Abstract

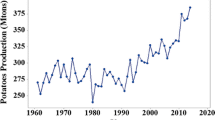

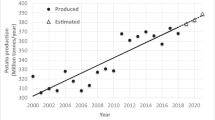

Potatoes (Solanum tuberosum L.) are starchy tuberous crops that represent the world’s fourth most important crop. According to the “Food and Agricultural Organisation of the United Nations,” 376 million metric tonnes of potatoes were produced globally in 2021. It is anticipated that around 8000 kilotons of potato peel waste might be generated in 2030, with related greenhouse gas emissions of 5 million tonnes of CO2 equivalent. Waste generated throughout the food supply chain, from potato farms to forks, contributes considerably to global warming. Apart from animal feed, technical processes in the potato processing industry generate waste organic residues with high amounts of bioactive compounds and carbohydrates, and thus extraction and bioconversion processes can produce high-value products. These include the isolation of functional ingredients for the formulation of nutraceuticals and pharma products, bioenergy-related products, enzymes, and fertilizers for the market, hence contributing to a more responsible production and consumption and, overall, circular economy. This review focuses on studies involving potato waste from industries such as pulp, processed water, peels, and mash showing the great prospects of the by-products from this crop for value-added supply chains and the reduction of undesired environmental effects. This work attempts to adhere upon several Sustainable Development Goals, specifically goals 7, 12, and 13, while also contributing to long-term growth targets and reducing negative environmental consequences produced by the food sector.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Over the past decade, it has been evident that the food industry, including production, supply chain, and consumption, contributes significantly to global warming. In order to reduce global warming potential and air pollution, the recent decades’ fast rise in the world economy and industrial output have increased the need for sustainable and renewable energy worldwide [1, 2]. On a worldwide basis, food waste (FW) is seen as a severe problem, and each year, around one-third of the world’s FW output is wasted. The vast amount of waste biomass generated has been perceived as a promising, clean, and workable alternative for future energy and fuels [3].

Potatoes are the fourth most significant agricultural vegetable recognized by the world as a food security crop. China is the largest producer of potatoes worldwide, accounting for roughly 1/3 of the global production. According to the estimates by the “Food and Agricultural Organization of the United Nations,” approximately 376 million metric tons of potatoes were produced globally in 2021 [4]. Figure 1 displays the distribution of potato production by the five major global potato-producing countries. India is significant on the global potato map because it is the second largest producer, accounting for 11.3% of the global potato area and 12.5% of the overall production area and a total production of 53.58 million metric tons in 2022 [5, 6]. India contributed to the establishment of the Central Potato Research Institute (CPRI) in Shimla, Himachal Pradesh, which was in charge of creating regionally adapted potato varieties, following India’s independence [7]. Seed potatoes (tubers) are in high demand due to vegetative propagation, accounting for 40–50% of total production costs, and therefore it is an important input in potato cultivation [8]. In the 1960s, India introduced the “seed plot technique,” which increased potato seed production during the country’s “Brown Revolution.” Utilization of potatoes in India is distributed around 68% for table purposes, 8.5% as seeds, 7.5% for processing, and the unexpended 16% is wasted owing to the management of pre-harvesting and post-harvesting activities. Some cultivars such as Kufri Chandramukhi, Kufri Jyoti, and Kufri Lauvkar are used in the woodchip industry from crops grown in warm regions with relatively high night temperatures of about 100 °C [9].

Five major potato-producing countries [4]

FW is currently perceived as a matter of massive concern since it contributes to the carbon footprint, making it a relevant challenge to tackle. It has established itself as a substantial source of various goods with value-added and as a great initial feedstock for many biorefinery processes [10]. Polyphenols and glycoalkaloids are two molecules found in potato peel (PP) that are both nutritionally and pharmacologically intriguing. These substances may be extracted and employed as natural antioxidants and steroid hormone precursors, respectively [11]. Considering its composition, potato peel waste (PPW) would therefore be an advantageous starting material for the manufacture of numerous bioproducts, the reduction of the final wastes, and the long-term growth of a circular bio-economy [12]. Taking into account the potential products that could be obtained from PPW, this strategy would unquestionably contribute achieve various UN Sustainable Development Goals (SDG), particularly SDG 12 on “Responsible Consumption and Production,” but also SDG 7 (“Affordable and Clean Energy”) and SDG 13 (“Climate Action”).

Growing population and rising affluence in emerging countries like India have led to a considerable increase in the demand for processed meals. The breakdown of organic wastes is the most frequent cause of environmental contamination in enterprises that prepare food. When bacteria and other biological entities utilize the chemicals as a food source, breakdown takes place which reduces the contaminant pollutants, and toxins. The recycling of food processing industry by-products is one of the key areas of focus [13, 14]. Due to the widespread use of potatoes in food industries, such as the production of commercial products including food items, a significant quantity of PPW is produced during unavoidable potato processing such as peeling, cutting, and trimming [15]. The current PPW management method of landfilling has a negative environmental impact by emitting greenhouse gases and poisonous leachates. It is estimated that around 8000 kilotons of PPW could be generated in 2030, with greenhouse gas emissions of 5 million tons of CO2 equivalent associated with its disposal [16]. The most common source of environmental contamination in food industries is the decomposition of organic wastes, which takes place when bacteria and other biological systems consume chemicals as food sources [17]. However, a significant amount of starch and lignocelluloses are present, making them a source for the production of bio-based products [18], including furanic compounds. The value of PP recycling has increased as a result of recent agricultural and environmental research that concentrates on cutting-edge methods for utilizing PPW in the food processing, pharmaceutical, and biosynthetic industries [19]. PPW has been intensively researched as a viable resource for the production of a diverse range of more valued products, such as biochar, biofuels, organic acids, enzymes, biopolymers, biochemicals, and bio-sorbents.

Previously, some references have covered different aspects of PPW utilization, focusing on the composition and some processes of several products, mostly [16, 20,21,22]. Only a few efforts have been made to explore and compile knowledge on the techniques to quantify uniform measurement of potato waste (PW) and theories which combine data on food product output and trade statistics with potato waste coefficients. It is also necessary to address circular economy to decrease the waste through the conversion of waste into useable products. These circular systems keep competitiveness in the market through diversity and support the circular economy as one of the strategies identified for sustainable economic growth.

To completely comprehend the physicochemical characteristics of potatoes, it is critical to emphasize their physical and chemical composition, as this will aid in the development of an environmentally friendly strategy and various methods for utilizing PPW. This article highlights on relevant initiatives for using PPs for food and non-food purposes, such as bioactive substance extraction, utilization, nutritional considerations, biotechnological usage, livestock feed, and other ad hoc uses of PPs as major industrial waste. Researchers may be inspired by the development of a biorefinery approach that could use PPW to produce favorable and commercial goods under their potential benefits. The overall goal of this study is to provide a quantitative overview of the emerging trends in separation, bioconversion, and catalytic processes from potato waste and their capability to supply high-value products to the market. This analysis will help provide insights for future investments in PW biorefineries.

2 Composition of potato: pulp and peel

The nutritional composition and chemical composition are depicted in the schematic illustration of the potato [23] (Fig. 2). The chemical composition of tubers is affected by variety, growing conditions (climate, weather, type of soil, fertilizers used, cultivation agrotechnical), tuber maturity, storage terms, conditions, etc. [24]. Carotenoids such as violaxanthin, lutein, and zeaxanthin are abundant in red and yellow potatoes. Minerals such as iron, zinc, magnesium, and copper can be found in abundance in potato flesh and skin [25]. Additionally, PP is rich in vitamins like vitamin C, B1, B2, and B3 and minerals such as calcium, iron, and phosphorous. Also, it is high in phytonutrients like dietary fiber, glycoalkaloids, anthocyanins (in colored types), and especially phenolic compounds [26].

2.1 Starch concentration and dry matter

Potatoes are classified as “starchy vegetables,” with carbohydrates as the primary macronutrient and starch as the primary carbohydrate type. In a constant ratio of 1:3, potato starch is made up of amylose and amylopectin [29]. A long, linear glucan with few branches that contain 99% (1,4) up to 1% (1,6) of linkages is amylose. On the other hand, amylopectin is a branched structure with 95% (1,4) and 5% (1,6) of linkages. On a fresh-weight (FW) basis, potatoes have a starch content of 13.5–15%, whereas, on a dry-weight (DW) basis, it is approximately 75–80% [30]. The starch component of potato dry matter is essential for the starch industry and the industrial production of ethanol. Starches from various Indian potato cultivars were evaluated because the potato food and non-food industries require information on the starch concentration of various potato varieties which is elucidated in Table 1. Starch is classified into three types based on its digestibility: rapidly digestible starch, slowly digestible starch, and resistant starch. Among these, resistant starch (RS) is very important due to its health-promoting properties [31] and has distinct gastrointestinal and absorptive qualities that may be beneficial to health. Yukon Gold, Dark Red Norland, and Russet Burbank, three widely used commercial varieties, were prepared using two different methods (baking or boiling), served at a variety of temperatures; hot (65 °C), chilled (4 °C), and reheated (4 °C for 6 days; reheated to 65 °C), and their starch content was assessed by modifying a widely used assay. The cooking method and serving temperature were found to affect RS content (g/100 g), but not in the potato variety as studied by [32]. To be used as an ethanol source, PPW has an adequate amount of starch, cellulose, hemicellulose, lignin, and fermentable carbohydrates. PP has a starch content of 52% DW but only 0.6% DW of it is fermentable. Since fermentation of PP is not feasible for this use, more fermentable reducing sugar must be produced by carbohydrate hydrolysis (either enzymatic or acidic). To ascertain fermentability and ethanol output, several batches of PPW were hydrolyzed with different enzymes and/or acids fermented by Saccharomyces cerevisiae var. bayanus. After fermentation, 18.5 g/L of reducing sugar and 7.6 g/L of ethanol were generated by enzymatic hydrolysis using a mixture of three different enzymes [27, 33]. The presence of adequate quantities of starch, which can be hydrolyzed into sugars and then fermented to produce ethanol, makes PPW a beneficial substrate. The saccharification and fermentation process was used to produce bioethanol from PPW under optimum process parameters: temperature (40 °C), pH (5.78), and 12.25% w/v with a maximum bioethanol concentration of 22.54 g/L and yield of 0.32 g/g [34].

The term “dry matter” refers to the substance that remains after the water has been removed, and “moisture content” indicates how much water is actually in the edible product. Along with starch, dry matter (DM) content is the major quality trait of potatoes. It is an early predictor of tuber quality and has an impact on the final yield of processed tuber products [35]. The composition of DM in six different Indian potato varieties was studied by [36]. Kufri Lalima, Kufri Sindhuri, Kufri Jyoti, Kufri Chandarmukhi, Kufri Pushkarand, and Kufri Pukhraj contains dry matter content of 16.73 ± 0.82%, 17.90 ± 2.30%, 15.63 ± 0.75%, 13.36 ± 1.74%, and 15.38 ± 2.02% respectively. The total dry matter content of a potato tuber is important in determining its end use because high DM content potato varieties are used for processing while low dry matter content varieties are used for table purposes [37].

2.2 Phenolic compounds

Phenolics are a diverse group of compounds derived from plant secondary metabolism. To form aromatic or aliphatic structures, at least one aromatic ring with one or more hydroxyl groups attached is present in phenolic substances [42]. Phenolics are well-known for their effectiveness as medicinal compounds in the treatment of a variety of diseases, including diabetes, cardiovascular and neurodegenerative diseases, and cancer [43]. They have antimicrobial properties and serve as food preservatives. Phenolic chemicals’ antibacterial activities have been demonstrated to impede microbial growth by possibly interfering with the cell membrane [44]. This interference will impede biological processes during the conversion of PPW into bioproducts via fermentation or anaerobic digestion.

The first step in the valorization of plant matrices is the extraction of bioactive components. Any target compound must be extracted as quickly and effectively as possible for the recovery to be economically viable and long-lasting. Due to their toxicity, high volatility, and non-renewable qualities, conventional extraction processes using volatile organic compounds like acetone, methanol, or ethanol solutions are not in the best interests of customers or the ecosystem. Solvent selection is a challenge for sustainable processes because it is a subject of interest in the study and commercial practice. Environmental policies also pose a challenge because their use is tightly controlled by international laws, such as REACH in the European Union [45, 46]. The difficulty remains to attain the best outcomes through procedures that do not affect the extract from the FW matrix without compromising the environment or the health of the customers, decreasing energy costs, and employing safe solvents. Microwave-assisted extraction (MAE), ultrasound-assisted extraction (UAE), and green extraction methods are examples of such treatments that have demonstrated positive aspects in extracting antioxidant and preservative compounds. Green methods have numerous benefits over conventional procedures, and they consequently are more environmentally friendly since they employ green solvents and more ecologically sound approaches with excellent extraction yields and compound preservation. Green solvents typically come from natural sources, are non-toxic, and degrade over time. More than 300 green solvents are listed in the databook on green solvents, along with comprehensive details on utilization guidelines, physical characteristics, health and safety risks, potential replacements, and which goods the solvent is advised for [47]. Consequently, considerable quantities of phenolic compounds and other toxic compounds, such as glycoalkaloids, which have severe inhibitory effects on numerous bacteria, must be extracted to yield value-added products by following microbial fermentation or anaerobic digestion [16] mentioned in Section 3.2 and 3.3. The chemical structure of phenolic acids, specifically the saturated chain length, position, and several substitutions in the core benzene ring, has been used to determine their antimicrobial potential [48]. In comparison to other common fruits and vegetables like carrots, onions, or tomatoes, potatoes have a greater total phenolic concentration. Flavonoids such as flavanols, flavonols, phenolic acids, and anthocyanins, as illustrated in Table 2, are examples of potato phenolic compounds and thus are natural antioxidants [49].

2.2.1 Phenolic acids

The most abundant phenolic acid in potatoes is chlorogenic acid (CGA), with both the skin and flesh of potatoes containing varying amounts (Table 3). The chlorogenic acid content of fresh potato flesh and peel ranges from 30 to 900 mg/kg and 1000 to 4000 mg/kg, respectively. Other phenolic acids are present in trace quantities, varying from 0 to 30 mg/kg [56]. Antioxidant activity and total polyphenolic content (TPC) of four cultivars of purple flesh and two cultivars of yellow flesh were also determined. TPC was determined using the Folin–Ciocalteau (FC) reagent which identifies reagent reduction by phenolic substances measured at 760 nm against gallic acid as a reference via the formation of a blue complex and diphenylpicrylhydrazyl (DPPH) method with the stable free radical 1,1-diphenyl-2-picrylhydrazyl to measure the antioxidant activity. The cultivars with purple flesh potatoes had an average of 4.68 g of gallic acid equivalent (GAE) per kg DM, compared to the cultivars of yellow flesh potatoes which showed 2.96 g GAE per kg DM [57].

The subcritical water technique was also used to extract other acids from PP in addition to CGA including coumaric, gallic, ferulic, syringic, p-hydroxyl benzoic, caffeic, and protocatechuic acid. Subcritical water has been evaluated to determine whether it can effectively replace organic solvents like methanol and ethanol for the separation of phenolic compounds from PP when used at 160 to 180 °C, 6 MPa, and 60 min. Then, it was discovered that 180 °C and 30 min of extraction duration produced high phenolic component yields (81.83 mg/100 g; wet basis), as opposed to 3 h from methanol extractions (46.59 mg/100 g wet basis) [55]. TPC extraction conditions were optimized to demonstrate that PPW is an excellent source of antioxidants. It was found that the primary phenolic chemicals found in the extracts were CGA and ferulic acids. Additionally, the capacity of PP extracts to regulate the oxidation of soybean oil’s lipids under accelerated circumstances was investigated. The findings showed that the extract could indeed successfully reduce oil oxidation [58]. Solid–liquid extraction (SLE) is an efficient method for recovering polyphenols from a waste matrix. Under optimized conditions, water/glycerol and water/ethanol mixtures could extract total polyphenols of 8.71- and 9.11-mg caffeic acid equivalents per gram DW respectively. CGA was the most prevalent substance discovered, to produce high-value-added products like natural antioxidants, nutraceuticals, and also pharmaceutical compounds [59].

2.2.2 Flavonoid content

Another class of secondary plant compounds with advantageous health properties is flavonoids. Their presence in plants is influenced by various factors, such as the abundance of plant nutrients, pest attacks, the environment, and pathogen infection [60]. Total flavonoid content (TFC) was measured in the flesh and skin of 60 different potato cultivars that had been grown at two experimental sites. Very remarkably, the skin of tubers had higher total flavonoid concentrations than the flesh. According to Marinova et al. (2005) [61], the aluminum chloride colorimetric test was used to quantify TFC. Fruits and vegetables were represented as mg catechin equivalents (CE)/100 g fresh mass for all formulations and constituents. The total flavonoids in the flesh varied from 0.51 to 9.50 mg CE/g DW and from 0.06 to 2.29 mg CE/g DW in the peel [62]. White flesh potatoes contain up to 30 g of polyphenols per 100 g FW, while red and purple flesh potatoes contain roughly twice as much. Epicatechin and catechin are the primary flavonoids found in potatoes that have been investigated [63]. Flavonoids were extracted from PP using six different solvent extracts and compared to the pulp of the sugar beet and extract of sesame cake in another study. The solvents used to extract flavonoids from PP were methanol, ethanol, acetone, hexane, diethyl ether, and petroleum ether, and the results of methanol extract with 0.96 0.03 mg of quercetin equivalent g/L DW were found to be dominant out of all extracts. As a result, the extracts have the potential to be used as preservatives in the culinary and/or pharmaceutical sectors if the organoleptic effects were acceptable [64].

2.2.3 Glycoalkaloid content

Glycoalkaloids are naturally occurring components of customary potato varieties that add to the classic flavor of potatoes in small quantities. Enhanced amounts of glycoalkaloids in potato give a bitter taste and may cause discomfort or sickness [65]. Thus, removal or separation process of glycoalkaloids from potatoes is recommended (Fig. 3). There are significant variations between potato varieties that are mainly decided by genetics, but amounts are also affected by environmental variables such as light and temperature during growth, harvest, and storage. During and after development, potatoes generate possibly poisonous glycoalkaloids, which appear to be more toxic to humans than to other animals. The anticholinesterase action of glycoalkaloids on the central nervous system, as well as cell membrane disruptions, has a severe impact on the digestive system and other organs producing toxicity [66]. The two most important glycoalkaloids are α-chaconine and α-solanine, which also carry the same aglycone, solanidine found in potatoes. Potato tuber glycoalkaloid concentration differs considerably and is affected by post-harvest variables such as storage conditions, light exposure, mechanical damage, and irradiation [11]. In vitro tests showed that α-solanine and especially α-chaconine are strong cytotoxins (IC50 = 4.1 µM) that cause cell lysis quickly. However, research from the recent decade has demonstrated that, based on the dosage and usage circumstances, these substances may have advantageous qualities like anti-inflammatory and anti-carcinogenic effects. Using steroidal alkaloids for medicinal purposes could thus benefit from chemical changes that maintain or even improve these bioactivities while lowering cytotoxicity to normally dividing cells [67]. As a consequence, research has been done to date to examine the impact of various extraction methods, such as SLE, UAE, pressurized-liquid extraction (PLE), and MAE on the recovery of glycoalkaloids from PP [68]. UAE using methanol to extract steroidal alkaloids (glycoalkaloids) from PPW was investigated by [67]. The optimal conditions were determined to be an amplitude of 61 µm and an extraction time of 17 min, resulting in a recovery of 1102 µg steroidal alkaloids/g dried potato peel (DPP). The amplitude of 61 µm and the extraction duration of 17 min were found to be ideal circumstances, which led to a recovery of 1102 µg steroidal alkaloids/g DPP. Individual glycoalkaloids extracted by UAE yielded 273, 542.7, 231, and 55.3 µg/g DPP for α-solanine, α-chaconine, solanidine, and demissidine, respectively. To produce biobutanol, acetone-butanol-ethanol (ABE) fermentation was carried out using Clostridium acetobutylicum as a substrate. The microbes used in production can, however, be inhibited by a variety of substances, including glycoalkaloids. The removal of 77–88% of the glycoalkaloids by organosolv pretreatment led to a high ABE yield of 24.8 g/L, suggesting PPW as an inhibitor-free substrate for butanol synthesis [69]. Therefore, understanding the biological properties of potato glycoalkaloids is essential to creating a technologically advanced, economically viable, and environmentally friendly recycling process to extract bioactive ingredients for various industries, especially the agricultural, food, and pharmaceutical industries, which demand natural, eco-friendly ingredients [70].

2.3 Carotenoid content

Animals require carotenoids for their provitamin and antioxidant activities. They play an essential function in plant metabolism and other biomolecule production [71, 72]. Absorption UV–VIS spectrophotometry was used to measure total carotenoid (TC), and the results were quantitatively examined (ANOVA and MANOVA variance analyses, Scheffe’s test). A study was conducted where researchers found that in 2004, the average TC was found to be 5.8 mg/kg (FW). TC found in the tubers of the Asterix and Ditta was 6.9 mg/kg FW and 5.3 mg/kg respectively. The Agria cultivar (18.9 mg/kg FW) type had the highest TC. In 2005, the average TC was higher than it was in 2004 (20.9 mg/kg FW). The statistical analysis findings revealed that the maturity of potato tubers and farming year significantly affects the overall amount of carotenoid content [72]. Twenty distinct vegetable composite samples were obtained from Peshawar’s local markets, and their concentration of carotene was using high-performance liquid chromatography (HPLC). The outcome showed that potato has the minimum content (> 80 g/100 g) [68]. Another study examined two types of Solanum phureja and 15 kinds of potatoes (Solanum tuberosum L.) with varying flesh colors, including white, yellow, red, and purple. Variety and location have an impact on carotenoids’ content. Additionally, the growing year had an impact on the carotenoid content. TC ranged in concentration from 0.779 to 13.3 mg/kg DM. Lutein was the predominant carotenoid across all species (54–93%) and the S. phureja varieties were found to have the highest carotenoid content [14]. Bioactive compounds analysis indicated that PP powder contains a high level of carotenoids with 135.76 mg/g of DW. The nutraceutical values of plant by-products contribute as food ingredients, reducing their contribution to environmental pollution [73].

3 Potato waste utilization; biorefinery approaches

The potato industry’s wastes and by-products include pulp, processed water, peels, and mash, all of which are plentiful and inexpensive [76]. Four categories are used to categorize these wastes: (1) PP, (2) fried products (fries, hash browns, batter, crumbles), (3) screen solids (small potatoes and pieces), and (4) wastewater recovery system material (belt solids, oxidation ditch, filter cake), PP being the most prevalent. The value-added products made from the processing of PP have a variety of applications, including those for biosorbents which are utilized to treat effluents and numerous other contaminated sources, such as metals, pigments, colors, biocomposites, and packaging materials in addition to being utilized as dietary fiber or medications. These materials can be utilized to create energy (biogas, biohydrogen, and biodiesel), biopolymer films, and create cellulose nanocrystals which also can be utilized in several industrial processes, including the production of paper, as a food additive, and in pet and animal food [3]. Food production uses 30% of all energy produced, so from the perspective of a circular economy, it appears quite sustainable that FW can also be used to produce energy [21, 77]. The circular economy combines the idea of closed-loop networks with the biorefining of organic waste, farming biomass, and forest biomass into biomaterials and biochemicals. By simply replacing main resources with secondary resources, it seeks to reduce drawbacks. These circular systems keep competitiveness in the market through diversity and support the circular economy as one of the strategies identified for sustainable economic growth [78]. These demands are conveyed by biorefineries, which also consider the needs of contemporary society. Through resource reutilization, waste reduction, and renewable energy production, circular economy fundamentally aims to increase availability of new technologies and economies of scale, which will greatly contribute to the creation of employment and the development of rural areas.The biorefinery scheme for PP (Fig. 4) will unquestionably boost the value of this waste by creating a variety of products with added value and greatly reducing waste creation [79].

3.1 Animal feed

Combating food insecurity and promoting sustainable agriculture can be aided by using feeding strategies and feedstuffs that increase livestock productivity while having a lower environmental impact than traditional animal production. Given that one-third of all food produced is lost or wasted globally, and that demand for animal feed is expected to rise, using FW as animal feed can help to alleviate the shortage of supplies [81]. Reducing the use of landfills for the disposal of FW can be substituted by diverting them toward livestock and poultry feed [82]. The process of preparing feedstock from PW has been a cutting-edge issue with extending of potato-based industries. Due to growing fertilizer prices and inclement weather, the price of animal feed is rising. This can lower environmental pollution and feed and disposal costs [13, 83]. Fermentation of PW provides ruminant animals with an excellent nitrogen source [84]. A study by Ncobela et al. 2017 [85] produces a strategy to use potato-by-product as an alternative feed for smallholder pigs. PP is also an excellent fish feed ingredient as well as studied by [86]. The fish fed PP for 30 days showed better nutritional characteristics in their muscles and liver tissue, including fat and protein [85]. Twenty-five percent cottonseed meal, 4% rice bran, 35% wheat bran, 1.5% limestone, 30% yellow maize, 1% sodium chloride, 3% molasses, and 0.5% vitamins and mineral combination makeup up to 50% of the concentrate feed mixture can be successfully replaced by PPW in sheep rations on in vitro and in vivo digestibility [87]. Table 4 shows the animals fed with PPW and their physiological changes.

3.2 Source of bioactive compounds for pharmacological application by extraction

Despite being labeled as a zero-value product, the culinary and pharmaceutical sectors can use the biologically significant components that are present in PP [90]. PPW can be used to make substances with apoptotic, chemopreventive, and anti-inflammatory effects because it includes steroidal alkaloids. These physiologically active secondary compounds, known as steroidal alkaloids, are prevalent in PP. Thus, Hossain et al. [67] extracted steroidal alkaloids from PPW using various methods like UAE and SLE by using methanol. The optimum treatment for maximizing the extraction of steroidal alkaloids from PP was 61 µm (amplitude) and 17 min (time). The effect of amplitude on extraction was higher than that of time. According to one such research conducted by Xu et al. [91], the ideal UAE is an efficient extraction method for extracting phenolic compounds at a specific recovery ratio that is one or two orders of magnitude faster than any other conventional solvent extraction (CSE) method because the CSE process involves emulsifying dried PP particles in a solvent and shaking the resulting mixture at 150 rpm. While shaking creates a turbulent motion in the solvent, each particle is always surrounded by a laminar flow layer. As a result, the diffusion of phenolic compounds both within and outside each particle, in the laminar layer, regulates the extraction rate. The yield of TPC and extraction rates are low at certain extraction times because this diffusion process is typically slow whereas in the UAE method the laminar layer that surrounds solvent-particle interfaces is typically eliminated by the acoustically induced streaming that is produced at the particle-solvent interface. The diffusion of the chemicals within PP particles regulates the extraction rates. Additionally, ultrasonic vibration speeds up compound diffusion rates within solids. As a result, the UAE method extraction rates are considerably higher than those of the CSE. Three separate techniques were used to quantify and analyze the yields of phenolic compounds from PPW. The two UAE techniques, direct UAE and indirect UAE, remove phenolic compounds much quicker than CSE. According to another study, the ideal UAE parameters for recovering 1102 g of DPP were an amplitude of 61 μm and an extraction time of 17 min. 710.51 glycoalkaloids μg/g DPP were obtained by SLE. Six steroidal glycoalkaloids (1–6) were examined for their chemical mechanisms, antitumor action, and structure activity by Ding et al. [92]. The methyl thiazolyl tetrazolium technique, flow cytometry, a colorimetric test, and an immunocytochemical method were all used to evaluate the compounds’ cytotoxicity. The substantial inhibition of MGC-803 cell proliferation by solasonine, b-1 solasoline, solamargine, and solanigroside in a dose- and time-dependent way raises the possibility that these compounds may be used to treat gastric cancer. In streptozotocin (STZ)-induced diabetic rodents, the potential of dietary PP powder to lower oxidative stress and hyperglycemia was examined [93]. Incorporating PP powder (5 and 10%) into the diet of diabetic rats led to substantially lower plasma glucose levels and polyuria in STZ diabetic rats, according to a 4-week feeding experiment. Microwave irradiation also promotes the direct interaction of massive electromagnetic waves with the target material; increased power assures enough microwave contact with the matrix to accelerate the separation of chemicals trapped in the cell wall. Thus, a combination of high temperature or power and a short irradiation period is advantageous for MAE and is also a beneficial process to extract PP antioxidants to use as a natural food additive [94]. Response surface methodology (RSM) was used by Singh et al. [95] to study the impact of microwave power, extraction duration, and solvent concentration on the number of phenolics in the extract. The extracted phenolic compounds were obtained at liquid concentrations of 67.33%, extraction time of 15 min, and microwave power levels of 14.67% from the maximum total phenolic content of 3.94 mg/g DW.

3.3 Source of renewable energy

Globally, the use of fossil fuels is increasing, and their rapid depletion is responsible for worldwide energy disputes, energy shortages, and climate disruption. As a result, waste-to-energy routes transform green refuse materials from farmland, industry, and household sources into usable energy forms like biohydrogen, biogas, and alcohol, among others, for the world’s sustainable development [96]. Biofuels, green hydrocarbons, and drop-in fuels, which are fluids generated from biomass, have emerged in recent years as a possible alternative to traditional energy sources. In order to convert biomass into gaseous or liquid fuels, anaerobic digestion (AD) and fermentation are used in combination with microorganisms, enzymes, etc. [97]. Therefore, the use of PPW for the potential recovery of organic wastes through AD is used to produce biogas [98]. Methane, carbon dioxide, and small amounts of other gases are combined to form biogas, which is produced by the AD of organic matter. The usual methane concentration is between 45 and 75% v/v, with the majority of the residual gas being CO2, and the lesser heating value is between 16 and 28 28 MJ/m3. Biogas is a combination composed of methane, CO2, and trace quantities of other gases generated by AD of organic materials. Methane concentration typically ranges from 45 to 75% v/v, with most of the remaining being CO2, and a lower heating value ranging from 16 to 28 MJ/m3 [99]. Anaerobic co-digestion of pig manure and potato tuber with effective process stability could also result in the production of methane [100]. Biogas is a biofuel alternative that can be produced under anaerobic conditions by the bacterial breakdown of biomass via anaerobic digestion. It is produced from a biochemical reaction and is the most widely utilized stillage valorization technique in the world. Production of biogas through untreated PPW is exhibited in Fig. 5 [101]. In the absence of oxygen, this conversion process employs mixed anaerobic microorganisms to break down organic feedstock into biogas (50–70% CH4). With the main goal of waste reduction, the AD system has been extensively used in the environmental control of wastewater sludge, municipal solid waste, and animal manure. In addition to increasing business profitability and decreasing greenhouse gas (GHG) pollution, biogas as a sustainable energy source has the potential to combat climate change [102]. Multiple feedstocks have been proposed and explored for their biomethane potential generation in recent years, in response to the worldwide demand for alternative sustainable energy resources. In one such research, Kryvoruchko et al. [103] anaerobically digested potato pulp, potato skin pulp, and potato fruit water at 37.5 °C for 28 to 38 days, yielding methane yields of 332, 377, and 323 lN (kg/volatile solids) respectively.

To produce bio-methane, Al-Zuhairi and Azeez [104] focused on using PPW as a co-substrate for co-digestion with sheep dung and further inoculating it with 10 v/v % of inoculum from rumen fluid. This study however proved to be an alternative source of energy with an appropriate amount of feedstock with the sheep manure. Furthermore, the valorization of PPW for bioethanol and biogas production was investigated in a study by Soltaninejad et al. [80]. The biorefinery method included enzymatic hydrolysis, ethanolic fermentation, solvent recovery, and anaerobic digestion of residues to generate 59.6 L of biomethane with 8112 kJ of energy per kilogram of dry PPW. AD of PP to produce biogas was performed by using three anaerobic digesters. These digesters were charged with different concentrations of PPW and inoculum which had total cumulative biogas yield of 62.9 L, 84.5 L, and 93.4 L in the three digesters [105]. As we know, anaerobic digestion has seen remarkable growth in the production of biogas, with the principal by-product being digestate. Traditional digestate land application raises environmental issues and demands a significant energy input. Alternately, by balancing the costs of nutrients and anaerobic digestate management, microalgae can efficiently utilize the digested waste nutrients to produce high-value biomass and reduce the process inputs [106]. Therefore, PPW could give a lot for the worldwide green economy development of recent agenda. The development of novel and ecologically responsible extraction techniques is presently in high demand as they will be very beneficial for reducing extraction time and solvent usage by employing profitable techniques that adhere to “Green Chemistry” principles. The green economy and eco-sustainability have drawn a lot of attention to deep eutectic solvents (DESs), novel solvents that are appearing as a potential and healthier substitute for traditional organic solvents. Natural deep eutectic solvents (NADESs) are those that are entirely constituted of natural components like amino acids, organic acids, sugars, or choline derivatives [107, 108]. DESs were utilized before fermentation in the extraction of rapeseed meal with yields up to 85.69% wt to use valuable fractions of phenolic acids. As a result of the high nitrogen concentration in the rapeseed meal, it was determined that it would be a feasible media for biopolymer synthesis employing Pseudomonas putida after extraction. As a result, the findings are advantageous for the creation of a sustainable biorefinery system [109]. The polyphenol content of PPs, which can be extracted using a range of methods based on the “green chemistry” idea and has positive effects on both the economy and the environment, is one of the most hopeful uses for PP extraction. A window of opportunity for biorefinery researchers exists because more research is necessary to maximize capital investment, energy usage, solvent nature, yield, and incorporation into current PPW processing lines.

Another type of fuel that can be utilized to generate heat and power is bio-oil. It is produced by the pyrolysis process at 450 °C. Pyrolysis is a thermochemical breakdown process that has shown potential in producing value-added products from biomass or waste materials when oxygen is low or nonexistent. It is an endothermic process that demands heat energy released at high temperatures in order for biomass/waste materials to decompose [1]. Biochar and syngas are two more pyrolysis by-products. Additionally, PPW also yielded aromatic chemicals, which can be converted into biofuels [15]. Since burning hydrogen gas produces a considerable amount of energy per unit of weight, it has also attracted interest as a source of energy. Production of biohydrogen from PPW is becoming more and more prevalent. Comparing pyrolysis to other biochemical and thermochemical methods of biomass waste treatment, the latter is more environmentally friendly. Given the enormous amounts of FW produced worldwide, the pyrolysis of FW to create various value-added products has a lot of potential. To improve the retention of water and nutrients, biochar made from pyrolyzed FW can be applied to soils. Additionally, biochar can be processed further to create other goods with a greater added value, like activated carbons [110]. Thus, pyrolysis is one of the most efficient, cost-effective, and practical methods of producing bio-oil in the absence of oxygen [111] described as an integrated biorefinery with three sequential processes: pyrolysis of residual lignin into biochar for pesticide contamination remediation; optimized hydrolysis and dehydration of glucose yielding the highest reported yields (54%) of 5-hydroxymethylfurfural (HMF) directly from PPs; and ultrasonic extraction to recover extractives for high activity antioxidants production. In the best-case scenario, it earned approximately $6300 per million tons of dry PPW. This opens up the possibility of successfully translating this technology into an economically profitable process that uses zero-value FW (Fig. 6). Because of the large amount of waste produced and the fact that it is an organic product, this type of waste is unquestionably a good source of bio-oil.

3.4 Production of different enzymes

In solid-state fermentation (SSF), PPW can be used as a substrate for microbial development, which is advantageous for the synthesis or production of useful by-products like different enzymes [116]. Bacillus subtilis was used to extract enzymes from PPs as a substrate [117]. The work was done to investigate microbe growth habits on standard media, standardize microbe growth conditions using PP, and assess the efficacy of filtrate as an enzyme source. The bacterial strain B. subtilis generated more amylase enzyme when incubated at room temperature for 48 h and was reported to be higher at 56.9 mg/g. Protease enzyme was also produced, and the yield was greater at 0.18 mg/g when the bacterial strain B. subtilis was also kept for incubation at room temperature for 48 h. Tian and Yuan [118] investigated how Aspergillus vacuum produces phytase from PW; researchers were able to perfect the optimal conditions of typical PW moisture content (79%) and inoculum size of 1.0 mL at room temperature for 144 h of incubation. Thus, the novel and economical conversion of waste to a high-value product with phytase activity of 5.17 ± 0.82 U/g dry substrate (ds) was developed. Also, Mukherjee et al. [119] used PP as a substrate in SSF for Aspergillus niger RBP7 to produce acidophilus amylase (KX100578.1). Then, after 72 h of incubation, the maximum acidophilus amylase enzyme activity of (210.67 2–1 U/g ds) was generated. Characterization and production of α-amylase by Aspergillus niger in SSF using PP as a substrate was also studied. The maximum yield of α-amylase (1267.27 ± 2.11 U/g) was recorded after optimizing the processed parameters like incubation time, pH, and inoculum size [120]. A recent study by Bansal and Katyal [121] used culled potatoes to produce α-amylase and glucoamylase to replace commercially available costly enzymes with economical ones. Optimization of different physicochemical parameters for maximum production of α-amylase and glucoamylase with RSM was performed. The α-amylase activity of 280.92 U mL−1 was observed when AM1 bacterial culture was used and other parameters were optimized with a value of 5.0% substrate concentration, 30 °C temperature, 24 h of incubation, and pH 5.0. The optimal circumstances for maximal Aspergillus niger glucoamylase production were pH 5.0, 4 days of incubation at 30 °C, 5% substrate content, and Aspergillus niger fungal culture. A promising technique for valorizing β-amylase from sweet potato slurry is the liquid biphasic system (LBS). LBS is a method for separating biomolecules that uses two aqueous phases made up of two water-soluble polymers, a polymer and a salt, or an alcohol and a salt. By mixing two incompatible polymers or a polymer solution with inorganic salts at a certain level until two immiscible phases develop, the idea of LBS is generated. Through the use of a liquid biphasic polyethylene glycol-citrate system, β-amylase was isolated from sweet potato slurry [122]. Thus, the study suggests that cull potatoes could be used as a substrate for the creation of essential enzymes for the industry.

3.5 Biofertilizers

Biofertilizers sustain a soil ecosystem abundant in micro- and macronutrients through nitrogen fixation, phosphate and potassium solubilization, or mineralization. It also promotes the creation of antibiotics and the biodegradation of organic matter in the soil, allowing for improved nutrient absorption and resistance to drought and moisture stress [123]. Chemical fertilizers, on the other hand, have a lot of negative consequences on the environment and agricultural sustainability. A sustainable agriculture system must use renewable inputs that maximize ecological benefits while minimizing environmental dangers. Chemical fertilizers have considerably contributed to the contamination of water, air, and soil. As a result, the current trend is to investigate the possibilities of complementing chemical fertilizers with organic fertilizers that are both environmentally benign and cost-effective. As a result, biofertilizers and growth-promoting microorganisms have been recommended as a substitute for chemical fertilizers in certain settings [58, 124].

PPW could be converted into biofertilizer to lessen its negative environmental effects, increase soil nutrition, minimize the need for synthetic chemical fertilizers, and directly increase food output. Using chemical hydrolysis to create a product that can be utilized as a biofertilizer from waste-derived digestate and compost is a novel alternative method. In places like swamps, lake bottoms, and animal intestines, AD takes place naturally to degrade organic materials [125]. Biofertilizers have been successfully made using PP since large levels of proteins and carbohydrates are present in it that soil bacteria can break down to increase the nitrogen content of manure [126]. To envisage environmental sustainability, a study by [127] applied saccharification and fermentation to PW to first convert it into ethanol and thus enrich the residue with seven different microorganisms (Nostoc muscorum, Fischerella musical, Anabaena variabilis, Aulosira fertilizing, Cylindrospermum musical, Azospirillium lipoferum) for producing bio-manure. This led to zero waste generation by the utilization of waste for value-added products. Researchers have also used an alternative technology of vermicomposting for the treatment of PW into nutrient-rich bio-fertilizers. Orhevba et al. (2020) [128] used Eudrilus eugeniae as the earthworm used for the study, in which fresh PP and DPP were introduced into the bins at a ratio of 5:1 (waste/worm) in grams. The results showed that the concentration of nitrogen, phosphorous, and potassium was higher in vermicompost when compared to the inorganic fertilizers. Increased biogas generation was achieved by combining fungal inoculum with a mixture of organic and agro-industrial wastes that was balanced in the chemical elements required for cell growth. As a result, the fertilization experiments using the digestates revealed that they exhibit growth and were suitable for enhancing crop yields [129].

3.6 Biosorbents

Agricultural biomasses, like PW, belong to a class of biosorbents that have several benefits, such as affordability, abundance in nature, and ease of acquiring and adsorbent use. Biosorption is an economical and ecologically responsible alternative to other decontamination techniques for removing toxic metals from wastewater [130]. PP was immobilized to create biosorbent beads for the biosorption of heavy metals to initially neutralize the pH as well as to maintain low ion concentrations for drinking water. When As and Pb ions were absorbed, the biosorption capacity of the beads considerably increased, whereas when Cd, Cu, Hg, and Ni ions were absorbed, it significantly decreased. The approximate equilibrium biosorption by PP beads of Cd, Cu, Hg, and Ni was 71–80% [131]. Another investigation focused on creating inexpensive, highly effective absorbent (activated carbon) from leftover potato material. Under ideal circumstances, the activated carbon (AC) was mesoporous. The results revealed that the prepared AC is a successful adsorbent for the removal of the organic dye when used to adsorb methylene blue (qe = 540 mg/g). According to the experimental findings, it was possible to create AC using potato residue as a precursor substance [132]. PP was also used as a biosorbent to remove anionic (Orange G) and cationic (Methylene blue) dyes from effluent. To examine the constitution of the biosorbent and concurrently clarify the nature of the adsorbent/dye interactions, ATR-FTIR spectroscopy was crucial [133]. The demand for advances in effluent treatment is growing in significance. Massive amounts of water would be contaminated by small levels of contaminated heavy metals. As a result, numerous studies are being performed to determine how well PP and adsorption processes work to remove heavy metal ions. The current findings suggest that PP are an exceptional biosorbent with exceptional potential for removing the heavy metal under investigation from aqueous solutions because they are economical, effective, and environmentally friendly.

3.7 Biopolymer films and cellulose nanocrystals

Biopolymers are polymers that are synthesized from biological substances modified by living organisms. As biopolymers are biodegradable and recyclable, they possess tremendous application in the field of biomedical and surgical sutures and materials, food packing, medicine, and pharmaceutical preparations [134]. High-pressure homogenization (HPH) and HPH coupled with heat treatment were investigated as previous treatment methods for the making of biopolymer films using glycerol and PP before casting the film. Biopolymer films made from HPH-treated had comparable mechanical and barrier qualities to those made from purified potato starch. Increased starch gelatinization from additional heat treatment of the peel mass increased the films’ barrier qualities and surface topography [135]. Biopolymers like cellulose, which is available and sustainable, are produced by a wide range of living things, including bacteria, amoebas, plants, and animals [136]. To extract cellulose nanocrystals from PPW, alkali treatment and acid hydrolysis were used [137]. The cellulosic substance found in PP was used to create cellulose nanocrystals. PPW was treated with an alkali to separate the cellulose. Additionally, PP cellulose nanocrystals and cellulose microcrystalline were produced through acid hydrolysis. Furthermore, these nanocrystals are superior to metallic nanoparticles in the field of nanocomposites due to their biodegradable nature [138]. For the food business, treating and managing waste from the food processing process is a major challenge. To address environmental problems, this waste could be used in the creation of biodegradable packaging film.

4 Global potato waste utilization

Global food demand will likely rise by 60–110% between 2005 and 2050 as a result of dietary changes and growing populations. Due to the increase in food consumption, massive amounts of agri-food wastes (AFWs) are produced. Numerous physicochemical and biological factors are taken into consideration while choosing a specific valorization process for waste utilization. AFW heterogeneity, preferred energy sources, by-product management, pricing, end-use applications, environmental legislation, and disposal procedures are other elements that are important to consider when choosing an appropriate technology. Valorization of AFW could have significant adverse effects on the environment and the economy. AFWs have received a lot of attention in the development of engineered added-value biomaterials and the generation of renewable energy [139].

Research on the use of FW and the production of biofuel is becoming attractive in different countries. In many European countries, the use of bio-ethanol as an alternative fuel or gasoline supplement in amounts up to 15% is highly recommended. As the considerable concern is caused by the problem of PPW in potato industries in Europe, bio-ethanol produced from PW has a large potential market [13, 140, 141]. Due to the various quantifying techniques used, findings from national studies on FW quantification in European countries are extremely inconsistent. A delegated act setting a common methodology and minimal quality standards for the uniform measurement of FW produced in the Member States has been published by the European Commission. One method for doing this is called Material Flow Analysis (MFA), and it combines data on food product output and trade statistics with FW coefficients. The alternative strategy relies on estimating FW using waste data. This could support the establishment of initial and legally binding goals to decrease FW throughout Europe [142]. In the UK, almost 1 million tonnes of raw potatoes are processed annually, which accounts for about 20% of the domestic crop. Geographical information systems (GIS) are outstanding digitalization tools that have allowed the monitoring of biodiversity, ecosystems, and essential climate variables to name a few examples [143]. As such, GIS has been put to use in the UK to analyze the distribution of PW across the territory and thus identify hotspots of interest through the supply chain [144]. Figure 7 illustrates the PW spatial distribution in the UK according to GIS. It is also evident that the localized generation of huge amounts of waste materials during industrial potato processing may result in environmental impacts, including greenhouse gas emissions, properly identified as well in the study [145]. The Carbon Navigation System, another example of GIS, was used to identify suitable sites for various scales of UK potato biomass plants based on carbon performance. The application of a digitalization tool like GIS in the UK opens a clear window of opportunity for a proper analysis of supply chains for other types of biomass. This will allow the identification of opportunities for valorization and rural development. In the case of this country, the waste products of potato processing are being subjected to a variety of technologies in the UK, including starch recovery systems which are being operated or planned by large potato processors, starch recovery plus protein recovery, single-cell protein production, methane production by anaerobic digestion of the wastes which may be used to counter factory fuel requirements, and PW fermentation which is another microbial technology to produce ethanol which may be used as a fuel or as a chemical feedstock. Hence, potato scraps were found to be the most promising feedstock [146].

Distribution of potato waste in the UK; adapted from [145]

India utilizes around 7.2% of the world’s extractive resources and 6.6% of the world’s fossil fuels due to its expanding population and material demand. Therefore, the country will greatly benefit by implementing principles across numerous industries that have an impact on its economy and produce waste that can be recycled [79, 147]. With a land area of 2.97 million km2 and a total geographic area of 3.29 million km2, India is the seventh-largest country in the world. A total of 60.5% (1.79 million km2) of the land is used for agriculture. Indian agriculture produces enormous amounts of biomass each year, most of which is made up of residues. A total of 840 million tons of agricultural waste were produced by Indian agriculture in 2010 and thus large volumes of PW are produced as a result of its widespread use across numerous sectors [21]. The output products from PW globally rely upon is comprehended in Table 5.

5 Conclusion and perspective

The massive generation of FW from farm to fork along the supply chain of the food industry is a challenge of global relevance. Keeping in mind the concept of circular economy, it is of paramount importance that as much FW as possible is used as starting material for biorefinery-related processes. PW, which is one of the major agro-based waste products produced in food processing industries, increases with each year’s growth in production and consumption. Its processing waste is an organic residual waste with a high phenolic content, a good source of antioxidants, vitamins, and minerals, and can be safely processed into food products for both humans and animals. Considering its potential, it could be a foundation for the development of a biorefinery, hence allowing for the production of biofuels, platform chemicals, and other bio-based compounds and materials. Based on the information highlighted in this article, PP can be used to produce bioactive compounds with high added value, such as polyphenols (phenolic acids and flavonoids), glycoalkaloids, and other natural antioxidants in addition to polysaccharides (starch). As a result, recovering these bioactive compounds not only helps the environment but would represent a significant incentive for the food industry’s profitability. Due to its carbohydrate-rich nature, PW products have undergone conversion to valuable products mostly through various fermentation processes subject to prior hydrolysis, e.g., bio-products such as methane, hydrogen, ethanol, enzymes, organic acids, chemicals, and fuels. In addition to fermentation, catalytic and thermochemical processes have also allowed the production of energy-related products like furans and bio-oil. Future development for the development of fermentative processes will come from the use of different or genetically modified microorganisms to optimize the production of the products of interest. In addition, current lab-scale catalytic and thermal processes from PPW still have a long road ahead before industrial implementation. This regards not only the optimization of operating conditions, but also thorough analyses of process integration, techno-economic analysis, and, finally, life cycle analysis. The latter will provide further insights into whether the processes make sense or not from the point of view of economic and environmental sustainability.

The development of these novel processes for PPW valorization targets UN SDG 12 (sustainable consumption and production). Enough evidence has been discovered that this procedure delivers affordable and sustainable agricultural development in an endeavor to minimize waste and harness its potential in the forthcoming years. However, valorization is still in its early stages due to the multiple hurdles involved in transforming waste into a variety of valuable activities. With basic knowledge already acquired on the exploitation of PPW, researchers should not only concentrate on the development of novel products but also the escalation of biorefinery technologies starting from agricultural and waste to higher technology readiness levels for a more successful transition to a circular economy. Finally, as proven by the work performed in the UK with potato crops, but also looking ahead in a wider overall context, the application of digitalized tools like GIS will become of great relevance to identify opportunities for biomass valorization. This element precisely represents one of the main future prospects for potato and FW valorization in general. GIS in combination with satellite remote sensing can identify solid waste dumping sites. With the aid of multicriteria decision analyses considering economic and social aspects, they can indicate the optimal sites for industry development around this biorefinery concept.

Data availability

This is a review paper, whose original files and drafts would be made available upon request.

References

Foong SY, Chan YH, Cheah WY, Kamaludin NH, Ibrahim TNBT, Sonne C, Peng W, Show PL, Lam SS (2021) Progress in waste valorization using advanced pyrolysis techniques for hydrogen and gaseous fuel production. Bioresour Technol 320:124299. https://doi.org/10.1016/j.biortech.2020.124299

Teigiserova DA, Hamelin L, Thomsen M (2019) Review of high-value food waste and food residues biorefineries with focus on unavoidable wastes from processing. Resour Conserv Recycl 149:413–426. https://doi.org/10.1016/j.resconrec.2019.05.003

Elgarahy AM, Eloffy MG, Alengebawy A, El-Sherif DM, Gaballah MS, Elwakeel KZ, El-Qelish M (2023) Sustainable management of food waste; pre-treatment strategies, techno-economic assessment, bibliometric analysis, and potential utilisations: a systematic review. Environ Res 225:115558. https://doi.org/10.1016/j.envres.2023.115558

FAO. Food and Agriculture Organization of the United Nations, FAOSTAT Statistical Database, 2021. https://www.fao.org/faostat/en/#data/QCL.

Buckseth T, Tiwari JK, Singh RK, Kumar V, Sharma AK, Dalamu D, Bhardwaj V, Sood S, Kumar M, Sadawarti M, Challam C, Naik S, Pandey NK (2022) Advances in innovative seed potato production systems in India. Front Agron 4:1–7. https://doi.org/10.3389/fagro.2022.956667

Scott GJ, Suarez V (2011) Growth rates for potato in India and their implications for industry. Potato J 38(2):100–112

Sood S, Bhardwaj V, Kumar V, Das R, Gupta VK, Mangal V, Luthra SK, Kumar R, Kumar S, Singh RK, Kumar M, Rathore A, Pandey NK, Singh AK (2022) Genetic progress in 50 years of potato breeding in India: where do we stand? Eur J Agron 141:126620. https://doi.org/10.1016/j.eja.2022.126620

Singh R, Buckseth T, Tiwari J, Sharma A, Singh V, Kumar D, Venkatasalam EP, Singh R, Sadawarti M, Challam C, Chakrabarti S (2019) Seed potato (Solanum tuberosum) production systems in India: a chronological outlook. Indian J Agric Sci 89:578–587. https://doi.org/10.56093/ijas.v89i4.88839

Pradel W, Gatto M, Hareau G, Pandey SK, Bhardway V (2019) Adoption of potato varieties and their role for climate change adaptation in India. Clim Risk Manag 23:114–123. https://doi.org/10.1016/j.crm.2019.01.001

Esteban J, Ladero M (2018) Food waste as a source of value-added chemicals and materials: a biorefinery perspective. Int J food Sci Technol 53:1095–1108. https://doi.org/10.1111/ijfs.13726

Schieber A, Marleny, bullet, Aranda Saldaña, MD (2009) Potato peels: a source of nutritionally and pharmacologically interesting compounds–a review. Food, 3. https://doi.org/10.7939/R33T9DM0H

Cristóbal J, Caldeira C, Corrado S, Sala S (2018) Techno-economic and profitability analysis of food waste biorefineries at European level. Bioresour Technol 259:244–252. https://doi.org/10.1016/j.biortech.2018.03.016

Gebrechristos HY, Chen W (2018) Utilization of potato peel as eco-friendly products: a review. Food Sci Nutr 6(6):1352–1356. https://doi.org/10.1002/fsn3.691

Hejtmánková K, Kotíková Z, Hamouz K, Pivec V, Vacek J, Lachman J (2013) Influence of flesh colour, year and growing area on carotenoid and anthocyanin content in potato tubers. J Food Compos Anal 32(1):20–27. https://doi.org/10.1016/j.jfca.2013.07.001

Liang S, McDonald AG (2014) Chemical and thermal characterization of potato peel waste and its fermentation residue as potential resources for biofuel and bioproducts production. J Agric Food Chem 62(33):8421–8429. https://doi.org/10.1021/jf5019406

Ebrahimian F, Denayer JFM, Karimi K (2022) Potato peel waste biorefinery for the sustainable production of biofuels, bioplastics, and biosorbents. Bioresour Tech 360:127609. https://doi.org/10.1016/j.biortech.2022.127609

Pan I, Dam B, Sen SK (2012) Composting of common organic wastes using microbial inoculants. 3 Biotech 2(2):127–134. https://doi.org/10.1007/s13205-011-0033-5

Ben Taher I, Bennour H, Fickers P, Hassouna M (2017) Valorization of potato peels residues on cellulase production using a mixed culture of Aspergillus niger ATCC 16404 and Trichoderma reesei DSMZ 970. Waste Biomass Valorization 8(1):183–192. https://doi.org/10.1007/s12649-016-9558-5

Wu D (2016) Recycle technology for potato peel waste processing: a review. Procedia Environ Sci 31:103–107. https://doi.org/10.1016/j.proenv.2016.02.014

Galhano dos Santos R, Ventura P, Bordado JC, Mateus MM (2016) Valorizing potato peel waste: an overview of the latest publications. Rev Environ Sci Biotechnol 15(4):585–592. https://doi.org/10.1007/s11157-016-9409-7

Pathak PD, Mandavgane SA, Puranik NM, Jambhulkar SJ, Kulkarni BD (2018) Valorization of potato peel: a biorefinery approach. Crit Rec Biotechnol 38(2):218–230. https://doi.org/10.1080/07388551.2017.1331337

Torres MD, Domínguez H (2020) Valorisation of potato wastes. Int J Food Sci Technol 55(6):2296–2304. https://doi.org/10.1111/ijfs.14228

Sawicka B, Umachandran K, Pszczółko P (2021) International Conference on Emerging Technology and Interdisciplinary Sciences ( ICETIS 2021 ) Innovative potato production technology and its influence on quality of tubers. Icetis 174–195. https://doi.org/10.57040/icetis.vi.16

Karpukhin MY, Keita F (2020) Biochemical composition of potato tubers of various varieties and the economic efficiency of its cultivation in the conditions of the Middle Urals. 03023. https://doi.org/10.1051/e3sconf/202022203023

Beals KA (2019) Potatoes, nutrition and health. Am J Potato Res 96(2):102–110. https://doi.org/10.1007/s12230-018-09705-4

Joshi A, Sethi S, Arora B, Azizi AF, Thippeswamy B (2020) Potato peel composition and utilization. Potato 229–245. https://doi.org/10.1007/978-981-15-7662-1_13

Javed A, Ahmad A, Tahir A, Shabbir U, Nouman M, Hameed A (2019) Potato peel waste—its nutraceutical, industrial and biotechnological applacations. AIMS Agric Food 4(3):807–823. https://doi.org/10.3934/agrfood.2019.3.807

Kot AM, Pobiega K, Piwowarek K, Kieliszek M, Błażejak S, Gniewosz M, Lipińska E (2020) Biotechnological methods of management and utilization of potato industry waste—a review. Potato Res 63(3):431–447. https://doi.org/10.1007/s11540-019-09449-6

Seung D (2020) Amylose in starch: towards an understanding of biosynthesis, structure and function. New Phytol 228(5):1490–1504. https://doi.org/10.1111/nph.16858

Dupuis JH, Liu Q (2019) Potato starch: a review of physicochemical, functional and nutritional properties. Am J Potato Res 96(2):127–138. https://doi.org/10.1007/s12230-018-09696-2

Lal MK, Kumar A, Raigond P, Dutt S, Changan SS, Chourasia KN, Tiwari RK, Kumar D, Sharma S, Chakrabarti SK, Singh B (2021) Impact of starch storage condition on glycemic index and resistant starch of cooked potato (Solanum tuberosum) tubers. Starch/Staerke 73(1–2):1900281. https://doi.org/10.1002/star.201900281

Raatz SK, Idso L, Johnson LAK, Jackson MI, Combs GF (2016) Resistant starch analysis of commonly consumed potatoes: content varies by cooking method and service temperature but not by variety. Food Chem 208:297–300. https://doi.org/10.1016/j.foodchem.2016.03.120

Arapoglou D, Varzakas T, Vlyssides A, Israilides C (2010) Ethanol production from potato peel waste (PPW). Waste Manage 30(10):1898–1902. https://doi.org/10.1016/j.wasman.2010.04.017

Chohan NA, Aruwajoye GS, Sewsynker-Sukai Y, Gueguim Kana EB (2020) Valorisation of potato peel wastes for bioethanol production using simultaneous saccharification and fermentation: Process optimization and kinetic assessment. Renew Energ 146:1031–1040. https://doi.org/10.1016/j.renene.2019.07.042

Crops F, Engineering AG (2020) Comparison of methods for dry matter content determination in potato using multi-environments field data and stability statistics. Turkish J Field Crop 25(2):197–207. https://doi.org/10.17557/tjfc.742244

Yadav V, Jha R, Kaushik P (2021) Biochemical composition of potato biowaste of popular North Indian cultivars. Indian J Biochem Biophys 58(1):100–104

Kapoor S, Mahajan BV, Sharma S, Gandhi N (2019) Storage behaviour of different potato varieties under ambient conditions. Agric Res J 56:576. https://doi.org/10.5958/2395-146X.2019.00090.5

Kaur S, Aggarwal P (2014) Original research article studies on Indian potato genotypes for their processing and nutritional quality attributes. Int J Curr Microbiol App Sci 3(8):172–177 (http://www.ijcmas.com)

Raigond P, Singh B, Dutt S, Dalamu JA (2017) Potential of Indian potatoes for the management of hyperglycemia. Indian J Hortic 74(1):103–108. https://doi.org/10.5958/0974-0112.2017.00023.8

Sharma J, Dalamu SV, Dua VK, Gupta VK, Kumar D (2017) Variations in micronutrient content in tubers of Indian potato varieties. Potato J 44(2):101–109

Singh B, Raigond P, Barwal S, Mehta A, Chopra S, Joshi A, Dutt S (2016) Glycoalkaloids in peels of Indian potatoes. Potato J 43(1):86–92

Ambriz-Pérez DL, Leyva-López N, Gutierrez-Grijalva EP, Heredia JB (2016) Phenolic compounds: natural alternative in inflammation treatment. A review. Cogent Food Agric 2(1):1131412. https://doi.org/10.1080/23311932.2015.1131412

Abotaleb M, Liskova A, Kubatka P, Büsselberg D (2020) Therapeutic potential of plant phenolic acids in the treatment of cancer. Biomolecules 10(2):1–23. https://doi.org/10.3390/biom10020221

Mithra MG, Padmaja G (2016) Phenolic inhibitors of saccharification and fermentation in lignocellulo-starch prehydrolysates and comparative efficacy of detoxification treatments. J Biomass Biofuel 3:1–15. https://doi.org/10.11159/jbb.2016.001

Esteban J, Vorholt AJ, Leitner W (2020) An overview of the biphasic dehydration of sugars to 5-hydroxymethylfurfural and furfural: a rational selection of solvents using COSMO-RS and selection guides. Green Chem 22(7):2097–2128. https://doi.org/10.1039/c9gc04208c

Ozturk B, Parkinson C, Gonzalez-miquel M (2018) Extraction of polyphenolic antioxidants from orange peel waste using deep eutectic solvents. Sep Purif Technol 206:1–13. https://doi.org/10.1016/j.seppur.2018.05.052

Leichtweis MG, Oliveira MBPP, Ferreira ICFR, Pereira C, Barros L (2021) Sustainable recovery of preservative and bioactive compounds from food industry bioresidues. Antioxidants 10(11):1–20. https://doi.org/10.3390/antiox10111827

Kumar N, Goel N (2019) Phenolic acids: natural versatile molecules with promising therapeutic applications. Biotechnol Rep 24:e00370. https://doi.org/10.1016/j.btre.2019.e00370

Akyol H, Riciputi Y, Capanoglu E, Caboni MF, Verardo V (2016) Phenolic compounds in the potato and its byproducts: an overview. Int J Mol Sci 17(6):835. https://doi.org/10.3390/ijms17060835

Ben Jeddou K, Kammoun M, Hellström J, Gutiérrez-Quequezana L, Rokka VM, Gargouri-Bouzid R, Ellouze-Chaabouni S, Nouri-Ellouz O (2021) Profiling beneficial phytochemicals in a potato somatic hybrid for tuber peels processing: phenolic acids and anthocyanins composition. Food Sci Nutr 9(3):1388–1398. https://doi.org/10.1002/fsn3.2100

Friedman M, Kozukue N, Kim HJ, Choi SH, Mizuno M (2017) Glycoalkaloid, phenolic, and flavonoid content and antioxidative activities of conventional nonorganic and organic potato peel powders from commercial gold, red, and Russet potatoes. J Food Compos Anal 62:69–75. https://doi.org/10.1016/j.jfca.2017.04.019

Kanatt SR, Chander R, Radhakrishna P, Sharma A (2005) Potato peel extracta natural antioxidant for retarding lipid peroxidation in radiation processed lamb meat. J Agric Food Chem 53(5):1499–1504. https://doi.org/10.1021/jf048270e

Rodríguez-Martínez B, Gullón B, Yáñez R (2021) Identification and recovery of valuable bioactive compounds from potato peels: a comprehensive review. Antioxidants 10(10):1–18. https://doi.org/10.3390/antiox10101630

Saeed KS, Ahmed SA, Hassan IA, Ahmed PH (2015) Effect of bio-fertilizer and chemical fertilizer on growth and yield in cucumber (cucumis sativus) in green house condition. Pak J Biol Sci 18(3):129–134. https://doi.org/10.3923/pjbs.2015.129.134

Singh PP, Saldaña MDA (2011) Subcritical water extraction of phenolic compounds from potato peel. Food Res Int 44(8):2452–2458. https://doi.org/10.1016/j.foodres.2011.02.006

Lewis CE, Walker JRL, Lancaster JE (1999) Changes in anthocyanin, flavonoid and phenolic acid concentrations during development and storage of coloured potato (Solanum tuberosum L) tubers. J Sci Food Agric 79(2):311–316. https://doi.org/10.1002/(SICI)1097-0010(199902)79:2%3c311::AID-JSFA199%3e3.0.CO;2-Q

Lachman J, Hamouz K, Orsák M, Pivec V, Dvořák P (2008) The influence of flesh colour and growing locality on polyphenolic content and antioxidant activity in potatoes. Sci Hortic 117(2):109–114. https://doi.org/10.1016/j.scienta.2008.03.030

Amado IR, Franco D, Sánchez M, Zapata C, Vázquez JA (2014) Optimisation of antioxidant extraction from Solanum tuberosum potato peel waste by surface response methodology. Food Chem 165:290–299. https://doi.org/10.1016/j.foodchem.2014.05.103

Paleologou I, Vasiliou A, Grigorakis S, Makris DP (2016) Optimisation of a green ultrasound-assisted extraction process for potato peel (Solanum tuberosum) polyphenols using bio-solvents and response surface methodology. Biomass Convers Biorefin 6(3):289–299. https://doi.org/10.1007/s13399-015-0181-7

Søltoft M, Nielsen J, Laursen KH, Husted S, Halekoh U, Knuthsen P (2010) Effects of organic and conventional growth systems on the content of flavonoids in onions and phenolic acids in carrots and potatoes. J Agric Food Chem 58(19):10323–10329. https://doi.org/10.1021/jf101091c

Marinova D, Ribarova F, Atanassova M (2005) Total phenolics and total flavonoids in Bulgarian fruits and vegetables. J Chem Technol Metall 40:255–260

Valcarcel J, Reilly K, Gaffney M, O’Brien N (2015) Total carotenoids and l-ascorbic acid content in 60 varieties of potato (Solanum tuberosum L.) grown in Ireland. Potato Res 58(1):29–41. https://doi.org/10.1007/s11540-014-9270-4

Brown CR (2005) Antioxidants in potato. Am J Potato Res 82(2):163–172. https://doi.org/10.1007/BF02853654

Mohdaly AAA, Sarhan MA, Smetanska I, Mahmoud A (2010) Antioxidant properties of various solvent extracts of potato peel, sugar beet pulp and sesame cake. J Sci Food Agric 90(2):218–226. https://doi.org/10.1002/jsfa.3796

Knuthsen P, Jensen U, Schmidt B, Larsen IK (2009) Glycoalkaloids in potatoes: content of glycoalkaloids in potatoes for consumption. J Food Compos Anal 22(6):577–581. https://doi.org/10.1016/j.jfca.2008.10.003

Friedman M, McDonald GM, Filadelfi-Keszi PM (1997) Potato glycoalkaloids: chemistry, analysis, safety, and plant physiology. Crit Rev Plant Sci 16(1):55–132. https://doi.org/10.1080/07352689709701946

Hossain MB, Tiwari BK, Gangopadhyay N, O’Donnell CP, Brunton NP, Rai DK (2014) Ultrasonic extraction of steroidal alkaloids from potato peel waste. Ultrason Sonochem 21(4):1470–1476. https://doi.org/10.1016/j.ultsonch.2014.01.023

Apel C, Lyng JG, Papoutsis K, Harrison SM, Brunton NP (2020) Screening the effect of different extraction methods (ultrasound-assisted extraction and solid–liquid extraction) on the recovery of glycoalkaloids from potato peels: optimisation of the extraction conditions using chemometric tools. Food Bioprod Process 119:277–286. https://doi.org/10.1016/j.fbp.2019.06.018

Abedini A, Amiri H, Karimi K (2020) Efficient biobutanol production from potato peel wastes by separate and simultaneous inhibitors removal and pretreatment. Renew Energ 160:269–277. https://doi.org/10.1016/j.renene.2020.06.112

Benkeblia N (2020) Potato Glycoalkaloids: occurrence, biological activities and extraction for biovalorisation – a review. Int J Food Sci 55(6):2305–2313. https://doi.org/10.1111/ijfs.14330

Nauman Ahamad M, Saleemullah M, Ullah Shah H, Khalil IA, Saljoqi A (2007) Determination of carotene content in fresh vegetatbles using high performance liquid chromatography. Sarhad J Agric 23(3):767–770

Kotíková Z, Hejtmánková A, Lachman J, Hamouz K, Trnková E, Dvořák P (2007) Effect of selected factors on total carotenoid content in potato tubers (Solanum tuberosum L.). Plant Soil Environ 53(8):355–360. https://doi.org/10.17221/2214-pse

Elhassaneen Y (2016) Improvement of bioactive compounds content and antioxidant properties in crackers with the incorporation of prickly pear and potato peels powder. Int J Food Sci Nutr 5(1):53. https://doi.org/10.11648/j.ijnfs.20160501.18

Chem B, Kim J, Soh SY, Bae H, Nam SY (2019) Antioxidant and phenolic contents in potatoes (Solanum tuberosum L.) and micropropagated potatoes. Appl Biol Chem. 62(1):1–9. https://doi.org/10.1186/s13765-019-0422-8

Lachman J, Hamouz K, Orsák M, Kotíková Z (2016) Carotenoids in potatoes - a short overview. Plant Soil Environ 62(10):474–481. https://doi.org/10.17221/459/2016-PSE

Suresh T, Sivarajasekar N, Balasubramani K, Ahamad T, Alam M, Naushad M (2020) Process intensification and comparison of bioethanol production from food industry waste (potatoes) by ultrasonic assisted acid hydrolysis and enzymatic hydrolysis: Statistical modelling and optimization. Biomass Bioenergy 142:105752. https://doi.org/10.1016/j.biombioe.2020.105752

Matharu AS, de Melo EM, Houghton JA (2016) Opportunity for high value-added chemicals from food supply chain wastes. Bioresour Technol 215:123–130. https://doi.org/10.1016/j.biortech.2016.03.039

Teigiserova DA, Hamelin L, Thomsen M (2020) Towards transparent valorization of food surplus, waste and loss: clarifying definitions, food waste hierarchy, and role in the circular economy. Sci Total Environ 706:136033. https://doi.org/10.1016/j.scitotenv.2019.136033

Priyadarshini P, Abhilash PC (2020) Circular economy practices within energy and waste management sectors of India: a meta-analysis. Bioresour Technol 304:123018. https://doi.org/10.1016/j.biortech.2020.123018