Abstract

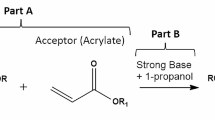

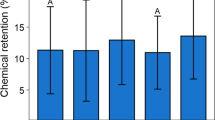

Filling wood cells with polymeric materials offers great opportunities to improve wood strength. Some applications, such as flooring, may require densification on one side of the material only. Yellow birch (Betula alleghaniensis Britt.), sugar maple (Acer saccharum Marsh.) and red oak (Quercus rubra L.) were surface densified through lateral chemical impregnation of monomers under vacuum followed by in situ electron beam polymerization. Lateral impregnation led to low mean chemical retention of 4% for sugar maple, 11% for red oak and 12% for yellow birch. X-ray densitometry and microtomography revealed an asymmetric density profile comparable to mechanically surface densified wood due to polymer-filled vessels. Scanning electron microscopy images showed presence of polymer-filled fibers beneath the surface. Brinell hardness of all species increased significantly compared to untreated wood. Low chemical retention significantly improved hardness due to localized polymer beneath the surface. Density profile characteristics were extracted from densitometry curves and correlated to hardness. Deep monomer penetration was more favorable to hardness than high surface density peak.

Similar content being viewed by others

References

Kutnar A, Sernek M (2007) Wood densification. Zbornik gozdarstva in lesarstva 82:53–62

Ibach R Rowell R (Ed.) (2012) Lumen Modifications. In: Handbook of Wood Chemistry and Wood Composites, 2 edition CRC Press, (pp. 599–626)

Sears C (1900) Process of preparing wood matrices. U.S. Patent No. 646,547

Cai X, Blanchet P (2011) Effect of vacuum time, formulation, and nanoparticles on properties of surface-densified wood products. Wood Fiber Sci 43:326–335

Cai X, Riedl B, Zhang SY, Wan H (2007) Formation and properties of nanocomposites made up from solid aspen wood, melamine-urea-formaldehyde, and clay. Holzforschung. https://doi.org/10.1515/HF.2007.027

Ellis WD, O’Dell JL (1999) Wood–polymer composites made with acrylic monomers, isocyanate, and maleic anhydride. J Appl Polym Sci 73:2493–2505. https://doi.org/10.1002/(SICI)1097-4628(19990919)73:12%3c2493::AID-APP18%3e3.0.CO;2-C

Fang C-H, Mariotti N, Cloutier A et al (2012) Densification of wood veneers by compression combined with heat and steam. Eur J Wood Wood Prod 70:155–163. https://doi.org/10.1007/s00107-011-0524-4

Kutnar A, Kamke FA, Sernek M (2008) The mechanical properties of densified VTC wood relevant for structural composites. Holz Roh Werkst 66:439–446. https://doi.org/10.1007/s00107-008-0259-z

Navi P, Girardet F (2000) Effects of thermo-hydro-mechanical treatment on the structure and properties of wood. Holzforschung 54:287–293. https://doi.org/10.1515/HF.2000.048

Uhmeier A, Morooka T, Norimoto M (1998) Influence of thermal softening and degradation on the radial compression behavior of wet spruce. Holzforschung 52:77–81. https://doi.org/10.1515/hfsg.1998.52.1.77

Gabrielli CP, Kamke FA (2010) Phenol–formaldehyde impregnation of densified wood for improved dimensional stability. Wood Sci Technol 44:95–104. https://doi.org/10.1007/s00226-009-0253-6

Neyses B, Karlsson O, Sandberg D (2020) The effect of ionic liquid and superbase pre-treatment on the spring-back, set-recovery and Brinell hardness of surface-densified Scots pine. Holzforschung 74:303–312. https://doi.org/10.1515/hf-2019-0158

Cai X, Blanchet P (2015) Electron-beam curing of acrylate/nanoparticle impregnated wood products. Bio Resour 10(3):3852–3864. https://doi.org/10.15376/biores.10.3.3852-3864

Cleland MR, Galloway RA, Berejka AJ et al (2009) X-ray initiated polymerization of wood impregnants. Radiat Phys Chem 78:535–538. https://doi.org/10.1016/j.radphyschem.2009.04.008

Trey SM, Netrval J, Berglund L, Johansson M (2010) Electron-beam-initiated polymerization of poly(ethylene glycol)-based wood impregnants. ACS Appl M Interfac 2:3352–3362. https://doi.org/10.1021/am100778q

Triquet J, Blanchet P, Landry V (2020) Hardness of chemically densified Yellow birch in relation to wood density, polymer content and polymer properties. Holzforschung. https://doi.org/10.1515/hf-2020-0076

Morrell JJ (2018) What is Wrong with Wood Modification in the U.S.? In: Proceeding of the 9th European Conference on Wood Modification (ECMW9). Arnhem, The Netherlands

Geldermann J, Kolbe LM, Krause A et al (2016) Improved resource efficiency and cascading utilisation of renewable materials. J Clean Prod 110:1–8. https://doi.org/10.1016/j.jclepro.2015.09.092

Tarkow H, Seborg RM (1968) Surface densification of wood. For Prod J 18:104–107

Chen C, Tu D, Zhou Q et al (2020) Development and evaluation of a surface-densified wood composite with an asymmetric structure. Constr Build M 242:118007. https://doi.org/10.1016/j.conbuildmat.2020.118007

Gong M, Lamason C, Li L (2010) Interactive effect of surface densification and post-heat-treatment on aspen wood. J M Proc Technol 210:293–296. https://doi.org/10.1016/j.jmatprotec.2009.09.013

Kariz M, Kuzman MK, Sernek M et al (2017) Influence of temperature of thermal treatment on surface densification of spruce. Eur J Wood Prod 75:113–123. https://doi.org/10.1007/s00107-016-1052-z

Laine K, Antikainen T, Rautkari L, Hughes M (2013) Analysing density profile characteristics of surface densified solid wood using computational approach. Int Wood Prod J 4:144–149. https://doi.org/10.1179/2042645313Y.0000000031

Laine K, Rautkari L, Hughes M (2013) The effect of process parameters on the hardness of surface densified Scots pine solid wood. Eur J Wood Prod 71:13–16. https://doi.org/10.1007/s00107-012-0649-0

Laskowska A (2017) The influence of process parameters on the density profile and hardness of surface-densified birch wood (Betula pendula Roth). Bio Resour 12(3):6011–6023. https://doi.org/10.15376/biores.12.3.6011-6023

M Petrič A Kutnar L Rautkari et al 2013 Influence of surface densification of wood on its dynamic wettability and surface free energy KL Mittal Ed Advances in contact angle, wettability and adhesion Wiley Hoboken, NJ, USA 279 296

Rautkari L, Properzi M, Pichelin F, Hughes M (2009) Surface modification of wood using friction. Wood Sci Technol 43:291–299. https://doi.org/10.1007/s00226-008-0227-0

Bekhta P, Proszyk S, Krystofiak T et al (2017) Effects of short-term thermomechanical densification on the structure and properties of wood veneers. Wood Mater Sci Eng 12:40–54. https://doi.org/10.1080/17480272.2015.1009488

Rautkari L, Properzi M, Pichelin F, Hughes M (2010) Properties and set-recovery of surface densified Norway spruce and European beech. Wood Sci Technol 44:679–691. https://doi.org/10.1007/s00226-009-0291-0

Rautkari L, Laine K, Laflin N, Hughes M (2011) Surface modification of Scots pine: the effect of process parameters on the through thickness density profile. J Mater Sci 46:4780–4786. https://doi.org/10.1007/s10853-011-5388-9

Laine K, Segerholm K, Wålinder M et al (2016) Wood densification and thermal modification: hardness, set-recovery and micromorphology. Wood Sci Technol 50:883–894. https://doi.org/10.1007/s00226-016-0835-z

Bekhta P, Proszyk S, Krystofiak T (2014) Colour in short-term thermo-mechanically densified veneer of various wood species. Eur J Wood Prod 72:785–797. https://doi.org/10.1007/s00107-014-0837-1

Cruz N, Bustos CA, Aguayo MG et al (2018) Impact of the chemical composition of pinus radiata wood on its physical and mechanical properties following thermo-hygromechanical densification. Bio Resour 13(2):2268–2282. https://doi.org/10.15376/biores.13.2.2268-2282

Diouf PN, Stevanovic T, Cloutier A et al (2011) Effects of thermo-hygro-mechanical densification on the surface characteristics of trembling aspen and hybrid poplar wood veneers. Appl Surf Sci 257:3558–3564. https://doi.org/10.1016/j.apsusc.2010.11.074

Jennings JD, Zink-Sharp A, Frazier CE, Kamke FA (2006) Properties of compression-densified wood, Part II: surface energy. J Adhes Sci Technol 20:335–344. https://doi.org/10.1163/156856106776381802

Kutnar A, Rautkari L, Laine K, Hughes M (2012) Thermodynamic characteristics of surface densified solid Scots pine wood. Eur J Wood Prod 70:727–734. https://doi.org/10.1007/s00107-012-0609-8

Hakkou M, Pétrissans M, Zoulalian A, Gérardin P (2005) Investigation of wood wettability changes during heat treatment on the basis of chemical analysis. Polym Degrad Stab 89:1–5. https://doi.org/10.1016/j.polymdegradstab.2004.10.017

Šernek M, Kamke FA, Glasser WG (2004) Comparative analysis of inactivated wood surfaces. Holzforschung 58:22–31. https://doi.org/10.1515/HF.2004.004

Ratnasingam J, Ioras F (2013) Finishing characteristics of heat treated and compressed rubberwood. Eur J Wood Prod 71:135–137. https://doi.org/10.1007/s00107-012-0642-7

Coqueret X (2017) Radiation-induced polymerization. In: Applications of ionizing radiation in materials processing. Inst Nucl Chem Technol, p 143

Belt T, Rautkari L, Laine K, Hill CAS (2013) Cupping behaviour of surface densified Scots pine wood: the effect of process parameters and correlation with density profile characteristics. J Mater Sci 48:6426–6430. https://doi.org/10.1007/s10853-013-7443-1

Wong ED, Zhang M, Wang Q, Kawai S (1998) Effects of mat moisture content and press closing speed on the formation of density profile and properties of particleboard. J Wood Sci 44:287–295. https://doi.org/10.1007/BF00581309

Heräjärvi H (2004) Variation of basic density and brinell hardness within mature finnish betula pendula and b. Pubescens stems Wood Fiber Sci 36:216–227

Rautkari L, Kamke FA, Hughes M (2011) Density profile relation to hardness of viscoelastic thermal compressed (VTC) wood composite. Wood Sci Technol 45:693–705. https://doi.org/10.1007/s00226-010-0400-0

Cai X, Blanchet P (2010) Acrylate wood densification: effects of vacuum time and nanoparticles on chemical retention, penetration, and resin distribution. Wood Fiber Sci 42:10

Ahmed SA, Chun SK, Miller RB et al (2011) Liquid penetration in different cells of two hardwood species. J Wood Sci 57:179–188. https://doi.org/10.1007/s10086-010-1168-4

Hansmann CH, Wimmer WGR, Teischinger A (2002) Permeability of wood-A review. Drevarsky Vyskum 47:1–16

Siau JF (1971) Flow in wood. Syracuse University Press

Fito P (1994) Modelling of vacuum osmotic dehydration of food. In: Water in Foods. Elsevier, pp 313–328 https://doi.org/10.1016/B978-1-85861-037-5.50022-9

Siau JF (1984) Transport processes in wood. Springer, Berlin Heidelberg, Berlin, Heidelberg

Panshin AJ, de Zeeuw C (1964) Textbook of wood technology. McGraw-Hill, New York

Ding W-D, Koubaa A, Chaala A et al (2008) Relationship between wood porosity, wood density and methyl methacrylate impregnation rate. Wood Mat Sci Eng 3:62–70. https://doi.org/10.1080/17480270802607947

Singh A, Dawson B, Franich R et al (1999) The relationship between pit membrane ultrastructure and chemical impregnability of wood. Holzforschung 53:341–346. https://doi.org/10.1515/HF.1999.056

Jeje AYA, Zimmermann MH (1979) Resistance to Water Flow in Xylem Vessels. J Exp Bot 30:817–827. https://doi.org/10.1093/jxb/30.4.817

Rautkari L, Laine K, Kutnar A et al (2013) Hardness and density profile of surface densified and thermally modified Scots pine in relation to degree of densification. J Mater Sci 48:2370–2375. https://doi.org/10.1007/s10853-012-7019-5

Cown DJ, Parker ML (1978) Comparison of annual ring density profiles in hardwoods and softwoods by X-ray densitometry. Can J For Res 8:442–449

Fu Q, Cloutier A, Laghdir A (2016) Optimization of the thermo-hygromechanical (THM) process for sugar maple wood densification. Bio Resour 11(4):8844–8859. https://doi.org/10.15376/biores.11.4.8844-8859

Bergès L, Nepveu G, Franc A (2008) Effects of ecological factors on radial growth and wood density components of sessile oak (Quercus petraea Liebl.) in Northern France. For Ecol Manage 255:567–579. https://doi.org/10.1016/j.foreco.2007.09.027

de Moura LF, Hernández RE (2006) Effects of abrasive mineral, grit size and feed speed on the quality of sanded surfaces of sugar maple wood. Wood Sci Technol 40:517–530. https://doi.org/10.1007/s00226-006-0070-0

Murmanis L, River BH, Stewart HA (1986) Surface and subsurface characteristics related to abrasive-planing conditions. Wood Fiber Sci 18(1):107–117

De Meijer M, Thurich K, Militz H (1998) Comparative study on penetration characteristics of modern wood coatings. Wood Sci Technol 32:347–365

Bessières J, Maurin V, George B et al (2013) Wood-coating layer studies by X-ray imaging. Wood Sci Technol 47:853–867. https://doi.org/10.1007/s00226-013-0546-7

Landry V, Blanchet P (2012) Surface preparation of wood for application of waterborne coatings. For Prod J 62(1):39–45. https://doi.org/10.13073/FPJ-D-10-00011.1

Rijckaert V, Stevens M, Van Acker J (2001) Effect of some formulation parameters on the penetration and adhesion of water-borne primers into wood. Holz als Roh- und Werkstoff 59:344–350. https://doi.org/10.1007/s001070100209

Alberti A, Bertini S, Gastaldi G et al (2005) Electron beam irradiated textile cellulose fibres. Eur Polym J 41:1787–1797. https://doi.org/10.1016/j.eurpolymj.2005.02.016

Ershov BG (1998) Radiation-chemical degradation of cellulose and other polysaccharides. Russ Chem Rev 67:315–334. https://doi.org/10.1070/RC1998v067n04ABEH000379

Schnabel T, Huber H, Grünewald TA, Petutschnigg A (2015) Changes in mechanical and chemical wood properties by electron beam irradiation. Appl Surf Sci 332:704–709. https://doi.org/10.1016/j.apsusc.2015.01.142

Starr T, Harper DP, Rials TG (2014) The effects of electron beam irradiation dose on the mechanical performance of red maple (Acer rubrum). Bio Resour 10(1):956–969. https://doi.org/10.15376/biores.10.1.956-969

Dawes K, Glover LC, Vroom DA (2007) The effects of electron beam and g-irradiation on polymeric materials. In: Mark JE (ed) physical properties of polymers handbook. Springer, New York, New York, NY, pp 867–887

Skvortsov SV (1990) Radiation degradation of lignin. Chem Nat Compd 26:1–9. https://doi.org/10.1007/BF00605186

Nguyen QN, Cloutier A, Achim A, Stevanovic T (2016) Fuel properties of sugar maple and yellow birch wood in relation with tree vigor. Bio Resour 11(2):3275–3288. https://doi.org/10.15376/biores.11.2.3275-3288

Acknowledgements

This work is part of the research program of Natural Sciences and Engineering Research Council of Canada (NSERC) Canlak Industrial Research Chair in Finishes for Interior wood products (CRIF) through programs CRD (RDCPJ 500157–16) and PCI (PCISA 514917–16). The authors are grateful to the NSERC-Canlak Industrial Research Chair in Finishes for Interior wood products (CRIF) Industrial partners for their help and support. This work was made possible through the crucial help of David Brown, Emily Craven, Matthew Trott and Shane Stutchbury from Mevex (Stittsville, Canada) with electron beam irradiation. The authors would also like to acknowledge collaborators who provided technical support: Dr Pascale Chevalier and the Research Center for Advanced Materials (CERMA—Université Laval) for SEM imaging, as well as all the technical team at the Renewable Materials Research Center (CRMR—Université Laval).

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: Stephen Eichhorn.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Triquet, J., Blanchet, P. & Landry, V. Chemical surface densification of hardwood through lateral monomer impregnation and in situ electron beam polymerization, Part I: density profile and surface hardness of three hardwood species. J Mater Sci 56, 11309–11323 (2021). https://doi.org/10.1007/s10853-021-06009-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06009-7