Abstract

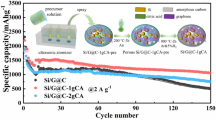

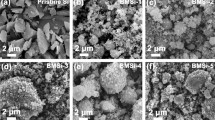

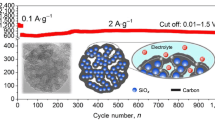

The co-utilization of silicon (Si) and graphite (G) has been considered as the preferred strategy to achieve high energy density anode materials, but the effective synergistic integration of Si and graphite is still a challenge and it is necessary to find a scheme to accommodate the large-scale production of Si/graphite anodes. In this work, silicon cutting waste from the photovoltaic industry was used as raw material, mixed with graphite, pitch, and polyvinylpyrrolidone, and subjected to high-energy ball milling. The mixture was then heated in an Ar atmosphere for the carbon coating, and the resulting Si/graphite/carbon (Si/G/C) composite was etched to remove the thicker SiOx layer formed on the Si surface to allow the pores between the Si and the carbon matrix to obtain Si@voids/G@C. Benefiting from the integrated structural design and the significantly enhanced electronic conductivity, the Si/G@voids@C composite exhibited the first discharge-specific capacity of 2530 mAh·g−1 with an initial coulombic efficiency (ICE) of 86.7%, and the remaining capacity exceeded 1000 mAh·g−1 after 550 cycles at 1.5 A·g−1. Notably, full lithium-ion batteries with a Si/G@voids@C anode and LiFePO4 cathode delivered a stable capacity of 140 mAh·g−1. The synthesis method is facile and cost-effective, providing an integration strategy for Si and G with a potential scheme for large-scale commercial applications.

Graphical abstract

摘要

硅和石墨的共同利用被认为是实现高能量密度阳极材料的首选策略, 但硅和石墨的有效协同整合仍是一个挑战, 同时也有必要找到一个适应硅/石墨阳极大规模生产的方案。在这项工作中, 以光伏行业中产生的硅切割废料为原料, 与石墨、沥青和聚乙烯吡咯烷酮混合后进行高能球磨, 然后将得到的混合物在氩气气氛中加热进行碳涂层, 并对得到的硅/石墨/碳复合材料进行蚀刻, 以去除在硅表面形成的较厚的SiOx层, 使硅和碳基体之间出现孔隙得到Si@voids/G@C复合材料。受益于集成的结构设计和明显增强的电子传导性, Si/G@voids@C复合材料表现出2530 mAh·g−1的首次放电比容量, 初始库仑效率为86.7%, 在1.5 A·g−1的电流密度下充放电循环550次后, 剩余容量超过1000 mAh·g−1, 值得注意的是, 采用Si/G@voids@C阳极和LiFePO4阴极组装成的锂离子全电池提供了140 mAh·g−1的稳定容量。该合成方法简单易行, 具有成本效益, 为硅和石墨提供了一种集成策略, 并且具有大规模商业应用的潜力。

Similar content being viewed by others

References

Wang JT, Lu SG, Wang Y, Huang B, Yang JY, Tan A. Improvement of cycle behavior of Si/Sn anode composite supported by stable Si–O–C skeleton. Rare Met. 2022;41(5):1647. https://doi.org/10.1007/s12598-014-0377-1.

Xi FS, Zhang Z, Hu Y. Li SY. Wang LZ. PSi@SiOx/nano-Ag composite derived from silicon cutting waste as high-performance anode material for Li-ion batteries. J Hazard Mater. 2021;414(7):125480. https://doi.org/10.1016/j.jhazmat.2021.125480

Lin L, Ma YT, Xie QS, Wang LS, Zhang QF, Peng DL. Copper-nanoparticle-induced porous Si/Cu composite films as an anode for lithium-ion batteries. ACS Nano. 2017;11(7):6893. https://doi.org/10.1021/acsnano.7b02030.

Wang B, Li XL, Zhang XF, Luo B, Jin MH, Liang MH, Shadi AD, Picraux ST, Zhi LJ. Adaptable silicon-carbon nano cables sandwiched between reduced graphene oxide sheets as lithium ion battery anodes. ACS Nano. 2013;7(2):1437. https://doi.org/10.1021/nn3052023.

Wang B, Li XL, Luo B, Jia YY, Zhi LJ. One-dimensional/two-dimensional hybridization for self-supported binder-free silicon-based lithium ion battery anodes. Nanoscale. 2013;5(4):1470. https://doi.org/10.1039/C3NR33288H.

Yoo JK, Kim J, Jung YS, Kang KJ. Scalable fabrication of silicon nanotubes and their application to energy storage. Adv Mater. 2012;24(40):5452. https://doi.org/10.1002/adma.201201601.

Yan ZL, Liu JY, Lin YF, Deng Z, He XQ, Ren JG, He P, Pang CL, Xiao CM, Yang DR, Yu HJ, Du N. Metal-organic frameworks-derived CoMOF-D@Si@C core-shell structure for high-performance lithium-ion battery anode. Electrochim Acta. 2021;390:138814. https://doi.org/10.1016/j.electacta.2021.138814

Jeong JH, Kim KH, Jung DW, Kim K, Lee SM, Oh ESJJOPS. High-performance characteristics of silicon inverse opal synthesized by the simple magnesium reduction as anodes for lithium-ion batteries. J Power Sources. 2015;300:182. https://doi.org/10.1016/j.jpowsour.2015.09.064

Jin Y, Zhang S, Zhu B, Tan YL, Hu X, Zhu J. Simultaneous purification and perforation of low-grade Si sources for lithium-ion battery anode. ACS Appl Mater Interfaces. 2015;15(11):44452. https://doi.org/10.1021/acs.nanolett.5b03932.

Luo W, Wang YX, Chou SL, Xu YF, Li W, Kong B, Dou SX, Liu HK, Yang JP. Critical thickness of phenolic resin-based carbon interfacial layer for improving long cycling stability of silicon nanoparticle anodes. Nano Energy. 2016;27:255. https://doi.org/10.1016/j.nanoen.2016.07.006.

Hu YC, Yu B, Qi XP, Shi BM, Fang S., Yu ZL. Yang JY. The preparation of graphite/silicon@carbon composites for lithium-ion batteries through molten salts electrolysis. J Mater Sci. 2020;55(23):10155. https://doi.org/10.1007/s10853-020-04756-7

Choi SH, Nam G, Chae S, Kim D, Kim N, Kim WS, Ma J, Sung J, Han SM, Ko MJaEM. Robust pitch on silicon nanolayer–embedded graphite for suppressing undesirable volume expansion. Adv Energy Mater. 2019;9(4):1803121. https://doi.org/10.1002/aenm.201803121

Zhu SS, Zhou JB, Guan Y, Cai WL, Zhao YY, Zhu YC, Zhu LQ, Zhu YC, QIan YT. Hierarchical graphene-scaffolded silicon/graphite composites as high performance anodes for lithium-ion batteries. Small. 2018;14(47):1802457. https://doi.org/10.1002/smll.201802457

Yang SC, Wan XH, Wei KX, Ma WH, Wang Z. Silicon recycling and iron, nickel removal from diamond wire saw silicon powder waste: synergistic chlorination with CaO smelting treatment. Minerals Eng. 2021;169(23):106966. https://doi.org/10.1016/j.mineng.2021.106966

Yang SC, Ma WH, Wei KX, Xie KQ, Wang Z. Thermodynamic analysis and experimental verification for silicon recovery from the diamond wire saw silicon powder by vacuum carbothermal reduction. Separation Purification Technol. 2019;228:115754. https://doi.org/10.1016/j.seppur.2019.115754

Wang L, Xi FS, Zhang Z, Li SY, Chen XH, Wan XH, Ma WH, Deng R, Chong C. Recycling of photovoltaic silicon waste for high-performance porous silicon/silver/carbon/graphite anode. Waste Manage. 2021;132:56. https://doi.org/10.1016/j.wasman.2021.07.014.

Xi FS, Zhang Z, Wan XH, Li SY, Ma W, Chen XH, Chen R, Luo B. Wang LZ. High-performance porous silicon/nanosilver anodes from industrial low-grade silicon for lithium-ion batteries. ACS Appl Mater Interfaces. 2020;12(43):49080. https://doi.org/10.1021/acsami.0c14157

Yang HL, Liu IT, Liu CE, Hsu HP, Lan C. Recycling and reuse of kerf-loss silicon from diamond wire sawing for photovoltaic industry. Waste Manage. 2019;84:204. https://doi.org/10.1016/j.wasman.2018.11.045.

Xi FS, Li SY, Ma WH, Chen Z, Wei KX, Wu JJ. A review of hydrometallurgy techniques for the removal of impurities from metallurgical-grade silicon. Hydrometallurgy. 2021;201:105553. https://doi.org/10.1016/j.hydromet.2021.105553

Xu J, Jeon IY, Seo JM, Dou S, Dai L, Baek JBJaM. Edge-selectively halogenated graphene nanoplatelets (XGnPs, X = Cl, Br, or I) prepared by ball-milling and used as anode materials for lithium-ion batteries. Adv Mater. 2014;26(43):7317. https://doi.org/10.1002/adma.201402987

Gan CH, Zhang CK, Wen WD, Liu YK, Chen J, L XT. Materials CJaA enhancing delithiation reversibility of Li15Si4 alloy of silicon nanoparticles-carbon/graphite anode materials for stable-cycling lithium ion batteries by restricting the silicon particle size. ACS Appl Mater Interfaces. 2019;11(39):35809. https://doi.org/10.1021/acsami.9b13750

Liu NT, Liu J, Jia DZ, Huang YD, Luo J, Mamat X, Yu Y, Dong Y, Hu GG. Multi-core yolk-shell like mesoporous double carbon-coated silicon nanoparticles as anode materials for lithium-ion batteries. Energy Storage Mater. 2019;18:165. https://doi.org/10.1016/j.ensm.2018.09.019.

Tong ZQ, Kang TX, Wu Y, Zhang F, Tang YB, Lee CS. Novel metastable Bi: Co and Bi: Fe alloys nanodots@carbon as anodes for high rate K-ion batteries. Nano Res. 2022;15:7220. https://doi.org/10.1007/s12274-022-4398-z.

Ruan DS, Wu L, Wang FM, Du K, Zhang ZH, Zou K, Wu XF, Hu GR. A low-cost silicon-graphite anode made from recycled graphite of spent lithium-ion batteries. J Electroanal Chem. 2021;884:115073. https://doi.org/10.1016/j.jelechem.2021.115073

Wang HR, Huang YS, Huang CF, Wang XS, Wang K, Chen HB, Liu SB, Wu YP, Xu Yu, Li WS. Reclaiming graphite from spent lithium ion batteries ecologically and economically. Electrochim Acta. 2019;313:423. https://doi.org/10.1016/j.electacta.2019.05.050

Zhang JK, Li SY, Xi FS, Wan XH, Ding Z, Chen ZJ, Ma WH, Deng R. Si@SiOx/Ag composite anodes with high initial coulombic efficiency derive from recyclable silicon cutting waste. Chem Eng J. 2022;447:137563. https://doi.org/10.1016/j.cej.2022.137563

Kang T, Tan J, Li X, Liang J, Lee CS. Armoring SiOx with a conformal LiF layer to boost lithium storage. J Mater Chem A. 2021;9:7807. https://doi.org/10.1039/D0TA12508C.

Bahruji H, Bowker M, Davies PRJIJOHE. Photoactivated reaction of water with silicon nanoparticles. Int J Hydrogen Energy. 2009;34(20):8504. https://doi.org/10.1016/j.ijhydene.2009.08.039

Xi FS, Zhang Z, Hu Y, Li SY, Ma WH, Chen XH, Wan XH, Chong C, Luo B, Wang LZ. PSi@SiOx/Nano-Ag composite derived from silicon cutting waste as high-performance anode material for Li-ion batteries. J Hazard Mater. 2021;414:125480. https://doi.org/10.1016/j.jhazmat.2021.125480

Peng J, Li W, Wu Z, Li H, Zeng P, Chen G, Chang B, Zhang X, Wang X. Si/C composite embedded nano-Si in 3D porous carbon matrix and enwound by conductive CNTs as anode of lithium-ion batteries. Sustain Mater Technol. 2022;32:100410. https://doi.org/10.1016/j.susmat.2022.e00410

Zhang H, Zong P, Chen M, Jin H, Bai Y, Li SW, Ma F, Xu H, Lian K. In situ synthesis of multilayer carbon matrix decorated with copper particles: enhancing the performance of Si as anode for Li-ion batteries. ACS Nano. 2019;13(3):3054. https://doi.org/10.1021/acsnano.8b08088.

Li B, Yang SB, Li SM, Wang B, Liu JH. From commercial sponge toward 3D graphene–silicon networks for superior lithium storage. Adv Energy Mater. 2015;5(15):107. https://doi.org/10.1002/aenm.201500289.

Gong X, Wang B, He Y, He W, Zhu Q. TiN-SiO2 double layer composite coating with enhanced oxidation resistance and reusability in anti-coking applications. Fuel. 2022;324:124808. https://doi.org/10.1016/j.fuel.2022.124808

Lin X, Dong Y, Liu X, Chen X, Li A, Song H. In-situ pre-lithiated onion-like SiOC/C anode materials based on metallasilsesquioxanes for Li-ion batteries. Chem Eng J. 2022;428:132125. https://doi.org/10.1016/j.cej.2021.132125

Liu Zh, Guan DD, Qiang Y, Xu L, Zhu T, Zhao DY Mai LQ. Monodisperse and homogeneous SiOx/C microspheres: a promising high-capacity and durable anode material for lithium-ion batteries. Energy Storage Mater. 2018;13:112. https://doi.org/10.1016/j.ensm.2018.01.004

Kong KJ, Xu GJ, Lan Y, Jin CX, Yue ZH, Li XM, Huang HB, Yuan JR, Zhou L. Effect of SiOx-coating crystallinity on electrochemical performance of Si@SiOx anode materials in lithium-ion batteries. Appl Surface Sci. 2020;515:146026. https://doi.org/10.1016/j.apsusc.2020.146026

Yao NN, Zhang Y, Rao XH, Yang Z, Zheng K, Świerczek K, Zhao HL. A review on the critical challenges and progress of SiOx-based anodes for lithium-ion batteries. Int J Miner Metall Mater. 2022;29:876. https://doi.org/10.1007/s12613-022-2422-7.

Yang SH, Kim JK, Jung DS, Kang YC. Facile fabrication of Si-embedded amorphous carbon@graphitic carbon composite microspheres via spray drying as high-performance lithium-ion battery anodes. Appl Surface Sci. 2022;606:154799. https://doi.org/10.1016/j.apsusc.2022.154799

Zhao XW, Zhang JW, Zhang JW, Gong CH, Gu XF, Ma ZH, Zhou JF, Yu LG, Zhang ZJ. Construction of spongy antimony-doped tin oxide/graphene nanocomposites using commercially available products and its excellent electrochemical performance. J Power Sources. 2015;294:223. https://doi.org/10.1016/j.jpowsour.2015.06.054.

Su X, Wu QL, Li JH, Xiao XC, Amber L, Lu WQ. Silicon-based nanomaterials for lithium-ion batteries: a review. Adv Energy Mater. 2013;4(1):1300882. https://doi.org/10.1002/aenm.201300882.

Kim JY, Jung S, Kang SH, Park J, Lee MJ. Jin D, Shin DO, Lee YG, Lee YM. Graphite–silicon diffusion-dependent electrode with short effective diffusion length for high-performance all-solid-state batteries. Adv Energy Mater. 2022;12:21031. https://doi.org/10.1002/aenm.202103108

Li HH, Wang JW, Wu XL, Sun HZ, Yang FM, Wang K, Zhang LL, Fan CY, Zhang JP. A novel approach to prepare Si/C nanocomposites with yolk–shell structures for lithium ion batteries. RSC Adv. 2014;4(68):36218. https://doi.org/10.1039/c4ra07043g.

He W, Liang YJ Tian HJ Zhang SL, Meng Z, Han WQ. A facile in situ synthesis of nanocrystal-FeSi-embedded Si/SiOx anode for long-cycle-life lithium ion batteries. Energy Storage Mater. 2017;8:119. https://doi.org/10.1016/j.ensm.2017.05.003

Feng XY, Wu HH, Gao B, Swiętosławski M, He X, Zhang QB. Lithiophilic N-doped carbon bowls induced Li deposition in layered graphene film for advanced lithium metal batteries. Nano Res. 2022;15(1):352. https://doi.org/10.1007/s12274-021-3482-0.

Fang S, Tong ZK, Nie P, Liu G, Zhang XG. Raspberry-like nanostructured silicon composite anode for high-performance lithium-ion batteries. ACS Appl Mater Interfaces. 2017;9(22):18766. https://doi.org/10.1021/acsami.7b03157.

Hu HY, Xiao Y, Ling W, Wu YB, Wang P, Tan SJ, Xu YS, Guo YJ, Chen WP, Tang RR, Zeng XX, Yin YX, Wu XW. A stable biomass-derived hard carbon anode for high-performance sodium-ion full battery. Energ Technol. 2021;9:2000730. https://doi.org/10.1002/ente.202000730.

Xiang B, An WL, Fu JJ, Mei SX, Guo SG, Zhang XM, Gao B. Graphene-encapsulated blackberry-like porous silicon nanospheres prepared by modest magnesiothermic reduction for high-performance lithium-ion battery anode. Rare Met. 2021;40(2):383. https://doi.org/10.1007/s12598-020-01528-9.

Lee SJ, Kim HJ, Hwang TH, Choi S, Park SH, Deniz E, Jung DS, Choi JW. Delicate structural control of Si–SiOx–C composite via high-speed spray pyrolysis for Li-ion battery anodes. Nano Lett. 2017;17(3):1870. https://doi.org/10.1002/adma.201904589.

Xu X, Chen B, Hu J, Sun B, Liang X, Li N, Yang SA, Zhang H, Huang W, Yu T. Heterostructured TiO2 spheres with tunable interiors and shells toward improved packing density and pseudocapacitive sodium storage. Adv Mater. 2019;31(46):1904589. https://doi.org/10.1002/adma.201904589.

Zhou XM, Liu Y, Ren Y, Mu TS, Yin XC, Du CY, Huo H, Cheng XQ, Zuo PJ, Yin GP. Engineering molecular polymerization for template-free SiOx/C hollow spheres as ultrastable anodes in lithium-ion batteries. Adv Func Mater. 2021;31(21):2101145. https://doi.org/10.1002/adfm.202101145.

Tian Y, An YL, Feng JK. Flexible and freestanding silicon/MXene composite papers for high-performance lithium-ion batteries. ACS Appl Mater Interfaces. 2019;11(10):10004. https://doi.org/10.1021/acsami.8b21893.

Wang J, Polleux J, Lim JK, Dunn B. Pseudocapacitive contributions to electrochemical energy storage in TiO2 (anatase) nanoparticles. J Phys Chem. 2007;111:14925. https://doi.org/10.1021/jp074464w.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. 51974143, 52274408, 5220041313, 52164050 and 51904134); Major Science and Technology Projects in Yunnan Province (Nos. 202102AB080016, 202103AA080004 and 202202AB080010); Yunnan Fundamental Research Projects (No. 202201AW070014); Yunnan Ten Thousand Talents Project (No. YNWR-QNBJ-2018-111), Yunnan High-level Talent Project (No. YNQR-GCC-2019-010) and the Program for Innovative Research Team in University of Ministry of Education of China (No. IRT_17R48).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, L., Jiang, Y., Li, SY. et al. Scalable synthesis of N-doped Si/G@voids@C with porous structures for high-performance anode of lithium-ion batteries. Rare Met. 42, 4091–4102 (2023). https://doi.org/10.1007/s12598-023-02472-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-023-02472-0