Abstract

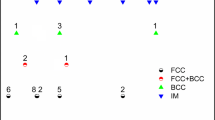

The evolution of element distribution during laser cladding involves two dynamic behaviors, i.e., liquid molten pool flow and FeCoCrNi high-entropy alloy (HEA) coatings solidification. However, it is quite difficult to characterize element distribution during the flow of the liquid molten pool rigorously. The current investigation conducted the optical microscopy, scanning electron microscopy, X-ray diffraction analysis and energy dispersive spectrometer to study the dilution, phase composition, microstructure of the FeCoCrNi coatings. The flow field was simulated to uncover the dynamic change mechanism of the molten pool and explain the experimental results. The results indicated that the coating is substantially composed of FCC and BCC solid solution with a typical dendrite microstructure. Gray Laves phase-(Ni, Co)2Ti and a small number of white dot particles, Fe–Cr phase, are dispersed in the inter-dendritic region. The HEA atoms (Fe, Co, Cr, Ni) gradually aggregate from the center to the side at the coating boundary region, while the Ti atom is the opposite. The Marangoni flow inflection point at the molten pool boundary will cause HEA atoms to aggregate. On the contrary, Ti atom enters the molten pool from the bottom with the heat buoyance flow and then migrates to the boundary along with the Marangoni flow. Therefore, the content of Ti in the coating boundary decreases. The Marangoni flow, heat buoyance flow, and recoil pressure flow are interwoven in the middle region of the coating, resulting in a more uniform element distribution than the boundary region.

Graphic Abstract

Similar content being viewed by others

References

D. Banerjee, J.C. Williams, Acta Mater. 61, 844 (2013)

C. Yang, X. Cheng, H. Tang, X. Tian, D. Liu, Surf. Coat. Technol. 337, 97 (2017)

D.G. Bansal, O.L. Eryilmaz, P.J. Blau, Wear 271, 2006 (2011)

P. Farahmand, R. Kovacevic, Surf. Coat. Technol. 276, 121 (2015)

O.S. Adesina, A.P.I. Popoola, S.L. Pityana et al., Int. J. Adv. Manuf. Technol. 95, 1265 (2018)

S.R. Al-Sayed Ali, A.H.A. Hussein, A.A.M.S. Nofal, S.E.I. Hasseb Elnaby, H.A. Elgazzar, H.A. Sabour, Materials 10, 1178 (2017)

X. Luo, J. Li, G.J. Li, J. Alloy. Compd. 626, 102 (2015)

J.M. Chen, C. Guo, J.S. Zhou, T. Nonferr, Metal. Soc. 22, 2171 (2012)

J.D. Majumdar, I. Manna, A. Kumar, P. Bhargava, A.K. Nath, J. Mater. Process. Tech. 209, 2237 (2009)

L. Jianing, C. Chuanzhong, Z. Lei, Int. J. Refract. Met. H. 29, 49 (2011)

J. Li, C. Chen, Z. Lin, T. Squartini, J. Alloy. Compd. 509, 4882 (2011)

Y.Q. Yang, H.C. Man, Surf. Coat. Technol. 201, 6928 (2007)

Y. Yu, J. Zhou, J. Chen, H. Zhou, C. Guo, L. Wang, L. Yang, Wear 274–275, 298 (2012)

L.L. Bai, J. Li, J. Chen, R. Song, J.Z. Shao, C.C. Qu, Opt. Laser Technol. 76, 33 (2016)

R. Song, J. Li, J.Z. Shao, L.L. Bai, J.L. Chen, C.C. Qu, Appl. Surf. Sci. 355, 298 (2015)

J.Z. Shao, J. Li, R. Song, L.L. Bai, J.L. Chen, C.C. Qu, Rare Metals 39, 304 (2020)

M.S. Selamat, L.M. Watson, T.N. Baker, J. Mater. Process. Tech. 142, 725 (2003)

C.G. Li, Y. Wang, L. Guo, J. He, Z. Pan, L. Wang, J. Alloy. Compd. 506, 356 (2010)

J. Li, Z. Yu, H. Wang, Thin Solid Films 519, 4804 (2011)

S. Feng, H.B. Tang, S.Q. Zhang, H.M. Wang, T. Nonferr, Metal. Soc. 22, 1667 (2012)

J.‐W. Yeh, S.‐K. Chen, S.‐J. Lin, J.‐Y. Gan, T.‐S. Chin, T.‐T. Shun, C.‐H. Tsau, S.‐Y. Chang, Adv. Eng. Mater. 6, 299 (2004)

Y. Ma, Q. Wang, B.B. Jiang, C.L. Li, J.M. Hao, X.N. Li, C. Dong, T.G. Nieh, Acta Mater. 147, 213 (2018)

H. Zhang, Y. Pan, Y.Z. He, Mater. Design 32, 1910 (2011)

J.Y. He, H. Wang, Y. Wu, X.J. Liu, H.H. Mao, T.G. Nieh, Z.P. Lu, Intermetallics 79, 41 (2016)

C. Huang, Y. Zhang, R. Vilar, J. Shen, Mater. Design 41, 338 (2012)

H.X. Zhang, J.J. Dai, C.X. Sun, S.Y. Li, J. Mater. Process. Tech. 282, 116671 (2020)

M. Guo, S. Chen, F. Shang et al., Laser cladding novel NiCrSiFeBW–CeO2 coating with both high wear and corrosion resistance. Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-020-00756-z

G.S. Ham, Y.K. Kim, Y.S. Na et al., Effect of Ti addition on the microstructure and high-temperature oxidation property of AlCoCrFeNi high-entropy alloy. Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-020-00708-7

T.M. Yue, H. Xie, X. Lin, H.O. Yang, G.H. Meng, J. Alloy. Compd. 587, 588 (2014)

G. Jin, Z. Cai, Y. Guan, X. Cui, Z. Liu, Y. Li, M. Dong, D. Zhang, Appl. Surf. Sci. 445, 113 (2018)

W.E. King, A.T. Anderson, R.M. Ferencz, N.E. Hodge, C. Kamath, S.A. Khairallah, A.M. Rubenchik, Appl. Phys. Rev. 2, 041304 (2015)

A. Sim, E.-J. Chun, D.-W. Cho, Met. Mater. Int. 26, 1207 (2020)

P. Campra, D. Millstein, Environ. Sci. Technol. 47, 12284 (2013)

Y.Q. Jiang, J. Li, Y.F. Juan, Z.J. Lu, W.L. Ji, J. Alloy. Compd. 775, 1 (2018)

S. Guo, C. Ng, J. Lu, C.T. Liu, J. Appl. Phys. 109, 103505 (2011)

S.A. Kube, S. Sohn, D. Uhl, A. Datye, A. Mehta, J. Schroers. Acta Mater. 166, 677 (2019)

J. Cieslak, J. Tobola, K. Berent, M. Marciszko, J. Alloy. Compd. 740, 264 (2018)

C. Zhang, F. Zhang, H. Diao, M.C. Gao, Z. Tang, J.D. Poplawsky, P.K. Liaw, Mater. Design 109, 425 (2016)

H.R. Sistla, J.W. Newkirk, F.W. Liou, Mater. Design 81, 113 (2015)

S. Guo, Q. Hu, C. Ng, C.T. Liu, Intermetallics 41, 96 (2013)

H.L. Wei, Y. Cao, W.H. Liao, T.T. Liu, 34, 101221 (2020).

S.A. Khairallah, A.T. Anderson, A. Rubenchik, W.E. King, Acta Mater. 108, 36 (2016)

X. Zhan, J. Chen, J. Liu, Y. Wei, J. Zhou, Y. Meng, Mater. Design 99, 449 (2016)

Acknowledgements

The authors gratefully acknowledge by the Foundation of National Key Laboratory of Science and Technology on Helicopter Transmission (Nanjing University of Aeronautics and Astronautics) (Grant No. HTL-A-19K02).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Duan, S., Zhan, X., Wu, M. et al. Analysis of Elements Non-Uniform Distribution of FeCoCrNi High-Entropy Alloy Coatings on Ti–6Al–4V Surface by Laser Cladding. Met. Mater. Int. 27, 467–480 (2021). https://doi.org/10.1007/s12540-020-00900-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00900-9