Abstract

Rockburst, coal bump, and mine earthquake are the most important dynamic disaster phenomena in deep mining. This paper summarizes the differences and connections between rockburst, coal bumps and mine earthquakes in terms of definition, mechanism, phenomenon, evaluation index, etc. The definition and evolution progress of the three disaster categories are summarized, as well as the monitoring, early warning, and prevention measures are also presented. Firstly, by combining theoretical research with specific technologies and engineering field cases, the main categories and failure mechanisms of rockburst, coal bumps and mine earthquakes are introduced. Then, the evaluation indexes of coal bump and mine earthquake are summarized, and a new evaluation index of rockburst is given. Finally, the characteristics of monitoring, early warning technologies and prevention methods of rockburst, coal bumps, and mine earthquakes are discussed in technology and application. At last, the future directions of rockburst, coal bump and mine earthquake are put forward.

Article highlights

-

The occurrence status, phenomena, definition, types and destruction mechanism of rockburst, coal bump and mine earthquake are explained, and their differences and connections are also discussed.

-

The corresponding evaluation index of rockburst, coal bump and mine earthquake are summarized, and the monitoring and early warning technology of dynamic disasters are reviewed.

-

Prevention and control technologies in high-stress environments are explored, and stress relief and energy absorbing support technologies in engineering are systematically summarized.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

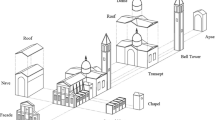

With the development of earth sciences, people are more and more aware that deep underground construction is a frontier issue facing earth sciences in the twenty-first century. At the same time, geoscientists and rock mechanics experts are also committed to exploring key scientific issues such as the mechanical behavior of deep underground rocks (Xie et al. 2022a, b). In addition, the shallow mineral resources are relatively depleted across the world. In China, most of the mines have entered into deep mining. However, deep mining presents difficulties and challenges that are not found in shallow mining (Ranjith et al. 2017; Zhou et al. 2023a, b). The basic characteristics of deep mining are superimposed with other factors to create a mining challenge, as shown in Fig. 1.

Deep mining faces dynamical disasters, such as rockburst, coal bump, mine earthquake, large-scale destabilization of the goaf, roof collapses, water surges, and so on. Many scholars (Feng et al. 2017; Shukla et al. 2021; Ke et al. 2021; Zhou et al. 2021b; Kishore and Khandelwal 2022; Chen and Zhou 2023; He et al. 2023; Qiu and Zhou 2023; Jiang et al. 2017a, b; Wang et al. 2023; Wei et al. 2022; Zhou et al. 2024) have researched rockburst, coal bump and mine earthquake, and have achieved encouraging results. However, in English, rockburst and coal bump have different names. This also reflects that scholars have not reached a consensus on the understanding of rockburst and coal bumps. The number of related papers from 1949 to 2021 was counted by searching related papers on rockburst, coal bump and mine earthquake on "cnki.net" and "web of science". As shown in Fig. 2.

Due to different industry backgrounds, there are still differences in the understanding of professional terms such as rockburst and coal bump. Some scholars believe that a coal bump is a rockburst, while others believe that a coal bump and a rockburst are the same problems (Zhang et al. 2017). From previous research, it can be seen that the conditions of occurrence, mechanisms, strength, and damage phenomena of rockbursts and coal bumps are not the same. Therefore, many academics believe that rockbursts occur in hard rock and metal mines, but coal bump occur in soft rock and coal mines (Feng et al. 2017; Jiang et al. 2017a, b). This paper summarizes the progress of monitoring, early warning and prevention of dynamic disasters in deep mining, as shown in Fig. 3.

In response to the current academic disputes over the concepts of rockburst and coal bump, it has been found that there are both connections and differences between rockburst, coal bump, and mine earthquake. Therefore, this paper discusses in detail the definitions, phenomena, occurrence conditions and mechanisms, monitoring and early warning, and prevention techniques of rockburst, coal bump and mine earthquake.

2 Occurrence status of rockburst, coal bump and mine earthquake

2.1 Phenomenon and occurrence conditions of rockburst, coal bump and mine earthquake

2.1.1 Phenomenon and occurrence conditions of rockburst

Rockbursts have brought huge disasters to underground mining of tunnels and metal mines, resulting in different destruction phenomena such as deformation of surrounding rock, roadway destruction, equipment destruction and casualties. There are no obvious signs before the rockburst occurs. When it occurs, it is accompanied by various levels of sound, most of which occur at the roof and side of the roadway. Figure 4 shows a rockburst in a mine, which caused rock ejection of the roof and a large area of rock thrown.

Rockburst destruction phenomenon (Feng et al. 2017): a rock ejection of the roof, b large area rock thrown

As mining depths increase, the occurrence of rockbursts under high-stress conditions becomes more serious. Rockbursts were first reported from a tin mine in England in the early eighteenth century (Askaripour et al. 2022). At the Kolar Gold Fields Mine in India, a rockburst destroyed surface buildings within 2 to 3 km (Lee et al. 2004). The energy generated by a large rockburst can be reached in an earthquake of magnitude 4.5 to 5.0 on the Richter scale. More than 750 rockbursts occurred during the construction of the diversion tunnel of the Sichuan Jinping II Hydropower Station, which is the largest buried depth of 2,525 m in China. Among them, a very strong rockburst disaster caused the death of 7 construction workers and serious damage to the equipment (Shan et al. 2010). In the Sangzhuling Tunnel of the Lhasa to Linzhi section of the Sichuan-Tibet Railway, the rockburst frequency is reached up to 20 times a day, and the rockburst flies up to a distance of 40 m (Zhou et al. 2021a). At the beginning of this century, South Africa carried out efficient mining of deep 3 ~ 5 km gold mines and studied the problems of rockbursts and high temperatures induced by mining (Grodner 2001). Rockbursts of varying intensity and impact have also occurred in mines in Africa, Australia, Canada, China, Chile, Korea, Norway, Russia, Sweden, and the United States (Ahmed et al. 2017). Rockburst disasters seriously endanger the safety of personnel and equipment in mines and tunnels. In addition, it can cause major disturbance to mine development and the safe operation of tunnels. Therefore, the prevention and treatment of rockbursts are particularly important.

Hard rock and high geostress environments are prerequisites for rockburst, and excavation disturbance and unloading effects are direct causes of rockbursts. The occurrence of rockburst must meet the following conditions: First, the rock mass must have the ability to effectively accumulate strain energy, and second, it must have high initial stress to provide an energy source for the occurrence of rockburst. In addition, there needs to be a suitable external condition that can cause the release of strain energy (Feng et al. 2017). It can be seen that the rockburst phenomenon is caused by a variety of conditions. The main sources are usually related to the excavation conditions and the geological structure of the rock mass. When the roadway excavation is close to the fault zone, the excavation stress redistribution causes strain energy release from the fault zone, as shown in Fig. 5. Initial stress changes of rock mass and sliding fault induce rockburst, as shown in Fig. 5a. Rock fracture and relative deformation of the fault plane due to roadway excavation through faults induce rockburst, as shown in Fig. 5b. Excavation of the roadway along a fault-filled zone causes relative deformation of the fault plane to induce rockburst, as shown in Fig. 5c.

2.1.2 Phenomenon and occurrence conditions of coal bump

Coal bump characteristics usually refer to the ejection, sound, air wave, vibration and other behaviors caused by the sudden failure of coal and rock mass. Before the coal bump occurs, sometimes there is a small popping sound, and sometimes there is no sound. When it happened, the coal-rock mass was thrown out suddenly. In severe cases, it is accompanied by different degrees of vibration, sound and shock waves, and even huge waves are set off. After the coal bump occurs, no obvious damage or deformation occurs on the roof and floor of the coal seam. The coal mass was destroyed and thrown out as a whole. And produce obvious sliding scratches and separation between the coal seam and the roof and floor. The essence of the coal bump phenomenon is the sudden instability failure of coal and rock mass under the action of the high-stress state.

It has become a difficult problem in mining and rock mechanics because of its sudden occurrence, no signs, numerous influencing factors, and serious destruction. Since the first occurrence of coal bump in the South Stafford coalfield in the UK in 1738, most of the world's mining countries, such as the United States, China, Canada, Russia, Australia, the Czech Republic, South Africa and others, have been threatened by coal bump (He et al. 2021). In coal mines, coal bump has the characteristics of danger, suddenness, complexity and inductivity. Along with the occurrence of coal bump, it can cause other disaster phenomena such as roof watering, roof fall, gas protrusion and coal seam roof collapse (Jiang et al. 2017a, b). In the event of a severe coal bump, it can cause casualties, roadway equipment and property damage, as shown in Fig. 6.

Coal bump destruction phenomenon (Zhu et al. 2020): a destruction of the working face, b destruction of the ventilation roadway

Many scholars believe that the occurrence of coal bumps is mainly due to the increase in mining depth and intensity (Zhao et al. 2019). The relationship between coal output, mining depth and the number of coal bump mines in China over the past 70 years is shown in Fig. 7. It can be seen that with the increase in coal output and mining depth, the number of coal bump mines in China has gradually increased. However, with the development of prevention and control technology in recent years, it began to decrease in 2019.

In addition, there are other contributing factors to the occurrence of coal bumps: mining depth, hard roof fracture (Gao et al. 2020), stress construction coal body fracture (Junjun et al. 2016), fault slip (Lu et al. 2018), engineering blasting (Wojtecki et al. 2017) and mining disturbance (Ma et al. 2023), etc. The induced factors of coal bump in coal mining are shown in Fig. 8. The first and periodic weighting on hard roof and the activity of high thick strata could cause strong vibration, which leads to widespread destruction of coal-rock bodies and induces coal bump. Mining of coal seams could cause widespread deformation of the surrounding rock and rupture of the coal body, which induces coal bump. During the relative movement of a fault plane, a large amount of elastic strain energy is accumulated in the coal-rock bodies, and the zone produces a high-stress concentration phenomenon, which provides favorable conditions for coal bump. The detonation of explosives within rock strata generates potent shock waves and stress waves that propagate in all directions, which causes vibration of the rock medium or even induced coal bump. Mining disturbances cause a constant redistribution of the stress field and accumulate energy within the coal-rock body, which induces coal bump.

2.1.3 Phenomenon and occurrence conditions of mine earthquake

In the continuous exploitation of mineral resources, there are many dynamic disasters. Mine earthquake is a phenomenon of vibration caused by the release of elastic energy of rock mass due to mining disturbance. The phenomenon of mine earthquake mainly has the characteristics of extensive, vibrating and catastrophic. In coal mines, metal mines, gypsum mines, etc., as long as underground solid resources are mined, there will be mine earthquakes (Zhu et al. 2022). Moreover, the most fundamental characteristic of mine earthquake is vibration. Therefore, the vibration is also an important symbol to identify the mine earthquake. Mine earthquakes can induce dynamic disasters such as rockburst, coal bumps, coal and gas outbursts, and even cause damage to ground buildings (Lovchikov 2013).

Mine earthquake has brought great harm to mine safety production, causing damage to underground equipment and sometimes ground vibrations. In 1738, the first mining earthquake was recorded in the South Stamford Coalfield in the United Kingdom, however, the earliest mining earthquake recorded in China was in Fushun Shengli Mine in 1933 (Zhu et al. 2022). In the past hundred years, due to the increasing intensity of mineral resource extraction and the area of underground space, the phenomenon of mine earthquake has become more and more intense in countries all over the world, such as South Africa, Canada, Australia, Poland and so on (Hudyma et al. 2010). As shown in Fig. 9, the depth and energy distribution of mine earthquakes occurred in the West 1 mining area of a mine in China.

Mine earthquake source distribution in the West 1 mining area of a mine (Wang et al. 2017)

According to previous studies, the occurrence of mine earthquakes mainly meets the following conditions (Liu and Zhang 2020a, b): (1) Mine earthquakes mainly occur in mining areas with complex geological structures, large in-situ stress and significant fault activities. (2) Mining activities on the ground and underground may cause the occurrence of mine earthquakes. Smaller mine earthquakes are not felt on the ground, and larger earthquakes will trigger the ground. (3) Mine roof caving, coal seam framing, surface subsidence, rockburst, coal and gas outburst, etc. can all cause mine earthquake.

2.2 Definition and types of rockburst, coal bump and mine earthquake

2.2.1 Definition and types of rockburst

Rockburst is a sudden and violent destruction of rock. The ejection of rock fragments and the rapid release of energy have caused serious disasters in underground engineering (He et al. 2023). Rockburst is characterized by suddenness, dynamic rock rupture and ejection, and rapid energy release. Rockburst has become a common concern of deep underground engineering at home and abroad (Askaripour et al. 2022; Du et al. 2016). Rockburst can be divided into different types according to their different manifestations, such as occurrence mechanism, structural characteristics, occurrence source, time, failure form, etc. (Askaripour et al. 2022; Feng et al. 2017). Considering the geological conditions, common rockburst occur mainly in geological fault zones and rock mass structural surfaces (Table 1). The rockburst is usually classified as a fault-slip type, pillar type, and strain type (Huang et al. 2017). Considering the characteristics of the rock mass structural surface, rockburst is divided into buckling type, shear type, collapse type, and extrusion type (He et al. 2023). In addition, many scholars have divided the types of rockburst from different perspectives, and have achieved wide recognition, as shown in Table 2.

2.2.2 Definition and types of coal bump

Coal bump is a dynamic disaster phenomenon in which the elastic deformation energy accumulated in the surrounding rock of the project is suddenly released by the excavation of underground rock mass or other external disturbances, resulting in severe damage (Jiang et al. 2017a, b). In the coal industry, this kind of dynamic disaster is usually called a coal bump, which is often accompanied by coal, rock mass throwing, loud noises and air waves, etc. It is extremely destructive and seriously threatens mine safety and efficient production. Considering the stress state, coal bump is a nonlinear dynamic process from steady-state energy accumulation to unsteady state energy release of the coal-rock mass, as well as a comprehensive response to the external loading environment and the mechanical properties of coal-rock mass (Jiang et al. 2015).

Due to the complex disaster-producing conditions of coal bump, numerous disaster-causing factors, different manifestation characteristics, and highly random spatial and temporal distribution characteristics of impact, there are many types of coal bump. Many scholars have proposed a large number of coal bump classification methods from different perspectives (He et al. 2023; Qian 2014a, b; Zhu et al. 2020). This paper summarizes the existing classification methods from the aspects of stress conditions, energy release characteristics and impact failure characteristics of coal-rock mass, as shown in Fig. 10.

2.2.3 Definition and types of mine earthquake

Mine earthquake is a kind of induced earthquake. Different from natural earthquakes and earthquakes induced by water injection, mining earthquakes are caused by rock mass fractures caused by large-area rock mass excavation (Kang et al. 2019). Mine earthquakes are accompanied by the rapid release of a large amount of elastic energy, which is transmitted out of the rock mass in the form of shock waves. Mine earthquakes can easily induce secondary disasters, posing a huge threat to underground engineering structures, ground structures and the safety of people's lives and property. Mine earthquakes are unnatural earthquakes that accompany human activities. Mine earthquakes account for a large proportion of unnatural earthquakes (Foulger et al. 2018; Wang et al. 2023). As of 2021, the proportion of global unnatural earthquake types is shown in Fig. 11.

At present, scholars have carried out a lot of research according to the types and characteristics of mine earthquakes. Mine earthquakes are divided into three types: mining fracture type, huge overburden type and high-energy vibration type(Dou et al. 2021a, b). Scholars called a mine earthquake with a magnitude greater than 0.5, maximum amplitude greater than 30 mm, and rock throwing volume greater than 1 ton as strong mine earthquake, and vice versa as a slight mine earthquake (Lovchikov 2013). On this basis, many scholars have classified mine earthquakes. It is mainly based on seismic phase characteristics, rock mass failure form, surrounding rock structure and stress characteristics, basic failure form, catastrophic nature, occurrence location, and comprehensive analysis methods(Horner et al. 1978; Dou et al. 2021a, b; Pan et al. 2012; Zhu et al. 2022). As shown in Fig. 12.

2.3 Destruction mechanism of rockburst, coal bump and mine earthquake

2.3.1 Destruction mechanism of rockburst

The rockburst usually goes through three processes: energy release, accumulation, and re-release (He et al. 2023; Qian 2014a, b). In the first stage of energy release, the elastic strain energy of the rock mass in the disturbance zone outside the roadway excavation damage zone is released. In the second stage of energy accumulation, the stress of the surrounding rock in the loose area and the damaged area is concentrated, and the internal cracks in the rock are first closed, then elastically deformed, and finally, cracks are generated. The process is accompanied by an obvious acoustic emission phenomenon. In the third stage of energy release, the fissures of the rock mass in the loosening area first expand steadily, then the crack penetrates, and finally, the detachment and ejection of the rock blocks are separated.

In recent years, v and rockburst tendency theory of rockburst mechanism has also been developed (Ma et al. 2018). These theories together with the strength, stiffness and energy theories constitute the theoretical system of the rockburst mechanism. According to the division of rockburst, common rockburst styles are mainly divided into strain rockburst, pillar rockburst, and fault-slip rockburst. The combined effect of the three rockburst potentials and the confinement effect is shown in Fig. 13a. Strain rockburst is caused by local stress concentration and elastic strain energy accumulation in the surrounding rock after excavation. The surrounding rock has experienced processes such as vertical slabbing, yield deformation, and rock ejection, as shown in Fig. 13b. The pillar type is the violent destruction of the pillar core or the complete collapse of the pillar caused by stress concentration, as shown in Fig. 13c. The volume of pillar-type damaged rock and affected surrounding rock is usually larger than that of strain-type. The fault-slip type is caused by dynamic sliding along the existing fault plane. Its shear stress exceeds the shear strength. Slip occurs when its degree of freedom changes, as shown in Fig. 13d. These types of rockburst usually occur in mining operations, and the geotechnical tunnels are commonly strain rockburst.

A structural rockburst is the result of the interaction between the original joint cracks and new cracks in the rock mass under stress disturbance (Li et al. 2017). The existence of structural surfaces has a significant effect on the scope and strength of rockbursts. The buckling type often occurs in vertical bedding, and the slabbing failure occurs due to high horizontal stress, as shown in Fig. 14a. The shear type is a phenomenon in which the rock mass is sheared along the structural plane under high stress, resulting in the ejection of broken rock, as shown in Fig. 14b. In the extrusion type, the rock mass is subject to tangential stress concentration, which causes the rock to eject along the structural plane, as shown in Fig. 14c. The collapse type is a failure phenomenon in which rock mass collapses along the structural plane under stress disturbance, as shown in Fig. 14d. Therefore, investigation and analysis of rock mass structural plane and optimization of excavation plans are the primary measures to prevent deep structural rockburst.

2.3.2 Destruction mechanism of coal bump

Scholars have done a lot of research on the mechanism of coal bumps, and have formed many theories (Askaripour et al. 2022; Linkov 1979). For example, the energy criterion, stiffness criterion, strength criterion, impact tendency theory, stick–slip instability theory, etc., provide a theoretical basis for the study of coal bumps.

Before stress disturbance, the coal-rock mass is a relatively balanced system. Once disturbed, the fractured area of the coal-rock mass increases (Dou et al. 2021a, b). If the broken zone is unstable, the limit equilibrium zone moves into the depth of rock mass and produces stress peaks. As the broken zone becomes unstable and destressed, the stress peaks move deeper into the rock mass and decrease. The original rock stress is also transferred deeper into the rock mass. At this point, the rock mass in the limit equilibrium zone loses its lateral restraint, causing the roof and floor to lose their original balancing force. Therefore, impact failure occurs in the coal-rock mass. As shown in Fig. 15.

The material instability type is that during the roadway excavation process, cracks development of coal-rock mass and reach the limit strength of coal-rock mass, resulting in ejection failure, as shown in Fig. 16a. The slip dislocation type is caused by the difference in stiffness between the roof and floor and the coal under the influence of mining, resulting in slip and extrusion of the coal seam, as shown in Fig. 16b. Structural instability type means that mining induces huge elastic energy release near the structural area, resulting in large-area impact outbursts of coal pillars or roadway surrounding rocks, as shown in Fig. 16c.

2.3.3 Destruction mechanism of mine earthquake

Mine earthquake is the sudden release of elastic energy that produces obvious vibration and sound when rock mass is damaged dynamically. When the mine earthquake energy is small, coal dust is generated in the mining space. When the energy is moderate, the rock mass sloshes slightly. When the energy is large, it leads to the destruction of the rock mass, and the resulting high-stress accumulation causes different degrees of damage to the working face. When a strong mine earthquake occurs, disasters such as coal bumps are induced. It even leads to ground shaking, surface collapse, damage to buildings and other hazards, which may easily cause casualties (Foulger et al. 2018). The source mechanisms of earthquakes and mine earthquakes are different. The source mechanism in seismology is assumed to be a single form of shear damage, whereas the source mechanism in mine earthquakes is complex. According to the mine earthquake destruction mechanism, the common mine earthquake damage factors include goaf roof caving, pillar collapse, tension fracture, normal fault, reverse fault and near-horizontal subduction fault, as shown in Fig. 17. Therefore, mining depth, faults, folds, pillars, hard roofs and mining speed are important factors that affect the frequency and energy of mine earthquakes.

Schematic diagram of mine earthquake damage types (Horner et al. 1978). a Roof caving in goaf. b pillar damage. c tension fracture. d normal fault. e reverse fault. f near-horizontal subduction fault

2.4 Differences and connections between rockburst, coal bump, and mine earthquake

Rockburst, coal bump and mine earthquake have obvious boundaries and differences, but they also have connections and common features. The main feature of mine earthquake is the seismic events that occur in mining engineering, while the main feature of rockburst and coal bumps is the destructiveness and catastrophic nature of the mining space. This paper summarizes the various features, phenomena and inducing factors of rockbursts, coal bump and mine earthquake. Rockburst, coal bump and mine earthquakes have both differences and connections, as shown in Fig. 18. (σ1 is max main stress; σc is uniaxial compressive strength).

According to the characteristics and appearances of rockburst, coal bump and mine earthquake, there are differences in 5 aspects (Liu et al. 2020a, b; Ranjith et al. 2017; Waqar et al. 2023): (1) In terms of the damage characteristics of coal and rock mass, rockburst and coal bump are dynamic phenomena caused by the ejection of coal and rock mass, while coal and rock ejection does not occur in mine earthquake. The rock damage caused by rockburst is a mainly flaky ejection, accompanied by sound. Rock damage caused by coal bumps has the characteristics of coal throwing, loud noise and air waves. (2) In terms of stress release, coal bump and mine earthquake are instantaneously released by elastic deformation energy, and mine earthquake is generated by the large-scale release of energy underground. The rockburst is the relaxation failure of the surrounding rock surface caused by stress release. (3) In terms of occurrence medium, coal bump occurs in coal mines with relatively soft rock mass, rockburst occurs in tunnelling or metal mine mining with hard rock mass, and mine earthquake occurs in both coal and metal mining. (4) In terms of damage appearance, the damage caused by coal bump is relatively large, and the coal-rock mass is damaged over a large area with a wide range of influence. The damage caused by rockburst is local destruction of rock mass, the damage intensity is large, but the impact range is small. Mine earthquake has the widest impact. In most cases, the vibration is small and causes little or no damage. However, in severe cases, it causes ground vibration, collapse and damage to buildings and casualties in the wells. (5) In terms of occurrence location, the source of coal bump and mine earthquake are deep in the coal-rock mass, while the source of rockburst is in the shallow part of the surrounding rock. Both rockburst and coal bumps occurred near the stress release site. The mine earthquake is caused by the stress disturbance, but it does not necessarily occur at the stress disturbance.

The connection between rockburst, coal bump and mine earthquake (Qian 2014a, b; Qi et al. 2020a, b; Zhu et al. 2022, 2020): (1) All are in an environment of high in-situ stress. When excavating coal and rock mass, the stress of surrounding rock is released instantaneously, accompanied by the vibration phenomenon of sound and shock waves. All these phenomena produce a certain degree of disaster, affecting the safe operation. (2) All are phenomena that occur in underground engineering. Mine earthquake is induced by the large-scale release of surrounding rock stress during the mining process of coal and metal mines. (3) When a mine earthquake occurs, coal bump or rockburst can be induced. On the contrary, coal bumps or rockburst can also induce mine earthquakes.

The generation of coal bump and rockburst is inseparable from the surrounding rock stress field and the mechanical parameters of coal and rock mass. The depth, lithology, maximum principal stress and compressive strength of rockburst locations in some areas were also calculated. The relationship between rockburst and coal bump and maximum main stress, uniaxial compressive strength and depth, As shown in Fig. 19.

3 Evaluation index of rockburst, coal bump and mine earthquake

3.1 Evaluation index of rockburst

Rockburst grade is an index describing the intensity and damage scale of rockburst. Hard rock impact propensity evaluation indexes and classification criteria are an important basis for predicting rockburst in underground mines and tunnels. Many scholars have conducted relevant studies through various research methods. However, the typical method is to study the rockburst propensity index through indoor tests. Scholars have determined the indoor evaluation index of rockburst tendency through a large number of indoor experiments (Du et al. 2023a, b; Du et al. 2021; Du et al. 2023a, b). The rockburst tendency indoor indicators include peak strain energy storage index WETP, post-peak stress reduction rate index SDR, residual elastic index AEF, and brittle index B. Rockburst tendency can be classified as none, weak, medium and strong, as shown in Table 2.

3.2 Evaluation index of coal bump

According to the existing Chinese standard coal impact propensity evaluation index contains dynamic failure time DT, elastic energy index WET, impact energy index KE, uniaxial compressive strength RC, residual energy index WRE and so on (Gong et al. 2022). On this basis, scholars have also successively proposed corresponding evaluation indexes from other perspectives (Chen 2019; Jiang et al. 2017a; Pan et al. 2010). For example, a ratio of base stress to strength Ic, elastic energy index WET, support impact resistance S, impact danger index U, impact energy velocity index WST, shock hazard index CW, coal burst hazard index T, and so on. These evaluation indexes provide reliable parameters for the study of coal bump, as shown in Table 3.

3.3 Evaluation index of mine earthquake

Whether or not a mine earthquake causes damage underground depends on the energy level of the mine earthquake and its location relative to the mining field. Not all high-energy mine earthquakes induce mining disasters such as coal bump and rockburst. Scholars have classified mine earthquake grades, as shown in Table 4.

4 Monitoring of rockburst, coal bump and mine earthquake

After years of development, a variety of monitoring methods have been formed for different dynamic disasters in the deep (Feng et al. 2017; Zhang et al. 2021a, b). Different monitoring equipment and methods have appeared due to different geological structures and stress environments. Usually, in order to improve the accuracy of monitoring, multiple monitoring methods can be used for comprehensive monitoring.

4.1 Monitoring of rockburst

Accurate and real-time monitoring is an important goal in the study of rockburst monitoring. At present, scholars have studied a variety of available monitoring instruments and equipment to monitor rockburst (Zhang et al. 2021a, b). Methods of on-site monitoring include microseismic method, geophysical forecasting method, rheological method, photoelastic method, seismic wave prediction method, infrared thermal imaging test method, microgravity method, moisture method and so on (Lin et al. 2022; Ma et al. 2022; Shi-Hang et al. 2012; Sun et al. 2016; Zhang et al. 2021a, b; Zhao et al. 2022). The microseismic method has more real-time monitoring and accuracy than other conventional monitoring methods and is adapted to deep hard rock stability monitoring. Therefore, it is widely used in the field of mining, tunneling and large-scale structural stability monitoring. Common rockburst monitoring methods are summarized in Fig. 20.

4.2 Monitoring of coal bump

The monitoring objectives and principles can be divided into two categories: the direct contact monitoring method and the geophysical method (He et al. 2019; Jiang et al. 2015). Direct contact monitoring methods include the drilling cuttings method, borehole stress measurement method, roof dynamic method, mine pressure observation method, support load method, surrounding rock deformation measurement method, etc. (Kang et al. 2023; Qin et al. 2018; Tian et al. 2014). It mainly monitors the deformation and stress of surrounding rock before a rockburst occurs. The geophysical method is mainly based on the elastic waves, geo-sound, electromagnetic waves and other signals released when the coal and rock are damaged (Jiang et al. 2017a, b; Lu et al. 2017; Whiteley et al. 2019). By capturing these signals, it is a non-contact and remote monitoring method. Geophysical methods mainly include electromagnetic radiation method, microseismic method, geo-sound method, seismic CT technology, charge induction monitoring, etc. The monitoring method and early warning system of coal bump are shown in Fig. 21.

At present, coal bump monitoring technology has achieved good application and development. But in general, the monitoring and early warning technology of coal bumps are still immature, and it relies on personnel operating instruments and equipment to carry out the prediction and early warning work. Moreover, the organic combination of coal bump catastrophic mechanism is not yet close. In the future, it is necessary to develop unmanned, intelligent, and information-based coal mine coal bump monitoring and early warning technology.

4.3 Monitoring of mine earthquake

Monitoring of the mine earthquake phenomenon is also an important part of the prevention of dynamic disasters. At present, the research on monitoring of mine earthquake dynamic phenomenon has also made some progress, and the research mainly focuses on the monitoring technology, algorithm, system platform and other aspects of mine earthquake dynamic phenomenon (Teodosio et al. 2022). At present, the research on the focal mechanical parameter system for mine earthquakes is relatively scarce. In recent years, the mine earthquake monitoring system at home and abroad has been gradually improved, the monitoring technology has made great progress, and the monitoring accuracy has been greatly improved. Table 5 shows the development history of mine earthquake monitoring technology at home and abroad.

5 Prevention and control of rock burst, coal bump and mine earthquake

There are three main methods for preventing rockburst, impact pressure and mine quake: one is to optimize the mining method, such as mining process optimization and pillar-less mining. The second is the use of stress relief measures, such as the blasting roofing method, large hole stress relief method, and hydraulic fracturing method. Third, optimize the support method, increase the support strength, and improve the impact resistance of the support structure.

5.1 Stress relief technology of rockburst, coal bump and mine earthquake

Stress relief mining uses the transfer principle to transfer the local high in-situ stress to the surrounding or deep surrounding rock through certain stress relief measures to improve the stress distribution state of the rock mass. And reduce the stress in the excavation area to ensure the safe operation of deep mining or tunnel excavation (Yan et al. 2015). With the development of deep mines and engineering tunnels, dynamic disasters have become increasingly prominent, and the surrounding rock in the disturbance zone is severely broken (Xie et al. 2022a, b). Pressure relief is to improve the stress and energy distribution in the local surrounding rock through certain technical means, and to reduce the occurrence of rock mass instability in deep mines and engineering tunnels. A schematic diagram of the tunnel excavation stress relief principle is shown in Fig. 22. Currently, the common methods applied in mines include roof cutting, blasting, hydraulic fracturing, large-diameter drilling and other stress relief methods. The main purpose is to reduce the integrity of the rock mass, block stress transfer and release high stress.

Schematic of the tunnel excavation stress relief principle (Yan et al. 2015)

5.1.1 Roof cutting stress relief

In coal mines, stress relief techniques are usually used to relieve pressure by cutting the roof. The purpose of stress relief is to reduce the stress concentration in the roadway or the rock mass to release the high stress, transfer the high stress to the inside of the rock mass, and maintain the safety and stability of the roadway (Sun et al. 2022). The roof-cutting stress relief is mainly to change the roof structure of the coal strata through manual intervention. Using the current roof-cutting technology, the stress transfer between the rock masses is cut off. Typically, Typically, after a coal seam is mined, a large area of hard roof overhang occurs. At this time, the coal pillar provides the fulcrum for the cantilever of a roof, and a large stress will be generated above the roadway, deforming the roadway and coal pillar. Cutting off the stress transfer from the roof, the stress will be transferred to the inside of the rock mass, reducing the stress above the roadway, as shown in Fig. 23.

Schematic diagram of rock formations before and after roof cutting (Sun et al. 2022). a Schematic diagram of the strata before roof cutting. b Schematic diagram of the rock stratum after roof cutting

5.1.2 Blasting stress relief

Blasting stress relief is to use the shock wave generated by the explosion of explosives to break the rock mass and generate cracks. A weak band eventually forms around the blast hole, freeing up space for high stress (Yan et al. 2015). The blast shock wave is a strong dynamic compression wave. When explosives explode, high-pressure, high-density gas is produced in a short period of time. It also impacts the rock mass around the blast hole and propagates in the form of shock waves, tearing the surrounding rock mass. The principle of blasting pressure relief, As shown in Fig. 24.

Blasting stress relief has strong adaptability to geological conditions, easy operation and remarkable stress relief effect. At present, blasting stress relief is used as a local relief measure for stress relief during excavation. However, because the selection of blasting stress relief parameters depends on the determination of the stress release position, the parameter design mostly depends on engineering experience and lacks the theoretical guidance of deep rock blasting. Combining with the principle of zonal fracturing of deep rock mass, Kang (Kang et al. 2021) proposed a safe and efficient advanced deep hole zonal blasting stress relief technology for areas with strong rockburst. According to the zonal fracture phenomenon in the deep rock mass, the blast holes for zonal blasting and stress relief are arranged, as shown in Fig. 25.

Zone blasting and stress relief blast hole arrangement (Kang et al. 2021)

5.1.3 Hydraulic fracturing technology

The main purpose of hydraulic fracturing technology is to weaken the overall strength of rock mass (He et al. 2016). Hydraulic fracturing technology pressurises water into a high-stress fracturing medium and injects it into the original rock mass. When the water pressure of the high-stress fracturing medium reaches the fracture initiation stress of the rock mass, the internal fractures of the rock mass expand and increase, and the strength decreases. At the same time, the initial stress of rock mass will be redistributed, forming an overall stress relief zone in the high-stress fracturing area. At present, directional hydraulic fracturing has been widely used in different types of projects and achieved good results.

Drilling a hole in the upper part of the roadway to the middle of the hard roof, and putting the hydraulic fracturing device into the hole. There is a directional slitting device at the end of the hydraulic device, and a hole sealer is used to seal the drill hole near the slitting device to prevent water leakage. In the process of hydraulic fracturing, through high-pressure water injection, the fracture-causing surface is cut at the slotting device. Arrange multiple hydraulic fracturing boreholes in a roadway, and directional cutting can generate a through fracturing surface. Finally, the integrity of the rock mass is cut off and the stress concentration of the rock mass is reduced. As shown in Fig. 26.

Schematic diagram of hydraulic fracturing (Sun et al. 2022)

5.1.4 Large-diameter drilling hole

Large-diameter drilling stress relief technology is one of the commonly used control methods in deep underground engineering. Drilling holes into the rock mass in the high-stress area provides a release space for the high stress, to achieve the purpose of stress relief (Hao et al. 2021). When the surrounding rock is disturbed by stress, the deformation of the surrounding rock mass is mainly realized by compressing the large-diameter drilling hole space. It is a drilling hole with a diameter of not less than 95 mm driven by a drilling hole in the rock mass. Realize the destruction and softening of the rock mass, and form an effective stress release space. Therefore, the high-stress concentration in the coal-rock mass is reduced or transferred and the process is simple and the operation is convenient. As shown in Fig. 27.

After the large-diameter drilling hole is carried out in the high-stress area, the deformation and failure process of the surrounding rock of the drilling can be divided into two stages (Xu 2021). In the first stage, the surrounding rock begins to deform and fail after drilling. The drilling hole is compressed and the drilling hole area is reduced. The compression zone is divided into fracture zone, plastic zone and elastic zone from inside to outside. The stress relief effect is mainly in the fracture zone. In the second stage, the deformation of the plastic zone and the fracture zone around the drilling hole increases with time. Its strength is further reduced when its bearing capacity is less than the surrounding rock stress. The drilling hole collapsed and gradually filled the free space of the drilling hole, and at the same time produced a certain support force on the boundary of the new fracture zone. When the supporting force in the slump zone is equal to the stress in the fracture zone, the force in the drilling hole area is balanced. The large-diameter stress relief hole completed the stress relief in the first stage. In the second stage, the stress reached a new equilibrium, and its equilibrium stress was the lowest stress after stress relief. As shown in Fig. 28.

Partition of failure state of surrounding rock of large-diameter drilling holes (Xu 2021)

5.2 Support technology of rockburst, coal bump and mine earthquake

One of the effective measures to prevent and control deep power disasters by tunnel enclosure control technology is the focus of research by scholars at home and abroad. Since the development of the New Austrian Method (NATM) in the 1960s, surrounding rock control technology has matured (Aygar 2020). Nowadays, energy-absorbing support techniques have been developed to prevent and control the dynamic loading of the surrounding rock. Gao (Gao et al. 2008) established a 3S structural mechanics model based on the impact effect of stress waves for the anti-scour and anti-seismic effect of the surrounding rock of the roadway. Feng (Feng et al. 2010) established a model of "surrounding rock, energy-absorbing material, steel support" based on the action principle of energy-absorbing coupling support.

Energy-absorbing support is an important support method to control the stability of the surrounding rock mass of the roadway under dynamic shock conditions such as deep rockburst, coal bumps and mine earthquake. With the use of energy-absorbing support, the high elastic energy accumulated in the rock mass is released slowly, and the high-stress rock mass is maintained in low energy storage, slow deformation of the stable state, which can effectively resist the reciprocating impact of the dynamic disaster. It is widely used for stability control of rockbursts, coal bump and mine earthquakes brought about by deep engineering.

Energy-absorbing structures are an important part of energy-absorbing support technology. Some scholars have studied the support structure, but the previous support structure cannot resist the dynamic impact of surrounding rock in a deep high-stress environment. In this paper, the impact damage site of the support structure in a Chinese mine was investigated, as shown in Fig. 29. In this background, many new types of energy-absorbing bolts appeared. The energy-absorbing bolt has high constant resistance and large deformation capacity. On the one hand, it can improve the mechanical state of the surrounding rock itself and increase the strength of the surrounding rock. On the other hand, the deformation energy of the energy-absorbing rock mass releases the energy in the surrounding rock. Therefore, it is necessary to develop energy-absorbing bolts with high constant resistance, high elongation and high prestress. Many scholars have done a lot of work on the research of energy-absorbing bolts, and have achieved fruitful research results (Wu et al. 2021). Since the emergence of energy-absorbing bolts in the 1980s, many scholars have continued to optimize and innovate energy-absorbing bolts, and have achieved a series of results (Du et al. 2022). Table 6 shows the development of some energy-absorbing bolts.

In this paper, based on the principle of energy-absorbing bolts operation, the energy-absorbing curve is schematically drawn, as shown in Fig. 30. When the energy-absorbing bolt is subjected to a strong impact load, the energy-absorbing sleeve first absorbs some of the energy. With the increase of load, reaching point A, the energy-absorbing device acts as a cushion and the elongation rate increases. Until point B, the energy-absorbing load of the energy-absorbing anchor reaches its limit and the elongation reaches its maximum value.

The development of energy-absorbing bolts has effectively improved the damage to the surrounding rock by dynamic disasters. In the future, underground engineering will gradually transfer to deeper parts, and it is also necessary to solve the dynamic support technology of surrounding rock in complex environments.

6 Future work

-

1.

At present, rockburst, coal bumps and mine earthquake monitoring and early warning technologies have achieved good application and development. But in general, monitoring and early warning technology are still immature, relying on personnel to operate instruments and equipment to carry out the forecast and early warning work. In the future, unmanned, intelligent and information-based monitoring and early warning technology must be developed.

-

2.

The biggest hazard of rockburst, coal bumps and mine earthquakes is to threaten the personal safety of construction workers during their operations. The key to solving the security threat to personnel is to use large-scale mechanized and intelligent construction to reduce manpower and unmanned construction.

-

3.

At present, the monitoring and prevention technologies of rockburst, coal bump and mine shock are not matched. The occurrence mechanism, monitoring, and prevention should be combined, and monitoring techniques for a certain mechanism should be proposed, as well as later prevention measures. Analyze the process of disaster events, extend the mechanism research to prevention, and develop early warning equipment and prevention methods from the perspective of disaster occurrence mechanisms.

-

4.

Rockburst, coal bump and mine earthquakes are the most prone mining disasters in deep mines. Energy-absorbing bolts and pressure relief technology play a key role in controlling rockburst, coal bumps and mine earthquakes. Research and develop effective mine dynamic support system, research efficient and convenient hard roof pre-splitting or cutting technology. It can provide technical support for safe and efficient mining in deep mines. And prevention research should rely on emerging technologies such as artificial intelligence, big data, and cloud computing. Improve the intelligence and precision level of monitoring, early warning and prevention, and realize safe and green production of mineral resources.

-

5.

At present, the knowledge literacy of management talents in mining enterprises is backward. Strengthen the technical management of the mine, cultivate high-tech talents, and improve the laws and regulations related to the mine.

7 Conclusions

Rockburst, coal bump and mine earthquakes are the three major dynamic disasters existing in underground engineering. There are both differences and connections between the three. This paper gives a detailed overview of the definition, connection, occurrence mechanism, damage method, monitoring and early warning, prevention and control technology among the three. The research achievements of domestic and foreign scholars on rockburst, coal bump and mine earthquakes are summarized, as well as the existing problems that have not been solved. These three disasters will still be the problems faced by the development of underground engineering in the future.

-

1.

The definitions and influencing factors of rockburst, coal bump and mine earthquake are described in detail. Coal bump occurs in coal mines, and rockburst occur in metal mines or tunnels in hard rock. Rockburst and coal bumps can both induce mine earthquakes, and mine earthquakes can also induce rockburst and coal bumps. The occurrence conditions of the three are affected by many factors, and the main inducing methods are mining disturbance and high-stress accumulation.

-

2.

The occurrence mechanism and characteristics of rockburst, coal bump and mine earthquake are revealed. The differences and connections between the three are analyzed. The failure characteristics, stress release, occurrence medium, failure appearance and occurrence location are discussed respectively. And according to different factors, the three were classified. Typical damage mechanisms of rockburst, coal bump and mine earthquake are analyzed separately.

-

3.

The monitoring and early warning technology of rockburst, coal bump and mine earthquakes are discussed. The principle of monitoring and early warning is analyzed. At present, many monitoring and early warning technologies and platforms have emerged, which can effectively and accurately predict the source area. The widely used methods are microseismic, geo-sound and drilling cuttings, which can effectively monitor rock mass vibration. It is convenient to take pressure relief and support measures in time to prevent the occurrence of dynamic disasters.

-

4.

The evaluation index of rockburst and coal bumps is mainly affected by various factors such as surface damage phenomenon, degree of damage to the project, characteristics of sound occurrence, damage characteristics of surrounding rock burst, and mechanical characteristics. This paper summarizes the evaluation indicators for rockburst, coal bump and mine earthquake.

-

5.

With the mining of deep mines, the influencing factors of rockburst, coal bumps and mine earthquake disasters are more complicated. Considering the influencing factors that induce dynamic disasters, high stress is the root cause of roadway deformation and damage, and bolt support is an external factor. Solving the problem of high stress and bolt support is the key to effectively preventing disasters. Although a lot of research has been carried out and great results have been achieved, these dynamic disasters have also been prevented in time. Commonly used prevention and control techniques include pressure relief and support. However, with the development of deep resources, the incidence of these dynamic disasters has gradually increased. Therefore, the future development of mines still needs to pay attention to these dynamic disasters.

-

6.

The terms rockburst, coal bump and mine earthquake are literally different. Their respective breeding environments, damage forms, evaluation scales, and prevention and control methods are different. In a narrow sense, the three should be treated differently and linked for research. In terms of terminology usage and engineering status, the distinction between rockburst and coal bump not only makes the researched scientific issues more pertinent but also facilitates the popularization of scientific knowledge and reduces misunderstandings. Combining different engineering backgrounds to distinguish and research, is also conducive to the comparative analysis of research results, and further promotes the solution of engineering problems.

References

Ahmed SS, Alheib M, Gunzburger Y, Renaud V (2017) Pillar burst assessment based on large-scale numerical modeling. ISRM Eur Rock Mech Symp Eurock 191:179–87. https://doi.org/10.1016/j.proeng.2017.05.170

Askaripour M, Saeidi A, Rouleau A, Mercier-Langevin P (2022) Rockburst in underground excavations: a review of mechanism, classification, and prediction methods. Undergr Space 7:577–607. https://doi.org/10.1016/j.undsp.2021.11.008

Aygar EB (2020) Evaluation of new Austrian tunnelling method applied to Bolu tunnel’s weak rocks. J Rock Mech Geotech Eng 12:541–556. https://doi.org/10.1016/j.jrmge.2019.12.011

Bao LH (2014) In situ stress measurement and surrounding rock stability analysis of the gaoligong mountain tunnel. Appl Mech Mater 501–504:1766–1773. https://doi.org/10.4028/www.scientific.net/AMM.501-504.1766

Cai W, Dou L, Li Z, Gong S, Liu J (2016) Verification of passive seismic velocity tomography in rock burst hazard assessment. Chin J Geophys-Chin Ed 59:252–262. https://doi.org/10.6038/cjg20160121

Chen C, Zhou J (2023) A new empirical chart for coal burst liability classification using Kriging method. J Central South Univ 30(4):1205–1216. https://doi.org/10.1007/s11771-023-5294-8

Chen, LM Jing, GC (2019) A quantitative evaluation method of coal burst hazard based on zone division and an analytic hierarchy process: a case study on Yanbei coal mine, Gansu Province, China. Geosci J. https://doi.org/10.1007/s12303-018-0081-5

Chen HZ, Shao ZS, Zhu YM, Han ZH (2022) The mechanism of time-delayed rockburst for deep tunnel. Chin J Appl Mech 39(1):19–25. https://doi.org/10.11776/j.issn.1000-4939.2022.01.003

Cui F, Zhang TH, Lai XP, Wang SJ, Chen JQ, Qian DY (2021) Mining disturbance characteristics and productivity of rock burst mines under different mining intensities. J China Coal Soc 12(46):3781–3793. https://doi.org/10.13225/j.cnki.jccs.2021.0184

Deng J, Gu DS (2018) Buckling mechanism of pillar rockbursts in underground hard rock mining. Geomech Geoeng: Int J. https://doi.org/10.1080/17486025.2018.1434241

Dou LM, Cao JR, Cao AY, Chai YJ, Bai JZ, Kan JL (2021a) Research on types of coal mine tremor and propagation law of shock waves. Coal Sci Technol 6(49):23–31. https://doi.org/10.13199/j.cnki.cst.2021.06.003

Dou LM, Gong SY, Liu P, Ding EJ, Hua G, He J, Liu P (2015) Remote online early warning platform of mine seismic and bump disaster. Coal Sci Technol 6(43):48–53. https://doi.org/10.13199/j.cnki.cst.2015.06.009

Dou LM, Li ZL, Zhang M (2016) Study on monitoring and early warning technology of mine pressure bump disaster. Coal Sci Technol 07(44):41–46. https://doi.org/10.13199/j.cnki.cst.2016.07.007

Dou LM, Zhou KY, Song SK, Cao AY, Cui H, Gong SY, Ma XT (2021b) Occurrence mechanism, monitoring and prevention technology of rockburst in coal mines. J Eng Geol 04(29):917–932. https://doi.org/10.13544/j.cnki.jeg.2021-0337

Du K, Luo X, Yang S, Danial JA, Zhou J (2023a) An insight from energy index characterization to determine the proneness of rockburst for hard rock. Geomech Energy Environ. https://doi.org/10.1016/j.gete.2023.100478

Du K, Sun Y, Yang S, Lv S, Wang S (2021) Differences of mechanical parameters and rockburst tendency indices between coal and non-coal rocks and modified rockburst tendency classification criteria for non-coal rocks. Appl Sci 11:2641. https://doi.org/10.3390/app11062641

Du K, Tao M, Li X, Zhou J (2016) Experimental study of slabbing and rockburst induced by true-triaxial unloading and local dynamic disturbance. Rock Mech Rock Eng 49:3437–3453. https://doi.org/10.1007/s00603-016-0990-4

Du K, Yang S, Zhou J, Wang L (2023b) Measurement and Classification Criteria of Strength Decrease Rate and Brittleness Indicator Index for Rockburst Proneness Evaluation of Hard Rocks. Materials (basel). https://doi.org/10.3390/ma16083101

Du Y, Li H, Chicas SD, Huo L (2022) Progress and perspectives of geotechnical anchor bolts on slope engineering in China. Front Environ Sci 10:55. https://doi.org/10.3389/fenvs.2022.928064

Feng X, Chen B, Li S, Zhang C, Xiao Y, Feng G, Zhou H, Qiu S, Zhao Z, Yu Y, Chen D, Ming H (2012) Studies on the evolution process of rockbursts in deep tunnels. J Rock Mech Geotech Eng 4:289–295. https://doi.org/10.3724/SP.J.1235.2012.00289

Feng X, Liu J, Chen B, Xiao Y, Feng G, Zhang F (2017) Monitoring, warning, and control of rockburst in deep metal mines. Engineering 3:538–545. https://doi.org/10.1016/J.ENG.2017.04.013

Feng XT, Xiao YX, Feng GL, Yao ZB, Chen BR, Yang CX, Su GS (2019) Study on the development process of rockbursts. Chin J Rock Mech Eng 04(38):649–673. https://doi.org/10.13722/j.cnki.jrme.2019.0103

Foulger GR, Wilson MP, Gluyas JG, Julian BR, Davies RJ (2018) Global review of human-induced earthquakes. Earth Sci Rev Int Geol J Bridging Gap Betw Res Articles Textbooks. https://doi.org/10.1016/j.earscirev.2017.07.008

Gao R, Yang J, Kuang T, Liu H (2020) Investigation on the ground pressure induced by hard roof fracturing at different layers during extra thick coal seam mining. Geofluids. https://doi.org/10.1155/2020/8834235

Gao MS, Dou LM, Zhang N, Wang K, Zheng BS (2008) Strong-soft-strong mechanical model for controlling roadway surrounding rock subjected to rock burst and its application. Rock Soil Mech 2(29):359–364. https://doi.org/10.16285/j.rsm.2008.02.005

Gong F, Si X, Li X, Wang S (2019) Experimental Investigation of Strain Rockburst in Circular Caverns Under Deep Three-Dimensional High-Stress Conditions. Rock Mech Rock Eng 5(52):1459-74. https://doi.org/10.1007/s00603-018-1660-5

Gong FQ, Pan JF, Jiang Q (2021) The difference analysis of rock burst and coal burst and key mechanisms of deep engineering geological hazards. J Eng Geol 04(29):933–961. https://doi.org/10.13544/j.cnki.jeg.2021-0555

Gong FQ, Zhao YJ, Wang YL, Peng K (2022) Research progress of coal bursting liability indices and coal burst “Human-Coal-Environment” three elements mechanism. J China Coal Soc 05(47):1974–2010. https://doi.org/10.13225/j.cnki.jccs.2022.0165

Grodner M (2001) Delineation of rockburst fractures with ground penetrating radar in the Witwatersrand Basin, South Africa. Int J Rock Mech Min Sci 38:885–891. https://doi.org/10.1016/S1365-1609(01)00054-5

Hao Z, Sun G, Wei H, Liu J, Tian M, Liu S, Xu Y (2021) Pressure-relief mechanism and application of large-diameter boreholes in coal seams with rockburst hazard. Geofluids. https://doi.org/10.1155/2021/5469999

Hao Y, Wu Y, Ranjith PG, Zhang K, Hao G, Teng Y (2020) A novel energy-absorbing rock bolt with high constant working resistance and long elongation : principle and static pull-out test. Constr Build Mater 2:43. https://doi.org/10.1016/j.conbuildmat.2020.118231

He H, Dou L, Gong S, He J, Zheng Y, Zhang X (2019) Microseismic and electromagnetic coupling method for coal bump risk assessment based on dynamic static energy principles. Saf Sci 114:30–39. https://doi.org/10.1016/j.ssci.2018.12.025

He L, An XM, Zhao XB, Zhao ZY, Zhao J (2018) Development of a Unified rock bolt model in discontinuous deformation analysis. Rock Mech Rock Eng 3(51):827–847. https://doi.org/10.1007/s00603-017-1341-9

He M, Cheng T, Qiao Y, Li H (2023) A review of rockburst: experiments, theories, and simulations. J Rock Mech Geotech Eng 15:1312–1353. https://doi.org/10.1016/j.jrmge.2022.07.014

He M, Sousa LE, Miranda T, Zhu G (2015) Rockburst laboratory tests database: application of data mining techniques. Eng Geol 185:116–130. https://doi.org/10.1016/j.enggeo.2014.12.008

He M, Xia H, Jia X, Gong W, Fei Z, Liang K (2012) Studies on classification, criteria and control of rockbursts. J Rock Mech Geotech Eng 4:18. https://doi.org/10.3724/SP.J.1235.2012.00097

He MC, DU S, Gong WL, Nie W (2022) Mechanical characteristics and engineering applications of bolt/cable with negative Poisson's ratio. Mech Eng 44(1):75–87. https://doi.org/10.6052/1000-0879-21-210

He Q, Suorineni FT, Oh J (2016) Review of hydraulic fracturing for preconditioning in cave mining. Rock Mech Rock Eng 49:4893–4910. https://doi.org/10.1007/s00603-016-1075-0

He X, Zhou C, Song D, Li Z, Cao A, He S, Khan M (2021) Mechanism and monitoring and early warning technology for rockburst in coal mines. Int J Miner Metall Mater 28:1097–1111. https://doi.org/10.1007/s12613-021-2267-5

Horner RB, Hasegawa HS (1978) The seismotectonics of southern Saskatchewan. Can J Earth Sci. https://doi.org/10.1139/e78-139

Huang H, Li J, Jiang H (2017) Theoretical derivation of basic mechanical property required for triggering mine-pillar rockburst. Acta Geophys 5(65):945–955. https://doi.org/10.1007/s11600-017-0081-2

Jager AJ (1992) Two new support units for the control of rockburst damage. Int J Rock Mech Min Sci Geomech Abstr 2(31):A97. https://doi.org/10.1016/0148-9062(94)93100-3

Jiang YD, Zhao YX (2015) State of the art:investigation on mechanism,forecast and control of coal bumps in china. Chin J Rock Mech Eng https://doi.org/10.13722/j.cnki.jrme.2015.1076

Jiang Y, Zhao Y, Wang H, Zhu J (2017a) A review of mechanism and prevention technologies of coal bumps in China. J Rock Mech Geotech Eng 9:180–194. https://doi.org/10.1016/j.jrmge.2016.05.008

Jiang FX, Liu Y, Zhai MH, Guo XS, Wen JL, Liu XG, Ma XF (2017b) Evaluation of rock burst hazard based on the classification of stress and surrounding rock. Chin J Rock Mech Eng 05(36):1041–1052. https://doi.org/10.13722/j.cnki.jrme.2016.1203

Jiang B, Wang Q, Wei HY, Xin ZX, He MC, Wu WR, Ma FL, Xu S, Wang YT (2021) Recent development and prospects of energy-absorbing bolt in underground engineering. J Min Sci Technol 05(6):569–580. https://doi.org/10.19606/j.cnki.jmst.2021.05.006

Jiang YD, Pan YS, Jiang FX, Dou LM, Ju Y (2014) State of the art review on mechanism and prevention of coal bumps in China. J China Coal Soc 02(39):205–213. https://doi.org/10.13225/j.cnki.jccs.2013.0024

Feng J, Feng E, Shen R, Chen L, Li X, Li N (2016) A coal shear fracture source model and its far-field seismic characteristics. J China Univ Min Technol 5:2. https://doi.org/10.13247/j.cnki.jcumt.000511

Kaiser PK, Cai M (2012) Design of rock support system under rockburst condition. J Rock Mech Geotech Eng 3(4):215–227. https://doi.org/10.3724/SP.J.1235.2012.00215

Kang JQ, Zhu JB, Zhao J (2019) A review of mechanisms of induced earthquakes: from a view of rock mechanics. Geomech Geophys Geo Energy Geo Resour. https://doi.org/10.1007/s40948-018-00102-z

Kang M, Hua D, Guo X (2023) Review on the influence of complex stratum on the drilling trajectory of the drilling robot. Appl Sci (basel). https://doi.org/10.3390/app13042532

Kang H, Yang J, Gao F, Li J (2020) Experimental study on the mechanical behavior of rock bolts subjected to complex static and dynamic loads. Rock Mech Rock Eng 11(53):4993–5004. https://doi.org/10.1007/s00603-020-02205-0

Kang YQ, Xue L, Sun CY, Guo YL, Meng HL (2021) Zonal destress blasting for tunnels with strong rock burst. Eng Blast 06(27):52–58. https://doi.org/10.19931/j.EB.20200179

Ke B, Khandelwal M, Asteris PG, Skentou AD, Mamou A, Armaghani DJ (2021) Rock-Burst Occurrence Prediction Based on Optimized Naïve Bayes Models. IEEE Access 9:91347-91360. https://doi.org/10.1109/ACCESS.2021.3089205

Kishore TB, Khandelwal M (2022) Prediction of Rockburst Using Supervised Machine Learning. In: Verma AK, et al. Proceedings of Geotechnical Challenges in Mining, Tunneling and Underground Infrastructures. ICGMTU 2021. Lecture Notes in Civil Engineering, vol 228. Springer, Singapore. https://doi.org/10.1007/978-981-16-9770-8_7

Lee SM, Park BS, Lee SW (2004) Analysis of rockbursts that have occurred in a waterway tunnel in Korea. Int J Rock Mech Min Sci 41:545. https://doi.org/10.1016/j.ijrmms.2003.12.135

Li D, Cai M, Masoumi H (2021) A constitutive model for modified cable bolts exhibiting cone shaped failure mode. Int J Rock Mech Min Sci. https://doi.org/10.1016/j.ijrmms.2021.104855

Li CC (2010) A new energy-absorbing bolt for rock support in high stress rock masses. Int J Rock Mech Min Sci 47:396–404. https://doi.org/10.1016/j.ijrmms.2010.01.005

Li T, Ma C, Zhu M, Meng L, Chen G (2017) Geomechanical types and mechanical analyses of rockbursts. Eng Geol 222:72–83. https://doi.org/10.1016/j.enggeo.2017.03.011

Lin M, Gao C, Xia Y, Zhang D, Liu X, Liang X (2022) Rock burst initiation and precursors in a model specimen based on acoustic emission and infrared monitoring. Arab J Geosci 15:1–19. https://doi.org/10.1007/s12517-021-09423-y

Linkov IMPM (1979) The theory of post-failure deformations and the problem of stability in rock mechanics. Int J Rock Mech Min Sci Geomech Abstr. https://doi.org/10.1016/0148-9062(79)91444-X

Lippmann H (1987) Mechanics of “bumps” in coal mines: a discussion of violent deformations in the sides of roadways in coal seams. Appl Mech Rev. https://doi.org/10.1115/1.3149548

Liu CY, Li HJ, Yu SW, Fan ZH, Lin W (2020a) Rockburst prediction technology combining rock mass structure analysis and electromagnetic emission monitoring: a case study of Uzbekistan Kamchik tunnel. Chin J Rock Mech Eng 02(39):349–358. https://doi.org/10.13722/j.cnki.jrme.2019.0830

Liu HX, Tan ZY, Wang X, Li GL, Cheng L (2020b) Prediction of rock burst risk in deep shaft excavation of Xincheng gold mine. J China Univ Min Technol 02(49):296–304. https://doi.org/10.13247/j.cnki.jcumt.001128

Lovchikov AV (2013) Review of the strongest rockbursts and mining-induced earthquakes in Russia. J Min Sci 49:572–575. https://doi.org/10.1134/S1062739149040072

Lu T, Liu S, Wang B, Wu R, Hu X (2017) A review of geophysical exploration technology for mine water disaster in China: applications and trends. Mine Water Environ 36:331–340. https://doi.org/10.1007/s10230-017-0467-z

Lu C, Liu Y, Zhang N, Zhao T, Wang H (2018) In-situ and experimental investigations of rockburst precursor and prevention induced by fault slip. Int J Rock Mech Min Sci 108:86–95. https://doi.org/10.1016/j.ijrmms.2018.06.002

Lurka A, Institute LACM, Katowice P (2008) Location of high seismic activity zones and seismic hazard assessment in Zabrze Bielszowice coal mine using passive tomography. J China Univ Min Technol. https://doi.org/10.1016/S1006-1266(08)60038-3

Ma T, Lin D, Tang L, Li L, Tang C, Yadav KP, Jin W (2022) Characteristics of rockburst and early warning of microseismic monitoring at qinling water tunnel. Geomat Nat Hazards Risk 13:1366–1394. https://doi.org/10.1080/19475705.2022.2073830

Ma T, Tang C, Tang S, Kuang L, Yu Q, Kong D, Zhu X (2018) Rockburst mechanism and prediction based on microseismic monitoring. Int J Rock Mech Min Sci 110:177–188. https://doi.org/10.1016/j.ijrmms.2018.07.016

Ma Z, Li S, Zhao X (2023) Energy accumulation characteristics and induced rockburst mechanism of roadway surrounding rock under multiple mining disturbances: a case study. Sustainability. https://doi.org/10.3390/su15129595

Ma XD, Li CY, Wang XH, Yuan GQ, Ma H (2020) Preliminary study on rockburst development law and rockburst prediction in excavation of layer I of underground powerhouse system in high geostress area of Shuangjiangkou hydropower station. Chin J Rock Mech Eng S1(39):2964–2972. https://doi.org/10.13722/j.cnki.jrme.2019.0690

Ohtsu M (1995) Acoustic-emission theory for moment tensor analysis. Res Nondestruct Eval 6:169–184. https://doi.org/10.1007/BF01606380

Qi QX, Pan YS, Li HT, Jiang DY, Shu LY, Zhao SK, Zhang YJ, Pan JF, Li HY, Pan P (2020a) Theoretical basis and key technology of prevention and control of coal-rock dynamic disasters in deep coal mining. J China Coal Soc 05(45):1567–1584. https://doi.org/10.13225/j.cnki.jccs.DY20.0453

Qi QX, Zhao SK, Li HT, Qin K (2020b) Several key problems of coal bump prevention and control in china’s coal mines. Saf Coal Mines 10(51):135–143. https://doi.org/10.13347/j.cnki.mkaq.2020.10.021

Qian QH (2014a) Definition, mechanism, classification and quantitative forecast model for rockburst and pressure bump. Rock Soil Mech 01(35):1–6. https://doi.org/10.16285/j.rsm.2014.01.028

Ortlepp WD, Stacey TR (1994) Rockburst mechanisms in tunnels and shafts. Tunn Undergr Space Technol 9:59–65. https://doi.org/10.1016/0886-7798(94)90010-8

Ortlepp WD (2000) Observation of mining-induced faults in an intact rock mass at depth. Int J Rock Mech Min Sci 1–2(37):423–436. https://doi.org/10.1016/S1365-1609(99)00117-3

Ortlepp WD (2001) The behaviour of tunnels at great depth under large static and dynamic pressures. Tunn Undergr Space Technol 1(16):41–48. https://doi.org/10.1016/S0886-7798(01)00029-3

Pan JF, Qi QX, Liu SH, Wang SW, Ma WT, Kang XC (2020) Characteristics, types and prevention and control technology of rock burst in deep coal mining in China. J China Coal Soc 01(45):111–121. https://doi.org/10.13225/j.cnki.jccs.YG19.1638

Pan YS, Geng L, Li ZH (2010) Research on evaluation indices for impact tendency and danger of coal seam. J China Coal Soc 12(35):1975–1978. https://doi.org/10.13225/j.cnki.jccs.2010.12.006

Pan YS, Jia BX, Wang S, Guo Y (2012) Three-dimension of model and its application mines seismic wave propagation. J China Coal Soc 11(37):1810–1814. https://doi.org/10.13225/j.cnki.jccs.2012.11.016

Qian QH (2014b) Definition, mechanism, classification and quantitative forecast model for rockburst and pressure bump. Rock Soil Mech 35:1–6. https://doi.org/10.16285/j.rsm.2014.01.028

Qin Z, Cao B, Li T, Liu Y, Chen G (2018) a new bumping danger warning method based on the growth trend of drilling cutting quantity Russian-Chinese symposium on coal in the 21st century. https://doi.org/10.2991/coal-18.2018.6

Qiu Y, Zhou J (2023) Short-term rockburst prediction in underground project: insights from an explainable and interpretable ensemble learning model. Acta Geotech 18(12):6655–6685. https://doi.org/10.1007/s11440-023-01988-0

Ranjith PG, Zhao J, Ju M, De Silva RVS, Rathnaweera TD, Bandara AKMS (2017) Opportunities and challenges in deep mining: a brief review. Engineering 3:546–551. https://doi.org/10.1016/J.ENG.2017.04.024

Shan Z, Yan P (2010) Management of rock bursts during excavation of the deep tunnels in Jinping II hydropower station. Bull Eng Geol Environ 69:353–363. https://doi.org/10.1007/s10064-010-0266-2

Shukla R, Khandelwal M, Kankar PK (2021) Prediction and Assessment of Rock Burst Using Various Meta-heuristic Approaches. Min Metallur Explor 38:1375–1381. https://doi.org/10.1007/s42461-021-00415-w

Shi TW, Pan YS, Wang AW, Dai LP (2020) Classification of rock burst in coal mine based on energy storage and release bodies. J China Coal Soc 02(45):524–532. https://doi.org/10.13225/j.cnki.jccs.2019.0184

Song T, Li T, Meng L, Ma C, Li C, Peng F (2021) Deformation and mechanical properties of a constant-friction-force energy-absorbing bolt. Adv Civ Eng. https://doi.org/10.1155/2021/4120873

Su YH, Cao WW, Zeng YJ (2021) Analysis of rockburst characteristics and influencing factors in a deep tunnel of Karakoram Highway. J Saf Environ 06(21):2586–2594. https://doi.org/10.13637/j.issn.1009-6094.2021.0111

Sun X, Xu H, Zheng L, He M, Gong W (2016) An experimental investigation on acoustic emission characteristics of sandstone rockburst with different moisture contents. Sci China Technol Sci 59:1549–1558. https://doi.org/10.1007/s11431-016-0181-8

Sun Y, Bi R, Sun J, Zhang J, Taherdangkoo R, Huang J, Li G (2022) Stability of roadway along hard roof goaf by stress relief technique in deep mines: a theoretical, numerical and field study. Geomech Geophys Geo Energy Geo Resour. https://doi.org/10.1007/s40948-022-00356-8

Tan YL, Guo WY, Xin HQ, Zhao TB, Yu FH, Liu XS (2019) Key technology of rock burst monitoring and control in deep coal mining. J China Coal Soc 01(13):160–172. https://doi.org/10.13225/j.cnki.jccs.2019.5088

Teodosio B, Wasantha PLP, Yaghoubi E, Guerrieri M, Fragomeni S, van Staden RC (2022) Monitoring of geohazards using differential interferometric satellite aperture radar in Australia. Int J Remote Sens 10(43):3769–3802. https://doi.org/10.1080/01431161.2022.2106457

Tian ZC, Liu YJ, Wang WC, Ren YH (2014) Study on pressure observation of fully mechanized caving faces in coal seams with rock burst danger in Xiagou Coal Mine. Appl Mech Mater 580–583:1331–1334. https://doi.org/10.4028/www.scientific.net/AMM.580-583.1331

Wang H, Zhao Y, Mu Z, Jiao Z, Lu Z (2017) The mechanism of rockburst in district coal pillar with high deviatoric stress and mining tremors impact and its prevention methods. Zhongguo Kuangye Daxue Xuebao/j China Univ Min Technol 46:1202–1210. https://doi.org/10.13247/j.cnki.jcumt.000729

Wang J, Guo ZB, Zhou F, Su FB, Li BL (2012) Measurement and the distribution law of in situ stresses at deep depth of Xingcun Coal Mine. Adv Mater Res 450–451:1601–1607. https://doi.org/10.4028/www.scientific.net/AMR.450-451.1601

Wang J, Yang L, Zhi BG, Jie WP, Liu B (2013) Measurement and the distribution law of in situ stresses of tingnan coal mine. Appl Mech Mater 275–277:282–285. https://doi.org/10.4028/www.scientific.net/AMM.275-277.282

Wang T, Bian Y, Zhang Y, Hou X. (2023) Classification of earthquakes , explosions and mining-induced earthquakes based on XGBoost algorithm. Comput Geosci 170. https://doi.org/10.1016/j.cageo.2022.105242

Wang AW, Pan YS, Zhao BY, Li ZH, Li GZ, Dai LP (2016) Coupling vibration characteristics of rock mass and energy-absorption bolt and its anti-impact mechanism. J China Coal Soc 11(41):2734–2742. https://doi.org/10.13225/j.cnki.jccs.2016.0458

Waqar MF, Guo S, Qi S (2023) A comprehensive review of mechanisms, predictive techniques, and control strategies of rockburst. Appl Sci (basel). https://doi.org/10.3390/app13063950

Wei C, Zhang C, Canbulat I, Song Z, Dai L (2022) A review of investigations on ground support requirements in coal burst-prone mines. Int J Coal Sci Technol. https://doi.org/10.1007/s40789-022-00485-1

Whiteley JS, Chambers JE, Uhlemann S, Wilkinson PB, Kendall JM (2019) Geophysical monitoring of moisture-induced landslides: a review. Rev Geophys 57:106–145. https://doi.org/10.1029/2018RG000603

Wojtecki, Konicek P, Schreiber J (2017) Effects of torpedo blasting on rockburst prevention during deep coal seam mining in the Upper Silesian Coal Basin. 岩石力学与岩土工程学报: 英文版;9:8 https://doi.org/10.1016/j.jrmge.2017.03.014

Wu K, Shao Z, Qin S, Wei W, Chu Z (2021) A critical review on the performance of yielding supports in squeezing tunnels. Tunn Undergr Space Technol 115. https://doi.org/10.1016/j.tust.2021.103815

Xie H, Lu J, Li C, Li M, Gao M (2022a) Experimental study on the mechanical and failure behaviors of deep rock subjected to true triaxial stress: a review. Int J Min Sci Technol 32:915–950. https://doi.org/10.1016/j.ijmst.2022.05.006

Xie S, Wu Y, Guo F, Zou H, Chen D, Zhang X, Ma X, Liu R, Wu C. (2022) Application of pre-splitting and roof-cutting control technology in coal mining : a review of technology. Energies (Basel). https://doi.org/10.3390/en15176489

Xing J, Wang JB, Jiang L, Dong XB (2019) In-situ stress characteristics and rock burst prediction of the Guigala Expressway tunnel. Hydrogeology and Engineering Geology 02(46):170–178. https://doi.org/10.16030/j.cnki.issn.1000-3665.2019.02.23

Xu P (2021) Research on key technology of large diameter pressure relief drilling. international conference on intelligent equipment and special robots (ICIESR 2021) 12127. https://doi.org/10.1117/12.2625053

Yan P, Zhao Z, Lu W, Fan Y, Chen X, Shan Z (2015) Mitigation of rock burst events by blasting techniques during deep-tunnel excavation. Eng Geol 188:126–136. https://doi.org/10.1016/j.enggeo.2015.01.011

Yan J, He C, Wang B, Meng W, Wu FY (2019) Inoculation and characters of rockbursts in extra-long and deep-lying tunnels located on Yarlung Zangbo suture. Chin J Rock Mech Eng 04(38):769–781. https://doi.org/10.13722/j.cnki.jrme.2018.1038

You P, Zhao XH, Li FQ, Liu Y (2018) Research on source positioning optimization of distributed microseism monitoring system. Coal Technol 03(37):226–228. https://doi.org/10.13301/j.cnki.ct.2018.03.086

Zhang JF, Jiang FX, Yang JB, Bai WS, Zhang L (2017) Rockburst mechanism in soft coal seam within deep coal mines. Int J Min Sci Technol 27:551–556. https://doi.org/10.1016/j.ijmst.2017.03.011

Zhang S, Tang C, Wang Y, Li J, Ma T, Wang K. (2021) Review on early warning methods for rockbursts in tunnel engineering based on microseismic monitoring. Appl Sci (Basel). https://doi.org/10.3390/app112210965