Abstract

The coatings based on carbon nanotubes (CNTs) are increasingly developed for their applications, among others, in medicine, in particular for implants in implantology, cardiology, and neurology. The present review paper aims at a detailed demonstration of different preparation methods for such coatings, their performance, and relationships between deposition parameters and microstructure and material, mechanical, physical, chemical, and biological properties. The thermal and electrostatic spraying, electrophoretic and electrocathodic deposition, and laser methods are presented. Characterization of microstructure of coatings, topography, morphology, adhesion of CNTs to a substrate, mechanical behavior, corrosion resistance, wettability, cytotoxicity, bioactivity, and antibacterial protection are reviewed for different deposition methods and parameters. The state-of-the-art in the field of carbon nanotubes shows a considerable number of research performed on CNTs coatings. The different forms of CNTs, deposition methods, parameters, and substrates were applied as process variables. The microstructures and surface homogeneity, chemical and phase compositions, mechanical properties at the micro- and nanoscale such as coating Young`s modulus and hardness, interface adhesion strength and delaminating force, open corrosion potential and corrosion current density, contact angle in wettability assessment, and bioactivity, cytotoxicity, and antibacterial efficiency among biological properties were determined. The summary of so far achievements, strengths and weaknesses, and important future research necessary for clarification of some weak points, development of non-toxic, mechanically and chemically resistant, bioactive, and antibacterial multicomponent coatings based on functionalized CNTs are proposed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Recent medical implantology has utilized or investigated a huge number of materials in the form of solid implants or scaffolds, and also meshes, sponges, hydrogels, and coatings to modify the surfaces of metallic implants. Among them, the most recently, have appeared different forms of elementary carbon, principally single-wall or multi-wall carbon nanotubes (SWCNTs or MWCNTs of different chirality) but also carbon fibers (CFs), graphene, mainly as graphene oxide (GO) or reduced graphene oxide (rGO), fullerenes (especially C60) [1, 2]. The carbon nanotubes were discovered by Iijima [3]. Various types of synthesis techniques for CNTs include the arc-discharge method, laser ablation method, chemical vapor deposition (CVD), vapor-phase growth, flame synthesis method, and plasma-assisted growth [2].

All nanocarbon forms, particularly carbon nanotubes (CNTs), demonstrate extraordinary mechanical, thermal, magnetic, optical, electrical, surface, and chemical properties. Their electronic properties, high electric and thermal conductivity, and stiffness and strength are over those shown by any other material [4]. Thanks to these features, the CNTs have been frequently applied or recommended for use in different fields of the economy: medicine, biomechanics, energy storage, molecular electronics, fabrics and fibers, air and water filtration, and others [5].

As an additive to construction materials, they are presumably mostly applied as a component of epoxy resins. They have been used to improve the electrical and mechanical construction of epoxy-based composites [6,7,8]. They were given as fillers to strengthen several construction polymers [2, 9, 10] and also as functionally graded CNTs reinforced composites [11]. They can be considered components of bifunctional electrocatalysts [12].

As a component of coatings, they have been proposed to enhance heat transfer of heat sinks [13], improve corrosion performance [14,15,16,17], reinforce the coatings [18], increase the friction behavior [19, 20], make coatings superhydrophobic and usable for different applications [15, 21,22,23], such as the abrasion-resistant, photothermal, and anti-icing [24], and self-adapting ultra-high-temperature ceramic coatings [25]. The CNTs were used in coatings for electromagnetic interference shielding [26] and as a flame-retardant coating or composite material [27,28,29]. They were applied against decontamination of organic chemical pollutants in water [30, 31] and also involved in building space stealth and cosmic radiation shielding [32].

They are widely used in electronics and energy systems. Their electrical and electronic properties are suitable for building artificial muscles, electrochemical, thermal actuators, solvent and vapor actuators, fiber-shaped batteries and supercapacitors, color-changed electroluminescent and electrochromic fibers, mechanical and electrochemical sensors [33], thermal management systems [33, 34], solar cells [35], high-performance metal-ion batteries [36,37,38], energy storage and conversion devices [39], nanogenerators for harvesting energy [40], NEMS and hydrogen storage modules [2].

They are also increasingly developed for medical applications. They can be applied in bone regeneration, artificial neural conduits, and in drug and gene delivery in cancer therapy, brain therapy [41, 42], vaccine delivery [42], tissue engineering, and regenerative medicine, in particular for bone and muscle, and nervous system regeneration by neuronal differentiation and neuronal stimulation [42,43,44,45], for culturing the human embryonic stem cells and preserving their viability [46], and dosage forms and biomedical substrates in the pharmaceutical industry [47], They can be utilized in diagnosis for biomedical imaging, biosensors, for biomolecular detection and nanotweezers [42, 48]. They are introduced as sensors, in drug targeting, cancer diagnosis, and treatment, as antibacterial and antifungal species [49]. The CNTs helped to create the coatings releasing the active ingredients [50] such as biphosphonates, nucleic acids, proteins, and statins [51]. The integration of CNTs with polymeric scaffolds is promising for cardiac regeneration [52, 53]. The carbon nanotubes reinforced with chitosan, poly(lactic acid) (PLA), poly(lactide-co-glycolide) (PLGA), poly(ethylene glycol) (PEG), polyvinyl alcohol (PVA), and polycaprolactone (PCL) can mimic the extracellular matrices of bone [54]. These unique properties make CNTs promising candidates for cancer treatment and regenerative medicine, for bone, and nerve restoration [43, 55]. The incorporation of CNTs into polymer scaffolds results, among others, in increased scaffold strength and flexibility, improved biocompatibility, retardation of cancer cells` division, and enhancement of angiogenesis [1]. They are microbial and anti-adhesive [56,57,58]. They are used in various biosensors for biomolecular detection [59].

Besides the advantages, CNTs have two serious drawbacks. The first disadvantage important for medical applications is their anticipated toxicity which is a permanent feature of each nanoparticle; their small size and high surface area to volume ratio are associated with significant chemical reactivity, change in permeability and conductivity membranes of cells, lung penetration, and lung cancer risk [60]. The bioactivity and cytotoxicity of CNTs are affected by their diameter, length, and functionalization in vitro and in vivo, as well as by the fabrication method with nickel catalyst [61] and may make CNTs toxic for living organisms or the environment [60, 62]. The toxicity can manifest itself as membrane damage, DNA damage, an appearance of oxidative stress, and changes in mitochondrial activity and intracellular metabolic routes as a consequence of the highly hydrophobic surface and the non-biodegradable nature of the CNTs [1]. However, the CNTs are considered to have carcinogenicity mainly to enhance lung tumors, and the carcinogenicity may attenuate with decreasing tube length [63]. The MWCNTs are likely to be a more neural-friendly interface than SWCNTs since they allow for a wider external surface and effective functionalization [64].

The second disadvantage is the weak adhesion of CNTs (and all carbon nanoforms) to any material. It is critical to functionalize CNTs not only to make them more soluble, but also to allow their integration into many organic, inorganic, and biological systems and applications, and eliminate or at least minimize their toxicity. A proper functionalization of the CNTs is nowadays carried out by a variety of methods [65,66,67,68]. It may follow two strategies: (1) chemical reactions occurring at the sidewalls and tips of CNTs and (2) oxidation followed by an appearance of carboxyl-based bonding [41]. Functionalization of carbon nanofibers can be performed by CVD and plating of some compounds, and by chemical or biochemical reactions [69].

This review aims to show the newest data on carbon nanotubes creating coatings or being components of such, in particular (1) various synthesis methods, in particular the electrophoretic deposition (EPD) technique as the most preferred, (2) their properties, such as surface morphology and topography, mechanical, corrosion, and biological properties, and the relationships between output and input variables to optimize the deposition process.

2 Forms of carbon nanotubes

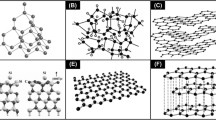

Carbon nanotubes are hollow structures created from rotating a graphene layer around one axis in a certain direction. It is an sp2 form of hybridization of carbon derive, where carbon atoms are organized with strong covalent bonds in a hexagonal lattice, very similar to graphene, graphite, and fullerenes. Carbon nanotubes can be divided into SWCNTs, double-wall carbon nanotubes (DWCNTs), and MWCNTs [70], which are demonstrated in Fig. 1. The first reported were MWCNTs by Iijima [3]. MWCNTs are composed of concentric cylinders with regular periodic interlayer spacing located around the ordinary central hollow. They form a layer construction with van der Waals bonding between cylinders [71,72,73].

CNTs types based on a number of walls, where A SWCNTs, B DWCNTs, and C MWCNTs. Figures A and C were reproduced with permission [74] Copyright 2011, InTech

Literature shows that the parameters of all types of carbon nanotubes are within certain limits as illustrated in Tables 1 and 2.

Besides the division grounding on the number of carbon nanotube walls, some SWCNTs forms differ in terms of wrapping to a cylinder structure, such as armchair (integers n = m), zigzag (integers m = 0), and chiral (other integers) [72]. Figure 2 illustrates schematic types of wrapping graphite sheet to form different forms of SWCNTs.

A scheme illustrating A forms of wrapping graphite to achieve different structures of the SWCNTs and B different structures of SWCNTs based on the chiral angle. The figure is reproduced with permission [82] Copyright 2016, JACS Directory©2016

There are several methods of synthesis of carbon nanotubes such as chemical vapor deposition, arc-discharge method, laser ablation method, spray pyrolysis, hydrothermal methods, and thermal plasma [48, 70, 85,86,87].

3 CNTs-containing coating types and their deposition methods

There are many types of CNT-included coatings, with ceramics, metals, polymers, or mixed. Examples of such coatings are shown in Fig. 3. Several deposition methods of CNTs-containing coatings, like the main groups: thermal spray, electrochemical deposition, and laser methods, are schematically shown in Fig. 7. The main advantages and disadvantages of the types of deposition methods are listed in Table 3. The examples of CNTs-containing coatings and their main parameters of synthesis with described impact on coatings properties are listed in Tables 4 and 5.

3.1 Thermal spraying

A thermal spray is a group of processes in which materials (metals, alloys, metal oxides, metal/ceramic blends, carbides, composite materials) are deposited using spraying. The processes differ from each other basically by the state of the material: molten, semi-molten, or solid state. The thermal spraying method is used in many fields in mechanical engineering, for corrosion protection, surface restoration, and repair, heat insulation or conduction; energy technology, and biomedical and industrial areas [88, 89]. Apart from many advantages, the technique has also some drawbacks. Covering parts with complex shapes, inner surfaces, and narrow parts is limited. Some advances in thermal spray technology enable covering a such surface, named the internal diameter thermal spray method [90, 91]. Figure 4 shows a schematic illustration of literature-based three most used methods of CNTs deposition techniques.

3.1.1 Plasma spraying

Plasma spraying (PS) is one of the thermal processes used to coat materials. This method uses a high-energy heat source, which melts (at a temperature of about 10,000 K) coating material inserted into a plasma jet and sprayed onto a prepared substrate [92,93,94]. The arc between two electrodes cathode (tungsten) and anode (copper) is initiated by high-frequency discharge in the presence of gases, such as Ar, He, H2, and N2 named plasma-forming gases [93, 94]. Figure 4 A shows a schematic illustration of the PS coating method.

3.1.2 Cold spraying

Cold spraying (CS) or cold gas dynamic spray (CGDS) is not only a thermal spraying process but also a solid-state spraying method. It differs from other thermal spraying methods by the state of powder feedstock, which is always unmelted. This method is used to produce metallic and metallic-ceramic coatings. Based on pressure level, the cold spraying process (Fig. 4C) can be divided into low-pressure cold spraying (LPCS) and high-pressure cold spraying (HPCS). This process is based on the acceleration of particles of the coating material by pressurized gas (air, N2, He, or mixture) in a diverging-converging nozzle, leading to preparation layer-by-layer [89, 95] coating. The best adhesion of the cold-sprayed coatings is achieved only above a critical particle velocity [96].

3.1.3 High-velocity oxy-fuel thermal spraying

High-velocity oxygen fuel (HVOF) is a thermal spray technique that uses fuel, such as H2, propylene, acetylene, or kerosene to achieve a high temperature that ranges from 2500 to 3000 °C and high pressure in the combustion chamber. Most commonly a powder, but also a suspension (another type of HVOF, named suspension high-velocity oxy-fuel SHVOF) is inserted in the nozzle and at the same time heated and accelerated (particle velocity of 550–1060 m/s) by a gas stream causing the formation of a relatively dense coating, with good adhesion properties. Coatings deposited by the HVOF method (Fig. 4 B) are widely used to enhance surface performance and protect against corrosion and wear, but it also is a convenient method to deposit nanomaterials [91, 97,98,99,100]

3.1.4 Low-velocity oxy-fuel thermal spraying

Low-velocity oxy-fuel (LVOF) thermal spraying is very similar to HVOF, except for particle velocities, which are here lower, with close (2300–2500 °C) or the same flame temperatures. At the same time, particle velocities in LVOF are higher than in plasma spraying [91, 101]. Coatings deposited by LVOF are corrosion- and wear-resistant [102].

3.2 Electrochemical methods

The electrochemical methods are among the most simple techniques. The deposition material is a suspension with charged micro- or nanoparticles, which are migrating to the substrate, mainly due to the applied electrical field. Figure 5 demonstrates electrochemical methods, which are mostly used to prepare CNTs coatings and CNTs coatings with additions.

3.2.1 Electrostatic spraying

The electrostatic spraying (electrospray method, ES, shown in Fig. 5C) is a simple technique used to deposit coatings by dispersing charged material under an applied electric field. The deposition system consists of a generator and micro-injector, where a charged coating suspension is placed. Coatings prepared using this method are characterized by good adhesion to the substrate [103].

3.2.2 Electrophoretic deposition

Electrophoretic deposition (EPD) is a simple method carried out in suspension, where two electrodes, an anode, and a cathode are placed parallel to each other and connected usually to a DC power supply (Fig. 5B). Due to the electric field, the particles suspended in the solution migrate to one of the electrodes (depending on particle charge) and coagulate, forming a coating [111, 112, 142, 143, 147].

3.2.3 Electrocathodic deposition

Electrocathodic deposition (ECD), which is also known as electrocathodically-assisted deposition (ECAD), electro-co-deposition, or electrolytic plating is a method used in water solutions of inorganic compounds appearing as cations and anions. Additionally, CNTs (or, e.g., their carboxylated complexes [148]) can be transported by large cationic particles with which they form hydrogen chemical bonds. Under an electric field, the cations or cation–CNTs complexes move toward the cathode being a covered substrate, and form coatings [149, 150]. A schematic diagram of electrocathodic deposition is shown in Fig. 5A.

3.3 Laser methods

High-speed laser cladding (HSLC) is one of the methods applied to prepare CNT coatings, as shown in Fig. 7. Traditional laser cladding (LC) uses laser energy to melt additional material with the surface layer of the substrate. The additional material could be in the form of powder, wire, or strip [104]. LC method allows preparing surfaces free from porosity and cracks [105], but still too thick to produce wear and corrosion protective coatings because the surface preparation rate ranges from 10 to 50 cm2/min. For ultra-high-speed laser cladding, the rate of cladding is approximately 500 cm2/min, which is more efficient resulting in coatings of 10–250 µm thick [106]. For better understanding, Fig. 6 schematically demonstrates the idea of the HSLC technique (Fig. 7).

4 Properties of composite coatings

4.1 Topography and morphology

Surface topography is a qualitative feature of a surface shape, which is characterized by a quantitative feature, named surface roughness, expressed by the surface Sa parameter (multiple lines) or line Ra parameter. Table 6 shows a short review of the roughness of CNTs coatings. When discussing topography, it is also essential to point to surface morphology, which describes the coating chemical and phase composition, thus Table 4 also provides such information.

Table 6 shows that the roughness of electrochemically prepared CNTs-containing coatings is lower compared to other methods. Also, the plasma electrolytic oxidation has a lowering effect on the CNT–Al coating image. The microstructure of each coating depends on the method of synthesis. Plasma-sprayed coatings generally have lamellar microstructure due to layer-by-layer deposition, where some microcracks, voids, and porosity can be distinguished [124, 125, 127, 136]. The porosity of Al–Si–CNTs coatings ranges from 10 to 12% and many agglomerates of size distribution 39÷57 µm could be observed [123]. For Ta2O5/CNT coatings the porosity ranges at 18÷26% and increases with the higher concentration of CNTs. Such coatings are intended for biomedical applications and reach a thickness of 540 ± 110 μm [31]. Generally, the coatings prepared using PS show regions, where the powder material is unmelted, partially melted or melted [94, 127]. Another method of CNTs coatings preparation is HSLC which gives coatings almost as flat as the substrate, without cracks in the micro-scale. For nickel-plated CNTs/Fe-based coatings, there could be seen phase transition from the columnar dendrite, through the crystal to amorphous resulting from a temperature gradient, and with the increase of CNTs content, all phases are refined [119]. CNTs coatings prepared with the CS method have flake-like morphology, whereas in cross-sectional images lamellar structure could be observed. Xie et al. reported CNT/AlSi coatings thickness to be several micrometers [108]. Moreover, 1wt%-CNT–Al coatings exhibit pores but their number and size are smaller than for the pure Al coating deposited on AZ91 Mg alloy [130]. EPD-prepared coatings have CNTs uniformly distributed. The other components such as nanometals and nanoceramics are mostly agglomerated [111, 142, 143] due to suspension instability and no possibility to stir during the process. Such coatings are also laser-modified, followed by scratches, folds, and bulges observed on their surface. The phases like TiC in the form of dendrites and spheres could be distinguished. The thickness of laser-modified MWCNTs coating was reported to be 7.88 ± 0.35 µm [112].

In materials science, morphology describes the shape, texture, and distribution of different elements and phases at a surface, whereas topography determines the quantitative 3D configuration of different geometrical features on a surface. The studies of both topography and morphology are always immanent parts of any materials investigations as their influence on bioactivity, i.e., bone growth rate, and also on corrosion behavior, is crucial. It might be assumed that in topography, the deciding is the proper development of the surface. For titanium, the geometry and dimensions of oxide nanotubes are important. In particular, the walls of rough and sharp nanotubes TiO2 provide suitable places for the nucleation of biospecies [151]. The presence of titanium dioxide in the form of nanopatterns with heights of about 1.5 nm and nanotubes influenced protein adsorption kinetics and the thickness and morphology of the resulting protein layer which was attributed mainly to electrostatic interactions [152, 153]. The nanopatterned arrays developed by the chemical hydrothermal process at high temperatures mimic the dragonfly wing and are suggested as the origin of their activity against different bacteria [154]. The shot peening of titanium causes the substantial appearance of the micro- and nanoscale oxide layers which strongly affect adhesion, proliferation, and osteogenic differentiation of human cells, additionally enhancing wettability [154]. But not only the presence of titanium oxide is a necessary condition for positive effects of topography. Osteoblasts showed a tendency to accelerate their proliferation on titanium spike structures [155]. The positive effects of the surface morphology, and micro and nano roughness, which improved osseointegration, were observed for hard titanium [155]. The additive designed manufacturing such as powder bed fusion (PBF) metal 3D printing makes porous structures of different local surface topography and pore shape that affects cell proliferation and differentiation. In particular, titanium with pores triangular and rectangular pores has higher roughness with a structure more concave (valley-like) than that with circular pores and effectively promotes the proliferation and differentiation of osteoblasts, thus improving osseointegration strength and implant fixation [156]. Similar phenomena were observed for porous topography for silicon [157, 158], hydroxyapatite [159, 160], poly(l-lactide) (PLLA) modified with femtosecond laser [161], poly(methyl methacrylate) (PMMA) [162]. For CNTs layers or composite coatings, there have been no important investigations, but it might be assumed that the presence of CNTs can enhance biological processes.

4.2 Adhesion between CNTs and metallic substrate

4.2.1 Adhesion mechanisms

The adhesion strength is mainly determined by mechanical and thermal interaction between particle and substrate depending on the method of coating synthesis. In the CS method deposition velocity and, thus, the degree of deformation plays an important role. At the critical velocity, the material is plastically deformed and a region (called adiabatic shear instability) where the temperature could reach the melting point of the material is formed, leading to viscoelastic material flow, formation of a conformal interface, and metallurgical bonding. Thus, the evaluation of adhesion strength is dependent on the particle velocity, particle or substrate temperature, substrate roughness, particle morphology, and mechanical properties of both the particle and the substrate [95, 163].

The CNTs formulate a mesh structure, with a large surface area, giving space for reaction. Direct reaction of CNTs with plasma plume in plasma spray method resulted in the generation of defects which leads to an increase in reaction sites [123]. In this method, there are seen three typical microstructures: fully melted region, partially melted region, and pores. In the fully melted region, some reduction processes may occur such as in the case of CNT–TiO2 coating for which the carbothermal reduction appears followed by the formulation of some TiO2-x species. In partially melted regions, CNTs and the other components stick to each other and bond with weak van der Waals forces [94].

Adhesion plays a very important role in implant coating. If the adhesion is poor, during implantation surgery the coating can be degraded or even totally removed. Therefore, even further properties are positive, the adhesion must be sufficient enough to counteract mechanical stresses during the insertion of whatever implant into the bone. Below different methods are described which are used to assess the anticipated integrity by measurements of the adhesion strength of the coating to the bone. Besides, as the coating is subject during surgery and after different loads, the coating must be also tough, but not brittle. Therefore, CNTs are added mainly to improve rigidity, hardness, and toughness.

Despite several described below tests to calculate adhesion strength, widely described in the literature, however, the best assessment of the coating behavior during implantation surgery is in vivo experiments on animals. The results of such successful studies are, however, not frequent. It is noted that to increase the clinical success rate of metal implants is to increase their bone-bonding properties, i.e., to develop a bone bioactive surface leading to reduced risks of interfacial problems. Much research has been devoted to modifying the surface of metals to make them bioactive. Many of the proposed methods include depositing a coating on the implant. However, there is a risk of coating failure due to low substrate adhesion. In [164], a method to obtain bioactivity combined with a high coating adhesion via a gradient structure of the coating [165]. The review of different techniques for HAp coatings on Ti6Al4V alloy, mostly still applied for hip joint implants, showed that three techniques, namely sputtering, IBAD (ion beam-assisted deposition) followed by heat treatment, and EPD give reasonably high adhesion values. To increase the adhesion, the substrate is usually properly prepared to develop its surface area and create micro and nanoforms such as grooves, pillars, columns, etc., by mechanical grinding, acidic and alkaline etching, chemical, electrochemical, and micro-arc oxidation, laser roughening, and patterning. In [166], such laser micromachining of titanium and its alloys created micro-grooves of diameter of about 10 µm, and then coating with arginine–glycine–aspartic acid to enhance cellular spreading and adhesion was deposited. The laser-grooved and coated rods had significantly higher pull-out strength than the only laser-grooved and control rods. This paper in an excellent way explains the core of this problem. To summarize, the coating for long-term implants must demonstrate several features, such as the bioactivity necessary to form quickly and strongly the bond between an implant and bone, mechanical behavior against anticipated stresses sufficient to avoid any serious damage or degradation, and high adhesion. Truly, we would like to achieve only bioactivity without cytotoxicity, but weak mechanical strength or weak coating adhesion might cause the coating to be destroyed and the main aim for its deposition will vanish.

4.2.2 Testing methods and adhesion strength of CNTs

Among different methods used to assess the adhesion of coatings, the standard ASTM F1044 based on shear testing of calcium phosphate and metallic coatings is the most often applied for CNTs composite coatings. It assesses the adhesion of coatings to substrates or the cohesion of a coating under shear stress to the interface. Commonly flat-coated specimens are glued to a proper counterpart and loaded up to the division of both parts. The more recent results of such investigations are shown in Table 7. The addition of the CNTs results in a significant increase in the adhesion strength, but as a rule at its higher contents or if a third component is present in a coating.

Exceptionally, the standard test method based on measuring adhesion force by tape test, ASTM D 3359-08, was applied for the chitosan–nanoHAp–CNTs on Ti substrate [171]. The tape tests displayed high adhesion strength (class 5B).

Nanoscratch testing is increasingly applied [141, 142] despite that mechanical force and not stress is measured which makes the results not comparable to those based on the shear technique. For the nanoHAp–CNTs coatings deposited on Ti and its alloys, [141], a critical load of 350 mN was noticed for the HAp–5% CNTs coating. In the other research [142] the values of critical force resulting in the delamination of coatings deposited on Ti13Nb13Zr alloy were 116.5 mN, 90.2 mN, and 60.4 mN under shear stress for CNTs, CNTs–HAp, and CNTs–nanometal coatings, respectively, at 0.27 wt% of CNTs only.

Finally, it is to emphasize a novel technique, called a nanomechanical pull-out method [172] that has used an atomic force microscopy cantilever acting as a force sensor and mounted vertically to a 3D piezo nanomanipulator. The interfacial shear strength and the maximum load-bearing capacity of the CNTs coatings on Al Ti and Zn substrates were 217 and 245 nN, and after quantitative analysis of the results, the shear stresses at the interfaces were calculated as 31÷40.01 MPa, depending on heat treatment, and 37.8 MPa, respectively [172, 173]. Based on the ASTM C-633 standard (European EN 582) and using the tensile tester for pull-out samples, the adhesion between cold-sprayed CNTs to Al matrix was assessed at 15–18 MPa [95].

Systematic research on the effects of some features and amounts of CNTs composites is rare. One of the reasons for increasing the adhesion strength with increasing the CNTs content in HAp coating is bridging formed by CNTs between coating and substrate [174, 175]. It is noted that an addition of CNTs has also been proposed for protective coatings based on epoxy resins [16].

4.3 Mechanical behavior

The mechanical behavior of a material is one of the most important features discussed when the material is considered for use in biomedical applications. Microhardness, nanohardness, elastic (Young`s) modulus, and yield strength less often, are the mechanical properties checked to describe the material and attribute it to an application. The difference between micro- and nanohardness is the area of the test. Microhardness gives information about the average hardness of a large area, while nanohardness is more specific and describes the little area using smaller loads. Young’s modulus is used to assess material stiffness and is a very important factor in terms of biomedicine because the mismatch of implant and bone in Young’s modulus could lead to complications for the patient and even the necessity to repeat the surgery. Usually, scientists are looking for materials, with lower values of elastic modulus than the natural bone elastic modulus, which is for cancellous bone about 3.78 GPa and cortical bone about 14.64 GPa [176]. Table 8 shows the mechanical properties of coatings composed of CNTs.

CNT-based coatings are deposited on different substrates with variable CNTs and other additions` contents. Considering the value of Young’s modulus of CNT-containing coatings for application in biomedicine we can observe that the coatings with 0.25 and 0.27 wt% addition of CNTs revealed elastic modulus values similar to cortical bone. The addition of nanometals and nanoceramics causes a decrease in Young’s modulus. The CNTs applied in the YSZ and Al-based coatings improve mechanical properties [125, 130]. For Al-based coatings, the CNTs enhance coatings properties through thermal expansion mismatch, and Orowan looping as CNTs are generating high dislocation density and limit dislocation migration. Also, CNTs play a reinforcing role, dependent on content and distribution [130].

4.4 Corrosion resistance

The corrosion resistance testing focuses on the electrochemical behavior of the deposit by, almost exclusively, the electrochemical potentiodynamic polarization test. The increase in current density means the corrosion resistance decreases. The conditions of the test can be changed, such as temperature, electrolyte composition, scanning rate, and potential range. For biomedical applications mostly the temperature of the body is imitated and SBF solution is used as an electrolyte. Before the main test, the open circuit potential (OCP) value is checked, which is the potential at zero current value and gives information about the thermodynamic stability of the examined material. Mostly OCP value is negative, but sometimes it could be positive, which means a passivation phenomenon of the coating can occur [136]. The OCP value also gives a clue about the potential range that should be used during the electrochemical polarization test. Table 9 shows a brief conclusion about the corrosion behavior of CNTs-based coatings.

For the coatings with YSZ, Cr, and Al prepared using PS the addition of CNTs enhanced the corrosion resistance [125, 127, 130, 136]. Tripathi et al. [136] reported better corrosion resistance for the Cr–CNT and Cr–YSZ–CNT compared to the bare Cr material, with the highest potential achieved for the Cr–YSZ–CNT coating. For the Cr substrate the corrosion current density and corrosion potential were 15.9 ± 3.7 µA/cm2 and − 534 ± 19 mV, respectively, and for Cr–CNT 6.9 ± 1.3 µA/cm2 and − 509 ± 23 mV, and Cr–YSZ–CNT 7.2 ± 0.9 µA/cm2 and − 470 ± 13 mV, what gives information that two-phase boundaries inhibit the cracks and limits corrosion [136]. On the other hand, the increase of MWCNTs content in MWCNTs/PU coatings increases the corrosion current density, thus weakening the corrosion resistance. This phenomenon could be explained by the formulation of micro-defects in the PU matrix, which facilitate the substrate metal corrosion. The maximum corrosion rate for MWCNTs/PU coating deposited on Q235 steel is at 8 wt% of MWNCTs and the maximum corrosion resistance appears for 2 wt% of MWCNTs [110]. The same effect was seen for 1 wt%-CNT–Al coating deposited on AZ91 Mg alloy, achieved using the CS method according to the substrate and pure Al coating. The phenomenon was explained by thermal mismatch between the Al matrix and CNTs, which can strengthen the matrix, limit dislocation looping, and suppress crack propagation [107, 130]. Maleki-Ghaleh et al. [145] prepared HAp–Ti–1wt%-MWCNTs coating using the EPD process on NiTi substrate, which possessed the best corrosion resistance in comparison to the substrate and coatings without MWCNTs addition. Nevertheless, there are the same reports about CNT coating EPD-deposited on Ti, which decreases corrosion resistance, due to the porous fibrous structure of the coating and the presence of TiO2 [140]. Thus, the results are ambiguous indicating the complex roles of components and microstructure, roughness, and uniformity of the surface.

Another method to check corrosion resistance on a micro-scale is the scanning Kelvin probe. The test allows for achieving information about electron work. The higher the escape electron work is, the higher the corrosion resistance. The test indicated the best corrosion resistance for the CNTs/Fe-based coating with 1 wt% of CNTs prepared by HSLC, confirmed by the electrochemical corrosion test. The increase in CNT content caused the decrease in corrosion current density, and the CNTs presence allowed to join the cracks improving corrosion resistance [119].

4.5 Wettability

The contact angle is used to describe the wettability of CNTs coatings. The higher the contact angle is the higher the wettability of a surface, and thus such a surface is named hydrophilic. In the literature, the contact angle between 40 and 60° is the best in terms of promoting cells adhesion and improving the bioactivity of the coating [178]. Lin et al. reported on the decrease in contact angle of the Ta2O5/CNT coating deposited on Ti6Al4V to 1÷3° [31]. The wettability of Cu–CNT–TiO2 coating is also hydrophilic (the contact angle value is 12.85°), due to the presence of TiO2 particles [135]. The pure CNT coatings prepared using the EPD technique deposited on Ti13Nb13Zr are also hydrophilic and their contact angle is about 56°, while the contact angle of CNTs coatings with HAp and nanometal additions highly increases to hydrophobic values, which is unwelcome in biomedical applications [142]. The impact of laser modification on the wettability of CNTs coatings was also checked and revealed the increasing contact angle to the value of about 80° [112]. The wettability of CNTs coatings is then strongly dependent on the bonding effect and the method of synthesis. Most MWCNTs used to prepare coatings employing electrochemical methods are functionalized to give a negative charge and enable the deposition. Such a modification and changes in the pH of the solution during the process may impact the linking of CNTs to other components of the suspension, thus changing the contact angle of the coating [142]. On the other hand, the wettability of CNTs coatings is dependent on the roughness.

4.6 Bioactivity and cytotoxicity

Most commonly the MWCNTs' bioactivity and cytotoxicity, namely positive and negative effects on adhesion, viability, proliferation, and mortality of cells were tested in human umbilical vein endothelial cells (HUVECs). Zhao et al. [52] examined three types of MWCNTs with different diameters, named XFM4 (diameter: 10–20 nm), XFM22 (length: 0.5–2 µm; diameter: 20–30 nm), and XFM34 (length: 0.5–2 µm; diameter: > 50 nm) and concluded that the smallest diameter, the higher level of cytotoxicity, the HUVECs are the most internalized, the level of cytokine released is the highest. They also observed the highest level of ER stress biomarkers, due to the highest specific surface area of the MWCNTs, causing autophagy of HUVECs, thus eliminating MWCNTs with such dimensions to be applied in biomedicine, especially in blood vessels. Also, the dose-dependence impact on cytotoxicity was seen. The MWCNTs with the smallest diameter exposed cytotoxicity at concentrations higher than 16 μg/mL. On the other hand, for higher MWCNTs diameters, a greater content of MWCNTs caused higher cytotoxicity to HUVECs, while its addition didn`t indicate obvious changes in the ultrastructure of HUVECs cells.

The MWCNTs diameter cytotoxicity impact on the other cells was also checked for NR8383 cells (normal rat alveolar macrophage cells) [179] and human mesothelial cell lines (MeT5A, E6/E7, and hTERT-immortalized human peritoneal mesothelial cells) [180] and the length impact of MWCNTs on cytotoxicity to HUVECs was investigated. Long et al. [181] examined two types of MWCNTs (XFM19 of length 10–30 µm and XFM22 of length 0.5–2 µm, both outer diameter of 20–30 nm and inner diameter of 5–10 nm) with different concentrations from 2 to 32 μg/mL. The longer the MWCNTs were, the higher level of cytotoxicity to HUVECs, the higher oxidative stress, the higher level of THP-1 monocyte adhesion to MWCNTs, the higher level of ER stress biomarkers were observed, which gives information about the inflammation-inducing effect of longer MWCNTs species. Another parameter discussed in the literature is a surface modification of MWCNTs, which could affect interaction with proteins and cells [182]. According to Sun et al. [183], pristine MWCNTs (XFM19, diameter: 28.97 nm, average length: 1181.14 nm), hydroxylated MWCNTs (XFM20, diameter: 30.46 nm, average length: 1323.94 nm), and carboxylated MWNCTs (XFM21, diameter: 31.03 nm, average length: 1256.59 nm) are cytotoxic to HUVECs and induce oxidative stress to a similar extent while used with MWCNTs concentration of 32 μg/mL or 64 μg/mL. Dinc et al. reported the functionalized (oxidized) MWCNTs were less toxic to HUVECs and MDA-MB-231 cells (breast cancer cells) than pristine MWCNTs [182]. Thus, MWCNTs with a longer length and smaller diameters could induce cytotoxicity to HUVECs, regardless of the type of used functionalization of MWCNTs. However, Dlugon et al. [140] checked the biological activity of CNTs coatings EPD deposited on Ti using the human osteoblast NHOst cell line and after 7 days observed higher cell viability for CNTs modified Ti than for pure substrate. Also, the SWCNTs were investigated in terms of cytotoxicity and showed that the oxidized SWCNTs caused malformed placentas in female mince already after administration of 100 ng/ml of oxidized SWCNTs [184, 185].

The toxicity of MWCNTs is then dependent on their dimensions, such as the diameter, length, and also physicochemical properties, like surface chemistry, and dose. So far studies show that the examined parameters in terms of cytotoxicity are: (1) the internalization of MWCNTs to human cells, (2) the release of inflammatory cytokines (THP-1 monocyte), (3) the mechanism of cytotoxicity activation-reactive oxygen species (ROS) or activation of endoplasmic reticulum (ER) stress biomarkers, such as ddit3 (DNA damage-inducible transcript 3) or other named chop (C/EBP homologous protein); xbp-1s (spliced X-box binding protein 1), and the protein level of BiP (binding immunoglobulin protein; GRP78, 78 kDa glucose-regulated protein) [52, 181, 183].

The cytotoxicity is a serious problem that has been attempted to limit by several solutions. In [186] the toxicity of CNTs was shown to be mainly related to their dimensions: toxicity decreases with increasing length of the nanotubes. The toxicity was also reduced for CNTs of small diameter [187], thus the use of smooth CNTs is favorable. Besides this passive way, the functionalization of CNTs is likely the single approach to decrease cytotoxicity, with effectiveness dependent on chemical structure. The carboxylic SWCNTs and MWCNTs, with cytotoxicity investigated by adsorption of human serum albumin [188], of bovine serum albumin [189, 190], and by MTT assay [191] were the least toxic as compared to hydroxylated SWCNTs and amined SWCNTs. The natural bio-resin shellac applied for the functionalization of CNTs also reduces cytotoxicity [192].

The bioactivity of CNTs has been seldom investigated as elementary carbon is an inert body. The high surface properties, including the creation of chemical covalent or van der Waals bonds, are achieved due to nanosized tubes. However, it is now well known that to make CNTs bioactive, chemical functionalization is necessary. There are several indirect evidence for an enhancement or improvement of bioactivity by CNTs in multicomponent coatings. In [193] the multivalent polyanion-dispersed CNTs were used after their functionalization with polyglycerol sulfate and deposited on PCL. That results in higher neural differentiation efficiency creating then highly bioactive nanostructured fibrous scaffolds. In [194] low-dimensional nanomaterials such as CNTs or graphene exhibited noticed in vitro bioactivity and osteoinductivity. In [195] polymer–bioglass–CNTs composite material was investigated. The results showed that the presence of MWCNTs in low quantities enhanced osteoblast-like cell attachment and proliferation compared to composites with high concentrations of MWCNTs, and the mechanism of CNTs-enhanced bioactivity is unclear. Considering the test results for [196] the coatings composed of functionalized multi-walled carbon nanotubes (f-MWCNTs) and hydroxyapatite on 316L steel, it was concluded that the addition of f-MWCNTs in the HAp increases the number of active sites responsible for the formation of carbonated apatite layer. In [197], the use of functionalized carbon nanotubes in the hybrid composition of chitosan/silica showed favorable tissue responses of the CNT-incorporated membrane.

The bioactivity is most often checked using in vitro tests, mostly in SBF solution. Lin et al. [31] reported a complete coverage by hemispherical-shaped particle samples of Ti6Al4V coated with Ta2O5 and Ta2O5/CNTs. Nevertheless, there could be an observed relationship between the increasing content of CNTs in the coating and with decreasing size of adhered apatite particles. The same team checked the adhesion of osteoblast-like cells, such as osteosarcoma MG-63 cells, which showed satisfactory adhesion and spreading behavior after 7 days of culture, but without an impact of CNTs presence. It means that CNT-decorated coatings could promote cell proliferation and differentiation, and thus they are candidates for use in biomaterials [183].

4.7 Antibacterial efficiency

CNTs have been reported to exhibit killing properties over a wide range of bacteria including human pathogens such as Escherichia coli (E. coli), Salmonella typhimurium, Bacillus subtilis (B. subtilis), Staphylococcus aureus (S. aureus), Micrococcus lysodeikticus and Streptococcus mutans. Several studies have disclosed that pristine CNTs exhibit antibacterial activity by physical contact and collisions leading to puncturing of the bacterial cell membrane and its damage [198, 199]. It was reported in [198] that the force of 100 nN is enough to make AFM-detectable holes in bacteria cells, even though the checked force is unrealistic to appear between bacteria and CNTs in normal conditions, thus this mechanism is unlike. The second mechanism assumed the CNTs are connecting to the bacteria cell membrane in the form of CNT dense network, thus changing cell membrane architecture, and its mechanical properties [198,199,200]. Liu et al. reported the SWCNTs after 10 min of exposure to E.coli and B. subtilis increasing cell wall roughness, causing increased cytoplasm leakage and bacteria cell death after 120 min [198], while Schifrano et al. reported a significant reduction of cell number after 24 h incubation in contact with CNTs [200]. Further investigation leads to the assertion that the antibacterial activity of CNTs is light-dependent [201, 202]. Rajavel et al. reported that the SWCNTs and MWCNTs are ROS generators (producing singlet oxygen 1O2, superoxide anions Ȯ2− and hydroxyl radicals ȮH) in sunlight with a light intensity of 903 lm/m2 and ambient light of 180 lm/m2 [201]. Such ROS production increases oxidative stress, makes bacteria cell membrane disruption (due to lipid peroxidation) and causes bacteria death [200,201,202]. Nevertheless, the antibacterial effectiveness of CNTs also depends on bacteria peptidoglycan cell wall thickness and strain resistance, showing the CNTs antibacterial properties are more significant for Gram-negative bacteria (e.g., E.coli, P. aeruginosa) than Gram-positive ones (e.g., S. aureus, B. subtilis) [198, 200]. The above mechanisms of antibacterial activity of CNTs are well established in [200], where both the mechanical injury and ROS production play important roles in the bactericidal effect of CNTs. Figure 8A shows a diagram, summarizing the antibacterial mechanisms of CNTs.

There are many reports about the antibacterial efficiency of CNTs with additions, where the main mechanism of antibacterial efficiency is again the generation of ROS. The cellulose acetate (CA)-CNT–Ag [203] was shown as effective against E. coli and S. aureus, with the CA matrix creating protection against the harmful effects of silver (i.e., argyria and argyrosis) [203]. Also, CNTs–Ag composites exhibit antibacterial properties against E.coli [204]. The addition of CNTs to Ag colloid lowers the minimal inhibitory concentration value of Ag particles in suspension, both against Gram-negative and Gram-positive bacteria. Here, a good dispersion of the Ag nanoparticles on the CNTs is the reason for the high antibacterial activity of CNT–Ag composites [204]. There is evidence about the antibacterial activity of MWCNTs–Ag composites against E. coli [205,206,207], S. aureus [203, 208,209,210,211], Staphylococcus haemolyticus [212], and also against B. subtilis and Pseudomonas aeruginosa [213]. The other CNTs-containing coating components were reported to have antibacterial properties [212], in particular for composite coatings such as the CNTs–ZnO [214, 215], hydroxyapatite/ZnO/CNT [216], Co doped-ZnO/MWCNTs [214] and MWCNTs–Ag/TiO2 [217] against E. coli and S. aureus. Also, the MWCNTs–TiO2 [218] and Ag–TiO2–MWCNT [219] were lethal to E. coli, and CNTs/TiO2/polyurethane films to S. aureus [220]. Also, SWCNTs composites with Ag nanoparticles inhibited the growth and multiplication of bacteria, such as S. aureus, B. cereus, E. coli, and P. aeruginosa [221]. Zhu et al. reported very strong antibacterial performance of SWCNTs in combination with silica and Ag against E. coli and S. aureus [222]. The same antibacterial activity showed SWCNTs–Ag/TiO2 hybrids [217]. Although CNT coating improves cell adhesion, and antibacterial properties and promotes osteoblast differentiation of Ti species [202, 223], pristine CNTs are reported to increase oxidative stress and cause cell death [202].

In the example of Ag–MWCNTs coating, the mechanisms of antibacterial activity slightly differ depending on the form of silver, either ionic Ag+ cations or NPs [153, 224, 225]. Both silver forms specifically interact with bacteria. For Ag NPs, the contact mechanism is typical which occurs through the touch of bacteria to silver particulates and ROS appearance, which leads to damage to the cell membrane and vacuolization of cytoplasm [226,227,228,229,230]. According to [231], all contacted Ag NPs influence the permeability and flow through the outer membrane, but only smaller Ag NPs can pass through the cell membrane, then interact with DNA, and affect the respiratory system. Whereas, the antibacterial mechanism for Ag+ starts with their adhesion to the bacteria cell, its adsorption inside the bacteria cell, and the production of ROS [226, 228, 229, 232]. As Zhao et al. propose [230], the silver ions on the cell membrane inhibit the expression of outer membrane proteins, i.e., retard the reproduction of bacteria cells by inducing the release of nucleic acids, what is according to Du et al. [232] typical of large agglomerates of Ag NPs. The synergy of the combination of CNTs with Ag enhances the bactericidal efficiency of the CNTs, thus the Ag NPs are characterized by a high surface-to-volume ratio and MWCNTs high aspect ratio, this way produce a higher contact area [199]. Figure 8 schematically illustrates the differences in antibacterial mechanisms of CNTs and CNTs with Ag addition.

4.8 Perspectives and challanges

The CNTs gain more and more attention in biomedical, energy and thermal applications due to its excellent properties, such as crack bridging, increase in elastic modulus, improvement of thermal conductivity and heat transfer, and lubricating effect, which lowers the friction coefficient and improves wear resistance of coatings composed of CNTs. What is more, the CNTs addition generally improves the corrosion resistance of coatings by sealing pores, increases coating adhesion strength, due to the formation of a network in the coating and has antibacterial properties, especially against gram-negative bacteria. In endoprosthesis applications, Young’s modulus near the cortical bone (of 15–30 GPa [233]), reported in [142] causes the MWCNTs coatings to be a suitable candidate for biomedical applications. Besides medical applications, the most promising perspectives for nanocarbon can be considered for the production of advanced, highly anticorrosive and self-repairing coatings [16], for green energy applications [234], for electronic and photonics [235].

Although there are many reports analyzing the properties of various CNTs coatings and composites, there are still several challenges and further questions to answer. The first one is the cytotoxicity issue of CNTs. Even if the studies demonstrate a general role of increasing the cytotoxicity of CNTs a high dose of CNTs in the coating, the smallest diameter, and the longer length of CNTs, the impact of functionalization on cytotoxic activity is still not enough known. The functionalization of CNTs enables its solubility, its deposition via electrochemical methods, thus the charged particles are required in this group of methods to prepare the coating, but there are also reports about its impact on decreasing the CNTs cytotoxicity [184,185,186,187,192], which still should be an open question to scientists.

Also, the adhesion mechanism of the CNTs coatings is a challenge to discuss. Up to now the adhesion of CNTs to some substrate occurs probably due to physical contact or weak van der Waals interaction, when describing coatings deposited electrochemically or by thermal sprayed methods. Nevertheless, the knowledge of CNTs adhesion mechanisms might be valuable when creating the solution for the problem with improvement of the adhesion strength of CNTs, which is also still challenging.

The same question might be posed on the subject of the bioactivity mechanism of CNTs, which is connected with the functionalization and adhesion strength of the CNTs-containing coating. The CNTs functionalization has an impact on coating surface architecture and thus cell adhesion, while the poor adhesion strength might be the reason for the excessive release of toxic substances in the human body.

The least but not last challenge for CNTs coatings is an improvement of its antibacterial properties against gram-positive bacteria. The gram-negative bacteria are protected by a narrow membrane, thus it is easier to break it and cause bacteria cell leakage, while gram-positive bacteria have up to 10 times thicker peptidoglycan walls and for, e.g., B. subtilis has peritrichous flagella structures which have smooth structure, so are unfavorable substrate for CNTs adhesion [198].

This review is a summary of coating properties composed of CNTs and different metals, ceramics and polymers, deposited on different substrates. The development of CNTs coatings still needs more research.

5 Conclusions

The state-of-the-art in the carbon nanotubes field shows a huge amount of research performed on CNTs coatings. The different forms of CNTs, deposition methods, and parameters, and substrates were applied as process variables. The microstructures, chemical and phase compositions, mechanical properties at the micro and nanoscale such as coating Young`s modulus and hardness, interface adhesion strength and delaminating force, open corrosion potential and corrosion current density, contact angle in wettability assessment, and bioactivity, cytotoxicity, and antibacterial efficiency among biological properties were determined. The following conclusions demonstrating valuable results and their implications, and still observed inefficiencies, can be drawn:

-

1.

The MWCNTs are the most frequently and promising carbon nanoforms presumably because of the highest strength and the lowest Young`s modulus which is important for the mechanical behavior of coatings on artificial implants.

-

2.

There is a diversity of deposition techniques applied for CNTs-containing coatings, all relatively similarly used, a choice of which depends on the expected properties and destination of the coated substrate.

-

3.

Electrophoretic deposition is widely used for titanium and its alloys at the most preferred voltage of 5–30 V, time 0.5–5 min.

-

4.

The roughness is the most plausible for biological application by coatings obtained by EPD, 0.2–1.0 µm, and the roughness of coatings prepared by thermal spray and plasma electrochemical oxidation seems excessive, 4–20 µm.

-

5.

The shear strength test seems the most used technique to assess the adhesion which ranges between 15 and 35 MPa. The nanoindentation scratch technique seems the most precise for a great number of softer coatings, but it urgently needs to be quantified and standardized.

-

6.

Hardness and Young`s modulus are measured by microhardness and nanoindentation tests and their values vary in wide limits depending on the substrate and phase and microstructure of a coating. The best hardness values reach 19 and 32 MPa for pure CNTs and CNTs strengthened with YSZ on steel substrate, relatively, and the lowest Young`s modulus is observed for the softer coatings on titanium and its alloys, 3–15 GPa. The use of either micro or nanohardness testing depends on the presumed toughness of a coating, and in such coatings is not highly accurate as evidenced by high values of standard deviations as compared to means.

-

7.

Corrosion current density is only determined by potentiodynamic technique, and the obtained values range between some or tens of µA/cm2. The corrosion resistance can presumably increase with a fraction of CNTs due to increasing inhomogeneity of coatings, still, however, remaining in a low corrosion rate area. The highest corrosion resistivity was observed for coatings with 1 wt% of CNTs.

-

8.

The coatings CNTs-containing are hydrophilic, but their increasing content seems to lead toward higher contact angles. Such an effect might be expected for carbon nanoforms and likely can disappear after proper CNTs` functionalization.

-

9.

The CNTs promote bioactivity assessed by the deposition of bone-like phosphates. However, the cytotoxicity of coatings implemented with long and narrow carbon nanotubes can be toxic, and this problem needs further thorough studies.

-

10.

The coatings based on the CNTs show significant killing properties against the number of various bacteria, including the most dangerous encountered in hospitals.

-

11.

Further research on the design and deposition of CNTs-including coatings is desired, in particular, to improve the adhesion of CNTs and the other components or a substrate, optimization of hardness and elasticity of coatings, and an assessment of relationships between cytotoxicity, functionalization, and content of CNTs in the coating.

Abbreviations

- ACCVD:

-

Alcohol catalytic chemical vapor deposition

- AFM:

-

Atomic force microscopy

- Ag NPs:

-

Silver nanoparticles

- CA:

-

Cellulose acetate

- CFs:

-

Carbon fibers

- CGDS:

-

Cold gas dynamic spray

- CNTs:

-

Carbon nanotubes

- CS:

-

Cold spraying

- CVD:

-

Chemical vapor deposition

- DWCNTs:

-

Double-wall carbon nanotubes

- ECD or ECAD:

-

Electrocathodic deposition, electroplating, electro-co-deposition

- EPD:

-

Electrophoretic deposition

- ER:

-

Endoplasmic reticulum

- ES:

-

Electrostatic spraying

- FM:

-

Fully melted

- f-MWCNTs:

-

Functionalized multi-walled carbon nanotubes

- GO:

-

Graphene oxide

- HAp:

-

Hydroxyapatite

- HPCS:

-

High-pressure cold spraying

- HSLC:

-

High-speed laser cladding

- HUVECs:

-

Human umbilical vein endothelial cells

- HVOF:

-

High-velocity oxygen fuel or oxy-fuel

- IBAD:

-

Ion beam-assisted deposition

- LC:

-

Laser cladding

- LPCS:

-

Low-pressure cold spraying

- LVOF:

-

Low-velocity oxy-fuel

- MTT:

-

3-(4,5-Dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide

- MWCNTs:

-

Multi-wall carbon nanotubes

- nanoAg:

-

Nanosilver

- nanoCu:

-

Nanocopper

- nanoHAp:

-

Nanohydroxyapatite

- NEMS:

-

Nanoelectromechanical system

- PBF:

-

Powder bed fusion

- PCL:

-

Polycaprolactone

- PECVD:

-

Plasma enhanced chemical vapor deposition

- PEG:

-

Poly(ethylene glycol)

- PEO:

-

Plasma electrolytic oxidation

- PLA:

-

Poly(lactic acid)

- PLGA:

-

Poly(lactide-co-glycolide)

- PLLA:

-

Poly(l-lactide)

- PM:

-

Partially melted

- PMMA:

-

Poly(methyl methacrylate)

- PS:

-

Plasma spraying

- PU:

-

Polyurethane

- PVA:

-

Polyvinyl alcohol

- rGO:

-

Reduced graphene oxide

- ROS:

-

Reactive oxygen species

- SBF:

-

Simulated body fluid

- SHVOF:

-

Suspension high-velocity oxy-fuel

- SWCNTs:

-

Single-wall carbon nanotubes

- YSZ:

-

Yttria-stabilized zirconia

References

Hopley EL, Salmasi S, Kalaskar DM, Seifalian AM (2014) Carbon nanotubes leading the way forward in new generation 3D tissue engineering. Biotechnol Adv 32:1000–1014. https://doi.org/10.1016/j.biotechadv.2014.05.003

Rathinavel S, Priyadharshini K, Panda D (2021) A review on carbon nanotube: an overview of synthesis, properties, functionalization, characterization, and the application. Mater Sci Eng B 268:115095. https://doi.org/10.1016/j.mseb.2021.115095

Iijima S (1991) Helical microtubules of graphitic carbon. Nature 354:56–58. https://doi.org/10.1038/354056a0

Thostenson ET, Ren Z, Chou T-W (2001) Advances in the science and technology of carbon nanotubes and their composites: a review. Compos Sci Technol 61:1899–1912. https://doi.org/10.1016/S0266-3538(01)00094-X

Khaniki HB, Ghayesh MH (2020) A review on the mechanics of carbon nanotube strengthened deformable structures. Eng Struct 220:110711. https://doi.org/10.1016/j.engstruct.2020.110711

Mousavi SR, Estaji S, Kiaei H et al (2022) A review of electrical and thermal conductivities of epoxy resin systems reinforced with carbon nanotubes and graphene-based nanoparticles. Polym Test 112:107645. https://doi.org/10.1016/j.polymertesting.2022.107645

Souto LFC, Henriques RR, Soares BG (2022) Influence of acidic and alkaline environmental anticorrosive performance of epoxy coatings based on polyaniline/carbon nanotube hybrids modified with ionic liquid. Prog Org Coat 173:107206. https://doi.org/10.1016/j.porgcoat.2022.107206

Li X, Wang J, Tian Y et al (2022) Thermal enhancement by constructing ordered-orienting hybrid network with modified boron nitride, graphene and carbon nanotubes in epoxy composite coatings. Prog Org Coat. https://doi.org/10.1016/j.porgcoat.2022.107078

Han W, Zhou J, Shi Q (2023) Research progress on enhancement mechanism and mechanical properties of FRP composites reinforced with graphene and carbon nanotubes. Alex Eng J 64:541–579. https://doi.org/10.1016/j.aej.2022.09.019

Qi X, Yang J, Zhang N et al (2021) Selective localization of carbon nanotubes and its effect on the structure and properties of polymer blends. Prog Polym Sci 123:101471. https://doi.org/10.1016/j.progpolymsci.2021.101471

Soni SK, Thomas B, Swain A, Roy T (2022) Functionally graded carbon nanotubes reinforced composite structures: an extensive review. Compos Struct 299:116075. https://doi.org/10.1016/j.compstruct.2022.116075

Deng H, Sheng L, Zhao X et al (2022) Non-noble metal FeMn and single-walled carbon nanotubes nanocomposites as effective bifunctional electrocatalysts in alkaline media for oxygen/hydrogen revolution reactions. Chin J Anal Chem 50:100110. https://doi.org/10.1016/j.cjac.2022.100110

Lee J, Kyeong D, Kim J, Choi W (2022) Layer-by-layer self-assembled functional coatings of carbon nanotube-polyethylenimine for enhanced heat transfer of heat sinks. Int J Heat Mass Transf. https://doi.org/10.1016/j.ijheatmasstransfer.2021.122344

Xia Y, Zhang S, Tong L et al (2022) Introducing cyano-functionalized multiwalled carbon nanotubes to improve corrosion resistance and mechanical performance of poly(arylene ether nitrile) coating. Surf Coat Technol 432:128058. https://doi.org/10.1016/j.surfcoat.2021.128058

Mao T, Li C, Mao F et al (2022) A durable anti-corrosion superhydrophobic coating based on carbon nanotubes and SiO2 aerogel for superior protection for Q235 steel. Diam Relat Mater 129:109370. https://doi.org/10.1016/j.diamond.2022.109370

Hosseinpour A, Rezaei Abadchi M, Mirzaee M, Tabar FA, Ramezanzadeh B (2021) Recent advances and future perspectives for carbon nanostructures reinforced organic coating for anti-corrosion application. Surf Interfaces 23:100994. https://doi.org/10.1016/j.surfin.2021.100994

Yan D, Zhang Z, Zhang W et al (2022) Smart self-healing coating based on the highly dispersed silica/carbon nanotube nanomaterial for corrosion protection of steel. Prog Org Coat 164:106694. https://doi.org/10.1016/j.porgcoat.2021.106694

Islam A, Pandey KK, Singh P et al (2022) Microstructural, mechanical and tribological properties of carbon nanotubes reinforced plasma sprayed molybdenum disulphide composite coatings. Ceram Int 48:32757–32766. https://doi.org/10.1016/j.ceramint.2022.07.200

Han B, Chen Y, Tan C et al (2022) Microstructure and wear behavior of laser clad interstitial CoCrFeNi high entropy alloy coating reinforced by carbon nanotubes. Surf Coat Technol 434:128241. https://doi.org/10.1016/j.surfcoat.2022.128241

Gu Y, Ma L, Yan M et al (2022) Strategies for improving friction behavior based on carbon nanotube additive materials. Tribol Int 176:107875. https://doi.org/10.1016/j.triboint.2022.107875

Zhu Z, Kang S, Chen H et al (2022) Construction of superhydrophobic alkyl siloxane-modified carbon nanotubes/epoxy coating. Diam Relat Mater 129:109351. https://doi.org/10.1016/j.diamond.2022.109351

Ma Y, Zhang J, Zhu G et al (2022) Robust photothermal self-healing superhydrophobic coating based on carbon nanosphere/carbon nanotube composite. Mater Des 221:110897. https://doi.org/10.1016/j.matdes.2022.110897

Zhang X, Mo Z, Arenal R et al (2023) Efficient oil-water separation by a robust superhydrophobic coating prepared directly from commercial lacquer using silanized multi-walled carbon nanotubes as filler. Appl Surf Sci 609:155208. https://doi.org/10.1016/j.apsusc.2022.155208

Liu Y, Shao Y, Wang Y, Wang J (2022) An abrasion-resistant, photothermal, superhydrophobic anti-icing coating prepared by polysiloxane-modified carbon nanotubes and fluorine-silicone resin. Colloids Surf A 648:129335. https://doi.org/10.1016/j.colsurfa.2022.129335

Liu N, Guo L, Kou G et al (2022) Carbon nanotube reinforced pyrocarbon matrix composites with high coefficient of thermal expansion for self-adapting ultra-high-temperature ceramic coatings. Ceram Int 48:15668–15676. https://doi.org/10.1016/j.ceramint.2022.02.101

Hu L, Kang Z (2021) Enhanced flexible polypropylene fabric with silver/magnetic carbon nanotubes coatings for electromagnetic interference shielding. Appl Surf Sci 568:150845. https://doi.org/10.1016/j.apsusc.2021.150845

Chen C, Xiao G, Zhong F et al (2022) Synergistic effect of carbon nanotubes bonded graphene oxide to enhance the flame retardant performance of waterborne intumescent epoxy coatings. Prog Org Coat 162:106598. https://doi.org/10.1016/j.porgcoat.2021.106598

Chen C, Xiao G, Zhong F et al (2022) Dendritic-hydroxyzinc stannate loaded carbon nanotubes for enhancing flame retardancy of composite coatings. Colloids Surf A Physicochem Eng Asp 648:129329. https://doi.org/10.1016/j.colsurfa.2022.129329

Zhan W, Ni L, Gu Z et al (2021) The influences of graphene and carbon nanotubes on properties of waterborne intumescent fire resistive coating. Powder Technol 385:572–579. https://doi.org/10.1016/j.powtec.2021.03.018

Agasti N, Gautam V, Priyanka N et al (2022) Carbon nanotube based magnetic composites for decontamination of organic chemical pollutants in water: a review. Appl Surf Sci Adv 10:100270. https://doi.org/10.1016/j.apsadv.2022.100270

Lin WT, Lin ZW, Kuo TY et al (2022) Mechanical and biological properties of atmospheric plasma-sprayed carbon nanotube-reinforced tantalum pentoxide composite coatings on Ti6Al4V alloy. Surf Coat Technol 437:128356. https://doi.org/10.1016/j.surfcoat.2022.128356

Cha JH, Jang WH, Noh JE et al (2022) A space stealth and cosmic radiation shielding composite: polydopamine-coating and multi-walled carbon nanotube grafting onto an ultra-high-molecular-weight polyethylene/hydrogen-rich benzoxazine composite. Compos Sci Technol 230:109711. https://doi.org/10.1016/j.compscitech.2022.109711

Wang F, Zhao S, Jiang Q et al (2022) Advanced functional carbon nanotube fibers from preparation to application. Cell Rep Phys Sci 3:100989. https://doi.org/10.1016/j.xcrp.2022.100989

Dong Z, Sun B, Zhu H et al (2021) A review of aligned carbon nanotube arrays and carbon/carbon composites: fabrication, thermal conduction properties and applications in thermal management. New Carbon Mater 36:873–892. https://doi.org/10.1016/S1872-5805(21)60090-2

Shahzad N, Lutfullah PT et al (2022) Counter electrode materials based on carbon nanotubes for dye-sensitized solar cells. Renew Sustain Energy Rev 159:112196. https://doi.org/10.1016/j.rser.2022.112196

Xia Y, Zhu X, Qiu P et al (2022) Nano-confinement coating strategy derived Matryoshka-like carbon nanotubes@anatase nanocrystalline@amorphous carbon nanofibers for ultrafast sodium ion storage. Electrochim Acta 428:140941. https://doi.org/10.1016/j.electacta.2022.140941

Zakaria MR, Omar MF, Zainol Abidin MS et al (2022) Recent progress in the three-dimensional structure of graphene-carbon nanotubes hybrid and their supercapacitor and high-performance battery applications. Compos Part 154:106756. https://doi.org/10.1016/j.compositesa.2021.106756

Khan N, Han G, Mazari SA (2022) Carbon nanotubes-based anode materials for potassium ion batteries: a review. J Electroanal Chem 907:116051. https://doi.org/10.1016/j.jelechem.2022.116051

Jyoti J, Gupta TK, Singh BP et al (2022) Recent advancement in three dimensional graphene-carbon nanotubes hybrid materials for energy storage and conversion applications. J Energy Storage 50:104235. https://doi.org/10.1016/j.est.2022.104235

Afsarimanesh N, Nag A, Eshrat e Alahi M et al (2022) A critical review of the recent progress on carbon nanotubes-based nanogenerators. Sens Actuators A 344:113743. https://doi.org/10.1016/j.sna.2022.113743

Tran PA, Zhang L, Webster TJ (2009) Carbon nanofibers and carbon nanotubes in regenerative medicine. Adv Drug Deliv Rev 61:1097–1114. https://doi.org/10.1016/j.addr.2009.07.010

Raphey VR, Henna TK, Nivitha KP et al (2019) Advanced biomedical applications of carbon nanotube. Mater Sci Eng C 100:616–630. https://doi.org/10.1016/j.msec.2019.03.043

Liu X, Miller AL, Park S et al (2017) Functionalized carbon nanotube and graphene oxide embedded electrically conductive hydrogel synergistically stimulates nerve cell differentiation. ACS Appl Mater Interfaces 9:14677–14690. https://doi.org/10.1021/acsami.7b02072

Xiang C, Zhang Y, Guo W, Liang X-J (2020) Biomimetic carbon nanotubes for neurological disease therapeutics as inherent medication. Acta Pharm Sin B 10:239–248. https://doi.org/10.1016/j.apsb.2019.11.003

Mezzasalma SA, Grassi L, Grassi M (2021) Physical and chemical properties of carbon nanotubes in view of mechanistic neuroscience investigations Some outlook from condensed matter, materials science and physical chemistry. Mater Sci Eng C 131:112480. https://doi.org/10.1016/j.msec.2021.112480

Sebaa M, Nguyen TY, Paul RK et al (2013) Graphene and carbon nanotube–graphene hybrid nanomaterials for human embryonic stem cell culture. Mater Lett 92:122–125. https://doi.org/10.1016/j.matlet.2012.10.035

Foldvari M, Bagonluri M (2008) Carbon nanotubes as functional excipients for nanomedicines: I. pharmaceutical properties. Nanomedicine 4:173–182. https://doi.org/10.1016/j.nano.2008.04.002

Murjani BO, Kadu PS, Bansod M et al (2022) Carbon nanotubes in biomedical applications: current status, promises, and challenges. Carbon Lett 32:1207–1226. https://doi.org/10.1007/s42823-022-00364-4

Anzar N, Hasan R, Tyagi M et al (2020) Carbon nanotube—a review on Synthesis, Properties and plethora of applications in the field of biomedical science. Sens Int 1:100003. https://doi.org/10.1016/j.sintl.2020.100003

Kravanja KA, Finšgar M (2022) A review of techniques for the application of bioactive coatings on metal-based implants to achieve controlled release of active ingredients. Mater Des 217:110653. https://doi.org/10.1016/j.matdes.2022.110653

Bjelić D, Finšgar M (2022) Bioactive coatings with anti-osteoclast therapeutic agents for bone implants: enhanced compliance and prolonged implant life. Pharmacol Res 176:106060. https://doi.org/10.1016/j.phrs.2022.106060

Zhao X, Chang S, Long J et al (2019) The toxicity of multi-walled carbon nanotubes (MWCNTs) to human endothelial cells: the influence of diameters of MWCNTs. Food Chem Toxicol 126:169–177. https://doi.org/10.1016/j.fct.2019.02.026

Barrejón M, Marchesan S, Alegret N, Prato M (2021) Carbon nanotubes for cardiac tissue regeneration: state of the art and perspectives. Carbon 184:641–650. https://doi.org/10.1016/j.carbon.2021.08.059

Arumugam S, Ju Y (2021) Carbon nanotubes reinforced with natural/synthetic polymers to mimic the extracellular matrices of bone—a review. Mater Today Chem 20:100420. https://doi.org/10.1016/j.mtchem.2020.100420

Zieliński A, Majkowska-Marzec B (2022) Whether carbon nanotubes are capable, promising, and safe for their application in nervous system regeneration. Some critical remarks and research strategies. Coatings 12:1643. https://doi.org/10.3390/coatings12111643

Teixeira-Santos R, Gomes M, Gomes LC, Mergulhão FJ (2021) Antimicrobial and anti-adhesive properties of carbon nanotube-based surfaces for medical applications: a systematic review. iScience 24:102001. https://doi.org/10.1016/j.isci.2020.102001

Horandghadim N, Ghazanfar-Ahari Y, Khalil-Allafi J (2022) Multiwalled-carbon nanotubes reinforced hydroxyapatite-tantalum pentoxide nanocomposite coating on Nitinol alloy: antibacterial activity and Electrochemical properties. Surf Interfaces 29:101773. https://doi.org/10.1016/j.surfin.2022.101773

Hadzhieva Z, Boccaccini AR (2022) Recent developments in electrophoretic deposition (EPD) of antibacterial coatings for biomedical applications—a review. Curr Opin Biomed Eng 21:100367. https://doi.org/10.1016/j.cobme.2021.100367

Dai B, Zhou R, Ping J et al (2022) Recent advances in carbon nanotube-based biosensors for biomolecular detection. TrAC Trends Anal Chem 154:116658. https://doi.org/10.1016/j.trac.2022.116658

Hurt RH, Monthioux M, Kane A (2006) Toxicology of carbon nanomaterials: status, trends, and perspectives on the special issue. Carbon 44:1028–1033. https://doi.org/10.1016/j.carbon.2005.12.023

Alshehri R, Ilyas AM, Hasan A et al (2016) Carbon nanotubes in biomedical applications: factors, mechanisms, and remedies of toxicity. J Med Chem 59:8149–8167. https://doi.org/10.1021/acs.jmedchem.5b01770

Kong H, Wang L, Zhu Y et al (2015) Culture medium-associated physicochemical insights on the cytotoxicity of carbon nanomaterials. Chem Res Toxicol 28:290–295. https://doi.org/10.1021/tx500477y

Kobayashi N, Izumi H, Morimoto Y (2017) Review of toxicity studies of carbon nanotubes. J Occup Health 59:394–407. https://doi.org/10.1539/joh.17-0089-RA

Gaillard C, Cellot G, Li S et al (2009) Carbon nanotubes carrying cell-adhesion peptides do not interfere with neuronal functionality. Adv Mater 21:2903–2908. https://doi.org/10.1002/adma.200900050

Abousalman-Rezvani Z, Eskandari P, Roghani-Mamaqani H, Salami-Kalajahi M (2020) Functionalization of carbon nanotubes by combination of controlled radical polymerization and “grafting to” method. Adv Colloid Interface Sci 278:102126. https://doi.org/10.1016/j.cis.2020.102126

Eskandari P, Abousalman-Rezvani Z, Roghani-Mamaqani H, Salami-Kalajahi M (2021) Polymer-functionalization of carbon nanotube by in situ conventional and controlled radical polymerizations. Adv Colloid Interface Sci 294:102471. https://doi.org/10.1016/j.cis.2021.102471

Hosseini H, Ghaffarzadeh M (2022) Surface functionalization of carbon nanotubes via plasma discharge: a review. Inorg Chem Commun 138:109276. https://doi.org/10.1016/j.inoche.2022.109276

Lavagna L, Nisticò R, Musso S, Pavese M (2021) Functionalization as a way to enhance dispersion of carbon nanotubes in matrices: a review. Mater Today Chem 20:100477. https://doi.org/10.1016/j.mtchem.2021.100477

Klein KL, Melechko AV, McKnight TE et al (2008) Surface characterization and functionalization of carbon nanofibers. J Appl Phys 103:061301. https://doi.org/10.1063/1.2840049

Asghar F, Murtaza B, Shakoor B et al (2022) Properties, assembly and characterization of carbon nanotubes: their application in water purification, environmental pollution control and biomedicines—a comprehensive review. Carbon Lett 33:275–306. https://doi.org/10.1007/s42823-022-00432-9

Banhart F (2020) Elemental carbon in the sp1 hybridization. ChemTexts 6:3. https://doi.org/10.1007/s40828-019-0098-z

Eatemadi A, Daraee H, Karimkhanloo H et al (2014) Carbon nanotubes: properties, synthesis, purification, and medical applications. Nanoscale Res Lett 9:393. https://doi.org/10.1186/1556-276X-9-393

Guler O, Bagci N (2020) A short review on mechanical properties of graphene reinforced metal matrix composites. J Mater Res Technol 9:6808–6833. https://doi.org/10.1016/J.JMRT.2020.01.077

Choudhary V, Gupt A (2011) Polymer/carbon nanotube nanocomposites. In: Silva Y (ed) Carbon nanotubes—polymer nanocomposites. InTech, pp 65–90. ISBN: 978-953-307-498-6. http://www.intechopen.com/books/carbon-nanotubes-polymer-nanocomposites/polymer-carbon-nanotube-nanocomposites. Accessed Sept 2023

Cai Shen H, Brozena A, Wang YuHuang (2011) Double-walled carbon nanotubes: challenges and opportunities. Nanoscale 3:503–518. https://doi.org/10.1039/C0NR00620C

Fonseca A, Hernadi K, Piedigrosso P et al (1998) Synthesis of single- and multi-wall carbon nanotubes over supported catalysts. Appl Phys A 67:11–22. https://doi.org/10.1007/S003390050732

Kang J, Al-Sabah S, Théo R (2020) Effect of single-walled carbon nanotubes on strength properties of cement composites. Materials 13:1305. https://doi.org/10.3390/ma13061305

Hussain A, Liao Y, Zhang Q et al (2018) Floating catalyst CVD synthesis of single walled carbon nanotubes from ethylene for high performance transparent electrodes. Nanoscale 10:9752–9759. https://doi.org/10.1039/C8NR00716K