Abstract

Securing “energy from waste” appeared as the most engrossed research area to find out global solutions for waste disposal and energy production. Watermelon peels (WMPs) are discarded as bulk waste in the whole oriental region that demands appropriate disposal to save environment from pollution. This study investigates the potential of yeast employing WMPs that embodies significant sugars to be fermented into ethanol. For this purpose, WMPs were subjected to dilute sulfuric acid hydrolysis under optimized conditions (6% H2SO4 at 50 °C for 60 min) elucidated by response surface methodology (RSM) of central composite design (CCD). The experimental design dealt with the optimization of fermentation influencing independent parameters which included pretreated WMP hydrolysate, synthetic medium ratio (X1), hydrolysis temperature (X2), and incubation period (X3) for maximal ethanol yield while employing standard (Saccharomyces cerevisiae K7) and experimental (Metchnikowia cibodasensis Y34) yeast isolates. The significance of the model for experimental yeast was envisaged by 6.22 F value (0.0060 P), 0.8616 R2 and 8.393 adequate precision. The optimized parameters were found as 52.03 mL WMP hydrolysate concentration at 29.46 °C after an incubation period of 15 days. Maximal ethanol yield (g/g reducing sugars) obtained from Saccharomyces cerevisiae K7 was 0.33 ± 0.05, while Metchnikowia cibodasensis Y34 showed as 0.38 ± 0.01. From this research, the ethanologenic and ethanol tolerant potential of yeast Metchnikowia cibodasensis Y34 is apparent to valorize WMPs.

Similar content being viewed by others

References

Söderström J, Pilcher L, Galbe M, Zacchi G (2003) Two-step steam pretreatment of softwood by dilute H2SO4 impregnation for ethanol production. Biomass Bioenerg 24(6):475–486

Rivas-Cantu RC, Jones KD, Mills PL (2013) A citrus waste-based biorefinery as a source of renewable energy: technical advances and analysis of engineering challenges. Waste Manage Res 31(4):413–420

Ch AK, Chan ES, Rudravaram R, Narasu ML, Rao LV, Ravindra P (2007) Economics and environmental impact of bioethanol production technologies: an appraisal. Biotechnol Mol Biol Rev 2(1):14–32

Goh CS, Tan KT, Lee KT, Bhatia S (2010) Bioethanol from lignocellulose: status, perspectives, and challenges in Malaysia. Biores Technol 101(13):4834–4841

Ghosh P, Ghose TK (2003) Bioethanol in India: recent past and emerging future. Biotechnology in India II:1–27

Choudhary J, Singh S, Nain L (2016) Thermotolerant fermenting yeasts for simultaneous saccharification fermentation of lignocellulosic biomass. Electron J Biotechnol 21:82–92

Hill J (2009) Environmental costs and benefits of transportation biofuel production from food-and lignocellulose-based energy crops: a review. Sustain Agric :125–139

Asli MS (2010) A study on SOE efficient parameters in batch fermentation of ethanol using Saccharomyces cerevesiae SC1 extracted from fermented siahe sardasht pomace. Afr J Biotechnol 9(20)

Fish WW, Bruton BD, Russo VM (2009) Watermelon juice: a promising feedstock supplement, diluent, and nitrogen supplement for ethanol biofuel production. Biotechnol Biofuels 2(1):1–9

Johnson JT, Iwang EU, Hemen JT, Odey MO, Efiong EE, Eteng OE (2012) Evaluation of anti-nutrient contents of watermelon Citrullus lanatus. Ann Biol Res 3(11):5145–5150

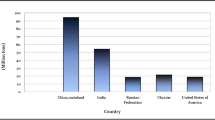

FAOSTAT (2018) Food and agriculture organization of the United Nations. FOA. Retrieved from http://www.fao.org/faostat/en/#data/QC.

Bhandari SV, Panchapakesan A, Shankar N, Kumar HA (2013) Production of bioethanol from fruit rinds by saccharification and fermentation. International Journal of Scientific Research Engineering & Technology 2(6):362–365

Alex S, Saira A, Nair DS, Soni KB, Sreekantan L, Rajmohan K, Reghunath BR (2017) Bioethanol production from watermelon rind by fermentation using Saccharomyces cerevisiae and Zymomonas mobilis. Indian J Biotechnol 16:663–666

Kassim MA, Hussin AH, Meng TK, Kamaludin R, Zaki MSIM, Zakaria WZEW (2022) Valorisation of watermelon (Citrullus lanatus) rind waste into bioethanol: an optimization and kinetic studies. Int J Environ Sci Technol 19(4):2545–2558

Sininart C, Bancha L (2013) Bioethanol from prebiotic extracted jackfruit seeds. 6th PSU-UNS International Conference on Engineering and Technology (ICET 2013), 15–17 May 2013(University of Novi Sad, Faculty of Technical Sciences) 2013: 1–5

Toquero C, Bolado S (2014) Effect of four pretreatments on enzymatic hydrolysis and ethanol fermentation of wheat straw. Influence of inhibitors and washing. Biores Technol 157:68–76

Loow Y, Wu TY, Md Jahim J, Mohammad AW, Teoh WH (2016) Typical conversion of lignocellulosic biomass into reducing sugars using dilute acid hydrolysis and alkaline pretreatment. Cellulose 23:1491–1520

Fernandes F, Farias A, Carneiro L, Santos R, Torres D, Silva J, Souza J, Souza E (2021) Dilute acid hydrolysis of wastes of fruits from Amazon for ethanol production. AIMS Bioengineering 8(3):221–234

Sierra-Ibarra E, Alcaraz-Cienfuegos J, Vargas-Tah A, Rosas-Aburto A, Valdivia-López Á, Hernández-Luna MG, Vivaldo-Lima E, Martinez A (2022) Ethanol production by Escherichia coli from detoxified lignocellulosic teak wood hydrolysates with high concentration of phenolic compounds. Journal of Industrial Microbiology and Biotechnology, 49(2): kuab077

Jahanbakhshi A, Salehi R (2019) Processing watermelon waste using Saccharomyces cerevisiae yeast and the fermentation method for bioethanol production. J Food Process Eng 42(7):13283

Mazaheri D, Ahi M (2021) Evaluation and optimization of bioethanol production from pomegranate peel by Zymomonas mobilis. Journal of Applied Biotechnology Reports 8(3):275–282

Fakayode OA, Akpabli-Tsigbe NDK, Wahia H, Tu S, Ren M, Zhou C, Ma H (2021) Integrated bioprocess for bio-ethanol production from watermelon rind biomass: ultrasound-assisted deep eutectic solvent pretreatment, enzymatic hydrolysis, and fermentation. Renewable Energy 180:258–270

Wagner E, Sierra-Ibarra E, Rojas NL, Martinez A (2022) One-pot bioethanol production from brewery spent grain using the ethanologenic Escherichia coli MS04. Renewable Energy 189:717–725

Robak K, Balcerek M (2018) Review of second generation bioethanol production from residual biomass. Food Technology Biotechnology 56(2):174–187

Tsegaye B, Balomajumder C, Roy P (2019) Optimization of microwave and NaOH pretreatments of wheat straw for enhancing biofuel yield. Energy Convers Manage 186:82–92

Hu L, Li R, Liu Y, Souliyathai D, Zhang W, Chen Y (2021) Energy-efficient photothermal catalysis of rubber seed oil for the preparation of biofuel compounds. Fuel 306:121683

Anderson WF, Akin DE (2008) Structural and chemical properties of grass lignocelluloses related to conversion for biofuels. J Ind Microbiol Biotechnol 35(5):355–366

Tibolla H, Pelissari FM, Menegalli FC (2014) Cellulose nanofibers produced from banana peel by chemical and enzymatic treatment. LWT-Food Science and Technology 59(2):1311–1318

Dubois M, Gilles KA, Hamilton JK, Rebers PT, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28(3):350–356

Zollner N, Kirsch K (1960) Separation of plasma lipids by column chromatography. 1. Methods and identification of fractions. Zeitschrift fur die gesamte experimentelle Medizin 134:10–28

Waterborg JH (2009) The Lowry method for protein quantitation. In The protein protocols handbook (pp. 7–10). Humana Press, Totowa

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31(3):426–428

Paez V, Barrett WB, Deng X, Diaz-Amigo C, Fiedler K, Fuerer C, Coates SG (2016) AOAC SMPR® 2016.002. J AOAC Int 99(4): 1122–1124

Lin L, Yan R, Liu Y, Jiang W (2010) In-depth investigation of enzymatic hydrolysis of biomass wastes based on three major components: cellulose, hemicellulose, and lignin. Biores Technol 101(21):8217–8223

Iqbal A, Schulz P, Rizvi SS (2021) Valorization of bioactive compounds in fruit pomace from agro-fruit industries: present insights and future challenges. Food Biosci 44:101384

Shahid MK, Batool A, Kashif A, Nawaz MH, Aslam M, Iqbal N, Choi Y (2021) Biofuels and biorefineries: development, application and future perspectives emphasizing the environmental and economic aspects. J Environ Manage 297:113268

Halsall-Whitney H, Taylor D, Thibault J (2003) Multicriteria optimization of gluconic acid production using net flow. Bioprocess Biosyst Eng 25(5):299–307

Bennett C (1971) Spectrophotometric acid dichromate method for the determination of ethyl alcohol. Am J Med Technol 37(6):217–220

Al-Sayed HM, Ahmed AR (2013) Utilization of watermelon rinds and sharlyn melon peels as a natural source of dietary fiber and antioxidants in cake. Annals of Agricultural Sciences 58(1):83–95

Bitaraf MS, Khodaiyan F, Mohammadifar MA, Mousavi SM (2012) Application of response surface methodology to improve fermentation time and rheological properties of probiotic yogurt containing Lactobacillus reuteri. Food Bioprocess Technol 5(4):1394–1401

Alvira P, Tomás-Pejó E, Ballesteros M, Negro MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Biores Technol 101(13):4851–4861

Unhasirikul M, Naranong N, Narkrugsa W (2012) Reducing sugar production from durian peel by hydrochloric acid hydrolysis. World Academy of Science, Engineering and Technology 6(9):394–399

Saleem A, Hussain A, Chaudhary A, Ahmad Q, Iqtedar M, Javid A, Akram AM (2020) Acid hydrolysis optimization of pomegranate peels waste using response surface methodology for ethanol production. Biomass Conversion and Biorefinery. https://doi.org/10.1007/s13399-020-01117-x

Van Dyk JS, Pletschke BI (2012) A review of lignocellulose bioconversion using enzymatic hydrolysis and synergistic cooperation between enzymes-factors affecting enzymes, conversion, and synergy. Biotechnol Adv 30:1458–1480

Leu SY, Zhu JY (2013) Substrate-related factors affecting enzymatic saccharification of lignocelluloses: our recent understanding. Bioenergy Research 6:405–415

Shyam Kumar R, Gandhi M, Rajeshwari R, Harikrishnan H (2011) Utilization of waste ripe banana and peels for bioethanol production using Saccharomyces cerevisiae. Journal of Bioscience and Research 2:67–71

Jahid M, Gupta A, Sharma DK (2018) Production of bioethanol from fruit wastes (banana, papaya, pineapple and mango peels) under milder conditions. Journal of Bioprocessing & Biotechniques 8:327

Chaudhary A, Hussain I, Ahmad Q, Hussain Z, Akram AM, Hussain A (2022) Efficient utilization of melon peels to produce ethanol: a step toward sustainable waste management. Biomass Conversion and Biorefinery. https://doi.org/10.1007/s13399-022-02687-8

Casabar JT, Unpaprom Y, Ramaraj R (2019) Fermentation of pineapple fruit peel wastes for bioethanol production. Biomass Conversion and Biorefinery 9:761–765

Krishnan MS, Ho NW, Tsao GT (1999) Fermentation kinetics of ethanol production from glucose and xylose by recombinant Saccharomyces 1400 (pLNH33). twentieth symposium on biotechnology for fuels and chemicals. Humana Press, Totowa NJ, pp 373–388

Author information

Authors and Affiliations

Contributions

A.C.: conceptualization; A. H.: writing — review and editing; Q–A. A.: methodology; T. A.: data curation; Q. M. and B. D.: formal analysis; S. K.: critical review.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chaudhary, A., Hussain, A., Ahmad, QuA. et al. Watermelon peel hydrolysate production optimization and ethanologenesis employing yeast isolates. Biomass Conv. Bioref. 14, 8671–8680 (2024). https://doi.org/10.1007/s13399-022-02923-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02923-1