Abstract

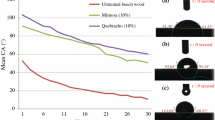

Sanding is a common practice required in order to prepare wood surfaces for coating. Little literature is available regarding the effect of sanding parameters on the quality of surfaces. Sugar maple wood surfaces were evaluated in samples that had been sanded using two types of abrasive minerals, three grit sizes and four feed speeds. Roughness, wetting properties and cell damage were used to assess surface quality. Both abrasives decreased roughness and cell damage from 100- to 120-grit sanding stage. Addition of a 150-grit stage did not further reduce the roughness, whereas the cell damage continued to decrease. Increasing feed speed led to rougher surfaces due to higher fibrillation. Surfaces produced by silicon carbide were smoother and less damaged than those obtained with aluminum oxide. However, the surfaces sanded with aluminum oxide were more wettable and showed no significant difference in wetting time as a function of grit size. For these surfaces, the wetting time was reduced as feed speed increased.

Similar content being viewed by others

References

Feist WC (1999) Making paint stick to wood siding and trim. J Light Constr 9:45–49

Garrett HE (1964) Contact angles and their significance for adhesion. In: Alner DJ (ed) Proceedings of conferences of the Northampton College of Advanced Technology. (Aspects of Adhesion) EC1, England, pp 19–41

Gray VR (1964) Contact angles, surface tensions and adhesion. In: Alner DJ (ed) Proceedings of conferences of the Northampton College of Advanced Technology. (Aspects of Adhesion) EC1, England, pp 42–48

Hernández RE, de Moura LF (2002) Effects of knife jointing and wear on the planed surface quality of northern red oak wood. Wood Fiber Sci 34:540–552

Hernández RE, Rojas G (2002) Effects of knife jointing and wear on the planed surface quality of sugar maple wood. Wood Fiber Sci 34:293–305

ISO 4287-1 (1984) Rugosité de surface – Terminologie – Partie 1: Surface et ses paramètres, International Organization for Standardization (ISO), Geneva

Juan J (1992) Comment bien usiner le bois. Centre technique du bois et de l’ameublement (CTBA), Paris

Koch P (1964) Wood machining processes. Ronald Press, New York

Lihra T, Ganev S (1999) Machining properties of eastern species and composite panels, Special pub No E-3277, Forintek Canada Corp, Quebec City

de Meijer M, Thurich K, Militz H (1998) Comparative study on penetration characteristics of modern wood coatings. Wood Sci Technol 32:347–365

de Moura LF, Hernández RE (2005) Evaluation of varnish coating performance for two surfacing methods on sugar maple wood. Wood Fiber Sci 37:355–366

Richter K, Feist WC, Knaebe MT (1995) The effect of surface roughness on the performance of finishes. Part 1. Roughness characterization and stain performance. Forest Prod J 45(7/8):91–97

Shi SQ, Gardner DJ (2001) Dynamic adhesive wettability of wood. Wood Fiber Sci 33:58–68

Stewart HA, Crist JB (1982) SEM examination of subsurface damage of wood after abrasive and knife planing. Wood Sci 14:106–109

Taylor JB, Carrano AL, Lemaster RL (1999) Quantification of process parameters in a wood sanding operation. Forest Prod J 49(5):41–46

Williams D, Morris R (1998) Machining and related mechanical properties of 15 B.C. wood species, Special pub No SP-39, Forintek Canada Corp, Vancouver

Wu S (1971) Calculation of interfacial tension in polymer systems. J Polym Sci C34:19–30

Wålinder MEP (2002) Study of Lewis acid-base properties of wood by contact angle analysis. Holzforschung 56:363–371

Acknowledgments

The authors thank Luc Germain, Torsten Lihra and Martin O’Connor for valuable assistance as well as Forintek Canada Corp. for technical support during sanding tests. This research was supported by the National Scientific and Technological Development Council of Brazil and by the Canada Economic Development for Quebec Regions.

Author information

Authors and Affiliations

Corresponding author

Additional information

An erratum to this article is available at http://dx.doi.org/10.1007/s00226-006-0077-6.

An erratum to this article can be found at http://dx.doi.org/10.1007/s00226-006-0077-6

Rights and permissions

About this article

Cite this article

de Moura, L.F., Hernández, R.E. Effects of abrasive mineral, grit size and feed speed on the quality of sanded surfaces of sugar maple wood. Wood Sci Technol 40, 517–530 (2006). https://doi.org/10.1007/s00226-006-0070-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-006-0070-0