Abstract

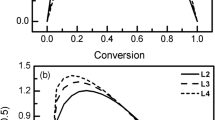

Influence of chemical pretreatment in thermal behavior of Nephelium lappaceum L. peels was studied through thermogravimetric analysis, SEM, X-ray diffraction, FTIR and EDXRF. Results of derivate thermogravimetry were deconvoluted with Fraser–Suzuki function, demonstrating that the distribution of pseudo-components is affected by chemical pretreatment, where sulfuric acid pretreated sample (Ras) has not indicated the cellulose pseudo-component peak and the phosphoric acid pretreated sample (Rap) also did not demonstrate the lignin peak, indicating itself to be an effective tool in the prediction of pseudo-components of lignocellulosic samples. This result corroborates with FTIR spectra and XRD. The sample Rna (sodium hydroxide treated) has indicated modifications in cellulose crystalline structure, conversion of cellulose I/II, revealed by XRD. An EDXRF analysis demonstrated that the chemical pretreatment also influenced the distribution of minerals, constituted essentially of Na, Mg, Fe, K, Al and Cl. This change is evidenced when carrying out statistical analysis of the samples, and principal component analysis applied in EDXRF data revealed statistical differences between samples, separating in distinct quadrants.

Similar content being viewed by others

References

Hussain A, Arif SM, Aslam M. Emerging renewable and sustainable energy technologies: state of the art. Renew Sustain Energy Rev. 2017;71:12–28. https://doi.org/10.1016/j.rser.2016.12.033.

Demirbas A. Waste management, waste resource facilities and waste conversion processes. Energy Convers Manag. 2011;52:1280–7. https://doi.org/10.1016/j.enconman.2010.09.025.

Nozela WC, Braz CEM, Almeida S, Ribeiro CA, Crespi MS. Mixture of biomass to energy reuse. J Therm Anal Calorim. 2018;131:765–9. https://doi.org/10.1007/s10973-017-6374-5.

Niu S, Chen M, Li Y, Lu T. Combustion characteristics of municipal sewage sludge with different initial moisture contents. J Therm Anal Calorim. 2017;129:1189–99. https://doi.org/10.1007/s10973-017-6262-z.

de Alfaia RGSM, Costa AM, Campos JC. Municipal solid waste in Brazil: a review. Waste Manag Res. 2017;35:1195–209. https://doi.org/10.1177/0734242X17735375.

Abrelpe. Panorama of solid waste in Brazil 2015. Panor dos Resíduos Sólidos no Bras 2015 2015;92.

do Sacramento CK, Andrade RA. Cultivo do rambotä. Rev Bras Frutic. 2014;36:79–85.

de Andrade RA, de Lemos EGM, Martins ABG, de Paula RC, Pitta Junior JL. Morphologic and chemical characterization of rambutan fruits. Rev Bras Frutic. 2008;30:958–63.

de Andrade RA. Rambuteira. Rev Bras Frutic Soc Bras Frutic. 2012;34:I–II.

Brasil. Lei no 12.305, de 02 de agosto de 2010: Institui a Política Nacional de Resíduos Sólidos; altera a Lei no 9.605, de 12 de fevereiro de 1998; e dá outras providências. Brasília: Brasil; 2010.

Gadonneix P, Sambo A, Nadeau MJ, Statham BA, Kim YD, Birnbaum L, et al. World Energy Resources 2013 Survey. London: World Energy Council London; 2013.

Ferreira ETDF, Balestieri JAP. Comparative analysis of waste-to-energy alternatives for a low-capacity power plant in Brazil. Waste Manag Res. 2018;36(3):247–58.

Leme MMV, Rocha MH, Lora EES, Venturini OJ, Lopes BM, Ferreira CH. Techno-economic analysis and environmental impact assessment of energy recovery from Municipal Solid Waste (MSW) in Brazil. Resour Conserv Recycl. 2014;87:8–20.

Shah MA, Khan MNS, Kumar V. Biomass residue characterization for their potential application as biofuels. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7560-9.

Alves JLF, da Silva JCG, Costa RL, Dos Santos Junior SF, da Silva Filho VF, Moreira RDFPM, Jose HJ. Investigation of the bioenergy potential of microalgae Scenedesmus acuminatus by physicochemical characterization and kinetic analysis of pyrolysis. J Therm Anal Calorim. 2019;135:3269–80. https://doi.org/10.1007/s10973-018-7506-2.

Mosier N, Wyman C, Dale B, Elander R, Lee YY, Holtzapple M, et al. Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol. 2005;96:673–86.

Singh R, Krishna BB, Kumar J, Bhaskar T. Opportunities for utilization of non-conventional energy sources for biomass pretreatment. Bioresour Technol. 2016;199:398–407. https://doi.org/10.1016/j.biortech.2015.08.117.

Pellera F, Gidarakos E. Chemical pretreatment of lignocellulosic agroindustrial waste for methane production. Waste Manag. 2018;71:689–703. https://doi.org/10.1016/j.wasman.2017.04.038.

Wang C, Li L. Thermal conversion of tobacco stem into gaseous products. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08010-4.

Pellera F, Santori S, Pomi R, Polettini A, Gidarakos E. Effect of alkaline pretreatment on anaerobic digestion of olive mill solid waste. Waste Manag. 2016;58:160–8.

De Rosa IM, Kenny JM, Maniruzzaman M, Moniruzzaman M, Monti M, Puglia D, et al. Effect of chemical treatments on the mechanical and thermal behaviour of okra (Abelmoschus esculentus) fibres. Compos Sci Technol. 2011;71:246–54. https://doi.org/10.1016/j.compscitech.2010.11.023.

Liu Q, Wang S, Zheng Y, Luo Z, Cen K. Mechanism study of wood lignin pyrolysis by using TG-FTIR analysis. J Anal Appl Pyrolysis. 2008;82:170–7.

Sebestyén Z, May Z, Réczey K, Jakab E. The effect of alkaline pretreatment on the thermal decomposition of hemp. J Therm Anal Calorim. 2011;105:1061–9.

Mothé CG, De Miranda IC. Study of kinetic parameters of thermal decomposition of bagasse and sugarcane straw using Friedman and Ozawa–Flynn–Wall isoconversional methods. J Therm Anal Calorim. 2013;113:497–505.

Brandová D, Svoboda R, Zmrhalová ZO, Chovanec J, Bulánek R, Romanová J. Crystallization kinetics of glassy materials: the ultimate kinetic complexity? J Therm Anal Calorim. 2018;134:825–34.

Nishikawa K, Ueta Y, Hara D, Yamada S, Koga N. Kinetic characterization of multistep thermal oxidation of carbon/carbon composite in flowing air. J Therm Anal Calorim. 2017;128:891–906. https://doi.org/10.1007/s10973-016-5993-6.

Chen T, Wu W, Wu J, Cai J, Wu J. Determination of the pseudocomponents and kinetic analysis of selected combustible solid wastes pyrolysis based on Weibull model. J Therm Anal Calorim. 2016;126:1899–909.

Perejón A, Sánchez-Jiménez PE, Criado JM, Pérez-Maqueda LA. Kinetic analysis of complex solid-state reactions. A new deconvolution procedure. J Phys Chem B. 2011;115:1780–91. https://doi.org/10.1021/jp110895z.

Chen C, Miao W, Zhou C, Wu H. Thermogravimetric pyrolysis kinetics of bamboo waste via Asymmetric Double Sigmoidal (Asym2sig) function deconvolution. Bioresour Technol. 2017;225:48–57. https://doi.org/10.1016/j.biortech.2016.11.013.

Fraser RDB, Suzuki E. Resolution of overlapping absorption bands by least squares procedures. Anal Chem. 1966;38:1770–3.

Poletto M, Zattera AJ, Forte MMC, Santana RMC. Thermal decomposition of wood: influence of wood components and cellulose crystallite size. Bioresour Technol. 2012;109:148–53. https://doi.org/10.1016/j.biortech.2011.11.122.

Luo S, Xiao B, Hu Z, Liu S. Effect of particle size on pyrolysis of single-component municipal solid waste in fixed bed reactor. Int J Hydrog Energy. 2010;35:93–7. https://doi.org/10.1016/j.ijhydene.2009.10.048.

Segal L, Creely JJ, Martin AE, Conrad CM. An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J. 1959;29:786–94.

Tomaz RMAG, Bittencourt E, Sabino NP, Kondo JI. Determinação dos índices de cristalinidade de fibras celulósicas. Bragantia. 1994;53:121–6.

Wojdyr M. Fityk: a general-purpose peak fitting program. J Appl Crystallogr. 2010;43:1126–8.

Santana AJ, dos Santos WNL, Silva LOB, das Virgens CF. Removal of mercury(II) ions in aqueous solution using the peel biomass of Pachira aquatica Aubl: kinetics and adsorption equilibrium studies. Environ Monit Assess Environ Monit Assess. 2016;188:293. https://doi.org/10.1007/s10661-016-5266-7.

Roman M, Winter WT. Effect of sulphate groups from sulphuric acid hydrolysis on the thermal degradation behaviour of bacterial cellulose. Biomacromolecules. 2004;5:1671–7.

Ahmad MS, Mehmood MA, Al Ayed OS, Ye G, Luo H, Ibrahim M, et al. Kinetic analyses and pyrolytic behavior of Para grass (Urochloa mutica) for its bioenergy potential. Bioresour Technol. 2017;224:708–13. https://doi.org/10.1016/j.biortech.2016.10.090.

Kroon-Batenburg LMJ, Kroon J. The crystal and molecular structures of cellulose I and II. Glycoconj J. 1997;14:677–90.

Carvalho MS, Virgens CF. Effect of alkaline treatment on the fruit peel of Pachira aquatica Aubl.: physico-chemical evaluation and characterization. Microchem J. 2018;143:410–5. https://doi.org/10.1016/j.microc.2018.08.021.

Motaung TE, Anandjiwala RD. Effect of alkali and acid treatment on thermal degradation kinetics of sugar cane bagasse. Ind Crops Prod. 2015;74:472–7. https://doi.org/10.1016/j.indcrop.2015.05.062.

Njoku VO, Foo KY, Asif M, Hameed BH. Preparation of activated carbons from rambutan (Nephelium lappaceum) peel by microwave-induced KOH activation for acid yellow 17 dye adsorption. Chem Eng J. 2014;250:198–204. https://doi.org/10.1016/j.cej.2014.03.115.

Alrozi R, Zamanhuri NA, Osman MS. Removal of methylene blue from aqueous solution by adsorption onto NaOH-treated rambutan peel. In: 2012 IEEE business, engineering & industrial applications colloquium. IEEE; 2012. p. 92–7.

Sun Y, Cheng J. Hydrolysis of lignocellulosic materials for ethanol production: a review. Bioresour Technol. 2002;83:1–11.

Lengowski EC, de Muniz GIB, Nisgoski S, Magalhães WLE. Cellulose acquirement evaluation methods with different degrees of crystallinity. Sci For Sci. 2013;41:185–94.

Langan P, Nishiyama Y, Chanzy H. A revised structure and hydrogen-bonding system in cellulose II from a neutron fiber diffraction analysis. J Am Chem Soc. 1999;121:9940–6.

Oliveira EIS, Santos JB, Paula A, Gonçalves B, José NM. Characterization of the Rambutan Peel Fiber (Nephelium lappaceum) as a lignocellulosic material for technological applications. Chem Eng Trans. 2016;50:391–6.

dos Santos WNL, Cavalcante DD, da Silva EGP, das Virgens CF, de Dias FS. Biosorption of Pb(II) and Cd(II) ions by Agave sisalana (sisal fiber). Microchem J. 2011;97:269–73.

Falcone JS, Bass JL, Angelella M, Schenk ER, Brensinger KA. The determination of sodium silicate composition using ATR FT-IR. Ind Eng Chem Res. 2010;49:6287–90. https://doi.org/10.1021/ie1002747.

Hori R, Wada M. The thermal expansion of cellulose II and IIIII crystals. Cellulose. 2006;13:281–90. https://doi.org/10.1007/s10570-005-9038-8.

Jin H, Zha C, Gu L. Direct dissolution of cellulose in NaOH/thiourea/urea aqueous solution. Carbohydr Res. 2007;342:851–8.

Alonso DM, Wettstein SG, Dumesic JA. Bimetallic catalysts for upgrading of biomass to fuels and chemicals. Chem Soc Rev. 2012;41:8075.

Rezende CA, De Lima M, Maziero P, Deazevedo E, Garcia W, Polikarpov I. Chemical and morphological characterization of sugarcane bagasse submitted to a delignification process for enhanced enzymatic digestibility. Biotechnol Biofuels. 2011;4:54.

Kobayashi T, Sakai Y, Iizuka K. Hydrolysis of cellulose in a small amount of concentrated sulfuric acid. J Agric Chem Soc Jpn. 1960;24:443–9.

Qin W, Wu L, Zheng Z, Dong C, Yang Y. Lignin hydrolysis and phosphorylation mechanism during phosphoric acid-acetone pretreatment: a DFT study. Molecules. 2014;19:21335–49.

Ioelovich M. Study of cellulose interaction with concentrated solutions of sulfuric acid. ISRN Chem Eng. 2012;2012:1–7.

Acknowledgements

The authors thank the Brazilian development agencies Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES) and Fundação de Amparo à Pesquisa do Estado da Bahia (FAPESB) for granting scholarships; Programa de Pós-Graduação em Química Aplicada (PGQA) for the infrastructure; and laboratories LAMUME/IDEIA (UFBA) for the analyses carried out.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Castro, J.D.S., das Virgens, C.F. Thermal decomposition of Nephelium lappaceum L. peel. J Therm Anal Calorim 138, 3541–3549 (2019). https://doi.org/10.1007/s10973-019-08289-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08289-3