Abstract

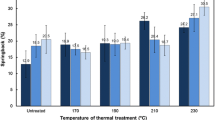

This paper addresses the effect of surface densification on the Brinell hardness of Scots pine sapwood. Densification was performed in an open system under heat and compression using different compression temperatures and closing times. The hardness was measured using a modified Brinell hardness method. Furthermore, the density profiles of the samples were measured and their correlation to hardness analysed. It was found that the process parameters strongly affected the hardness of surface densified solid wood. This knowledge is relevant when optimising the densification process according to the properties required of the end-product. At 150 °C compression temperature and 0.5 min closing time, the average Brinell hardness (23.4 N/mm2) was double to that at 200 °C and 5 min closing time (11.6 N/mm2).

Zusammenfassung

In dieser Studie wird der Einfluss einer Oberflächenverdichtung auf die Brinell Härte von Kiefernsplintholz untersucht. Die Prüfkörper wurden in einem offenen System unter Wärme und Druckbeanspruchung bei verschiedenen Temperaturen und Schließzeiten verdichtet. Die Härte wurde anhand eines modifizierten Verfahrens zur Bestimmung der Brinell Härte ermittelt. Darüber hinaus wurden die Dichteprofile der Prüfkörper bestimmt und ihre Korrelation mit der Härte untersucht. Es wurde gezeigt, dass die Prozessparameter einen starken Einfluss auf die Härte von oberflächenverdichtetem Massivholz haben. Diese Erkenntnis kommt zum Tragen, wenn der Prozess entsprechend der gewünschten Eigenschaften des Endprodukts optimiert werden soll. Bei einer Presstemperatur von 150 °C und einer Schließzeit von 0,5 min war die mittlere Brinell Härte (23,4 N/mm²) doppelt so hoch wie bei einer Temperatur von 200 °C und einer Schließzeit von 5 min (11,6 N/mm²).

Similar content being viewed by others

References

Fang C-H, Mariotti N, Cloutier A, Koubaa A, Blanchet P (2011) Densification of wood veneers by compression combined with heat and steam. Eur J Wood Wood Prod 70:155–163

Gong M, Lamason C, Li L (2010) Interactive effect of surface densification and post-heat-treatment on aspen wood. J Mater Process Technol 210:293–296

Inoue M, Norimoto M, Otsuka Y, Yamada T (1990) Surface compression of coniferous wood lumber I. Mokuzai Gakkaishi 36:969–975

Inoue M, Norimoto M, Tanahashi M, Rowell RM (1993) Steam or heat fixation of compressed wood. Wood Fib Sci 25:224–235

Lamason C, Gong M (2007) Optimization of pressing parameters for mechanically surface densified aspen. For Prod J 57:64–68

Navi P, Girardet F (2000) Effects of thermo-hydro-mechanical treatment on the structure and propertied of wood. Holzforschung 54:287–293

Niemz P, Stübi T (2000) Investigations of hardness measurements on wood based materials using a new universal measurement system. In: Proceedings of the symposium on wood machining, properties of wood and wood composites related to wood machining, Vienna, Austria

Rautkari L, Properzi M, Pichelin F, Hughes M (2009) Surface modification of wood using friction. Wood Sci Technol 43:291–299

Rautkari L, Laine K, Laflin N, Hughes M (2010) Surface modification of Scots pine: the effect of process parameters on the through thickness density profile. J Mater Sci 46:4780–4786

Rautkari L, Kamke F, Hughes M (2011) Density profile relation to hardness of viscoelastic thermal compressed (VTC) wood composite. Wood Sci Technol 45:693–705

Tarkow H, Seborg R (1968) Surface densification of wood. For Prod J 18:104–107

Unsal O, Candan Z (2008) Moisture content, vertical density profile and Janka hardness of thermally compressed Pine wood panels as a function of press pressure and temperature. Dry Technol 26:1165–1169

Acknowledgments

The researchers would like to acknowledge Mr. Nick Laflin of the BioComposites Centre, Bangor University, UK and Miss Cara Leitch for technical support in this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Laine, K., Rautkari, L. & Hughes, M. The effect of process parameters on the hardness of surface densified Scots pine solid wood. Eur. J. Wood Prod. 71, 13–16 (2013). https://doi.org/10.1007/s00107-012-0649-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-012-0649-0