Abstract

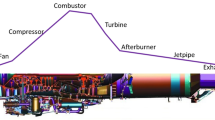

Thermal barrier coatings (TBCs) with high thermal strain tolerance and erosion resistance are commonly applied onto the inner and outer diameters of hot sections of gas-turbine engine components. In this work, strain-tolerant, segmented TBCs were developed using the SinplexPro-cascaded torch. Design of experiments were carried out to study the effect of process variables such as plasma power, powder feeding rate, spraying distance and surface speed on the coating microstructure and properties. Optimized process parameters for the segmented coating microstructures at shorter spray distance (<75mm) and longer spray distance (>114mm) are achieved, which are targeted for spraying inner diameter (ID) and outer diameter (OD) engine components, respectively. The plasma torch hardware life was evaluated by torch cycle duration runs. Examples of highly strain-tolerant TBCs onto the ID and OD engine components were demonstrated, highlighting the wide versatility and process range of the SinplexPro.

Similar content being viewed by others

References

R.A. Miller, Thermal Barrier Coatings for Aircraft Engines: History and Directions, J. Therm. Spray Technol., 1997, 6, p 35-42

A.G. Evans, D.R. Mumm, J.W. Hutchinson, G.H. Meier, and F.S. Pettit, Mechanisms controlling the durability of thermal barrier coatings, Progr. Mater. Sci., 2001, 46, p 505-553

N.P. Padture, M. Gell, and E.H. Jordan, Thermal Barrier Coatings for Gas-Turbine Engine Applications, Science, 2002, 296, p 280-284

S. Sampath, U. Schulz, J. Ophelia, S. Kuroda, S. Processing science of advanced thermal-barrier systems, MRS Bulletin, 2012, 37, p 903-910.

T. A. Taylor, US Patent No. 5073433, 1991.

D. M. Gray, Y. C. Lau, C. A. Johnson, M. P. Boron, W. A. Nelson, US Patent 5,830,586 (1996).

H.B. Guo, S. Kuroda, and H. Murakami, Effect of Hollow Spherical Powder Size Distribution on Porosity and Segmentation Cracks in Thermal Barrier Coatings, J. Am. Ceram. Soc., 2006, 89(12), p 3797-3804

H.B. Guo, S. Kuroda, and H. Murakami, Microstructures and Properties of Plasma-Sprayed Segmented Thermal Barrier Coatings, J. Am. Ceram. Soc., 2006, 89(4), p 1432-1439

H.B. Guo, S. Kuroda, and H. Murakami, Effects of Heat Treatment on Microstructures and Physical Properties of Segmented Thermal Barrier Coating, Mater. Trans., 2005, 46(8), p 1775-1778

H.B. Guo, S. Kuroda, and H. Murakami, Thermal Cycling Behavior of Plasma Sprayed Segmented Thermal Barrier Coatings, Mater. Trans., 2006, 47(2), p 306-309

H.B. Guo, R. Vaßen, and D. Stöver, Atmospheric plasma sprayed thick thermal barrier coatings with high segmentation crack density, Surf. Coat. Technol., 2004, 186(3), p 353-363

M. Karger, R. Vaßen, and D. Stöver, Atmospheric plasma sprayed thermal barrier coatings with high segmentation crack densities: Spraying process, microstructure and thermal cycling behavior, Surf. Coat. Technol., 2011, 206, p 16-23

J.L. Smialek, Improved Oxidation Life of Segmented Plasma Sprayed 8YSZ Thermal Barrier Coatings, J. Therm. Spray Technol., 2004, 13(1), p 66-75

D. Schwingel, R. Taylor, T. Haubold, J. Wigren, and C. Gualco, Mechanical and thermophysical properties of thick PYSZ thermal barrier coatings: correlation with microstructure and spraying parameters, Surf. Coat. Technol., 1998, 108–109, p 99-106

D. Hawley, Improved Quality, Reduced Cost and Cycle Times, Sulzer Tech. Rev., 2007, 3, p 14-16

D. Chen, O. Sabouni, C. Dambra, Influence of process parameters and feedstock selection on coating microstructures and properties with a cascaded SinplexPro plasma torch. ITSC2014, p 48–52.

S. Kentaro, J. Colmenares-Angulo, A. Valarezo, and S. Sampath, Effect of Deposition Rate on the Stress Evolution of Plasma-Sprayed Yttria-Stabilized Zirconia, J. Therm. Spray Technol., 2012, 21(6), p 1224-1233

Acknowledgments

The authors would like to acknowledge Manfred Stapgens, Robert Harmon and Colin Rojas for the work on coating microstructure characterization.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is an invited paper selected from presentations at the 2018 International Thermal Spray Conference, held May 7–10, 2018, in Orlando, Florida, USA, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Chen, D., Rocchio-Heller, R. & Dambra, C. Segmented Thermal Barrier Coatings for ID and OD Components Using the SinplexPro Plasma Torch. J Therm Spray Tech 28, 1664–1673 (2019). https://doi.org/10.1007/s11666-019-00920-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-019-00920-x