripening, etc., for the catalyst during the synthesis process is also essential to simplify the synthesis process and shorten the synthesis time, which cannot be ignored.

In view of the ORR pathways are multiple, during which there are abundant and complex intermediates/products, and they are also related to the active site of the catalyst and are vital for the revelation of the ORR mechanism. However, extensive works have confirmed that they will also occur in a series of conversions and reconstructions under experiment conditions, resulting in them being hard to be distinguished accurately [50, 51], and their transient evolutions are difficult to capture due to the fast rate of the catalytic reaction [52,53,54]. As well as, the postprocess nature of common ex-situ characterization techniques limit the recognition of their true changes in real time. Hence, the exploitation of in-situ characterization techniques to accurately determine the evolutionary behavior of the intermediates (adsorption/desorption) or products (such as nucleation, growth, and reconstruction) is very necessary and should be equally emphasized [48]. Expressly, in-situ techniques can reveal their dynamic changes during the reaction and do not require the dismantling of the test cell, thus obtaining more valuable information to reversely clarify the active site and intuitively elucidate the ORR mechanism [55,56,57]. Notably, the electrolyte anions have competitive adsorption features with intermediates on the catalyst surface, which can cause catalyst surface poisoning and thus affect the reaction pathway. Thus, the chemisorption of electrolyte anions on the catalyst surface is a non-negligible object to be detected during ORR, which can provide information on the dynamic evolution of the catalyst surface closer to the experimental conditions. Furthermore, to ensure accurate identification of active site and precise elucidation of ORR mechanism, a great deal of works have been devoted to combining theoretical calculations to assist in facilitating the assignment of detected signals [58, 59]. Of course, the proper in-situ cell design is a guarantee for efficient in-situ detection and has also received a lot of attention [45, 60]. And each technique has its own unique detection characteristics and limitations; therefore, the combination of techniques to provide more adequate and useful information has also been the focus of researchers.

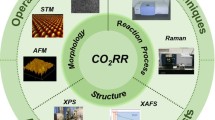

This work reviews the main advances in characterizing the catalytic processes of different catalysts in fuel cells and metal–O2/air batteries by using various in-situ techniques, and with a focus on Pt-based, M–N–C and some oxide catalysts (Fig. 1). In detail, the discuss starts with the accepted ORR mechanism form the representative batteries, and listing possible intermediates and products involved in the reaction. The working principles of various in-situ techniques and their unique detection for ORR are briefly outlined. The direct in-situ characterizations of catalyst structure evolution during ORR are systematically summarized, while, in part, covering a discussion of its morphological monitoring in the synthesis process. Then, the focus is on outlining the dynamic evolution information of intermediates and products, and providing some chemisorption information of solvent anions. These two sections reveal the factors affecting the catalytic performance of catalysts from direct or indirect perspectives and thus guide the direction of optimization of their structural design. More importantly, these provide important guidance to clarify the active center and elucidate the ORR mechanism. In addition, the integration of theoretical calculations is further emphasized to promote in-situ signals assignment. The design of in-situ cells, and the coupling of several techniques are also covered to ensure accurate information acquisition. Finally, based on achievements and challenges of present in-situ techniques, some future research directions are proposed for overcoming challenges for a better understanding of the ORR mechanism.

2 Brief Overview of the ORR Mechanism and Intermediates

2.1 Mechanism of ORR in Fuel Cells and Intermediates

For different fuel cells, the difference is the anode reaction, the cathode reaction is the same, namely ORR. Taking PEMFC (typical one) as an example, its ORR occurs at the cathode, where O2 get electrons to produce a series of oxygen-containing species [61, 62]. Specifically, the oxygen molecules first diffuse to the catalysts surface to form adsorbed oxygen molecules (O2*, where * denotes the active site) (Fig. 2a). Then the adsorbed oxygen molecules, O2*, undergo a reduction reaction, which can be divided into three pathways based on the breakage order of the O–O bonds. The first pathway is the dissociation pathway, where the O–O bonds directly break to form O* intermediates, followed by the successive reductions to OH* and H2O*. The second pathway is the association pathway, where O2* first forms OOH*, and then the O–O bonds are cleaved to produce O* and OH* intermediates. The third pathway is the peroxide pathway, where O2* intermediates are reduced sequentially to OOH* and HOOH* before the breaking of O–O bonds. This means monitoring the catalytic process and capturing intermediates information are beneficial for elucidating the ORR mechanism.

Notably, the peroxide pathway is the two-electron pathway, which only needs to overcome an energy barrier of 146 kJ mol−1 [23, 63]. However, the peroxide intermediates are difficult to be completely reduced, and some may be reversibly decomposed to form oxygen molecules, resulting in low current efficiency [64, 65]. Also, these intermediates can oxidize/corrode the catalytic active center and carbon carrier, thus significantly weakening the activity and stability of the catalyst. In contrast, the former two pathways both are the four-electron pathways, although with a higher energy barrier to overcome, but can efficiently convert oxygen molecules to H2O without producing oxidizing/corrosive intermediates. Thus, it is essential to monitor the intermediate changes during the reaction and further clarify the catalytic pathway, which can help guide the design of highly active and stable catalyst (i.e., following a four-electron pathway not a two-electron pathway).

Moreover, the adsorption/desorption process of oxygen-containing intermediates (e.g., O2*, *O, *OH, *OOH, and HOOH*) on the catalyst surface is the key to affecting the ORR kinetics [66, 67]. The adsorption process of O2 (i.e., O2 → O2*), as the initial step, determines the course of the subsequent reaction steps. The adsorption/desorption of OH occurs at a high potential, which determines the initial potential at which the reaction begins to proceed. Also, the amount of OH adsorbed determines the number of available active centers, while the ability of adsorbed OH to bind with proton/electron further limits the reaction rate. More importantly, the adsorption energy of intermediates on the given catalyst surface is positively correlated with the ORR catalytic activity [68,69,70]. It is often considered as a catalytic activity descriptor, which can be obtained by the theoretical calculation. If the adsorption strength is too weak, it will limit the proton/electron transfer; conversely, too strong adsorption will cause desorption and become difficult. Therefore, it is necessary to combine theoretical calculations to guide the design of catalysts with moderate adsorption energy.

2.2 Mechanism of ORR in Metal–O2/Air Batteries and Intermediates

For a series of metal–O2/air batteries, the ORR is responsible for their discharge processes and undergoes similar reaction mechanism. Taking a typical Li–O2 battery as an example (Fig. 2b), the dominant reaction equation is as follows:

The forward direction is the discharge reaction, during which different kinds of intermediates (i.e., lithium oxides/mixtures) and ideal Li2O2 products can be produced by reduction reaction of O2 [71,72,73]. Concretely, the first step is the O2 combines one electron, resulting in superoxide ion (O2−), and followed by meeting the Li+ to form LiO2. Then, LiO2, as the intermediator, is thermodynamically unstable and can rapidly convert to Li2O2. Based on the degree of solvent solubilization of the cations produced by LiO2, the growth process of Li2O2 can be divided into two categories [74,75,76,77].

Firstly, for electrode surface growth mechanism, in the weak Li+ solubilized solution, LiO2 will be adsorbed on catalysts surface of the electrode, forming LiO2*,

Then, LiO2* undergoes disproportionation to form Li2O2* and O2; or it receives a single e− and Li+ from the electrode and electrolyte, respectively, and continues to be reduced to Li2O2*,

Secondly, for solution growth mechanism, in a strong Li+ solubilized solution, adsorbed LiO2* breaks away from the electrode surface to form soluble LiO2(sol) and dissolves into electrolyte, followed forming Li+ (sol) and \({\text{O}}_{{2\left( {{\text{sol}}} \right)}}^{ - }\),

In addition, the LiO2(sol) can also be grown from the reaction between soluble superoxide ion \({\text{O}}_{{2\left( {{\text{sol}}} \right)}}^{ - }\) and Li+,

Finally, the formed Li+ (sol) and O2 (sol) in the electrolyte can either undergo disproportionation to form Li2O2 and O2, or again undergo a single e− transfer electrochemical process to produce Li2O2,

This means adopting in-situ characterization techniques to monitor the intermediates behavior, such as LiO2* et al., can help to reveal the ORR mechanism.

Furthermore, O2 can be reduced to Li2O by a four-electron transfer process, following,

Notably, a discharge of Li2O can augment the theoretical specific energy, but the electrochemical irreversibility of it results in an even higher charge overpotential [78]. So that it is desired to design the catalyst to help to form the ideal Li2O2 product during ORR process.

3 Succinct Overview of Various In-Situ Characterization Techniques

In this section, the operational principles, unique characteristics, and drawbacks of each characterization-technique have been summed up. An in-depth comprehension of characteristics for each technique will facilitate its targeted use in the ORR dynamic monitoring process. Some summaries of related in-situ cells are also included.

3.1 In-Situ X-Ray Diffraction (XRD)

XRD, as a form of elastic scattering, can provide unique diffraction patterns for periodically structured materials, revealing their precise crystallographic information [47, 79]. Concretely, the size, dimension, shape, and orientation of the crystal unit determine the location of the diffraction peak, and the type and location of the atoms determine the intensity of the diffraction peak [60, 80]. In-situ XRD can detect the crystalline phases during ORR in real time, and the time-varying diffraction patterns can exhibit phase transition information on catalysts and intermediates. For real-time detection, the special in-situ cell needs to be assembled, such as, a tailor-made cell with a radial X-ray penetration window for XRD analysis was designed by Liu et al. [81]. Also, the experimental conditions were integrated in their cell (Fig. 3a), including MesoCoNC@GF, Zn plate, Whatman glass microfiber filter, and KOH + zinc acetate, as the air cathode, anode, separator, and electrolyte. However, if the intermediates are very thin with very low crystallinity, the existing in-situ XRD cannot complete the detection, in addition, it is not possible to detect the local sites of the catalyst.

a Schematic diagram of in-situ XRD cell and detection principle for Meso-CoNC@GF air electrode during ORR in Zn–Air battery [81]; Reused with approval; Copyright 2017 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. b Sketch map of in-situ XAS cell, with WE, i.e., carbon paper coated with catalysts and CE, i.e., carbon rod dipped in KOH solution (1 M) [84]; Reused with approval; Copyright 2018 American Chemical Society. c The model of Au@SiO2 NPs on low-index (111) Pt surface, and the ORR mechanism promulgated by in-situ SHINERS, with Au core (golden), SiO2 shell (transparent), Pt (silver-white), O (red), and H (white) [89]; Reused with approval; Copyright 2018 Springer Nature. d Schematic diagram of in-situ ATR-IR cell, with Pt/C nanoparticles as catalysts in HClO4 solution (0.1 M) [93]; Reused with approval; Copyright 2018 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. (Color figure online)

3.2 In-Situ X-Ray Absorption Spectroscopy (XAS)

XAS (also name as X-ray absorption fine structure, XAFS), is a form of inelastic scattering, including X-ray absorption near-edge structure (XANES) (with a region up to ~ 25 eV above the edge), and extended X-ray absorption fine structure (EXAFS) (with a region of higher energies) [48, 79]. The former (XANES) can reveal the oxidation state and electronic configuration information. In detail, the target atom of a higher oxidation state, always with a higher effective charge of its nucleus, requires extra energy to excite its core electrons in comparison to other atoms [82]. The latter (EXAFS) is used to supply information on interatomic spacing or coordination numbers, which are attributed to the constructive or deconstructive interference caused by electron scattering, respectively [83]. Thus, in-situ XAS is regarded as a mighty tool for in-situ verification of electronic structure changes around the excited atom during ORR. As shown in Fig. 3b [84], an in-situ cell was made by Teflon material with chemical inert, in which the working electrode (WE) was constructed by spraying the catalyst layer (with thick of 40 μm) on carbon paper (200 μm). Also, it had an X-ray penetration window, and the electrolyte thickness was less than 200 μm, both ensuring highly quality data acquisition for in-situ XAS analysis. To reduce the IR drops induced by the thin electrolyte layer resistance, the reference electrode (RE) was linked to the cell via a salt bridge. Regrettably, it is unable to research low atomic number elements, despite it can in-situ characterize amorphous materials, also with a wider range of X-ray photon energies.

3.3 In-Situ Raman Spectroscopy

Raman spectroscopy, also as inelastic scattering, can identify structural information of molecules with Raman active vibrational modes [85, 86]. To improve the Raman intensity of necessarily and randomly adsorbed intermediates in ORR, the development of surface-enhanced Raman spectroscopy (SERS) or surface enhanced resonance Raman scattering (SERRS) is essential, especially in-situ Raman analysis [87, 88]. In-situ shell-separated nanoparticle-enhanced Raman spectroscopy (SHINERS) is the most in-depth research, particularly, revealing for ORR mechanism of low-index Pt (hkl) surface on Au@SiO2 nano-particles (NPs) [89]. In detail, Au nanoparticles act as cores, for amplifying signals; thin silica with pinhole-free acts as shells, for separating the target molecules from the core, thereby eliminating the interrelated effects (Fig. 3c). Even in aqueous solutions (weak scatterers), the vibrational and rotational energy levels of intermediates on the Pt surface can be acquired in real time. Nevertheless, Raman spectroscopy is not detectable in certain catalytic devices, such as pure metal catalysts.

3.4 In-Situ Fourier Transform Infrared (FT-IR) Spectroscopy

FT-IR spectroscopy, as an absorption spectrum, can check diversification in dipole moments triggered by rotations and vibrations of bonds in fragment molecules, radicals, and functional groups [90]. In-situ FT-IR allows real-time tracking of groups generated on the catalyst surface during ORR, with the frequencies or intensities in spectrum interrelated with category or homologous substance quantity, respectively [91]. Prominently, in-situ attenuated total reflection infrared (ATR-IR) spectroscopy with better spectral reproducibility focuses on measuring IR radiation variations after contacting with intermediates in real time, providing further insight into the ORR mechanism [92]. To avoid mass transport limitations during ORR, Nayak et al. [93] developed a modified cell, with a flow field of electrolyte around catalysts, to proceed in-situ ATR-IR testing, its work mechanism likes that of a rotating disk electrode (Fig. 3d). Regretfully, in the aqueous phase experiments, the IR light is sensitive to H2O molecules, making the signal of in-situ FT-IR exceedingly weak.

3.5 In-Situ Transmission Electron Microscope (TEM)

TEM is another intuitive means to observe the nano-materials morphology [94]. Also, it can be applied in the authentication of the crystal structure to gain information on interplanar spacing, owing to its electron diffracted beams being related to the atomic structure of the material [45]. Thus, in-situ TEM can monitor morphological variations of catalysts during ORR in real time, and it can also realize the simultaneous dynamic monitoring of chemical reactions. Notably, in-situ aberration-corrected scanning/transmission electron microscopy (S/TEM) allows real-time characterization of material structures through quantum mechanical interactions induced by incident electron wave fields and atomic potentials [95]. There exist two imagery models, bright-field imagery, and high-angle annular dark-field (HAADF) imaging, particularly, the latter as the main one can in-situ exposit structure information from the perspective of atoms. Moreover, this in-situ test is always equipped with electron energy loss spectroscopy (EELS) and energy dispersive X-ray spectroscopy (EDX) to facilitate the provision of elemental, component, and electronic configuration information of the catalyst. More importantly, it is also possible to further introduce optical, electrical, and thermal signals into the cell to undergo this in-situ test. For example, Gong et al. [96] added a heat source into the cell to ensure in-situ observation of the ORR at variable temperature conditions (Fig. 4a); also, in-situ HAADF and elemental distributions were amassed from the relevant detectors by rotating the tomography holder under the scope of tilt angles (Fig. 4b). However, in-situ TEM places relatively stringent requirements on the material preparation and operating environment, especially for high-resolution measurements under the liquid solution.

Elementary diagram of the in-situ TEM cell: a special heating holder and chip, b electron tomography, with HAADF and EDX detectors for collecting 2D HAADF and elemental allocation images at diverse orientations by rotating the holder [96]; Reused with approval; Copyright 2021 Elsevier Ltd. c Schematic diagram of in-situ SI-SECM cell and relevant titration mechanism (with OCP as open circuit potential); d The kinetic rate reflected by ln [Cu(I)]) against tdelay; Reused with approval [101]; Copyright 2020 Elsevier Ltd. e The working principle diagram of ETS and CV at the same time in a three-electrode system (with CE, RE, WE) (S, source; D, drain); f The schematic diagram of in-situ ETS cell, with PtNWs electrode and aqueous electrolyte, with anions adsorbed on the IHP [103]; Reused with approval; Copyright 2018 American Chemical Society. g The illustration of in-situ 57Fe Mössbauer cell for in-situ testing Fe active site during ORR [109]; Reused with approval; Copyright 2020 Elsevier

3.6 In-Situ Atomic Force Microscopy (AFM)

AFM, based on force, is a typical surface scanning technique, also known as scanning probe microscopy (SPM) [86]. For the main application in ORR of metal–O2/air battery, in-situ AFM, especially contact mode, can trace the morphological varies of the catalyst surface/interface in real time. Namely, it can in-situ scan the vertical morphology of the catalyst surface using a constant repulsive force between the probe and surface [90]. Notably, it is appropriate to a wide range of materials, independent of the electrical conductivity, and can work in a liquid solution due to there being no beam or lenses. Even though, to enhance the stable contact of probe and surface, it is crucial to ensure in-situ cell with an undisturbed liquid environment during ORR. That is, it is better to start in-situ AFM detection after the electrolyte saturating with O2 [97, 98]. The challenges for in-situ AFM are the contacting way of the cantilever beam with the electrode, and the inertness of the sample on the electrode.

3.7 In-Situ Scanning Electrochemical Microscopy (SECM)

SECM, as another SPM technique, is based on current and can offer electrochemical imaging information for a wide range of catalyst surface/interface with insulating/conducting [90]. It does not require surface contact (unlike AFM) and consists of three operating modes: generation, acquisition, and feedback, with the last one being the most used. Recently, in-situ SECM is widely applied to elucidate the active site number and catalytic kinetic rate of the catalyst for ORR and it is conducted by connecting a workstation bipotentiostat. Typically, in-situ SECM cell (Fig. 4c) contains aligned tip (for generating titrant) and substrate (for distributing catalyst) ultramicroelectrodes (UMEs), also, the inter-electrode distance is always controlled in less than 5 μm [99, 100]. When the titrant detects the active intermediate formed on the catalyst surface quantitatively and sensibly at given potentials in real time, the active site number information can be offered. When a delay time (tdelay) is adopted between tip and given potential on the substrate (i.e., time-delay titration), the residual active sites can be in-situ quantified, further the kinetic rate information can be obtained. In the work of Li et al. [101], the Cu(I) was easily oxidated by FcMeOH+ (tip-generated titrant) rather than O2, during Cu SAC catalytic ORR, supporting in-situ time-delay titration test, and more kinetic information derived from the log-integrated charge density (ln [Cu(I)]) against tdelay (Fig. 4d). However, the nanoscale resolution for SECM is challenging, being limited by the tip size and its distance to the substrate.

3.8 In-Situ Electrical Transport Spectroscopy (ETS)

ETS is an electrochemical interface analysis technique, based on the fact that the chemical sensitivity of metal nano-catalysts can be converted to electrical signals [102]. For in-situ ETS, cyclic voltammetry (CV) and ETS are simultaneously measured in a three-electrode system in real time by a dual-channel source measure unit (SMU). More precisely (Fig. 4e), one supplies gate voltage (VG) for the working electrode (WE) and reference electrode (RE), while the Faradaic current (IG, in line with CV electrochemical current) is collected through counter electrode (CE). The other applies a petty bias voltage (VSD) for the source/drain electrode (i.e., WE), simultaneously, the electrical conduction current (ISD) is collected, namely, ETS signals. For ultrafine metallic nano-catalysts [103], the solution anions tend to adsorb on the inner Helmholtz plane (IHP, among solid and liquid interfaces), with difficult access for the radiation, making in-situ ETS essential for monitoring their surface adsorbed behavior. Taking platinum nanowire (PtNW) as an example, in-situ ETS provided a semaphore that was extremely susceptive to the dynamic evolution of surface states during ORR, thus revealing the effect of surface anions adsorption on ORR. In the cell (Fig. 4f), the PtNW was placed among source and drain electrodes with gold protection, also it only responded to the strong scattering effect of adsorbed anions, thus ensuring easy detection by the current. Nevertheless, for some catalysts only with weak chemical sensitivity, it is difficult for using in-situ ETS to track the related scattering effect signals on their surface.

3.9 In-Situ Mössbauer Spectroscopy

Mössbauer spectroscopy, based on the Mössbauer effect, is a technique for detecting the nuclear state of certain specific elements (e.g., Fe, Sn, Ru, and Au). In-situ Mössbauer spectroscopy can track nuclei states of these elements in real time, including chemical state, coordination symmetry, spin state, and magnetic moment [104, 105]. Specifically, the isomer shift (IS) parameter, interrelated with the electronic structure, can ascertain the information about the chemical shifts. The quadrupole splitting (QS) parameter can reveal the electronic symmetry, further reflecting the spin state. The magnetic Zeeman splitting (B) parameter is invariably used to furnish the magnetic structure information [105, 106]. Recently, in-situ 57Fe Mössbauer spectroscopy has been widely used to reveal dynamic evolutions of spin state and chemical shift of Fe active site in Fe–N–C catalyst during ORR [107, 108]. Notably, to avoid excessive attenuation of γ-rays, the width for the electrode chamber of in-situ cell should be limited to a smaller size. For example, the compartment was restricted in a plastic cavity by Li et al., with a width of less than 5 mm (Fig. 4g) [109]. Unfortunately, only a limited number of nuclei have the Mössbauer effect, and the experimental conditions are harsh.

In summary, in-situ characterizations can ensure the real-time detection of catalytic process as much as possible, thereby deepening our understanding of the ORR mechanism. Also, these are very helpful to clarify relationship between the structure of the catalyst and ORR activity, further guiding the reasonable design of catalyst. Notably, each in-situ characterization technique exhibits its unique characteristic, as summarized in Table 1, and shares complementary advantages from each other. An appropriate in-situ technique should be selected based on its characteristics that match the requirements of the target catalyst. In the subsequent section, we will outline the various applications of in-situ techniques for monitoring dynamic evolution of the ORR process from multiplex perspectives.

4 In-Situ Monitoring the Dynamic Evolution of Catalysts during ORR

In this section, we summarize the applications of multiple in-situ characterization techniques for direct monitoring of catalyst dynamic evolution during ORR (Fig. 5, left part). This in-situ revelation can help to elucidate the active site, simultaneously help to guide the synthesis of the catalyst. That is, it can help to realize the reasonable design of catalyst from the source, which in turn promotes the efficient ORR. Notably, the potential values are all relative to the reversible hydrogen electrode (RHE) in the following each section, which will not be repeated later.

4.1 Monitoring of the Phase Transitions

Dynamic detection of crystal phase changes for the catalyst during ORR helps to ascertain active site with efficient catalytic effect in the reaction. It is also useful to identify the optimal structure of catalyst with higher activity, and provides a basis for further adjusting the structure design. Notably, the ADT is the abbreviation of accelerated durability testing in this part and will not be repeated. The correlated works are as follows.

The phase transitions also often occur in the catalyst surface coverings, more notably in the case of rare earth Pt alloy catalysts (i.e., PtxY and PtxGd). Escudero-Escribano et al. [110] investigated the phase transitions of active Pt overlayer on the Gd/Pt (111) single crystalline electrode during ORR in PEMFC by using in-situ synchrotron grazing incidence XRD (GI-XRD). For Gd/Pt (111) R0 (i.e., the alloy phase on the crystal with no rotate), in-situ GI-XRD revealed that the compressive strain in Pt overlayer displayed slight relaxation as the cycling gradually entering the relevant region of ORR (i.e., 0.6–1.0 V). After 3000 cycles, the structure of Pt overlayer tended to be stable, and persisted in about 0.8% compressive strain (8.3 Å) after 8000 cycles. This confirmed that the active phase was a compressed Pt overlayer formed on the Gd/Pt (111) electrode, with a relatively stable structure during ORR long cycling. For Gd/Pt (111) R30 (with 30° rotation), no structure varies in Pt overlayer were observed in-situ GI-XRD as the cycling from open-circuit potential to 1.0 V. After the cycling potential increasing above 1.2 V, the strain in Pt overlayer relaxed strongly, and up to 1.3 V, its crystalline part thickness increased. This could be attributed to the oxidation of Pt and the leaching of Gd, leading to Pt overlayer becoming rough and loosely thickened. This indicated that the phase transitions of the Pt overlayer were related to the cyclic potential, and the higher potential leaded to its degradation. Thus, this work indicates that Pt overlayer with a compressed strain can act as the main activity site for ORR, also determine the excellent ORR stability, further providing a basis for the construction of catalytic layers on the catalyst surface.

Interestingly, catalysts can not only catalyze phase transitions in ORR, but also participate in phase transitions in reaction. As an example, Gao et al. [111] discovered the phase transitions of LiCoO2 (LCO) catalyst by in-situ XRD/Raman and revealed its self-reinforcing effect as a catalyst for Li–O2 battery (LOB). In detail, highly ordered LCO as the ORR catalyst exhibited splendid activity during discharge (i.e., ORR), with no phase changes, also accompanied by the accumulation of Li2O2 products. During charging, the LCO underwent phase change by the extraction of Li+ and transformed to LixCoO2 phase (i.e., Li0.6CoO2 (L0.6CO)). As shown in Fig. 6a, Eg bending (O–Co–O) and A1g stretching (Co–O) vibrations of LCO gradually became weaker and changed to A1g stretching (Co–O) vibration of Li1−xCoO2. Then the formation of L0.6CO induced Li/oxygen vacancy and Co4+, which damaged the symmetry of CoO6 octahedron, further boosting the oxygen evolution reaction (OER). Synchronously, the L0.6CO reverted to the original phase (LCO), which continued to promote the next ORR. In summary, in-situ analysts of this work revealed that LiCoO2 could achieve self-adjustment among LCO and L0.6CO, thus performing higher ORR and OER performance. Thus, the phase changes of LCO catalyst induced by the intercalation or extraction of Li+ do exist in ORR, which can modulate the torsional deformation and recovery of the CoO6 octahedron, (i.e., active sites), further adjusting the catalysis activity to the best. Also, in-depth research on the self-reinforcing catalysts can bring up new ideas for the design of LOB catalysts.

a In-situ Raman spectrum of LCO in Li–O2 battery during the first recharge [111]; Reused with approval; Copyright 2020 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. b In-situ Cu K-edge XANES spectrum (with Cu foil and CuO standard as reference), c in-situ Pt L3-edge XANES (with Pt foil as reference) of Int-PtCuN/KB during ORR in PEMFC [113]. Reused with approval; Copyright 2021 American Chemical Society. d The changes of ln(I1/I2) for Co K-edge (at 7722.5 eV) and Mn K-edge (at 6553.0 eV) in Co1.5Mn1.5O4/C under the cyclic potential sweep, with the inset of the CV test [84]; Reused with approval; Copyright 2019 American Chemical Society. In-situ XANES spectra of e Zn K-edge, f Cu K-edge, and g in-situ EXAFS spectrum of Cu K-edge, for the Cu/Zn-NC under several constant potentials [115]; Reused with approval; Copyright 2021 WILEY–VCH GmbH. In-situ XANES spectra of Mn-SAS/CN at potentials h from 0.9 to 0.3 V (also at open circuit and ex situ), i from 0.3 to 0.9 V [116]; Reused with approval; Copyright 2020 WILEY-VCH GmbH

Notably, the monitoring of phase transitions is an essential descriptor for guiding the reasonable design of ordering degrees for the bimetallic nano-catalyst (BN). For example, Gong et al. [112] used in-situ XAS to probe the varies in local and electronic structure of the fcc-phased PtFe ordered alloy (O–PtFe) catalyst during 10 k cycles ADT for ORR in PEMFC. The Pt L3-edge XANES exhibited that the O-PtFe was mainly in the metal state (Pt0), and with a slight negative shift, proving that Pt was reduced to form an alloy with Fe. This was consistent with the fact in EXAFS that its Pt–Pt bond length (2.708 Å) was shorter than that of pure Pt (2.775 Å). The smaller coordination number (CN) of Fe (ca. 2.6) than Pt (ca. 7) further offered evidence that the O-PtFe surface was Pt-rich. These testified that the ultrathin Pt shell phase formed on the surface of O-PtFe, as the main activity site, for the splendid ORR activity (0.68 A mg−1Pt) than that of the disordered PtFe alloy (D-PtFe). In-situ Pt L3-edge XANES and EXAFS revealed that the ordered structure of O-PtFe with the ultrathin Pt shell was largely preserved, both in peak position and intensity. While the Fe K-edge XANES spectra showed a slight decrease in the surface Fe leaching rate, proving that the ultrathin Pt shell layer ensured the chemical stability of O–PtFe to Fe leaching. Thus, the monitoring of phase transition indicates that the O–PtFe can exhibit excellent ORR activity and stability than D-PtFe due to the formed ultrathin and stable Pt shell phase. Namely, improving the ordering degree is a good method to modify BN, for higher ORR performance.

The role of this descriptor (i.e., the monitoring of phase transition) for the BN is further applied in the N-doped bimetallic nano-catalyst (N-doped BN). Zhao et al. [113] exploited the local and electronic structure changes of the N-doped rhombohedral ordered PtCu catalyst loaded on Ketjenblack (KB) (i.e., Int-PtCuN/KB) during ORR in PEMFC by in-situ XAS. In detail, some weak oxidations of Cu in Int-PtCuN/KB were proved by in-situ Cu K-edge XANES (Fig. 6b) with white line exhibiting slight positive shift as potential increasing, but the varies were enough less than Int-PtCu/KB (without N) and D-PtCuN/KB (disordered). The results testified that the more ordered structure and N dopants in PtCu BN were favorable for increasing the intrinsic corrosion resistance, and promoting the formation of Cu–N bond to further improve the corrosion resistance, respectively. In-situ Pt L3-edge XANES of Int-PtCuN/KB (Fig. 6c) reflected a little enhanced main peak (white line) along with increased potential, which was induced by some Pt oxide, in line with EXAFS analysis (i.e., with a weak Pt oxide phase peak at 1.6 Å). Compared to Int-PtCu/KB and D-PtCuN/KB, the little varies of Pt oxide phase transitions revealed that the Pt oxidation on its surfaces was prohibited, contrarily, more effective Pt active sites were exposed. This confirmed that the Pt monolayer shell was formed on Int-PtCu/KB surface, also effectively alleviating the corrosion of Cu. Further, the distance of Pt–Pt bond was 2.693 Å in Int-PtCuN/KB, which is shorter than 2.701 Å (IntPtCu/KB). This meant the presence of N dopants introduced compressive strain on the Pt surface in BN, as the main activity site, to modulate the intermediates adsorption, thus improving ORR activity. This work offers worthy insights to the design of the BN that is to ensure the synergistical effect of ordered structure with N-doping on ORR.

These conclusions declare that the correlation between the catalyst nanostructure and its ORR performance can be revealed by in-situ monitoring of and the phase transitions of the surface coverings and catalyst itself. In detail, the catalyst with little Pt overlayer [110], or higher orderliness [112, 113], dopant [113], etc. are beneficial to the ORR performance. Also, the direct changes in electronic structure, and lattice parameter, are more intuitive to show that the defect and strain are favorable for catalyst activity enhancement.

4.2 Monitoring of the Valence Variations

For some special catalyst with complex valence, mainly transition metal-based catalyst, the determination of its effective active center depends on the in-situ dynamic monitoring of the chemical valence states during ORR. Thus, the more studies focus on it, and some relative works will be summarized in this part.

For the typical single transition metal-based catalyst, it often undergoes valence changes during its catalytic process. Such as Qin et al. [114] explored the effect of the valence of Co in a polypyrrole (PPy)-revised carbon-loaded metal Co catalyst (Co-PPy-BP) towards ORR in DBFC by in-situ XAFS and XRD. Firstly, in-situ XANES of Co-PPy-BP evolved into standard Co (OH)2, and then into CoOOH, which implied that the valence of Co underwent Co0 → Co2+ → Co3+ during ORR. Namely, both Co0/Co2+ and Co2+/Co3+ existed in Co-PPy-BP, and as the active centers for the higher ORR activity. Moreover, in-situ XRD exhibited that two Co crystal peaks (15.7° and 20.1°) were observed at first and gradually disappeared during ORR; finally, two new peaks emerged at 15.2° and 21.61° attributed to CoOOH under a maximum current. This further confirmed that Co (OH)2 was largely an intermediate phase, and the lower valence of Co could ensure a richer redox transition, thus as the main active center for favoring the ORR activity. Namely, this work provides a guidance that single transition metal-based catalyst with the lower initial valence is pivotal to ensure the rich redox transition during ORR.

For the dual transition metal-based catalyst, especially for transition metal oxide, in-situ monitoring of valence changes is also key for identifying the effective active center, further revealing the synergistic catalytic effect of dual transition metals on ORR. For example, Yang et al. [84] utilized in-situ XANES to pursue the valence varies of Co and Mn in the synthesized Co1.5Mn1.5O4/C bimetallic catalyst during ORR in PEMFC, and explored the synergistic interaction of Co and Mn. In-situ XANES of Mn K-edge indicated that the Mn valence existed in a lower value during ORR at more negative potentials. Also, linear combination fitting (LCF) of the Mn valence revealed that its average valence decreased from 3.15 to 2.91 as the potential decreased (1.15–0.4 V). Further the fact that Mn (III, IV) largely converted to Mn (II, III), indicating that various Mn could do duty for active centers for ORR. In-situ XANES and LCF of Co K-edge illustrated that the average valence of Co also decreased (2.75 → 2.57), namely, large numbers of Co (III) converted to Co (II), as the potential decreased. This change was synchronized with Mn, and thus Co and Mn were considered as co-active centers for ORR. Under the non-steady state, the valence states of Mn and Co in Co1.5Mn1.5O4/C changed periodically along with cyclic potential and synchronized with each other. As shown in Fig. 6d, the relative X-ray intensities (ln(I1/I2), I1 as incident, I2 as transmitted) of Co and Mn changed from minimum (higher valence Co, Mn, at 1.25 V) to maximum (lower valence Co, Mn, at 0.42 V), as potentials declining from 1.4 V (upper limit) to 0.3 V (lower limit). The actual boundary potential of 0.42/1.25 V corresponded to the oxidation/reduction currents for the cyclic voltammetry (CV) (Fig. 6d, inset). That was, Mn (III, IV) → Mn (II, III) and Co (III) → Co (II) occurred at the same time, which further indicated that Co and Mn had a synergistic catalytic mechanism for ORR. Notably, for a single transition metal-based catalyst (e.g., the above work), lower initial valence for the transition metal can ensure excellent ORR activity. For dual transition metal oxide, two high-valence transition metals can act as the bridges for e transfer when O2 is reduced to form H2O, which is more favorable to ensure the synergistic effect on efficient ORR.

There is also a synergistic effect of two transition metals in the transition metal-based SAC, and this effect can also be reflected by the valence change of the contained metals. Recently, Tong et al. [115] monitored the changes in the electronic structures of Zn and Cu in Cu/Zn bimetallic single atoms complexed with nitrogen-doped carbon (Cu/Zn-NC) catalyst during ORR in PEMFC through in-situ XAS. In-situ Zn K-edge XANES spectrum (Fig. 6e) showed that the main peak occurred a slight positive shift, owing to the electron transform (Zn to Cu) and intermediates adsorption. Notably, the higher valence than + 2 of Zn in Cu/Zn-NC was another evidence of its electron transfer to Cu. However, neither the length nor ligand number of Zn–N bond occurred changes, indicating that Zn was not the active center. In contrast, in-situ Cu K-edge XANES spectrum (Fig. 6f) showed that the main peak underwent a distinct positive shift as potential decreasing, then its energy decreased obviously at a potential of 0.4–0.3 V, and finally, it returned to initial state only with a little positive shift. In-situ Cu K-edge EXAFS spectrum (Fig. 6g) further revealed that the Cu–N bond (~ 1.5 Å) gradually weakened as potential decreasing, while a new Cu-Cu bond (~ 2.2 Å) generated at a potential of 0.4–0.3 V and disappeared after the reaction. This indicated that Cu single atoms (derived from Cu-N4) aggregated into Cu clusters driven by an external electric field, and finally returned to initial state (i.e., isolated and dispersed). In conclusion, in-situ results showed that Cu-N4 was the main active center for efficient ORR, and during the catalytic process, it changed from atomic dispersion (with Cu–N bond) to cluster (with Cu–Cu bond), with the cooperation of Zn–N4, and finally returned to a single atom state (with Cu–Cu bond disappearing). Notably, the cooperation effect of Zn–N4 referred to the electron transform of Zn to Cu regulating the Cu2+/Zn2+ ratio in Cu/Zn-NC, which further drove the high activity. Thus, this work opens a new insight into understanding of synergy mechanism, which can guide the rational design of dual transition metal-based SAC. That is, the synthesized catalyst contains the special transition metal pairs, which can ensure electron transfer from one transition metal to another.

For the transition metal single-atom site (SAS) catalyst, it is also necessary to monitor their valence changes during ORR and thus clarify the active center composition. For example, Han et al. [116] utilized in-situ XAS to pursue the valence changes of Mn-based SAS catalyst with Mn–N4 structure (Mn-SAS/CN) during ORR in Zn–Air battery. In in-situ XANES spectrum of Fig. 6h, both the absorption edge and the main peak occurred positive shift under open-circuit, compared to ex-situ condition. Also, both shifted to lower energy as potential decreased, corresponding to an increase in ORR overpotential. Notably, both could shift back, as potential reversed (Fig. 6i). These indicated that more Mn sites were reduced to lower valence states as overpotential increased, correspondingly, their surface OH adsorption decreased while OH− desorption accelerated. Namely, low-valent MnL+–N4 was identified as the active center, which easily promoted electron transfer to *OH and facilitated *OH desorption (corresponding the transformation of OHads–MnH+–N4/MnL+–N4), further exhibiting efficient ORR. Thus, this work provides evidence that the ORR performance of SAS catalyst is correlated with the valence state of the activity center, and it offers an idea for the design of a highly active SAS catalyst through a coordination modulation strategy.

This part reveals that in-situ XAS technique is crucial to the disclosure the valence information in the activity site of the catalyst during ORR. In detail, this technique can effectively monitor the dynamic changes of the electronic structure and partial atomic coordination for the transition metal-based catalyst active center in the working environment. The obtained information can reveal that different catalysts have different optimal valence states contributing to higher catalytic activity. As summarized above, the low valence state makes more contribution in M–N–C like catalysts [114, 116], while high valence is better for applying in transition metal oxides [84]. Moreover, the synergistic effect often existed in dual transition metal systems, with the electron transfer between them [115]. Thus, the design of the catalyst structure should be tailored to these properties.

4.3 Monitoring of the Morphological Evolutions

Not only does the phase and valence state affect the catalytic activity of the catalyst, but also the morphology is an important factor. Also, structural and valence variations are frequently accompanied by morphological changes, thus the development of various in-situ imaging techniques is crucial. There are several types of researches for investigating microstructural transitions of the catalyst at different scales and high temporal resolution during the synthesis process, as reviewed below.

Many in-situ morphological monitoring efforts have mustered on the application of synthesis process for the ORR catalysts. This is crucial to reveal the synthesis mechanism, which can help to offer guidance for optimizing the synthesis strategy, and further synthesizing high activity catalysts. As an example, Ma et al. [117] utilized in-situ TEM to view the oriented attachment process of Pt nanoparticles (NPs) on the (100) lattice planes in the synthesis of one-dimensional (1D) Pt-based nanowires (NWs) catalysts by hydrogen assisted solid-phase method. In detail (Fig. 7a), the intermediate products were collected for in-situ monitor at different reaction time during the synthetic process. At 20 s, three Pt NPs were in a different orientation, with Pt (111) fringes as reference. At 80 s, the upper Pt NP rotated to turn its (100) lattice plane toward the middle Pt NP, then approached at 160 s, attached at 240 s, and coalesced at 320 s. The same process was done for the bottom Pt NPs. Notably, the growth kinetics, including rotation, approach, attachment, and coalescence, of the NPs during the synthesis were related to the Pt surface modifications. Concretely (Fig. 7b), H2 preferentially adsorbed on the (100) lattice plane of Pt NP (upper and bottom), forming activated Pt–H complexes. Then special Pt–H ensured a lower diffusion potential barrier, accelerating the local diffusion rate of the modified (100) lattice plane. Finally, the attachment and coalescence tended to occur in this specific plane. In conclusion, the synthesis mechanism of 1D Pt-based NWs was that the oriented attachment of solid-state Pt NP with aid of the metal surface diffusion, which was induced by the adsorption modification of hydrogen molecules. Thus, this work further provides the scalable insight for the preparation of 1D Pt-based NWs with excellent activity for catalytic ORR in PEMFC.

a In-situ TEM images at 20 s, 80 s, 160 s, 240 s, 320 s, and b the corresponding oriented attachment schematics, for the formation of Pt-NW [117]; Reused with approval; Copyright 2017 WILEY-VCH Verbg GmbH&Co. KGaA, Weinheim. c In-situ TEM images of single Pt–Cu NF with 3D visualization at 300 °C, 500 °C, 600 °C, 700 °C, with Pt (red), Cu (green), and orange derived from color overlay [96]; Reused with approval; Copyright 2021 Elsevier Ltd. d The schematics (upper) of Pt (red) and Ni (green) distributing, and the corresponding in-situ HRTEM images (bottom) of PtNi1.5 NP at 50 °C, 200 °C, 300 °C, 400 °C, 500 °C [118]. Reused with approval; Copyright 2018 American Chemical Society. (Color figure online)

For the Pt-based intermetallic catalyst, in-situ visualization of the morphological changes during the ordered process is essential to reveal the mechanism of its ordering, further helping to reconstruct its structure. Gong et al. [96] used three-dimensional (3D) tomography assisted in-situ STEM to monitor the morphological changes of the Pt-Cu nano-frame (NF) catalyst during the ordering process under in-situ heating conditions. Concretely (Fig. 7c), under 300 °C, the single Pt–Cu NF had no deformation, owing to no interatomic migration and rearrangement; but a slight Pt segregation formed on the surface induced by the high surface energy of nanomaterials. Heating to 500 °C, the NF occurred a slight shrinkage, especially, since its concave part shrank/clustered rapidly, gradually forming an octopod structure. Next to 600 °C, the NF exhibited the most evident octopod structure, with uniformly dispersed Pt and Cu on its surface, also, with a formed Pt skin. Final to 700 °C, the NF entirely evolved into solid nanoparticle (NP), also with a formed Pt–Cu@Pt (i.e., Pt-Cu wrapped by Pt) core–shell structure. Notably, at 660 °C, the transient-state NP suddenly changed into a molten state, at which the atoms migrated rapidly and rearranged into the ordered phase. This ordered process improved the resistance of NF to Cu leaching, also boosting the stability of the Pt-Cu NF catalyst for ORR in PEMFC. In conclusion, high temperature treatment could reduce atomic migration barrier, accelerate atomic diffusion, further promoting the ordering of NF. However, higher temperatures could induce overmuch atomic migration, further leading to the collapse and aggregation of NF structure. Thus, a reasonable temperature selection is conducive to the preparation of a highly active Pt-based intermetallic NF catalyst. Also, it is necessary to exploit the more available method to control the rate of atomic diffusion thereby realizing the controllable synthesis of the ordering Pt-based intermetallic catalyst.

For the Pt-M NP catalyst, considering that its catalytic activity is ascertained by the chemical structure and composition of the outmost atomic layer, it is crucial to in-situ monitor the dynamic morphological changes of them during the synthesis process for devising more efficient ORR catalyst. Gocyla et al. [118] adopted in-situ TEM to observe the morphological evolutions of outmost atomic layer for the octahedral PtNi1.5 nanoparticle (PtNi1.5 NP) catalyst in in-situ heating synthesis process. Specifically, at initial 50 °C, the PtNi1.5 NP had the concave octahedral structure, with rich Pt edges and rich Ni facets (Fig. 7d). Heating to 200 °C, the octahedra were partially filled with the Pt {111} [100] facets, as Pt diffused from edges to the {111} facets. Next, a truncated octahedron gradually formed, with flat Pt {111} facets and additional Pt {100} facets, as Pt continued to diffuse. Up to 300 °C, a cuboctahedron with thin Pt shell gradually formed, during which the diffusion process of Pt continuously proceeds, promoting the further truncation, and increasing the Pt {100} surface area. Then, the cuboctahedra with a gradual loss of flat Pt {111} facets, exhibited in rounding in partial facets at 400 °C, and eventually forming the spherical NP at 500 °C. In summary, the morphological evolution sequence of the PtNi1.5 NP followed concave octahedra, octahedra partially with Pt {111} facets (further to truncated octahedron), cuboctahedra, cuboctahedra with partial rounding facets, and spherical NP. Notably, the flat Pt {111} facet could act as the main component for a thin Pt shell, further boosting the catalytic activity. Thus, this work proves that optimizing the ratio of Pt {111} and Pt {100} facets, and adjusting an appropriate thickness of Pt shell can provide synthetic possibilities for the synthesis of highly stable and active Pt-M NP catalyst for ORR in PEMFCs.

Similar research is the work of Dai et al. [119], they also used in-situ TEM to check into the surface composition of the disordered Pt3Co NP, and the morphological dynamic changes of its surface during in-situ heating process. Specifically, the Co segregation occurred on Pt {111} rather than on Pt {100} surface. Then, a few Co oxidation to form CoO layer occurred on the outermost Pt {111} surface, blocking the exposure of the underlying Pt in O2, and preventing its diffusion and reconstruction. In contrast, the Pt {100} surface possessed oxidation resistance, as a pivotal role to preserve the ORR activity of the disordered Pt3Co NPs catalyst. In brief, the Pt {100} surface was the main active composition for the disordered Pt3Co NP. Compare to the above work of PtNi1.5 NP, it could be concluded that the main active composition for the Pt-M NP catalyst was relative with the element (Ni, or Co, etc.) alloyed with Pt. Thus, the real time monitoring of dynamic evolutions of surface composition and morphology can provide precise information about the active site during in-situ heating synthesis process, further providing a new light (with a rich Pt surface) on the design of the Pt–M NP catalyst.

For the non-platinum metal-based catalyst, such as ZIF-derived catalyst with high activity in fuel cell, the actual pyrolysis process is also usually simulated under in-situ TEM heating test to reveal the relationship of morphological changes and catalytic activity. Wang et al. [120] applied ZIF-67 as a matrix to investigate the effect of temperature on the microstructure evolutions of derived catalyst at every stage of pyrolysis by in-situ TEM. In detail, ZIF-67 remained initial structure at 300 °C, while its ordered structure collapsed and turned to disorder at 442 °C. Then, its unit cell (i.e., CoN4 tetrahedron) gradually decomposed at 500 °C, resulting in N loss and Co precipitation. Next, a new Co@N–C structure gradually formed at 550 °C, along with a hierarchical and 3D connected porous structure in carbon matrix, owing to the precipitated Co nanoparticles (NP) grew and catalyzed carbon graphitization. Finally, the matrix eventually occurred carbonization at 800 °C, due to the further growth to large one of Co NP, and further loss of N. Notably, the ZIF-derived Co@N–C catalyst exhibited the excellent ORR activity in PEMFC. The results proved that it was necessary to ensure the suitable N content, graphitization degree, and hierarchical and 3D connected porous structure, for efficient ZIF-derived catalyst. Moreover, the synergistic effect among Co single atom and Co encapsulated by less layer graphene, was also the key factor for its enhanced ORR activity. Thus, this work provides strong evidence that the ZIF-derived catalyst, prepared at relatively low temperatures, has higher performance, also with the energy-saving advantage.

In summary, in-situ TEM can directly observe the morphology varies of the catalyst itself during the synthesis process in real time, further providing some crucial information for guiding the design of more efficient ORR catalyst. Specifically, the special way, such as the hydrogen assisted solid-phase method, is essential for the synthesis of the special morphology catalyst. The rational pyrolysis temperature is proven to be important for PtM NP catalyst, which can adjust the crystal face ratio or enrich the Pt skin for high activity NP; also, it is essential for regulating N content, pore structure and graphitization for M–N–C catalyst.

4.4 Monitoring of Electronic Structure

Many works have confirmed that the maximum exposure of active sites and the increase of intrinsic activity in each active site are key tactics to elevate the ORR activity of catalyst. Although massive progress has been acquired in the design of catalysts through the two strategies, the changes in the electronic structure of the active site remain controversial. In this part, the progress of in-situ techniques applied to identify the related changes is reviewed.

Typically, the activity of the bimetallic catalyst often exceeds that of any single metal, but the real activity site of the catalyst for its enhanced performance always remains unclear. Considering that the real activity site is always related to the electron transfer between the two metals, it is essential to monitor the electron structure changes of the catalyst. Such as, to ascertain the active site of the CuAg catalyst, Gibbons et al. [121] monitored its electron transfer behavior via in-situ XAS during ORR. In-situ Ag L3 edge XANES of CuAg (Fig. 8a) (compare with Ag) showed that the main peak (~ 3353 eV), owing to Ag 2p3/2 electron being excited to its first non-occupied level, was unaffected by Cu, with almost no electronic changes, at 0.75 V. Other peaks (~ 3369, 3377, and 3397 eV) varied in intensity and position with or without Cu, which were caused by Cu scattering rather than Ag electronic state, thus further indirectly proving that the electronic state of Ag in CuAg with no changes. The relevant in-situ EXAFS of CuAg (Fig. 8b) showed that the first-shell peak (~ 2.9 Å) had no tensile strain, and with no peak of Ag–Cu interaction, only with a decrease of the extended peak (~ 5 Å) due to Cu-induced lattice deformation, at 0.75 V. This meant that there was no obvious change in Ag geometric state of CuAg. Conversely, in-situ Cu K-edge XANES of CuAg (Fig. 8c) (compare with Cu) showed that the edge peak shifted by a few eV, at 0.75 V. The XANES with Cu standard as reference (Fig. 8d) showed that the Cu peak in CuAg was like a mixing of metal Cu0 and Cu+ oxide, while the Cu peak in pure Cu was like standard Cu2+ oxide, thus Cu in CuAg existed in a more reduced state. Thus, the electronic state and local bonding of Ag in CuAg remained unchanged, while the electronic state of Cu changed dramatically, thus the high activity of CuAg catalyst was due to electronic rather than geometric effect. That is, it was more useful to create a Cu-center active site than to add an Ag-center active site for high activity CuAg bimetallic catalyst for ORR. This gives an idea of the identity of the real active site of the bimetallic catalyst.

a The derivatives of in-situ Ag L3-edge XANES, and b the relevant EXAFS, for CuAg and Ag during ORR at 0.75 V; c In-situ Cu K-edge XANES spectra, and d the derivatives of XANES with Cu standard as reference, for CuAg and Cu also at 0.75 V [121]; Reused with approval; Copyright 2022 Wiley-VCH GmbH. e Titration curves from left to right for CoFe-PPy, Fe-PPy, and Co-PPy in FcMeOH (0.5 mM), KOH (0.01 M) and NaClO4 (0.1 M), respectively; f The curves of titrated site density against substrate potential, with inset for the schematic of in-situ SECM cell [122]; Reused with approval; Copyright 2019 American Chemical Society. g In-situ 57Fe Mössbauer spectra of Fe–NC–S with 57Fe during ORR under various potentials; the OCV was open-circuit voltage, the AFT was after ORR [109]; Reused with approval; Copyright 2020 Elsevier

When it comes to specifying the number of active sites in bimetallic catalyst, in-situ SECM often plays an important role and is to be used for quantification. For example, Li et al. [122] adopted in-situ surface-interrogation SECM (Fig. 8f, inset) to quantify active sites of the CoFe-PPy catalyst (Co and Fe highly distributed on polypyrrole (PPy) derived C), revealing the reason for its high activity. In-situ SI-SECM titration curves (Fig. 8e) of catalysts all showed obvious growth in feedback currents as substrate potentials in more negative, indicating that active intermediates gradually formed and increased. Then, the plots of site densities against applied potentials (Fig. 8f) revealed that, for CoFe-PPy, active intermediates formed at the lowest overpotential, also with the highest site density (40.68) in it than Co-PPy (28.2) and Fe-PPy (21.57) at 0.8 V. Moreover, the catalytic kinetics quantified by in-situ SI-SECM exhibited that, for CoFe-PPy, the binding rate to O2 was much faster than Co-PPy and Fe-PPy. Consequently, the bimetallic CoFe-PPy was testified to have the largest number of active sites, and each site with higher intrinsic activity, so it has the excellent activity. Thus, this work gives high-resolution proof to quantify not only the active site density, but also the kinetic rate, for the bimetallic catalyst.

For Men+/Me(n+1)+ series of catalyst, the catalytic OOR process is often accompanied by electron transfer behavior, as mentioned in Sect. 4.2. However, there are exception, and it is more important for such exception to identify their active sites. For example, in the work of Wang et al. [123], the polypyrrole-based carbon-loaded cobalt oxyhydroxide (CoOOH-PPy-BP) catalyst did not undergo any electron transfer in the catalytic ORR of DBFC. Considering that the active site was not the conventional Con+/Co(n+1)+, they used in-situ XRD and XAS to confirm the real effective active site. The results showed that no phase transitions or valence varies were recognized during the reaction. Contrarily, oxygen vacancy was markedly detected by the Fourier transformed k2-weighted EXAFS function analysis. Additionally, they proposed a new ORR mechanism, namely, the electron hole arising from oxygen vacancy captured electron from the anode further forming [Co3+ + e], then, the adsorbed O2 (on the vacancy) captured electron from [Co3+ + e] and occurred in reduce. In conclusion, this work testifies that the oxygen vacancy can sometimes substitute Con+/Co(n+1)+ as the active site for the corresponding transition metal-based catalyst. Also, it lights a thought for designing catalysts with higher ORR activity by artificially introducing oxygen vacancy.

Notably, for the M–N–C catalyst, especially for the Fe–N–C catalyst, the exploration of its active site has been recognized as the meaningful work. With the development of technique, the special in-situ 57Fe Mössbauer spectroscopy become the most powerful monitoring method. Li et al. [124] adopted this technique to identify the real active site for Fe–N–C catalyst, and studied the contribution of different active sites to its catalytic activity and stability. In-situ 57Fe Mössbauer spectra revealed that it contained high-spin (HS) S1 site (identified as HS FeN4C12) and low- or medium- spin (L or MS) S2 site (identified as L or MS FeN4C10) for contributing to the catalytic activity in Fe–N–C catalyst. In the subsequent reaction, S1 was degraded by conversion to iron oxide (III/II), namely a direct/indirect process of demetallation, in which the indirect route was initiated by the local oxidation of carbon surface or the protonation of basic N in S1. While S2 remained unchanged in structure and quantity, and still with obvious contribution for high ORR activity after 50 h of operation. That was due to S2 with more locally graphitized structure, less reactive oxygen species (ROS) product, or due to an active carbon top surface. In conclusion, there existed two active sites for Fe–N–C catalyst, both of which contributed to ORR activity in the early stage, while only S2 with contribution in late stage. Thus, this work indicated that the special in-situ 57Fe Mössbauer technique did can act as the impactful way for ascertaining and tracing the active site for Fe–N–C catalyst during ORR in fuel cell. And it offers support that the S2 site, i.e., L or MS FeN4C10, is more significant for the development of Fe–N–C catalyst, which should be emphatically considered in the synthesis process.

Similar, in-situ 57Fe Mössbauer spectroscopy was also used by Li et al. [109] to identify the effective active sites and monitor their evolutions of Fe–NC (with four N-coordinated), FeNC–S0.2 (with 0.2 mL 1H-1,2,3-triazole), Fe–NC–S0.4 (0.4 mL), and Fe–NC–S (1.5 mL, with six N-coordinated) catalysts for the ORR of PEMFC. Taking Fe–NC–S with the highest ORR activity as an example, in-situ 57Fe Mössbauer spectra (Fig. 8g) showed that three Fe electronic states all existed in each spectrum at different potential. In detail, the low-spin (LS) Fe2+(D1), medium-spin (MS) Fe2+ (D2), and high-spin (HS) Fe2+ (D3) were attributed in sequence to FeIIN4C12, FeIIN4C10, and N-FeIIN4C10. At 0.9 V, the D3 exhibited in decrease with the relative increase of D1, reflecting that O2 adsorbed on the D3, also forming a O2−–FeIIN5 intermediate. At this stage, the Fe–N bond gradually shorten with the approaching of Fe in N–FeIIN4C10 to N4-plane, also with the electronic state conversion of Fe2+ from HS to LS. Conversely, at 0.7 V and 0.5 V, the D3 exhibited in gradual increase with the relative decrease of D1, reflecting that O2 adsorbed on the D1, also forming a O2−–FeIIN4 intermediate. Here, the Fe–N bond gradually lengthen with the moving of Fe in FeN4C12 away from N4-plane, synchronously, the LS Fe2+ returned to HS. These results showed that there existed three activity sites and occurred dynamic cycle during ORR, also accompanied by the formation of some correlated intermediates. Thus, this work confirms the importance of in-situ Mössbauer technique, and points out that the dynamic cycle of the sites is crucial for the reaction process. That is, the design of the catalyst can focus on the integration of different sites.

Moreover, for the modified Fe–N–C catalyst, such as with heteroatom doping, has shown the excellent ORR activity, also with different effective active site than conventional Fe–N–C catalyst. Thus, exploring the active site of the modified Fe–N–C catalyst is a necessary work, also can help to optimize idea for catalyst modification. Recently, Chen et al. [125] used in-situ 57Fe Mössbauer spectroscopy to ascertain the effective active site of sulfur(S)–doped Fe1–NC catalyst for ORR in fuel cell. The results showed that the spin-polarized configuration of Fe1-NC occurred conversion with the adding of S in its second coordination sphere. And the active site of the S–doped Fe1–NC catalyst was identified as the low spin (LS) single-Fe3+-atom in C–FeN4–S part. Moreover, this LS Fe site could facilitate the desorption of OH*, further boosting the ORR activity. In conclusion, S-doping could improve the catalytic activity of the catalyst by modulating the spin state of the central Fe atom in Fe1–NC. This provides a new insight to clarify the effect of heteroatom on improving the ORR activity for the Fe–N–C catalyst. Also, this work can act as a reliable basic for the design of heteroatom doped Fe–N–C catalyst.

In this part, advanced in-situ techniques have been shown to straightly observe the active site structure of the catalyst, particularly, even the spin state of Fe site in Fe–N–C like catalyst can be clarified by in-situ Mössbauer spectroscopy. In addition, the electronic structure and number of the active site in catalyst are proved to be related to its intrinsic property, thus, the detection of electron transfer can also promulgate the structure of the active site in reverse. More importantly, some active sites, such as vacancies, atom-dispersed active sites with certain spin states, heteroatom doping sites, have been identified with more contribute to the high ORR activity of the prepared catalyst.

To sum up, the application of in-situ X-ray technique (XRD, XAS), electron technique (TEM, HRTEM), scanning probe technique (SECM), and Mössbauer spectroscopy can probe the phase, valence, morphology, and electronic structure varies of the catalysts in real time (Fig. 1). These are helpful to determine the active site of the catalyst and provide direction for the structural design of the catalyst. Specifically, the specific dynamic changes of the structure, morphology and electronic states of the catalyst corresponding to different in-situ techniques are depicted in Table 2. In addition, in-situ TEM monitoring of the morphology evolution is helpful to determine the reasonable synthesis conditions and to better synthesize the catalyst from the source. It has a spatial resolution of up to 0.1 nm, unlike the other two in-situ scanning probe technique techniques (SECM mentioned above; AFM to be mentioned soon) with morphological characterization capabilities. The uniqueness of each technique is also reaffirmed as above works.

5 Applying In-situ Characterization Techniques to Revealed the ORR Mechanism

As is well known, the ORR of the fuel cell is an extremely complex process, which can be two-step pathways (with two electrons transform) or one-step pathways (with four electrons transform) (Fig. 2a). The latter is the preferred pathway, and there exist two possible mechanisms, namely, association or dissociation. Any reaction pathway involves various evolutions of reaction intermediates. Thus, it is essential to monitor and capture the evolution state information on intermediates in a hurry, further facilitating the clarification of the ORR mechanism. In addition, the ORR of the metal–O2/air battery is also a complex reaction process with abundant catalytic products (Fig. 2b). Timely capture of the interrelated evolution state information on products is also crucial to reveal its mechanism. Meanwhile, in-situ monitoring process of reaction intermediates and products is also conducive to indirectly reveal the factors affecting the activity of the catalyst, and guide its structure design (Fig. 5, right part). In this section, many relevant in-situ characterization procedures are reviewed below. Notably, the markings in the following works, including ad/ads and *, all mean the surface-adsorbed, that will not be repeated later.

5.1 Monitoring of the Evolutions for Reaction Intermediates

The evolution state information on reaction intermediates can directly help to exposit the specific ORR pathway. Also, the information can indirectly help to identify active site and reveal the reason for enhanced activity, which in turn can help in the design of the catalyst with two or four-electron pathway facilitation for applying in fuel cell. Moreover, considering that the intermediates have characteristics of short survival, low coverage, and vulnerability to other co-adsorbed species, it is essential to use in-situ techniques with high sensibility and quick respond capacity to monitor their dynamic evolutions. The following provides an overview of the representative efforts for in-situ monitoring the reaction intermediates.

Typically, monitoring the dynamic evolutions of intermediates on Pt/C catalyst during catalytic ORR is useful to ascertain their state and lay the basis for clarifying the complex pathways of the reaction. For example, to explore the surface chemistry changes on the surface of Pt/C catalyst, Nayak et al. [93] used in-situ ATR-IR to monitor the ORR process in fuel cell. In-situ IR spectrum showed that three oxygen-containing intermediates adsorbed on the Pt outside surface during ORR in 0.1 M HClO4 (O2-saturated) (Fig. 9a). Compared to bare carbon carriers, the three peaks were proved to belong to the O–O stretching model (1212 ± 3 cm−1) in superoxide (OOHad), the OOH bending model (1386 ± 4 cm−1) in hydroperoxide (HOOHad), and the O–O stretching model (1468 cm−1) in weakly adsorbed oxygen (O2, ad), respectively. Further, compared to in-situ IR spectrum of Pt/C during ORR in 0.1 M HClO4 (Ar-saturated) (Fig. 9a), it confirmed that the 1114 and 1030 cm−1 peaks belonged to the asymmetric ClO4 stretching model of the electrolyte and the symmetric ClO3 stretching model of the adsorbed ClO4, ads, respectively. Next, the 1435 and 1330 cm−1 peaks, observed on both Pt/C and bare carbon, were classified as carbon surface functional groups. More, the occasional small peak was discovered at 1260 cm−1 due to the Si–O–Si band of the silicone glue for sealing the optic. More importantly, the integral intensity of the intermediates fitted peak varied with the potential, which confirmed that OOHad and HOOHad could increase synchronously and dominated in the ORR process under below 0.8 V. This meant that an additional association pathway did exist in the ORR process, and with the greatest contribution at lower potentials. In general, this work gives IR information for the identification of intermediates on Pt/C catalyst surface, also can act as evidence that the association pathway and dissociation pathway often parallel in the ORR.

a In-situ IR spectra of Pt/C in 0.1 M HClO4 in O2 and in Ar [93]; Reused with approval; Copyright 2018 WILEY-VCH Verbg GmbH&Co. KGaA, Weinheim. b In-situ ATR-IR spectrum of CoNOC in 0.1 M HClO4 with O2 saturated; c The comparative spectrum of CoNOC and CoNC in the band near 1220 cm−1 [128]. Reused with approval; Copyright 2021 American Chemical Society. d In-situ SHINERS spectrum of Pt (311) in 0.1 M HClO4 with O2 saturated; e The isotopic control spectra on the Pt (311) surface, at 0.7 V, in aqueous with 18O2 (red curve), in deuterated 0.1 M HClO4 (blue curve); f In-situ SHINERS spectra of different Pt (hkl) surfaces at 0.8 V [129]; Reused with approval; Copyright 2020 American Chemical Society. (Color figure online)