Abstract

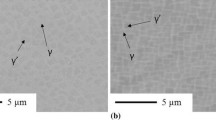

Unconventional plasma sprayed thermal barrier coating (TBC) systems were produced and evaluated by interrupted or cyclic furnace oxidation life testing. First, approximately 250 µm thick 8YSZ coatings were directly sprayed onto grit blasted surfaces of PWA 1484, without a bond coat, to take advantage of the excellent oxidation resistance of this superalloy. For nominal sulfur (S) contents of 1 ppmw, total coating separation took place at relatively short times (200 h at 1100°C). Reductions in the S content, by melt desulfurization commercially (0.3 ppmw) or by hydrogen (H2) annealing in the laboratory (0.01 ppmw), improved scale adhesion and extended life appreciably, by factors of 5–10. However, edge-initiated failure persisted, producing massive delamination as one sheet of coating. Secondly, surfaces of melt desulfurized PWA 1484 were machined with a grid of grooves or ribs (∼250 µm wide and high), resulting in a segmented TBC surface macrostructure, for the purpose of subverting this failure mechanism. In this case, failure occurred only as independent, single-segment events. For grooved samples, 1100 °C segment life was extended to ∼1000h for 5 mm wide segments, with no failure observed out to 2000 h for segments ≤2.5 mm wide. Ribbed samples were even more durable, and segments ≤6 mm remained intact for 2000 h. Larger segments failed by buckling at times inversely related to the segment width and decreased by oxidation effects at higher temperatures. This critical buckling size was consistent with that predicted for elastic buckling of a TBC plate subject to thermal expansion mismatch stresses. Thus, low S substrates demonstrate appreciable coating lives without a bond coat, while rib segmenting extends life considerably.

Similar content being viewed by others

References

R.A. Miller and J.K. Doychak: “Plasma Sprayed Ceramic Thermal Barrier Coating for NiAl-based Intermetallic Alloys,” US Patent 5,302,465, April 12, 1994.

J.C. Schaeffer, W.H. Murphy, W.B. Connor, B.A. Nagaraj, and H.B. Vakil: “Thermal Barrier Coating System Having No Bond Coat,” US Patent 5,538,796, July 23, 1996.

A.M. Freborg, B.L. Ferguson, W.J. Brindley, and G.J. Petrus: “Modeling Oxidation Induced Stresses in Thermal Barrier Coatings,” Mater. Sci. Eng., 1998, A245, pp. 182–90.

M.Y. He, A.G. Evans, and J.W. Hutchinson: “The Ratcheting of Compressed Thermally Grown Thin Films on Ductile Substrates,” Acta Mater., 2000, 48, pp. 2593–601.

G.H. Meier, F.S. Pettit, and J.L. Smialek: “The Effects of Reactive Element Additions and Sulfur Removal on the Adherence of Alumina to Ni- and Fe-Base Alloys,” Werkstoffe Korrosion, 1995, 46, pp. 232–40.

J.L. Smialek: “Maintaining Adhesion of Protective Al2O3 Scales,” JOM, 2000, 52(1), pp. 22–26.

J.L. Smialek: “Advances in the Oxidation Resistance of High-Temperature Turbine Materials,” Surf. Interface Anal., 2001, 31, pp. 582–92.

J.L. Smialek: “Toward Optimum Scale and TBC Adhesion on Single Crystal Superalloys” in High Temperature Corrosion and Materials Chemistry, 98–9, E.J. Opila, P.Y. Hou, D. Shores, M. McNallan, and R. Oltra, ed., The Electrochemical Society, Pennington, NJ, 1998, pp. 211–20.

J.L. Smialek and B.A. Pint: “Optimizing Scale Adhesion for Single Crystal Superalloys,” Mater. Sci. Forum, 2001, 369–372, pp. 459–66.

J.L. Smialek and G.N. Morscher: “Delayed Alumina Scale Spallation on Rene’N5: Moisture Effects and Acoustic Emission,” Mater. Sci. Eng. A. 2002, 332(1–2), pp. 11–24.

J.A. Haynes, B.A. Pint, K.L. Moore, I.G. Wright, and J.L. Smialek: “Superalloy Substrate Influences on the Oxidation Behavior of Aluminide Bond Coatings” in John Stringer Symposium on High Temperature Corrosion, P.F. Tortorelli, I.G. Wright, and P.Y. Hou, ed., ASM International, Materials Park, OH, 2002, in press.

I.G. Wright, B.A. Pint, W.Y. Lee, K.B. Alexander, and K. Prüßner: “Some Effects of Metallic Substrate Composition on Degradation of Thermal Barrier Coatings” in High Temperature Surface Engineering, Book 693, J. Nicholls and D. Rickerby, ed., Institute of Materials, London, UK, 2000, pp. 95–113.

W.Y. Lee, Y. Zhang, I.G. Wright, B.A. Pint, and P.K. Liaw: “Effect of Sulfur Impurity on the Scale Adhesion Behavior of a Desulfurized Ni-based Superalloy Aluminized by Chemical Vapor Deposition,” Metall. Trans., 29A, pp. 833–41 (1998).

B.A. Pint, I.G. Wright, W.Y. Lee, Y. Zhang, K. Prüßner, and K.B. Alexander: “Substrate and Bond Coat Compositions: Factors Affecting Alumina Scale Adhesion,” Mater. Sci. Eng., 1998, A245, pp. 201–11.

J.L. Smialek: “Scale Adhesion, Sulfur Content, and TBC Failure on Single Crystal Superalloys,” Ceram. Eng. Sci. Proc., 2002, 23(4), pp. 485–95.

J.L. Smialek, “Segmented Thermal Barrier Coating,” U.S. Patent 6,316,078, Nov. 13, 2001.

X. Peng and D.R. Clarke: “Piezospectroscopic Analysis of Interface Debonding in Thermal Barrier Coatings,” J. Am. Ceram. Soc., 2000, 83(5), pp. 1165–70.

V. Sergo and D.R. Clarke: “Observation of Subcritical Spall Propagation of a Thermal Barrier Coating,” J. Am. Ceram. Soc., 1998, 81(12), pp. 3237–42.

R. Janakiraman, G.H. Meier, and F.S. Pettit: “The Effect of Water Vapor on the Oxidation of Alloys that Develop Alumina Scales for Protection” in Cyclic Oxidation of High Temperature Materials, M. Schutze and W.J. Quadakkers, ed., European Federation of Corrosion, Institute of Materials, London, UK, 1999, pp. 38–62.

J.K. Tien and J.M. Davidson: “Oxide Spallation Mechanisms” in Stress Effects and the Oxidation of Metals, J.V. Cathcart, ed., AIME, New York, 1975, pp. 200–19.

D. Zhu, L.J. Ghosn, and R.A. Miller: “Effect of Layer-Graded Bond Coats on Edge Stress Concentration and Oxidation Behavior of Thermal Barrier Coatings” in High Temperature Materials Chemistry, 98–9, P.Y. Hou, M.J. McNallan, R. Oltra, E.J. Opila, ed., Electrochemical Society, Pennington, NJ, 1998, pp. 170–89 (also NASA TM 1998-208505, Washington, DC, 1998).

K. Kokini, A. Banerjee, and T.A. Taylor: “Thermal Fracture of Interfaces in Precracked Thermal Barrier Coatings,” Mater. Sci. Eng., 2002, A323, pp. 70–82.

H.E. Evans, G.P. Mitchell, R.C. Lobb, and D.R.J. Owen: “A Numerical Analysis of Oxide Spallation,” Proc. R. Soc. London, 1993, 440A, pp. 1–22.

M.D. Thouless: “Combined Spalling and Cracking of Films,” J. Am. Ceram. Soc., 1993, 76, pp. 2936–38.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Smialek, J.L. Improved oxidation life of segmented plasma sprayed 8YSZ thermal barrier coatings. J Therm Spray Tech 13, 66–75 (2004). https://doi.org/10.1007/s11666-004-0051-5

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/s11666-004-0051-5