Abstract

Techniques capable of producing small-sized probiotic microcapsules with high encapsulation yields are of industrial and scientific interest. In this study, an innovative membrane emulsification system was investigated in the production of microcapsules containing Lacticaseibacillus rhamnosus GG® (Lr), sodium alginate (ALG), and whey protein (WPI), rice protein (RPC), or pea protein (PPC) as encapsulating agents. The microcapsules were characterized by particle size distribution, optical microscopy, encapsulation yield, morphology, water activity, hygroscopicity, thermal properties, Fourier-transform infrared spectroscopy (FTIR), and probiotic survival during in vitro simulation of gastrointestinal conditions. The innovative encapsulation technique resulted in microcapsules with diameters varying between 18 and 29 μm, and encapsulation yields > 93%. Combining alginate and whey, rice, or pea protein improved encapsulation efficiency and thermal properties. The encapsulation provided resistance to gastrointestinal fluids, resulting in high probiotic viability at the end of the intestinal phase (> 7.18 log CFU g−1). The proposed encapsulation technology represents an attractive alternative to developing probiotic microcapsules for future food applications.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The Food and Agriculture Organization of the United Nations (FAO) and the World Health Organization (WHO) have defined probiotics as “live microorganisms which, when administered in adequate amounts, confer a health benefit on the host” (FAO/OMS, 2001; Hill et al., 2014). The global probiotics market was valued at USD 58.17 billion in 2021 and is expected to expand at a compound annual growth rate (CAGR) of 7.5% from 2021 to 2030 (Grand View Research, 2021). The health promotion provided by these microorganisms has been the main driving force of this niche market. Recent studies and clinical evidence have shown that the L. rhamnosus GG strain has promoted health and reduced the risk of some diseases, such as the antiviral effect against the SARS-CoV-2 virus (Tang et al., 2021), control and reduction of serum cholesterol (Lu et al., 2022) and diabetes (Gu et al., 2022), antiobesity activity (Huang et al., 2021a), and reduced risk of colon cancer (Celebioglu et al., 2021).

Probiotics must reach the human gut in adequate amounts to colonize it and exert some benefits on human health (Hill et al., 2014; Misra et al., 2022). However, most probiotics have a considerable loss of viability after passing through the digestive tract due to their low stomach pH tolerance and high concentration of bile salts in the small intestine (Premjit & Mitra, 2021). In addition, when incorporated into commercial products, intrinsic or process factors such as low pH, high water activity, high shear stress during food manufacturing, or high cooking temperatures can negatively affect the integrity of the probiotic strain (Arepally et al., 2022; Camelo-Silva et al., 2022; Sharma et al., 2022). In this sense, microencapsulation has been disseminated as a technology that protects probiotic cells within a polymeric matrix. This method is defined as the process in which cells are retained within an encapsulating membrane to reduce or minimize the loss of probiotic bacteria (Verruck et al., 2019). Microencapsulation techniques, including extrusion, emulsification, spray-drying, and freeze-drying, have been accepted to protect probiotic cells within a polymeric matrix (Fangmeier et al., 2019; Manassi et al., 2022). Nevertheless, these techniques produce microcapsules of varying sizes, generally larger than recommended (< 100 µm) to avoid sensory rejection due to the “gritty sensation” during product consumption (Bampi et al., 2016; Heidebach et al., 2012).

The membrane emulsification technique is a relatively new method with great potential to overcome the limitations of conventional techniques. The main advantages are the production of uniform microcapsules with controlled size (control by membrane pore size), low shear stress, low energy expenditure, high flexibility, and operation under mild temperature conditions (Piacentini et al., 2014). In addition, controlling the microcapsule’s final size and size distribution is a valuable advantage for food applications. Most of the published studies present pilot or laboratory scale experiments, reporting that membrane emulsification is technically feasible for encapsulating several compounds such as vitamin B5 (Konovalova et al., 2023), probiotics (Camelo-Silva et al., 2022), essential oils (Reis et al., 2022), polyphenols (Junjing Wang et al., 2020), and drugs (Lagreca et al., 2020). In 2014, Spyropoulos et al. indicated that most of the commercial applications of membrane emulsification were in the pharmaceutical area. More recently, Zhi et al. (2022) highlighted that attention has been given to food applications, given the higher number of studies and patents in this field. Even though the investigations show the technical feasibility of producing such encapsulated materials, they do not evaluate environmental and economic aspects, which could help design industrial-scale production. To our knowledge, there is only one documented case regarding a commercial product obtained through membrane emulsification: the “Yes light,” a low-fat butter substitute produced by Moringa Milk Industry in Japan (Spyropoulos et al., 2014). On the other hand, finding new applications for applying the technology in the food industry may induce companies to support research and scale-up practices.

So far, a single study on membrane emulsification for encapsulating a probiotic bacteria strain (Song et al., 2003) can be found. The authors used a microporous glass (SPG) membrane with a pore diameter between 4 and 6.4 μm to encapsulate Lacticaseibacillus casei YIT 9018. The dry microcapsules obtained had a size between 31–52 μm and were resistant to gastric fluid and bile (< 106 log CFU g−1). Yeast encapsulation using membrane emulsification has also been reported. Morelli et al. (2017) encapsulated Saccharomyces cerevisiae cells using a flat disc metallic membrane with a pore diameter of 30 μm. The size of the droplets (wet suspension) containing S. cerevisiae cells varied between 60 and 340 μm. Still, more studies are needed to elucidate the response of each strain to the membrane emulsification method parameters and encapsulating agents.

Different encapsulating materials, known as carrier agents, have been used in microencapsulation. Sodium alginate (ALG) is widely used due to its low cost, biocompatibility, food-grade, and targeted delivery of probiotics (soluble in basic media, e.g., in the intestine) (Marcial-Coba et al., 2019). However, microcapsules made of ALG tend to be porous, favoring the permeation of substances harmful to the probiotic (e.g., stomach acidity). Proteins have been combined with ALG to increase the stability of these microencapsulated microorganisms during adverse conditions, for example, in simulated gastrointestinal conditions, or to increase encapsulation yield (Apiwattanasiri et al., 2022; Gao et al., 2022). Premjit and Mitra (2021) encapsulated the probiotic strain Leuconostoc lactis (NCDC 200) by electrospraying technique using an emulsion system based on soy protein isolate (SPI) (12–15% w/v) and sunflower oil (SO) (0–5% w/v). The authors observed that a simultaneous increase in the concentration of SPI and SO led to a significant increase in encapsulation yield. Using vegetable proteins such as rice (RPC) and pea (PPC) seems to be an attractive and innovative strategy. The available literature on using these proteins as probiotic encapsulating agents is still scarce. In October 2022, we performed an advanced search in the Scopus database using the keywords “probiotic,” “encapsulat*,” “rice protein,” and “pea protein.” Only one study on rice protein was published in 2021, while eight studies on pea protein were published between 2010 and 2021. They are known for their hypoallergenic potential and high nutritional value, with a high digestibility rate ranging from 92 to 99% for pea protein concentrate and 88% for rice protein concentrate (Fabian & Ju, 2011). Another important finding is that lactic acid bacteria can hydrolyze these proteins and generate peptides and amino acids to be used as substrates more efficiently than the native protein (Allahdad et al., 2022).

The membrane emulsification technique was not previously used to encapsulate L. rhamnosus GG; therefore, this study is a pioneer in the area. This work proposes to develop an innovative protection system combining ALG with whey protein isolate, rice, and pea proteins to produce probiotic microcapsules, using membrane emulsification as a first step in microencapsulation.

Material and Methods

Materials

A freeze-dried probiotic culture composed of L. rhamnosus GG (Lr) (Chr. Hansen, Hønsholm, Denmark) was used as the active material for the microcapsules. Sodium alginate (ALG) (Êxodo Científica, Brazil), rice protein concentrate (RPC) (80.00 g protein 100 g−1) (VeganWay, Brazil), pea protein concentrate (PPC) (80.00 g protein 100 g−1) (VeganWay, Brazil), whey protein isolate (WPI) (95.00 g protein 100 g−1) (Essentia Pharma, Brazil), refined soybean oil (Coamo, Brazil), CaCl2.2H2O (dihydrated calcium chloride), and NaCl (calcium chloride) (Neon, Brazil) were used for microcapsule preparation. De Man, Rogosa, and Sharpe (MRS) broth and MRS Agar (Kasvi, Brazil) were used for bacterial growth. The emulsifier sorbitan monooleate (SPAN 80), bacteria gram-stain kit, enzymes α-amylase (28.75 U mg−1 protein), pepsin from porcine gastric mucosa (400 U mg−1 protein), pancreatin from porcine pancreas (digestive power: 8 × USP specifications), and the bovine bile salts were supplied by Sigma-Aldrich, Brazil. The viability of the probiotic bacteria was assessed with the BacTiter-Glo™ Viability Kit (Promega, USA). All chemicals were of analytical grade or with equivalent purity.

Probiotic Suspension Preparation

For the preparation of the stock solution, freeze-dried probiotic cells of L. rhamnosus GG were rehydrated in sterile skimmed milk (25 g L−1) and glycerol (20 g L−1) and stored in sterile falcon vials at − 20 ± 2 °C (Camelo-Silva et al., 2022b). The stock solution was added to the MRS broth and incubated at 37 ± 1 °C for 48 h. After the incubation period, probiotic cells were harvested by centrifugation (1000 × g) for 10 min (Centrifuge-SL 700 from Solab, Brazil) at 25 ± 1 °C and washed twice with sodium chloride solution (0.9 g 100 mL−1). L. rhamnosus GG cell pellets were kept at 4 ± 1 °C until encapsulation.

Microencapsulation Process

The probiotic microcapsules were prepared by membrane emulsification, following the method proposed by Morelli et al. (2017) and Vinner et al. (2019), with modifications. A scheme with the steps of the procedure is shown in Fig. 1.

Four emulsions were produced and denominated Lr-ALG, Lr-ALG-WPI, Lr-ALG-RPC, and Lr-ALG-PPC. Before encapsulation, RPC and PPC proteins were solubilized in water with the pH corrected to 7.0 (0.5 M NaOH) and stirred at room temperature overnight (Jiapei Wang et al., 2014). Briefly, the dispersed phase of the Lr-ALG sample was prepared by mixing 1.0% (w/v) sodium alginate and the probiotic suspension (~ 9 log CFU mL−1). The dispersed phases of the Lr-ALG-WPI, Lr-ALG-RPC, and Lr-ALG-PPC samples were prepared with 1.0% (w/v) of sodium alginate, probiotic suspension (~ 9 log CFU mL−1), and 0.5% (w/v) protein (WPI, PRC, or PPC, respectively). The continuous phase consisted of soybean oil (3:1) with 3% (v/v) of SPAN 80.

The microcapsules were obtained using a membrane emulsification system coupled to a specially designed module with a porous (~ 20 μm) stainless steel filter (181 cm2 of effective area). The membrane was soaked in the continuous phase and treated for 30 min in an ultrasonic bath before the microencapsulation process to avoid its wetting by the dispersed phase. The shear stress for droplet detachment was provided by a bladed rotor (25 mm long and 6 mm high) that generates a radial flow pattern. The distance between the bladed rotor and the membrane surface was 5 mm, and the rotation speed was 250 rpm. The membrane (c) was placed in the module, and the continuous phase of the emulsion was poured into the container. Then, the dispersed phase (b) was gently fed into the cell by an infusion pump (Insight, Brazil), forcing it to permeate through the membrane pores. The dispersed phase injection rate was adjusted to 1 mL min−1, and the emulsification experiments were conducted at room temperature.

When emulsification was complete, a 1.5% (w/v) solution of calcium chloride dihydrate was gently added to the emulsion (stirring at 250 rpm) and allowed to stand for 30 min. Then, the emulsion was centrifuged (1000 × g for 10 min), and the supernatant was discarded. Gelled microcapsules were separated by vacuum filtration, washed with sodium chloride solution (0.9 g 100 mL−1), and analyzed in terms of optical microscopy, size distribution, and encapsulation yield.

Characterization of Gelled Microcapsules

Microstructure and Microcapsule Size

The microstructure of the gelled microcapsules containing L. rhamnosus GG and free L. rhamnosus GG (fixed by gram stain) was determined from images obtained under a bright-field microscope (Olympus BX41, Olympus Optical Ltd., Japan) connected with a digital camera (Q-imaging). The determination of the mean microcapsule size and size distribution was performed by dynamic light scattering (DLS) (LUMiSizer, LUM GmbH, Germany) (Alves et al., 2021). The mean microcapsule size was calculated from a normal Log model using Origin 8.5 software (OriginLab, USA). The width of the size distribution was expressed by the Span value calculated according to Eq. 1.

where \({D}_{10}\), \({D}_{50}\), and \({D}_{90}\) correspond to the microcapsule diameters obtained at 10%, 50%, and 90% of the cumulative size distribution curve.

Encapsulation Yield (EY)

The encapsulation yield was determined according to Ji et al. (2019), with modifications. One gram of the gelled probiotic microcapsules was resuspended in 9 mL of PBS (phosphate buffer saline) at pH 7.4, 0.1 mol L−1, and stirred with a vortex (Norte Científica, Brazil) for five 1-min cycles, with 1-min rest intervals between cycles. Then, 100 µL of the sample was mixed with 50 µL of BacTiter-Glo™ reagent and submitted to a microplate reader (GloMax® Explorer System model GM3500, Promega, USA) to quantify the number of viable cells released from the microcapsules. The results obtained from the microplate reader were correlated with a calibration curve constructed based on plate counts. Results were expressed as log colony-forming units per gram (log CFU g−1). The encapsulation yield (%) was calculated using Eq. 2.

where \({N}_{0}\) and \(N\) are the number of viable cells (CFU g−1) before and after encapsulation, respectively.

Dried-Gelled Microcapsules and Characterization

The gelled probiotic microcapsules were frozen at −18 ± 2 °C for 4 h in a domestic freezer (Electrolux, Brazil) and then at − 80 ± 2 °C for 24 h in a vertical freezer (Glacier, USA) on the same day they were produced. They were dried in a freeze-dryer (Liotop L101, Brazil), setting the pressure to 0.200–0.300 μHg and condenser temperature at −54 °C for 24 h.

Morphology of L. rhamnosus GG Microcapsules

For this analysis, the samples were dried using critical point dryer equipment (model EM CPD 030/LEICA) (Silveira et al., 2022). The morphology of the dried probiotic microcapsules was observed with a scanning electron microscope (model JSM 6390 LV, Jeol, Japan). The microcapsules powder was spread over the carbon tape and covered with a thin layer of gold and then analyzed at an accelerating voltage of 10 kV and micrographs at magnifications between 100 and 2000 ×.

Water Activity (Aw)

Water activity was measured at 25 ± 1 °C using a water activity analyzer (Aqua lab, Decagon Devices, USA).

Hygroscopicity (HG)

The hygroscopicity of the probiotic microcapsules was determined according to the method described by Bhusari et al. (2014) and Caparino et al. (2012). Briefly, 1 g of the freeze-dried capsules was placed in Petri dishes in a glass desiccator containing a saturated solution of sodium chloride (75.3% RH at 25 ± 1 °C) for 7 days. HG (%) was calculated using Eq. 3.

where \({\Delta }_{m}\) (g) is the increase in weight of the microcapsules after equilibrium, \(M\) (g) is the initial mass of the microcapsules, and \({M}_{i}\) (% wb) is the free water content of the microcapsules before exposure to the humid air environment.

Thermal Analysis

The melting temperature of probiotic microcapsules and wall materials was obtained by differential scanning calorimetry (DSC) (Shimadzu DSC-60, Japan). A standard reference of indium was used for the preliminary calibration of equipment. Approximately 8.0–10.0 mg of the samples was placed in aluminum pans with lids and scanned between 30 and 220 °C at a heating rate of 10 °C min−1 under a nitrogen flow of 50 mL min−1. An empty crucible was used as a reference (Ashwar et al., 2018).

Interaction Between Microcapsule Components

The dried probiotic microcapsules, encapsulating materials, soybean oil, and L. rhamnosus GG were analyzed by Fourier transform infrared spectroscopy (FTIR) (IRPrestige-21, Shimadzu Scientific Instruments Inc., USA). The samples were homogenized in KBr (potassium bromide) pellets, and the spectra were acquired from 400 to 4000 cm−1 with a resolution of 4 cm−1. Measurements were performed at room temperature.

Resistance of Free and Microencapsulated L. rhamnosus GG During In Vitro Digestion

Probiotic cell viability was evaluated in simulated salivary fluid (SSF), simulated gastric fluid (SGF), and simulated intestinal fluid (SIF) according to INFOGEST, a standardized protocol for static digestion (Table 1) (Brodkorb et al., 2019).

Five grams of free or microencapsulated L. rhamnosus GG was homogenized with SSF stock solution 1:1 (w/w). The α-amylase was added in the concentration of 75 U mL−1, and the prepared oral bolus was kept at 37 °C for 2 min at 200 rpm. Then, the oral bolus was mixed with SGF 1:1 (w/w) and porcine pepsin (2000 U mL−1), and the pH was adjusted to 3.0 with HCl 1 mol L−1. Then, it was incubated at 37 °C with constant shaking at 50 rpm for 2 h. Finally, the gastric chyme was mixed with SIF 1:1 (w/w) pancreatin solution (trypsin activity 100 U mL−1) and 10 mM of bile salts and incubated at 37 °C for a further 2 h at 50 rpm. The samples were centrifuged, and the viable cell count was performed according to item 2.4.2. L. rhamnosus GG performance under in vitro gastrointestinal steps was also evaluated by the recovery rate (%) (Eq. 4) (Verruck et al., 2017).

where \({N}_{1}\) is the L. rhamnosus GG viable cells count (log CFU g−1) after exposure to each in vitro gastrointestinal step, and \({N}_{0}\) is L. rhamnosus GG viable cells count (log CFU g−1) before in vitro gastrointestinal exposure.

Statistical Analysis

The mean and standard deviation (SD) was calculated from data obtained in triplicate. The one-way analysis of variance (ANOVA) was conducted using the STATISTICA version 13.3 software (TIBCO Software Inc., USA). Differences between means were tested using Tukey at a significance level of 0.05.

Results and Discussion

Microstructure and Microcapsule Size

Figure 2 shows the microstructure of the probiotic L. rhamnosus GG (a) and the gelled microcapsules. The surface of the microcapsules in Fig. 2b presents a thin oily film, indicating that the encapsulation technique was adequate for producing a W/O emulsion. Furthermore, the gelled microcapsules are spherical and with a polydisperse size distribution. Dark spots can be found inside some microcapsules (Fig. 2c, d, e, and f), suggesting the existence of the probiotic suspension dispersed within the gelled microcapsules.

The gelled microcapsule size distribution curves are shown in Supplementary Fig. S1, while gelled microcapsule size and span are presented in Table 2. The distribution curves for gelled microcapsules were narrow, and the microcapsule size (Table 2) was close to the membrane pore size. Particles larger than 20 μm (nominal membrane pore size) can result from the coalescence of droplets as soon as they leave the membrane pore (because of the proximity of adjacent pores) and also from the membrane pore size distribution. It is well known that the average droplet diameter can be from 2 to 10 times larger than the membrane pore size (Williams et al., 1998; Reis et al., 2022). The control microcapsules (alginate microcapsule without probiotic) had an average size of 19.5 μm, indicating that adding the probiotic did not alter the gelled microcapsule size. In turn, the span ranged from 1.52 to 2.77, proving the potential of the membrane emulsification technique in producing microcapsules with a narrow width of the size distribution (Kaade et al., 2020). According to Spyropoulosa et al. (2011), membrane emulsification produces emulsion droplets individually/one at a time, which allows their size distribution and size to be carefully controlled. The microcapsule size distribution behavior found in this study is in agreement with what was reported in works that used a similar dispersion cell for membrane emulsification (Consoli et al., 2020; Ilić et al., 2017; Imbrogno et al., 2015; Morelli et al., 2017; Piacentini et al., 2013; Richards et al., 2021).

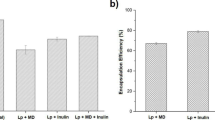

Encapsulation Yield (EY)

The encapsulation yield of L. rhamnosus GG (Table 2) is related to the number of viable cells trapped in the microcapsules and the probiotic strains’ survival rate after the encapsulation process. The EY was higher than 93% for the four microcapsules prepared. The high encapsulation yield obtained in this study may be due to the mild conditions employed during the membrane emulsification process, such as mild temperature and the non-use of organic solvents. Jiang and Charcosset (2022) and Consoli et al. (2020) obtained similar yields (between 94.5 and 97.7%) using membrane emulsification to encapsulate curcumin and resveratrol, respectively. On the other hand, we observe that the combination of alginate and protein (WPI, RPC, or PPC) improved (p < 0.05) the entrapment of probiotic cells in the microcapsules and promoted the achievement of encapsulation yields higher than 95%. Our results are consistent with those of Morsy et al. (2022), who found that the formulation containing ALG 2% (w/v) and WPI 2% (w/v) was more effective in trapping (EY: 98%) L. rhamnosus GG. Obradović et al. (2022) reported that the combination of ALG 1% (w/v) and WPI 15% (w/v) improved the encapsulation yield (82.46%) of a blend of lactic acid bacteria probiotics after freeze-drying. Another study revealed that freeze-dried microcapsules containing a mixture of alginate 2% (w/v), inulin 1% (w/v), and concentrated soy protein 10% (w/v) improved the encapsulation yield (90.43%) of L. casei ACCC10171 (Kouamé et al., 2023). This behavior occurs because of the superior gelling properties of the proteins. The hydroxyl groups present in the chemical structure of alginate can react with the amino groups of the side chain of the peptides, resulting in cross-linking (Massounga Bora et al., 2021). These bonds form a tough and rigid layer preventing the early migration of bacterial cells to the outside of the microcapsule. Using proteins in the microcapsules showed a more remarkable effect on protecting L. rhamnosus GG in simulated gastrointestinal conditions (“Resistance of free and microencapsulated L. rhamnosus GG during simulated gastrointestinal digestion”). Finally, our results suggest that RPC and PPC are comparable to the WPI considering encapsulation capacity (verified by the similar yield obtained), supporting the promising trend of using vegetable source materials in the food industry.

Morphology, Water Activity, and Hygroscopicity of the Dried Microcapsules Containing L. rhamnosus GG

Figure 3 shows the morphology of the dried probiotic microcapsules. All samples showed the same surface characteristics, indicating that the type of protein did not influence the morphology of the dried microcapsules. The microcapsules were irregular spheres with rough surfaces. They presented no apparent porosity. As also observed for the encapsulation yield, low porosity is essential to ensure better protection and retention of the encapsulated material, avoiding gas exchange with the environment or the early permeation of substances harmful to probiotics. Furthermore, the microcapsules formed agglomerates (Fig. 4e), corroborating the results of Holkem et al. (2016), who produced alginate microcapsules with Bifidobacterium animalis subsp. lactis BB-12 dried by freeze-dried and with those by Rama et al. (2020), who encapsulated Lacticaseibacillus paracasei ATR6 with cheese whey in a spray-dryer.

The moisture content of freeze-dried probiotic microcapsules is a critical factor that influences the stability of the bacteria during storage (Holkem et al., 2016). The water activity (in the range of 0.33–0.47) of the microcapsules (Table 2) was affected (p < 0.05) by the type of protein used, following the order WPI < PPC < RPC. This difference may be associated with plant proteins’ higher water-holding capacity (WRC). Rafe et al. (2016) observed that gels made with pea protein-whey protein had reduced WRC compared to those made with pea protein alone. Similar results were obtained by Ashwar et al. (2018), who evaluated the viability and physicochemical properties of rice starch microcapsules containing Levilactobacillus brevis (MTCC 01), Lacticaseibacillus casei (MTCC 297), and Lactiplantibacillus plantarum (MTCC 021), obtained by emulsification followed by freeze-drying. According to Silva et al. (2018), aw around 0.3 is considered satisfactory for dried probiotic microcapsules since conditions with aw < 0.2 may favor lipid oxidation, consequently reducing the number of viable cells. On the other hand, when aw > 0.4, water absorption is enhanced, which may accelerate the probiotic viability loss. The water activity observed in the Lr-ALG-WPI (0.33) favors the application of these microcapsules in low-moisture food matrices and can increase the stability of probiotic powders during prolonged storage. It is worth emphasizing that the Lr-ALG-PPC sample also presented an aw within the recommended limit, demonstrating the potentiality of pea protein to produce probiotic powders with low water activity.

Hygroscopicity (HG) is closely related to the survival of the probiotic during storage. As shown in Table 2, although the wall material influenced the HG values (p < 0.05), the highest HG obtained was 2.39% (Lr-ALG-WPI), still below the values found in the literature for probiotic powders: (9.55–13.97%) (Barajas-Álvarez et al., 2022), (7.6–8.7%) (Hernández-López et al., 2018), (11.19–13.58%) (Rajam & Anandharamakrishnan, 2015), and (10.00–19.40%) (Soukoulis et al., 2014). The HG values depend on the number of hydrophilic groups present in the structure of the microcapsule wall material, which can bind to the H2O molecules present in the surrounding air and absorb water (Šipailienė & Petraitytė, 2018). Although several hydrophilic groups exist in the structure of the proteins used in this study, mainly carboxyl and amine groups, the effect was not considerable. Holkem et al. (2016) attributed the low HG value (2.0%) of alginate capsules containing Bifidobacterium animalis subsp. lactis BB-12 to the formation of a film with an oily residue on the particle surface. This film reduced the exposed area (cavities and pores) and resulted in environmental lower moisture absorption.

Thermal Analysis

Thermograms of pure wall materials and microcapsules containing L. rhamnosus GG are shown in Fig. 4. The endothermic peak at 101.6 °C for pure sodium alginate (ALG) is consistent with other works and may indicate water loss from the matrix (Han et al., 2020). The WPI presented an endothermic event at 87 °C, possibly due to the heat-induced transitions in whey proteins (mainly β-lactoglobulin and α-lactalbumin) (Han et al., 2020). The endothermic peaks at 83.6 °C and 82.6 °C for RPC and PPC, respectively, indicate the thermal denaturation of the peptide fractions of these proteins (Perrechil et al., 2021; Tanger et al., 2020).

After encapsulation, the melting temperature increased from 101.6 °C (pure sodium alginate) to 129 °C (cross-linked sodium alginate, Lr-ALG). This temperature rise may be associated with the ionic cross-linking of Ca+2 in the alginate layer (egg box model). Generally, an increase in the melting temperature indicates a strengthening of the interfacial structure, giving higher stability to microencapsulated probiotics when subjected to high temperatures (Beldarrain-Iznaga et al., 2020). Furthermore, mixing WPI, RPC, or PPC with sodium alginate shifted the endothermic peaks of all probiotic microcapsules to temperatures > 120 °C. The increase in endothermic peaks in the microencapsulated material compared to the pure materials suggests that the alginate-protein interaction can form a firm and dense network due to strong electrostatic and hydrophobic interactions, producing a heat-resistant film. Thus, more energy was necessary to break the bonds between the chains and decompose them. These results corroborate previous studies that related the increase of the thermal stability of complex particles to the protein-polysaccharide complexes (Ghobadi et al., 2021; Luo et al., 2020). These results are relevant and could provide probiotic bacteria with higher thermal resistance, allowing the probiotication of foods that undergo heat treatments, such as bakery products and pasteurized or blanched foods.

Interaction Between Microcapsule Components

FTIR spectroscopy allowed for analyzing the main interactions between the materials used in probiotic microcapsule manufacture (Fig. 5). The WPI, RPC, and PPC proteins displayed the same characteristic bands (Fig. 5) but with different intensities. Typical absorption peaks of the spectrum of WPI, RPC, and PPC proteins were between 3168 and 3677 cm−1 (NH stretching and hydrogen bonding from amide A) and between 1222 and 1681 cm−1 (C = O stretching/hydrogen bonding and COO- from amide I, CN stretching and NH bending modes from amide II, and CN stretching and NH bending from and amide III). Peaks from 2842 to 3025 cm−1 correspond to the axial deformation of carbon-hydrogen (-CH) bonds. Similar results have been reported for WPI (Shi et al., 2023; Tao et al., 2023), RPC (Jia et al., 2022; Perrechil et al., 2021), and PPC (Vergara et al., 2023; Wang et al., 2022). Regarding the spectra of raw materials and microcapsules, the functional groups in the microcapsules closely resembled the functional groups of proteins, ALG, soybean oil, and Lr. Previous studies have suggested that the main interactions between protein–polysaccharides are electrostatic and that absorption peaks are often displaced. For example, Luo et al. (2022) observed that the characteristic peak of amide I in WPI moved from 1633 to 1621 cm−1, indicating some electrostatic interactions formed between ALG and WPI. Carpentier et al. (2021) reported that PPC amide I, II, and III peaks changed from 1631, 1523, and 1232 cm−1 to 1638, 1536, and 1233 cm−1, respectively, after complexation with tragacanth gum. They attributed this shift to conformational changes in the α-helix structures toward the β-sheet configuration.

A broad peak between 3677 and 3168 cm−1 occurred in all samples except soybean oil. This event represents the stretching vibration of intramolecular primary and secondary hydroxyl groups bound (Dehkordi et al., 2020). In addition, a smoother peak was observed between 1222 and 1005 cm−1 in the probiotic microcapsules and the Lr sample. This finding was also observed by Hosseini et al. (2022), who attributed this result to the probiotic L. rhamnosus cells inside the liposomes. According to Huang et al. (2021b), this vibration can indicate the phosphodiester backbone of nucleic acid (P = O group) and components of the cell wall (C − O − C group) of L. rhamnosus. Amplification of the spectral profile of the bands (3025 to 2842 cm−1) was also observed in all probiotic microcapsules. The broadening of the spectral profile of these bands is generally attributed to a decrease in the conformational order of the lipid acyl chains and an increase in their dynamics. This widening is attributed to the insertion of protein chains between the oil acyl chains (Herrero et al., 2011).

Proteins have both hydrophobic and hydrophilic polypeptide side chains in their structure. The hydrophobic side chains tend to be preferentially located towards the oily layer of the microcapsules. In contrast, the hydrophilic side chains tend to be located towards the encapsulating materials inside the capsule. This preferential orientation of hydrophobic side chains in the oil involves interactions between structurally different acyl and protein chains, which cause the soybean oil lipid chain’s disordering upon the addition of vegetable proteins (Pintado et al., 2015). An intense peak between 1789 and 1681 cm−1 was also detected in all probiotic microcapsules. This event is attributed to the stretching vibration of a carbonyl ester functional group (CO double bond) of soybean oil (Pizzo et al., 2022), typical in microcapsules produced in combination with oils (Premjit & Mitra, 2021). Furthermore, a band at 721 cm−1 indicates the overlapping of the CH2 rocking and out-of-plane vibrations of cis-disubstituted olefins, characteristic of long-chain fatty acids such as soybean oil (Pereira et al., 2022). Finally, the peak at 1455 cm−1 in all probiotic microcapsules is due to the asymmetric and symmetrical stretching carboxyl groups (− COO −) of sodium alginate, as observed by Dehkordi et al. (2020) and Beldarrain-Iznaga et al. (2020).

Resistance of Free and Microencapsulated L. rhamnosus GG During Simulated Gastrointestinal Digestion

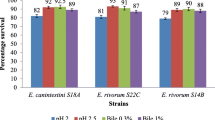

The viable cell count and recovery rate of free and microencapsulated L. rhamnosus GG after oral, gastric, and intestinal phases exposure are shown in Table 3 and Fig. 6, respectively.

Compared to the initial count, when exposed to simulated mouth conditions (SSF), a decrease (p < 0.05) in viable cell count was detected for Lr-ALG, Lr-ALG-PPC microcapsules, and free bacteria. The number of viable cells for Lr-ALG-WPI and Lr-ALG-RPC microcapsules remained unchanged (p > 0.05). This behavior is attributed to the higher initial cell concentration for the Lr-ALG-WPI and Lr-ALG-RPC samples.

At the end of the simulated gastric phase (SGF), the number of viable cells and the recovery rate of free and encapsulated L. rhamnosus GG decreased (p < 0.05). This behavior is related to the interfacial structure formed in each microcapsule. Non-encapsulated cells decreased by 3.73 log CFU−1, while Lr-ALG, Lr-ALG-WPI, Lr-ALG-RPC, and Lr-ALG-PPC microcapsules decreased by 1.80, 0.69, 0.84, and 1.55 log CFU g−1, respectively. These results are consistent with those of Zhang et al. (2015). They attributed the low decrease in the number of viable cells of L. salivarius in the gastric phase to improved survivability after encapsulation. For microcapsules, the greatest reduction was observed for Lr-ALG (p < 0.05), suggesting that the combination of alginate with whey, rice, or pea proteins provided enhanced protection for probiotics against gastric fluids (Zhang et al., 2015). The improved probiotic protection capacity for Lr-ALG-WPI, Lr-ALG-RPC, and Lr-ALG-PPC is due to the buffering capacity of alginate and the insolubility of the proteins (protein isoelectric point-pI). ALG at acidic pH can sequester protons and convert them to insoluble alginic acid, thus promoting a pH buffering effect that improves the survival of encapsulated probiotics (Tan et al., 2022). The pI of the proteins studied in the present study is in the pH range of 4.6 to 4.8 (Kornet et al., 2021; Lan et al., 2018; Zhang et al., 2021). When WPI, RPC, and PPC are in a medium below their pI, they will have a positive net charge, interacting with anionic polysaccharides (e.g., ALG) to form a complex (Mun et al., 2020). These insoluble complexes/clusters can create a protective barrier, preventing pepsin and gastric fluids from reaching cells. Although gastric juice (pH 3.0) and pepsin are highly harmful to the probiotic, viable cell counts and recovery rate remained above 6 log CFU g−1 and 60% after this step for all samples, respectively. The maintenance of high viable counts and recovery rate for the microcapsules at this stage may also be related to the presence of the oily film on the surface of the particles. The soybean oil layer limits the diffusion of H+, organic acids, water, and oxygen through the capsule membrane and minimizes cell death. These results corroborate those of hygroscopicity since the oily film present on the surface of the microcapsules reduced the absorption of ambient water by the microcapsules and contributed to low HG values.

At the end of the intestinal phase, all microcapsules showed adequate levels (> 6 log CFU g−1) to confer some benefit to the health of the host and followed the order of probiotic viability Lr-ALG-RPC = Lr-ALG-WPI > Lr-ALG-PPC > Lr-ALG. However, viable counts and recovery rates for all the samples decreased significantly (p < 0.05). A drastic reduction of 5.81 log CFU g−1 was seen for free cells, while moderate decreases were noted for microcapsules. The microcapsules that contained proteins in their formulation resulted in viable cell counts > 7.18 log CFU g−1 and recovery rate > 76.32%. The microcapsules produced only with alginate (Lr-ALG) presented a count of 6.76 log CFU g−1 and a recovery rate of 72.88%. The reduction in viable cell counts and recovery rate for these microcapsules is due to the lipolysis of the oily film on the surface of the microcapsules caused by pancreatic lipases. This process causes the demulsification of the microcapsules, which finally exposes the phospholipids of the cell membrane of L. rhamnosus to the action of bile salts (Zhang et al., 2015). Bile salts have a detergent effect and dissolve bacterial membranes causing growth inhibition and even cell death (Madureira et al., 2011). The higher viability for the Lr-ALG-WPI, Lr-ALG-RPC, and Lr-ALG-PPC samples is attributed to the protection the proteins provided. Our results are consistent with those of Obradović et al. (2022), who found that a formulation containing ALG 1% (w/v) and WPI 15% (w/v) dried in a spray dryer reduced only 0.36 log CFU mL−1 for a mixture of probiotic lactic bacteria under simulated intestinal conditions. According to the authors, the positive effect of WPI on the protection of probiotic cells can be explained by the exposure of sulfhydryl and hydrophobic groups due to denaturation, which leads to a decrease in cell diffusion in the medium. As observed in the DSC analysis, the combination of ALG with WPI, RPC, or PPC can form a dense network due to electrostatic and hydrophobic interactions, limiting the diffusion of bile salts in the microcapsules and delaying the interaction with probiotic bacteria. This effect allows the bacteria to colonize the small and large intestines and thus provide health benefits to the host (Martins et al., 2018).

Conclusions

A membrane emulsification system was used to produce microcapsules containing Lacticaseibacillus rhamnosus GG®. Combining alginate with whey, rice, or pea protein did not affect the microcapsules’ average size. The latter was comparable to the membrane pores’ diameter or morphology. Furthermore, proteins improved encapsulation efficiency and thermal properties and provided higher resistance to gastrointestinal fluids. In general, all microcapsules prepared showed promising results. Using vegetable proteins, especially rice, resulted in microcapsules with similar characteristics to those produced with whey. The high viability of microencapsulated L. rhamnosus in the final stage of digestion suggested that the encapsulation strategy employed is a promising alternative to include probiotics in some food matrices and improve their viability during processing, gastrointestinal conditions, and storage. Finally, our outstanding achievement was in particle size distribution and encapsulation efficiency. We obtained microcapsules between 18.26 and 28.76 μm with encapsulation yields > 93%, confirming the potential of the membrane emulsification method in the microencapsulation of probiotic strains. Future work could investigate the stability of these microcapsules during prolonged storage and in gastrointestinal conditions in vivo.

Data Availability

All data generated or analyzed during this study are included in this published article.

References

Allahdad, Z., Manus, J., Aguilar-Uscanga, B. R., Salmieri, S., Millette, M., & Lacroix, M. (2022). Physico-chemical properties and sensorial appreciation of a new fermented probiotic beverage enriched with pea and rice proteins. Plant Foods for Human Nutrition, 1–9. https://doi.org/10.1007/s11130-021-00944-1

dos Alves, M. J., & S., Freitas, P. M. C. T. de, Monteiro, A. R., & Valencia, G. A. (2021). Impact of the acidified hydroethanolic solution on the physicochemical properties of starch nanoparticles produced by anti-solvent precipitation. Starch, 73, 2100034. https://doi.org/10.1002/star.202100034

Apiwattanasiri, P., Charoen, R., Rittisak, S., Phattayakorn, K., Jantrasee, S., & Savedboworn, W. (2022). Co-encapsulation efficiency of silk sericin-alginate-prebiotics and the effectiveness of silk sericin coating layer on the survival of probiotic Lactobacillus casei. Food Bioscience, 46, 101576. https://doi.org/10.1016/J.FBIO.2022.101576

Arepally, D., Ravula, R., & S., Tridib, Goswami, K., & Coorey, R. (2022). A review on probiotic microencapsulation and recent advances of their application in bakery products. Food and Bioprocess Technology, 15, 1677–1699. https://doi.org/10.1007/s11947-022-02796-2

Ashwar, B. A., Gani, A., Gani, A., Shah, A., & Masoodi, F. A. (2018). Production of RS4 from rice starch and its utilization as an encapsulating agent for targeted delivery of probiotics. Food Chemistry, 239, 287–294. https://doi.org/10.1016/j.foodchem.2017.06.110

Bampi, G. B., Backes, G. T., Cansian, R. L., De Matos, F. E., Maria, I., Ansolin, A., Poleto, B. C., Corezzolla, L. R., & Favaro-Trindade, C. S. (2016). Spray chilling microencapsulation of Lactobacillus acidophilus and Bifidobacterium animalis subsp. lactis and its use in the preparation of savory probiotic cereal bars. Food and Bioprocess Technology, 9, 1422–1428. https://doi.org/10.1007/s11947-016-1724-z

Barajas-Álvarez, P., González-Ávila, M., & Espinosa-Andrews, H. (2022). Microencapsulation of Lactobacillus rhamnosus HN001 by spray drying and its evaluation under gastrointestinal and storage conditions. LWT - Food Science and Technology, 153. https://doi.org/10.1016/j.lwt.2021.112485

Beldarrain-Iznaga, T., Villalobos-Carvajal, R., Leiva-Vega, J., & Sevillano Armesto, E. (2020). Influence of multilayer microencapsulation on the viability of Lactobacillus casei using a combined double emulsion and ionic gelation approach. Food and Bioproducts Processing, 124, 57–71. https://doi.org/10.1016/j.fbp.2020.08.009

Bhusari, S. N., Muzaffar, K., & Kumar, P. (2014). Effect of carrier agents on physical and microstructural properties of spray dried tamarind pulp powder. Powder Technology, 266, 354–364. https://doi.org/10.1016/j.powtec.2014.06.038

Brodkorb, A., Egger, L., Alminger, M., Alvito, P., Assunção, R., Ballance, S., Bohn, T., Bourlieu-Lacanal, C., Boutrou, R., Carrière, F., Clemente, A., Corredig, M., Dupont, D., Dufour, C., Edwards, C., Golding, M., Karakaya, S., Kirkhus, B., Le Feunteun, S., … Recio, I. (2019). INFOGEST static in vitro simulation of gastrointestinal food digestion. Nature Protocols, 14(4), 991–1014. https://doi.org/10.1038/s41596-018-0119-1

Camelo-Silva, C., Barros, E. L. da S., Verruck, S., Maran, B. M., Canella, M. H. M., Esmerino, E. A., Silva, R., & Prudencio, E. S. (2022a). How ice cream manufactured with concentrated milk serves as a protective probiotic carrier? An in vitro gastrointestinal assay. Food Science and Technology, 42, e28621. https://doi.org/10.1590/fst.28621

Camelo-Silva, C., Verruck, S., Ambrosi, A., & Di Luccio, M. (2022b). Innovation and trends in probiotic microencapsulation by emulsification techniques. Food Engineering Reviews, 14, 462–490. https://doi.org/10.1007/s12393-022-09315-1

Caparino, O. A., Tang, J., Nindo, C. I., Sablani, S. S., Powers, J. R., & Fellman, J. K. (2012). Effect of drying methods on the physical properties and microstructures of mango (Philippine ‘Carabao’ var.) powder. Journal of Food Engineering, 111(1), 135–148. https://doi.org/10.1016/J.JFOODENG.2012.01.010

Carpentier, J., Conforto, E., Chaigneau, C., Vendeville, J. E., & Maugard, T. (2021). Complex coacervation of pea protein isolate and tragacanth gum: Comparative study with commercial polysaccharides. Innovative Food Science & Emerging Technologies, 69, 102641. https://doi.org/10.1016/J.IFSET.2021.102641

Celebioglu, H. U., Erden, Y., & Ozel, H. B. (2021). In vitro cytotoxic effects of lactobacilli grown with lime honey on human breast and colon cancer cells. Food Bioscience, 41, 101020. https://doi.org/10.1016/J.FBIO.2021.101020

Consoli, L., Hubinger, M. D., & Dragosavac, M. M. (2020). Encapsulation of resveratrol using Maillard conjugates and membrane emulsification. Food Research International, 137, 109359. https://doi.org/10.1016/J.FOODRES.2020.109359

da Silveira, J. M., Soares, L. B., Cesca, K., da Silva, A. F. V., Longo, L., Zanella, E., Stambuk, B. U., Biazi, L. E., & Ienczak, J. L. (2022). Immobilization of Spathaspora passalidarum NRRL Y-27907 in calcium alginate aiming the production of second-generation ethanol. BioEnergy Research, 15, 264–279. https://doi.org/10.1007/s12155-021-10309-w

Dehkordi, S. S., Alemzadeh, I., Vaziri, A. S., & Vossoughi, A. (2020). Optimization of Alginate-whey protein isolate microcapsules for survivability and release behavior of probiotic bacteria. Applied Biochemistry and Biotechnology, 190(1), 182–196. https://doi.org/10.1007/s12010-019-03071-5

Fabian, C., & Ju, Y.-H. (2011). A review on rice bran protein: Its properties and extraction methods a review on rice bran protein: Its properties and extraction methods. Critical Reviews in Food Science and Nutrition, 51(9), 816–827. https://doi.org/10.1080/10408398.2010.482678

Fangmeier, M., Lehn, D. N., Maciel, M. J., & Claucia, & & De Souza, F. V. (2019). Encapsulation of bioactive ingredients by extrusion with vibrating technology: Advantages and challenges. Food and Bioprocess Technology, 12, 1472–1486. https://doi.org/10.1007/s11947-019-02326-7

FAO, OMS. (2001). Probiotics in food: Health and nutritional properties and guidelines for evaluation. Food and Nutrition Paper, 85, 413–426.

Gao, H., Ma, L., Sun, W., McClements, D. J., Cheng, C., Zeng, H., Zou, L., & Liu, W. (2022). Impact of encapsulation of probiotics in oil-in-water high internal phase emulsions on their thermostability and gastrointestinal survival. Food Hydrocolloids, 126, 107478. https://doi.org/10.1016/J.FOODHYD.2021.107478

Ghobadi, M., Varidi, M. J., Koocheki, A., & Varidi, M. (2021). Effect of heat treatment on the structure and stability of grass pea (Lathyrus sativus) protein isolate/Alyssum homolocarpum seed gum nanoparticles. International Journal of Biological Macromolecules, 182, 26–36. https://doi.org/10.1016/J.IJBIOMAC.2021.03.170

Grand View Research. (2021). Probiotics Dietary supplements market report. https://www.grandviewresearch.com/industry-analysis/probiotics-dietary-supplements-market

Gu, Y., Li, X., Chen, H., Sun, Y., Yang, L., Ma, Y., & Yong Chan, E. C. (2022). Antidiabetic effects of multi-species probiotic and its fermented milk in mice via restoring gut microbiota and intestinal barrier. Food Bioscience, 47, 101619. https://doi.org/10.1016/J.FBIO.2022.101619

Han, C., Xiao, Y., Liu, E., Su, Z., Meng, X., & Liu, B. (2020). Preparation of Ca-alginate-whey protein isolate microcapsules for protection and delivery of L. bulgaricus and L. paracasei. International Journal of Biological Macromolecules, 163, 1361–1368. https://doi.org/10.1016/J.IJBIOMAC.2020.07.247

Heidebach, T., Först, P., & Kulozik, U. (2012). Microencapsulation of probiotic cells for food applications. Critical Reviews in Food Science and Nutrition, 52(4), 291–311. https://doi.org/10.1080/10408398.2010.499801

Hernández-López, Z., Rangel-Vargas, E., Castro-Rosas, J., Gómez-Aldapa, C. A., Cadena-Ramírez, A., Acevedo-Sandoval, O. A., Gordillo-Martínez, A. J., & Falfán-Cortés, R. N. (2018). Optimization of a spray-drying process for the production of maximally viable microencapsulated Lactobacillus pentosus using a mixture of starch-pulque as wall material. LWT - Food Science and Technology, 95, 216–222. https://doi.org/10.1016/j.lwt.2018.04.075

Herrero, A. M., Carmona, P., Pintado, T., Jiménez-Colmenero, F., & Ruíz-Capillas, C. (2011). Olive oil-in-water emulsions stabilized with caseinate: Elucidation of protein-lipid interactions by infrared spectroscopy. Food Hydrocolloids, 25(1), 12–18. https://doi.org/10.1016/j.foodhyd.2010.04.014

Hill, C., Guarner, F., Reid, G., Gibson, G. R., Merenstein, D. J., Pot, B., Morelli, L., Canani, R. B., Flint, H. J., Salminen, S., Calder, P. C., & Sanders, M. E. (2014). The international scientific association for probiotics and prebiotics consensus statement on the scope and appropriate use of the term probiotic. Nature Reviews Gastroenterology & Hepatology, 11(8), 506–514. https://doi.org/10.1038/nrgastro.2014.66

Holkem, A. T., Raddatz, G. C., Nunes, G. L., Cichoski, A. J., Jacob-Lopes, E., Ferreira Grosso, C. R., & de Menezes, C. R. (2016). Development and characterization of alginate microcapsules containing Bifidobacterium BB-12 produced by emulsification/internal gelation followed by freeze drying. LWT - Food Science and Technology, 71, 302–308. https://doi.org/10.1016/j.lwt.2016.04.012

Hosseini, S. F., Ansari, B., & Gharsallaoui, A. (2022). Polyelectrolytes-stabilized liposomes for efficient encapsulation of Lactobacillus rhamnosus and improvement of its survivability under adverse conditions. Food Chemistry, 372(September 2021), 131358. https://doi.org/10.1016/j.foodchem.2021.131358

Huang, E., Kim, S., Park, H., Park, S., Ji, Y., Svetoslav, T., & D., Lim, S.-D., Wilhelm & Holzapfel, H. (2021a). Modulation of the gut microbiome and obesity biomarkers by Lactobacillus plantarum KC28 in a diet-induced obesity murine model. Probiotics and Antimicrobial Proteins, 1, 3. https://doi.org/10.1007/s12602-020-09720-0

Huang, R.-M., Feng, K., Li, S.-F., Zong, M. H., Wu, H., & Han, S.-Y. (2021b). Enhanced survival of probiotics in the electrosprayed microcapsule by addition of fish oil. Journal of Food Engineering, 307, 110650. https://doi.org/10.1016/j.jfoodeng.2021.110650

Ilić, J. D., Nikolovski, B. G., Petrović, L. B., Kojić, P. S., Lončarević, I. S., & Petrović, J. S. (2017). The garlic (A. sativum L.) extracts food grade W1/O/W2 emulsions prepared by homogenization and stirred cell membrane emulsification. Journal of Food Engineering, 205, 1–11. https://doi.org/10.1016/J.JFOODENG.2017.02.006

Imbrogno, A., Dragosavac, M. M., Piacentini, E., Vladisavljević, G. T., Holdich, R. G., & Giorno, L. (2015). Polycaprolactone multicore-matrix particle for the simultaneous encapsulation of hydrophilic and hydrophobic compounds produced by membrane emulsification and solvent diffusion processes. Colloids and Surfaces b: Biointerfaces, 135, 116–125. https://doi.org/10.1016/J.COLSURFB.2015.06.071

Ji, R., Wu, J., Zhang, J., Wang, T., Zhang, X., Shao, L., Chen, D., & Wang, J. (2019). Extending viability of Bifidobacterium longumin chitosan-coated alginate microcapsules using emulsification and internal gelation encapsulation technology. Frontiers in Microbiology, 10, 1–10. https://doi.org/10.3389/fmicb.2019.01389

Jia, X., Li, L., Teng, J. W., Li, M., Long, H., & Xia, N. (2022). Glycation of rice protein and d-xylose pretreated through hydrothermal cooking-assisted high hydrostatic pressure: Focus on the structural and functional properties. LWT, 160, 113194. https://doi.org/10.1016/J.LWT.2022.113194

Jiang, T., & Charcosset, C. (2022). Premix membrane emulsification for the preparation of curcumin-loaded nanoemulsions. Journal of Food Engineering, 316, 110836. https://doi.org/10.1016/j.jfoodeng.2021.110836

Kaade, W., Güell, C., Ballon, A., Mellado-Carretero, J., De Lamo-Castellví, S., & Ferrando, M. (2020). Dynamic membranes of tunable pore size for lemon oil encapsulation. LWT, 123, 109090. https://doi.org/10.1016/J.LWT.2020.109090

Konovalova, V., Kolesnyk, I., Savchenko, M., Marynin, A., Bubela, H., Kujawa, J., Knozowska, K., & Kujawski, W. (2023). Preparation of chitosan water-in-oil emulsions by stirred cell membrane emulsification. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 661, 130929. https://doi.org/10.1016/J.COLSURFA.2023.130929

Kornet, R., Shek, C., Venema, P., Jan van der Goot, A., Meinders, M., & van der Linden, E. (2021). Substitution of whey protein by pea protein is facilitated by specific fractionation routes. Food Hydrocolloids, 117, 106691. https://doi.org/10.1016/J.FOODHYD.2021.106691

Kouamé, K., & J., E-A., Bora, F., M., A., Li, X., Sun, Y., Tian, S., Hussain, M., Liu, L., & Coulibaly, I. (2023). Development and characterization of probiotic (co)encapsulates in biopolymeric matrices and evaluation of survival in a millet yogurt formulation. Journal of Food Science, 88, 9–27. https://doi.org/10.1111/1750-3841.16375

Lagreca, E., Onesto, V., Di Concetta, N., La Manna, S., Netti, P. A., & Vecchione, R. (2020). Recent advances in the formulation of PLGA microparticles for controlled drug delivery. Progress in Biomaterials, 9, 153–174. https://doi.org/10.1007/s40204-020-00139-y

Lan, Y., Chen, B., & Rao, J. (2018). Pea protein isolate–high methoxyl pectin soluble complexes for improving pea protein functionality: Effect of pH, biopolymer ratio and concentrations. Food Hydrocolloids, 80, 245–253. https://doi.org/10.1016/J.FOODHYD.2018.02.021

Lu, M., Sun, J., Zhao, Y., Zhang, H., Li, X., Zhou, J., Dang, H., Zhang, J., Huang, W., Qi, C., & Li, D. (2022). Prevention of high-fat diet-induced hypercholesterolemia by Lactobacillus reuteri Fn041 through promoting cholesterol and bile salt excretion and intestinal mucosal barrier functions. Frontiers in Microbiology, 11. https://doi.org/10.3389/fnut.2022.851541

Luo, X., Fan, S., He, Z., Ni, F., Liu, C., Huang, M., Cai, L., Ren, G., Zhu, X., Lei, Q., Fang, W., & Xie, H. (2022). Preparation of alginate-whey protein isolate and alginate-pectin-whey protein isolate composites for protection and delivery of Lactobacillus plantarum. Food Research International, 161, 111794. https://doi.org/10.1016/J.FOODRES.2022.111794

Luo, Y., Niu, L., Li, D., & Xiao, J. (2020). Synergistic effects of plant protein hydrolysates and xanthan gum on the short- and long-term retrogradation of rice starch. International Journal of Biological Macromolecules, 144, 967–977. https://doi.org/10.1016/J.IJBIOMAC.2019.09.174

Madureira, A. R., Amorim, M., Gomes, A. M., Pintado, M. E., & Malcata, F. X. (2011). Protective effect of whey cheese matrix on probiotic strains exposed to simulated gastrointestinal conditions. Food Research International, 44(1), 465–470. https://doi.org/10.1016/j.foodres.2010.09.010

Manassi, C. F., de Souza, S. S., Hassemer, G. de S., Sartor, S., Lima, C. M. G., Miotto, M., De Dea Lindner, J., Rezzadori, K., Pimentel, T. C., Ramos, G. L. de P. A., Esmerino, E., Holanda Duarte, M. C. K., Marsico, E. T., & Verruck, S. (2022). Functional meat products: Trends in pro-, pre-, syn-, para- and post-biotic use. Food Research International, 154, 111035. https://doi.org/10.1016/J.FOODRES.2022.111035

Marcial-Coba, M. S., Knøchel, S., & Nielsen, D. S. (2019). Low-moisture food matrices as probiotic carriers. FEMS Microbiology Letters, 366(2), 1–11. https://doi.org/10.1093/femsle/fnz006

Martins, I. B. A., & Deliza, & R., Dos Santos, & K. M. O., Walter, E. H. M., Martins, J. M., & Rosenthal, & A. (2018). Viability of probiotics in goat cheese during storage and under simulated gastrointestinal conditions. Food and Bioprocess Technology, 11, 853–863. https://doi.org/10.1007/s11947-018-2060-2

Massounga Bora, A. F., Li, X., Liu, L., & Zhang, X. (2021). Enhanced in vitro functionality and food application of lactobacillus acidophilus encapsulated in a whey protein isolate and (-)-epigallocatechin-3-gallate conjugate. Journal of Agricultural and Food Chemistry, 69(37), 11074–11084. https://doi.org/10.1021/acs.jafc.1c02158

Misra, S., Pandey, P., Dalbhagat, C. G., & Mishra, H. N. (2022). Emerging technologies and coating materials for improved probiotication in food products: A review. Food and Bioprocess Technology, 15, 998–1039. https://doi.org/10.1007/S11947-021-02753-5

Morelli, S., Holdich, R. G., & Dragosavac, M. M. (2017). Microparticles for cell encapsulation and colonic delivery produced by membrane emulsification. Journal of Membrane Science, 524, 377–388. https://doi.org/10.1016/j.memsci.2016.11.058

Morsy, M. K., Morsy, O. M., Abdelmonem, M. A., & Elsabagh, R. (2022). Anthocyanin-colored microencapsulation effects on survival rate of Lactobacillus rhamnosus GG, color stability, and sensory parameters in strawberry nectar model. Food and Bioprocess Technology, 15, 352–367. https://doi.org/10.1007/s11947-022-02758-8

Mun, S., Surh, J., & Shin, M. (2020). Methods to improve rice protein dispersal at moderate pH. Food Science and Biotechnology, 29, 1401–1406. https://doi.org/10.1007/s10068-020-00799-3

Obradović, N., Volić, M., Nedović, V., Rakin, M., & Bugarski, B. (2022). Microencapsulation of probiotic starter culture in protein–carbohydrate carriers using spray and freeze-drying processes: Implementation in whey-based beverages. Journal of Food Engineering, 321, 110948. https://doi.org/10.1016/J.JFOODENG.2022.110948

Pereira, S. N. G., Lima, A. B. S. De, Oliveira, T. D. F., Batista, A. S., Jesus, J. C. De, Ferrão, S. P. B., & Santos, L. S. (2022). Non-destructive detection of soybean oil addition in babassu oil by MIR spectroscopy and chemometrics. LWT - Food Science and Technology, 154, 112857. https://doi.org/10.1016/j.lwt.2021.112857

Perrechil, F., Louzi, V. C., Alves da Silva Paiva, L., Valentin Natal, G. S., & Braga, M. B. (2021). Evaluation of modified starch and rice protein concentrate as wall materials on the microencapsulation of flaxseed oil by freeze-drying. LWT - Food Science and Technology, 140, 110760. https://doi.org/10.1016/J.LWT.2020.110760

Piacentini, E., Drioli, E., & Giorno, L. (2014). Membrane emulsification technology: Twenty-five years of inventions and research through patent survey. Journal of Membrane Science, 468, 410–422. https://doi.org/10.1016/j.memsci.2014.05.059

Piacentini, E., Giorno, L., Dragosavac, M. M., Vladisavljević, G. T., & Holdich, R. G. (2013). Microencapsulation of oil droplets using cold water fish gelatine/gum arabic complex coacervation by membrane emulsification. Food Research International, 53(1), 362–372. https://doi.org/10.1016/J.FOODRES.2013.04.012

Pintado, T., Ruiz-Capillas, C., Jiménez-Colmenero, F., Carmona, P., & Herrero, A. M. (2015). Oil-in-water emulsion gels stabilized with chia (Salvia hispanica L.) and cold gelling agents: Technological and infrared spectroscopic characterization. Food Chemistry, 185, 470–478. https://doi.org/10.1016/j.foodchem.2015.04.024

Pizzo, J. S., Cruz, V. H. M., Santos, P. D. S., Silva, G. R., Souza, P. M., Manin, L. P., Santos, O. O., & Visentainer, J. V. (2022). Instantaneous characterization of crude vegetable oils via triacylglycerols fingerprint by atmospheric solids analysis probe tandem mass spectrometry with multiple neutral loss scans. Food Control, 134, 108710. https://doi.org/10.1016/j.foodcont.2021.108710

Premjit, Y., & Mitra, J. (2021). Optimization of electrospray-assisted microencapsulation of probiotics (Leuconostoc lactis) in soy protein isolate-oil Particles using box-behnken experimental design. Food and Bioprocess Technology, 14(9), 1712–1729. https://doi.org/10.1007/s11947-021-02670-7

Rafe, A., Vahedib, E., & Hasan-Sarei, A. G. (2016). Rheology and microstructure of binary mixed gel of rice bran protein–whey: effect of heating rate and whey addition. Journal of the Science of Food and Agriculture, 96, 3890–3896. https://doi.org/10.1002/jsfa.7586

Rajam, R., & Anandharamakrishnan, C. (2015). Spray freeze drying method for microencapsulation of Lactobacillus plantarum. Journal of Food Engineering, 166, 95–103. https://doi.org/10.1016/j.jfoodeng.2015.05.029

Rama, G. R., Kuhn, D., Beux, S., & Mônica, & , Maciel, J., Claucia, & & De Souza, F. V. (2020). Cheese whey and ricotta whey for the growth and encapsulation of endogenous lactic acid bacteria. Food and Bioprocess Technology, 13, 308–322. https://doi.org/10.1007/s11947-019-02395-8

Reis, D. R., Ambrosi, A., & Luccio, M. Di. (2022). Encapsulated essential oils: a perspective in food preservation. Future Foods, 5, 100126. https://doi.org/10.1016/J.FUFO.2022.100126

Richards, K., Malik, D. J., Richards, K., Malik, D. J., Alves, D. R., & Abedon, S. T. (2021). Microencapsulation of bacteriophages using membrane emulsification in different pH-triggered controlled release formulations for oral administration. Pharmaceuticals, 14(5), 424. https://doi.org/10.3390/ph14050424

Sharma, R., Rashidinejad, A., & Seid, · & Jafari, M. (2022). Application of spray dried encapsulated probiotics in functional food formulations. Food and Bioprocess Technology, 15, 2135–2154. https://doi.org/10.1007/s11947-022-02803-6

Shi, G., Shi, C., Luo, Y., Hong, H., Zhang, J., Li, Y., & Tan, Y. (2023). Interaction and phase behavior of whey protein and propylene glycol alginate complex condensates. Food Chemistry, 404, 134556. https://doi.org/10.1016/J.FOODCHEM.2022.134556

Silva, M. P., Tulini, F. L., Martins, E., Penning, M., Fávaro-Trindade, C. S., & Poncelet, D. (2018). Comparison of extrusion and co-extrusion encapsulation techniques to protect Lactobacillus acidophilus LA3 in simulated gastrointestinal fluids. LWT - Food Science and Technology, 89(November 2017), 392–399. https://doi.org/10.1016/j.lwt.2017.11.008

Šipailienė, A., & Petraitytė, S. (2018). Encapsulation of probiotics: Proper selection of the probiotic strain and the influence of encapsulation technology and materials on the viability of encapsulated microorganisms. Probiotics and Antimicrobial Proteins, 10(1), 1–10. https://doi.org/10.1007/s12602-017-9347-x

Song, S. H., Cho, Y. H., & Park, J. (2003). Microencapsulation of Lactobacillus casei YIT 9018 using a microporous glass membrane emulsification system. Journal of Food Science, 68(1), 195–200. https://doi.org/10.1111/j.1365-2621.2003.tb14139.x

Soukoulis, C., Behboudi-Jobbehdar, S., Yonekura, L., Parmenter, C., & Fisk, I. (2014). Impact of milk protein type on the viability and storage stability of microencapsulated Lactobacillus acidophilus NCIMB 701748 using spray drying. Food and Bioprocess Technology, 7, 1255–1268. https://doi.org/10.1007/s11947-013-1120-x

Spyropoulos, F., Lloyd, D. M., Hancocks, R. D., & Pawlik, A. K. (2014). Advances in membrane emulsification. Part B: Recent developments in modelling and scale-up approaches. Journal of the Science of Food and Agriculture, 94(4), 628–638. https://doi.org/10.1002/jsfa.6443

Spyropoulosa, F., Hancocks, R. D., & Norton, I. T. (2011). Food-grade emulsions prepared by membrane emulsification techniques. Procedia Food Science, 1, 920–926. https://doi.org/10.1016/J.PROFOO.2011.09.139

Tan, L. L., Mahotra, M., Chan, S. Y., & Loo, S. C. J. (2022). In situ alginate crosslinking during spray-drying of lactobacilli probiotics promotes gastrointestinal-targeted delivery. Carbohydrate Polymers, 286, 119279. https://doi.org/10.1016/J.CARBPOL.2022.119279

Tang, H., Bohannon, L., Lew, M., Jensen, D., Jung, S.-H., Zhao, A., Sung, A. D., Wischmeyer, P. E., & Wischmeyer, P. (2021). Randomised, double-blind, placebo-controlled trial of probiotics to eliminate COVID-19 transmission in exposed household contacts (PROTECT-EHC): A clinical trial protocol. BMJ, 11, e04706. https://doi.org/10.1136/bmjopen-2020-047069

Tanger, C., Engel, J., & Kulozik, U. (2020). Influence of extraction conditions on the conformational alteration of pea protein extracted from pea flour. Food Hydrocolloids, 107, 105949. https://doi.org/10.1016/J.FOODHYD.2020.105949

Tao, X., Chen, C., Li, Y., Qin, X., Zhang, H., Hu, Y., Liu, Z., Guo, X., & Liu, G. (2023). Improving the antioxidant activity, in vitro digestibility and reducing the allergenicity of whey protein isolate by glycosylation with short-chain inulin and interaction with cyanidin-3-glucoside. Food Hydrocolloids, 139, 108586. https://doi.org/10.1016/J.FOODHYD.2023.108586

Vergara, L. P., dos Santos Hackbart, H. C., Jansen Alves, C., Reissig, G. N., Wachholz, B. S., Borges, C. D., Chim, J. F., & Zambiazi, R. C. (2023). Encapsulation of phenolic compounds through the complex coacervation technique for the enrichment of diet chewable candies. Food Bioscience, 51, 102256. https://doi.org/10.1016/J.FBIO.2022.102256

Verruck, S., de Carvalho, M. W., de Liz, G. R., Amante, E. R., Vieira, C. R. W., de Amboni, R. D., & M. C., & Prudencio, E. S. (2017). Survival of Bifidobacterium BB-12 microencapsulated with full-fat goat’s milk and prebiotics when exposed to simulated gastrointestinal conditions and thermal treatments. Small Ruminant Research, 153, 48–56. https://doi.org/10.1016/j.smallrumres.2017.05.008

Verruck, S., de Liz, G. R., Dias, C. O., & de Mello Castanho Amboni, R. D., & Prudencio, E. S. (2019). Effect of full-fat goat’s milk and prebiotics use on Bifidobacterium BB-12 survival and on the physical properties of spray-dried powders under storage conditions. Food Research International, 119, 643–652. https://doi.org/10.1016/J.FOODRES.2018.10.042

Vinner, G. K., Richards, K., Leppanen, M., Sagona, A. P., & Malik, D. J. (2019). Microencapsulation of enteric bacteriophages in a pH-responsive solid oral dosage formulation using a scalable membrane emulsification process. Pharmaceutics, 11(9). https://doi.org/10.3390/pharmaceutics11090475

Wang, J., Korber, D. R., Low, N. H., & Nickerson, M. T. (2014). Entrapment, survival and release of Bifidobacterium adolescentis within chickpea protein-based microcapsules. Food Research International, 55, 20–27. https://doi.org/10.1016/J.FOODRES.2013.09.018

Wang, Junjing, Martínez-Hernández, A., de Lamo-Castellví, S., Romero, M. P., Kaade, W., Ferrando, M., & Güell, C. (2020). Low-energy membrane-based processes to concentrate and encapsulate polyphenols from carob pulp. Journal of Food Engineering, 281, 109996. https://doi.org/10.1016/J.JFOODENG.2020.109996

Wang, Q., Xie, Y., Xiong, Z., Gu, X., Nie, X., Lan, Y., & Chen, B. (2022). Structural and physical properties of spray-dried fish oil microcapsules via pea protein isolate based emulsification or complex coacervation with sugar beet pectin. Journal of Food Engineering, 335, 111173. https://doi.org/10.1016/J.JFOODENG.2022.111173

Williams, R. A., Peng, S. J., Wheeler, D. A., Morley, N. C., Taylor, D., Whalley, M., & Houldsworth, D. W. (1998). Controlled production of emulsions using a crossflow membrane: Part II: Industrial scale manufacture. Chemical Engineering Research and Design, 76, 902–910. https://doi.org/10.1205/026387698525702

Zhang, X., Zuo, Z., Yu, P., Li, T., Guang, M., chen, Z., & Wang, L. (2021). Rice peptide nanoparticle as a bifunctional food-grade pickering stabilizer prepared by ultrasonication: Structural characteristics, antioxidant activity, and emulsifying properties. Food Chemistry, 343, 128545. https://doi.org/10.1016/J.FOODCHEM.2020.128545

Zhang, Y., Lin, J., & Zhong, Q. (2015). The increased viability of probiotic Lactobacillus salivarius NRRL B-30514 encapsulated in emulsions with multiple lipid-protein-pectin layers. Food Research International, 71, 9–15. https://doi.org/10.1016/J.FOODRES.2015.02.017

Zhi, Z., Liu, R., Wang, W., Dewettinck, K., & Bockstaele, F. V. (2022). Recent progress in oil-in-water-in-oil (O/W/O) double emulsions. Critical Reviews in Food Science and Nutrition. https://doi.org/10.1080/10408398.2022.2029346

Acknowledgements

The authors are grateful to CAPES (Coordination of Improvement of Higher Education Personnel) for the scholarship (Finance code 001) and CNPq (National Council for Scientific and Technological Development, Brazil) (project number 200246/2022-4). The authors are grateful to the EQA/UFSC Analysis Center, “Laboratórios de Simulação Numérica de Sistemas Químicos e de Transferência de Massa” (LABSIN-LABMASSA/UFSC), “Laboratório Multiusuário de Estudos em Biologia” (LAMEB/UFSC), “Laboratório Central de Microscopia Eletrônica” (LCME/UFSC), “Laboratório Interdisciplinar para o Desenvolvimento de Nanoestruturas” (LINDEN/UFSC), “Laboratório de Propriedades Físicas de Alimentos” (PROFI/UFSC), “Laboratório de Controle e Processos de Polimerização” (LCP/UFSC), and “Laboratório de Engenharia Biológica” (LIEB/UFSC) for providing their infrastructure to conduct the experimental tests and microcapsule characterization. VeganWay and Chr. Hansen are acknowledged for supplying vegetable proteins and probiotic bacteria, respectively.

Funding

This work was financially supported by the CNPq (National Council for Scientific and Technological Development, Brazil) (420275/2018–5, 307576/2018–3, 200246/2022–4).

Author information

Authors and Affiliations

Contributions

Callebe Camelo-Silva: conceptualization, data curation, formal analysis, investigation, methodology, software, writing—original draft. Lais Leite Figueredo: data curation, methodology. Karina Cesca: methodology, writing—review & editing. Silvani Verruck: conceptualization, data curation, formal analysis, methodology, writing-review & editing. Alan Ambrosi: conceptualization, data curation, formal analysis, methodology, writing-review & editing. Marco Di Luccio: conceptualization, formal analysis, methodology, funding acquisition, project administration, resources, supervision, writing—review & editing.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Camelo-Silva, C., Figueredo, L.L., Cesca, K. et al. Membrane Emulsification as an Emerging Method for Lacticaseibacillus rhamnosus GG® Encapsulation. Food Bioprocess Technol 16, 2651–2667 (2023). https://doi.org/10.1007/s11947-023-03099-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-023-03099-w