Abstract

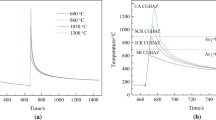

The critical temperature condition for softening behavior of AISI P21 steel during laser-assisted heat treatment is suggested by three-dimensional transient simulation with a finite different method. Temperature history of the cross-sectional region during laser-assisted heat treatment at 1273 K was simulated. The critical temperature condition for formation of the softening zone was assumed to range from 900 to 1008 K, based on this peak temperature history. Formation of the softening zone was simulated based on the assumed critical temperature condition. Morphology and area of simulated softening zone was compared with the experimentally obtained results, and these were well matched. In this regard, critical temperature condition for formation of the softening zone during laser-assisted heat treatment was identified to range from 900 to 1008 K.

Graphic Abstract

Similar content being viewed by others

References

G. Singh, A. Verma, A brief review on injection moulding manufacturing process. Mater. Today Proc. 4, 1423–1433 (2017)

F.J.G. Silva, R.P. Martinho, R.J.D. Alexandre, A.P.M. Baptista, Increasing the wear resistance of molds for injection of glass fiber reinforced plastics. Wear 271, 2494–2499 (2011)

J. Bergstrom, F. Thuvander, P. Devos, C. Boher, Wear of die materials in full scale plastic injection moulding of glass fiber reinforced polycarbonate. Wear 251, 1511–1521 (2001)

G. Zhao, I. Hussainova, M. Antonov, Q. Wang, T. Wang, Friction and wear of fiber reinforced polyimide composites. Wear 301, 122–129 (2013)

N. Crisan, S. Descartes, Y. Berthier, J. Cavoret, D. Baud, F. Montalbano, Tribological assessment of the interface injection mold/plastic part. Tribol. Int. 100, 388–399 (2016)

I. Martínez-Mateo, F.J. Carrión-Vilches, J. Sanes, M.D. Bermúdez, Surface damage of mold steel and its influence on surface roughness of injection molded plastic parts. Wear 271, 2512–2516 (2011)

D.C. Wen, Microstructure and corrosion resistance of the layers formed on the surface of precipitation hardenable plastic mold steel by plasma-nitriding. Appl. Surf. Sci. 256, 797–804 (2009)

M.H. Ghasemi, B. Ghasemi, H.R.M. Semnani, Investigation of microstructure and wear properties of plasma nitrided astaloy Mo. Met. Mater. Int. 25, 1008–1018 (2019)

K. Bobzin, C.H. Hopmann, A. Gillner, T. Brögelmann, N.C. Kruppe, M. Orth, M. Steger, M. Naderi, Enhanced replication ratio of injection molded plastic parts by using an innovative combination of laser structuring and PVD coating. Surf. Coat. Technol. 332, 474–483 (2017)

J. Kim, S.S. Park, H.W. Park, Corrosion inhibition and surface hardening of KP1 and KP4 mold steels using pulsed electron beam treatment. Corros. Sci. 89, 179–188 (2014)

E.J. Chun, M.S. Kim, H. Nishikawa, C. Park, J. Shu, Laser-assisted selective fusing of thermal sprayed Ni-based self-fluxing alloys by using high-power diode lasers. Opt. Lasers Technol. 100, 317–324 (2018)

B. Syed, S.M. Shariff, G. Padmanabham, S. Lenka, B. Bhattacharya, S. Kundu, Influence of laser surface hardened layer on mechanical properties of re-engineered low carbon steel sheet. Mater. Sci. Eng. A 685, 168–177 (2017)

S. Guarino, M. Barletta, A. Afilal, High power diode laser (HPDL) surface hardening of low carbon steel: fatigue life improvement analysis. J. Manuf. Process 28, 266–271 (2017)

G. Telasang, J.D. Majumdar, G. Padmanbham, I. Manna, Structure-property correlation in laser surface treated AISI H13 tool steel for improved mechanical properties. Mater. Sci. Eng. A 599, 255–267 (2014)

G. Telasang, J.D. Majumdar, G. Padmanbham, I. Manna, Wear and corrosion behavior of laser surface engineered AISI H13 hot working tool steel. Surf. Coat. Technol. 261, 69–78 (2015)

S.M. Shariff, T.K. Pal, G. Padmanabham, S.V. Joshi, Influence of chemical composition and prior microstructure on diode laser hardening of railroad steels. Surf. Coat. Technol. 228, 14–26 (2013)

S. Santhanakrishnan, R. Kovacevic, Hardness prediction in multi-pass direct diode laser heat treatment by on-line surface temperature monitoring. J. Mater. Process. Technol. 212, 2261–2271 (2012)

C. Park, J. Kim, A. Sim, I.D. Park, H. Jang, E.J. Chun, Influence of high-power diode laser heat treatment on wear resistance of a mold steel. J. Mech. Sci. Technol. 33(2), 829–836 (2019)

A. Liu, B. Previtali, Laser surface treatment of grey cast iron by high power diode laser. Phys. Procedia 5, 439–448 (2010)

A. Bartkowska, A. Pertek, M. Kulka, L. Klimek, Laser surface modification of boronickelized medium carbon steel. Opt. Laser Technol. 74, 145–157 (2015)

L. Orazi, A. Fortunato, G. Cuccolini, G. Tani, An efficient model for laser surface hardening of hypo-eutectoid steels. Appl. Surf. Sci. 256, 1913–1919 (2010)

K.M. Adel, Enhancement of dry sliding wear characteristics of CK45 steel alloy by laser surface hardening processing. Procedia Mater. Sci. 6, 1639–1643 (2014)

X.M. Zhang, H.C. Man, H.D. Li, Wear and friction properties of laser surface hardened En31 steel. J. Mater. Process. Technol. 69, 162–166 (1997)

I.R. Pashby, S. Barnes, B.G. Bryden, Surface hardening of steel using a high power diode laser. J. Mater. Process. Technol. 139, 585–588 (2003)

H. Ki, S. So, S. Kim, Laser transformation hardening of carbon steel sheets using a heat sink. J. Mater. Process. Technol. 214, 2693–2705 (2014)

Z. Yu, C. Li, Z. Chen, Y. Li, X. Han, Sensitivity analysis of laser quenching parameters of ASTM 1045 of disk laser based on response surface method. Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00437-6

E.J. Chun, A. Sim, M.S. Kim, N. Kang, Microstructural characterization of surface softening behavior for Cu-bearing martensitic steels after laser surface heat treatment. Metals 8(6), 470 (2018)

D.W. Cho, J.H. Park, H.S. Moon, A study on molten pool behavior in the one pulse one drop GMAW process using computational fluid dynamics. J. Heat. Mass. Transf. 139, 848–859 (2019)

D.W. Cho, D.V. Kiran, W.H. Song, S.J. Na, Molten pool behavior in the tandem submerged arc welding process. J. Mater. Process. Technol. 214, 2233–2247 (2014)

W.I. Cho, S.J. Na, T. Thomy, F. Vollertsen, Numerical simulation of molten pool dynamics in high power disk laser welding. J. Mater. Process. Technol. 212, 262–275 (2012)

F. Kong, S. Santhanakrishnan, D. Lin, R. Kovacevic, Modeling of temperature field and grain growth of a dual phase steel DP980 in direct diode laser heat treatment. J. Mater. Process. Technol. 209, 5596–6003 (2009)

Acknowledgements

This work was supported by the Technology Innovation Program (or Industrial Strategic technology development program, No. 10076430) funded By the Ministry of Trade, industry & Energy (MI, Korea) and Korea Institute of Machinery and Materials (NK217C).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sim, A., Chun, EJ. & Cho, DW. Numerical Simulation of Surface Softening Behavior for Laser Heat Treated Cu-Bearing Medium Carbon Steel. Met. Mater. Int. 26, 1207–1217 (2020). https://doi.org/10.1007/s12540-019-00577-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00577-9