Abstract

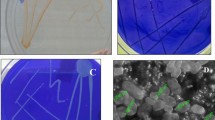

Klebsiella is one of the genera that has shown unbeatable production performance of 2,3-butanediol (2,3-BD), when compared to other microorganisms. In this study, two Klebsiella strains, K. pneumoniae (DSM 2026) and K. oxytoca (ATCC 43863), were selected and evaluated for 2,3-BD production by batch and fed-batch fermentations using glucose as a carbon source. Those strains’ morphologies, particularly their capsular structures, were analyzed by scanning electron microscopy (SEM). The maximum titers of 2,3-BD by K. pneumoniae and K. oxytoca during 10 h batch fermentation were 17.6 and 10.9 g L−1, respectively; in fed-batch cultivation, the strains showed the maximum titers of 50.9 and 34.1 g L−1, respectively. Although K. pneumoniae showed higher productivity, SEM showed that it secreted large amounts of capsular polysaccharide, increasing pathogenicity and hindering the separation of cells from the fermentation broth during downstream processing.

Similar content being viewed by others

References

Winfield ME (1945) The catalytic dehydration of 2,3-butanediol to 1,3-butadiene. J Council Sci Ind Res 18:412–423

Emerson RR, Flickinger MC, Tsao GT (1982) Kinetics of dehydration of aqueous 2,3-butanediol to methyl ethyl ketone. Ind Eng Chem Prod Res Dev 21:473–477

Yu EKC, Saddler JN (1982) Power solvent production by Klebsiella pneumoniae grown on sugars present in wood hemicelluloses. Biotechnol Lett 4:121–126

Garg SK, Jain A (1995) Fermentative production of 2,3-butanediol: a review. Bioresour Technol 51:103–109

Harden A, Walpole GS (1906) 2,3-Butylene glycol fermentation by Aerobacter aerogenes. Proc Roy Soc B 77:399–405

Syu MJ (2001) Biological production of 2,3-butanediol. Appl Microbiol Biotechnol 55:10–18

Ji XJ, Huang H, Ouyang PK (2011) Microbial 2,3-butanediol production: a state-of-the-art review. Biotechnol Adv 29:351–364

Celińska E, Grajek W (2009) Biotechnological production of 2,3-butanediol—current state and prospects. Biotechnol Adv 27:715–725

Ma C, Wang A, Qin J, Li L, Ai X, Jiang T, Tang H, Xu P (2009) Enhanced 2,3-butanediol production by Klebsiella pneumoniae SDM. Appl Microbiol Biotechnol 82:49–57

Barrett EL, Collins EB, Hall BJ, Matoi SH (1983) Production of 2,3-butylene glycol from whey by Klebsiella pneumonia and Enterobacter aerogenes. J Dairy Sci 66:2507–2514

Jansen NB, Tsao FT (1983) Bioconversion of pentoses to 2,3-butanediol by Klebsiella pneumoniae. Adv Biochem Eng Biotechnol 27:85–99

Jansen NB, Flickinger MC, Tsao FT (1984) Production of 2,3-butanediol from d-xylose by Klebsiella oxytoca ATCC 8724. Biotechnol Bioeng 26:362–369

Champluvier B, Decallonne J, Rouxhet PG (1989) Influence of sugar source (lactose, glucose, galactose) on 2,3-butanediol production by Klebsiella oxytoca NRRL-B199. Arch Microbiol 152:411–414

Grover BP, Garg SK, Verma J (1990) Production of 2,3-butanediol from wood hydrolysate by Klebsiella pneumoniae. World J Microbiol Biotechnol 6:328–332

Afschar AS, Bellgardt KH, Rossel CE, Czok A, Schaller K (1991) The production of 2,3-butanediol by fermentation of high test molasses. Appl Microbiol Biotechnol 34:582–585

Frazer FR, McCaskey TA (1991) Effect of components of acid-hydrolysed hardwood on conversion of d-xylose to 2,3-butanediol by Klebsiella pneumoniae. Enzyme Microb Technol 13:110–115

Cao N, Xia Y, Gong CS, Tsao GT (1997) Production of 2,3-butanediol from pretreated corn cob by Klebsiella oxytoca in the presence of fungal cellulose. Appl Biochem Biotechnol 63:129–139

Ji XJ, Huang H, Du J, Zhu JG, Ren LJ, Li S, Nie ZK (2009) Development of an industrial medium for economical 2,3-butanediol production through co-fermentation of glucose and xylose by Klebsiella oxytoca. Bioresour Technol 100:5214–5218

Biebl H, Zeng AP, Menzel K, Deckwer WD (1998) Fermentation of glycerol to 1,3-propanediol and 2,3-butanediol by Klebsiella pneumonia. Appl Microbiol Biotechnol 50:24–29

da Silva GP, Mack M, Contiero J (2009) Glycerol: a promising and abundant carbon source for industrial microbiology. Biotechnol Adv 27:30–39

Zheng Y, Zhang HY, Zhao L, Wei LJ, Ma XY, Wei DZ (2008) One-step production of 2,3-butanediol from starch by secretory over-expression of amylase in Klebsiella pneumoniae. J Chem Technol Biotechnol 83:1409–1412

Ji XJ, Huang H, Du J, Zhu JG, Ren LJ, Hu N, Li S (2009) Enhanced 2,3-butanediol production by Klebsiella oxytoca using a two-stage agitation speed control strategy. Bioresour Technol 100:3410–3414

Ji XJ, Huang H, Du J, Zhu JG, Ren LJ, Nie ZK, Du J, Li S (2010) Engineering Klebsiella oxytoca for efficient 2,3-butanediol production through insertional inactivation of acetaldehyde dehydrogenase gene. Appl Microbiol Biotechnol 85:1751–1758

Zhang L, Yang Y, Sun Jian, Shen Y, Wei D, Zhu J, Chu J (2010) Microbial production of 2,3-butanediol by mutagenized strain of Serratia marcescens H30. Bioresour Technol 101:1961–1967

Cheng KK, Liu HJ, Liu DH (2005) Multiple growth inhibition of Klebsiella pneumoniae in 1,3-propanediol fermentation. Biotechnol Lett 27:19–22

Woolley EM, George RM (1974) Ionization constants for water and for very weak organic acids in aqueous organic mixtures. J Sol Chem 3:119–126

Riffat R, Krongthamchat K (2006) Specific methanogenic activity of halophilic and mixed cultures in saline wastewater. Int J Environ Sci Technol 2:291–299

Simoons-Smit AM, Verweij-van Vught AM, MacLaren DM (1986) The role of K antigen as virulence factors in Klebsiella. J Med Microbiol 21:133–137

Lin MH, Hsu TL, Lin SY, Pan YJ, Jan JT, Wang JT, Khoo KH, Wu SH (2009) Phosphoproteomics of Klebsiella pneumoniae NTUH-K2044 reveals a tight link between tyrosine phosphorylation and virulence. Mol Cell Proteomics 8:2613–2623

Guo NN, Zheng ZM, Mai YL, Liu HJ, Liu DH (2010) Consequence of cps mutation of Klebsiella pneumoniae on 1,3-propanediol fermentation. Appl Microbiol Biotechnol 86:701–707

Acknowledgments

The authors thank Mi Yeon Cho and Duk-Ki Kim for their technical assistance on cell cultures and analytical procedures. This work was supported by the Industrial Strategic Technology Development Program (No. 10035241) funded by the Ministry of Knowledge Economy (MKE, Korea).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cho, JH., Rathnasingh, C., Song, H. et al. Fermentation and evaluation of Klebsiella pneumoniae and K. oxytoca on the production of 2,3-butanediol. Bioprocess Biosyst Eng 35, 1081–1088 (2012). https://doi.org/10.1007/s00449-012-0691-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-012-0691-7